Mechanical sorting in post-harvest technology offers rapid, consistent grading of produce by size, weight, and color, enhancing efficiency and reducing labor costs. Manual sorting, while labor-intensive, allows for nuanced decision-making and quality assessment based on subtle defects and ripeness that machines might miss. Balancing mechanical and manual sorting optimizes overall grading accuracy and throughput in agricultural processing.

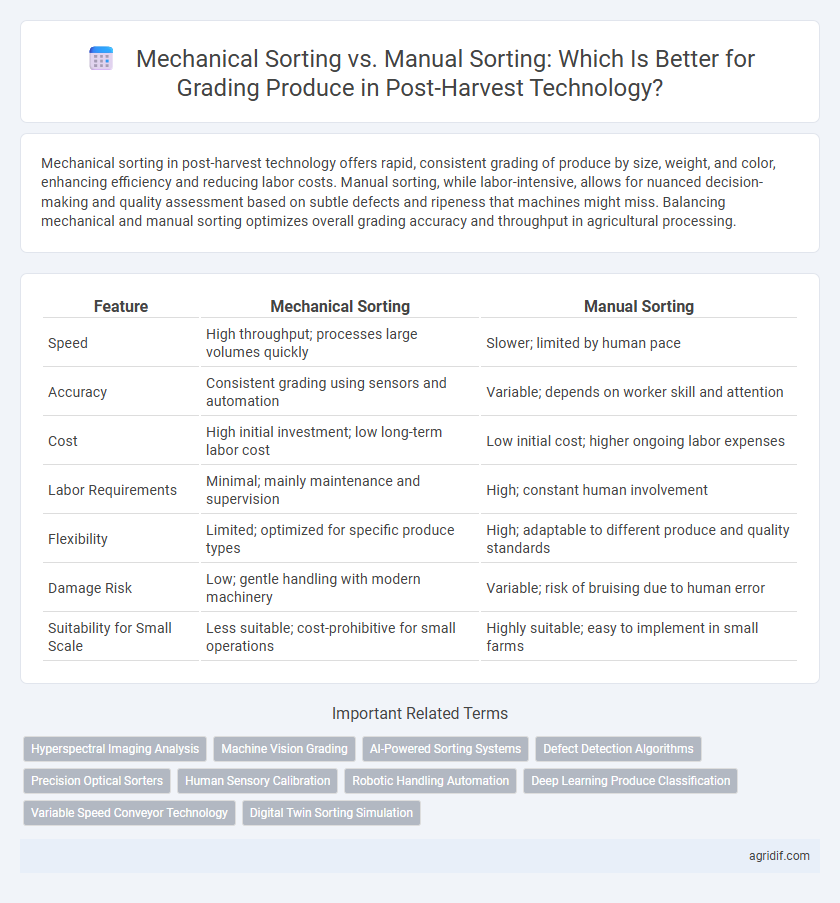

Table of Comparison

| Feature | Mechanical Sorting | Manual Sorting |

|---|---|---|

| Speed | High throughput; processes large volumes quickly | Slower; limited by human pace |

| Accuracy | Consistent grading using sensors and automation | Variable; depends on worker skill and attention |

| Cost | High initial investment; low long-term labor cost | Low initial cost; higher ongoing labor expenses |

| Labor Requirements | Minimal; mainly maintenance and supervision | High; constant human involvement |

| Flexibility | Limited; optimized for specific produce types | High; adaptable to different produce and quality standards |

| Damage Risk | Low; gentle handling with modern machinery | Variable; risk of bruising due to human error |

| Suitability for Small Scale | Less suitable; cost-prohibitive for small operations | Highly suitable; easy to implement in small farms |

Introduction to Sorting Methods in Post-Harvest Technology

Mechanical sorting in post-harvest technology utilizes automated machines equipped with sensors and cameras to rapidly grade produce based on size, color, and weight, enhancing accuracy and throughput. Manual sorting relies on human labor to visually inspect and separate produce, offering flexibility in recognizing subtle defects but often resulting in slower processing times and higher labor costs. Effective grading methods improve produce quality, reduce post-harvest losses, and streamline packaging and distribution processes.

Principles of Mechanical Sorting in Agriculture

Mechanical sorting in agriculture relies on principles such as size, shape, weight, and color differentiation to efficiently grade produce. Advanced sensors and imaging technologies enable high-throughput sorting by detecting physical and optical attributes, ensuring consistent quality standards. This automation reduces human error and enhances processing speed, optimizing post-harvest handling and market readiness.

Manual Sorting: Techniques and Labor Requirements

Manual sorting in post-harvest technology involves the careful visual inspection and selection of produce based on size, color, shape, and defects to ensure quality standards. Techniques include handpicking, grading by color charts, and tactile assessment, requiring skilled labor familiar with crop characteristics. Labor intensity varies with crop type and volume, necessitating trained workers to maintain consistency and reduce damage during handling.

Efficiency Comparison: Mechanical vs Manual Sorting

Mechanical sorting significantly increases grading efficiency by processing thousands of produce items per hour, reducing labor costs and minimizing human error. Manual sorting, while allowing for nuanced quality assessment, is time-consuming, labor-intensive, and subject to subjective inconsistencies. Integrating advanced mechanical sorting technologies, such as optical sensors and conveyor systems, streamlines post-harvest processing and enhances overall throughput.

Accuracy and Consistency in Grading Produce

Mechanical sorting technology enhances accuracy and consistency in grading produce by using advanced sensors and imaging systems to detect size, color, and defects with minimal human error. Manual sorting relies on human judgment, which can vary due to fatigue, experience, and subjective assessment, leading to inconsistent grading results. High-throughput mechanical sorting systems enable uniform quality standards, increasing marketability and reducing post-harvest losses.

Impact on Post-Harvest Loss Reduction

Mechanical sorting significantly reduces post-harvest losses by enabling faster, more precise grading of produce compared to manual sorting. Automated systems use advanced sensors and imaging technologies to detect defects and classify fruits or vegetables with high consistency, minimizing human error and product spoilage. This enhanced accuracy and speed in sorting improve overall supply chain efficiency and extend the shelf life of harvested crops.

Cost Analysis: Investments and Operational Expenses

Mechanical sorting systems require significant upfront investments in equipment, installation, and training, while offering lower long-term operational expenses through reduced labor costs and increased throughput. Manual sorting involves minimal initial capital but incurs higher ongoing labor expenses, variability in sorting efficiency, and slower processing times. Evaluating cost-effectiveness depends on the scale of operations, produce type, and desired grading precision, with mechanical sorting favored in large-scale, high-volume settings due to improved consistency and cost savings over time.

Human Factors: Labor, Safety, and Skill Sets

Mechanical sorting significantly reduces labor requirements by automating grading processes, enhancing safety by minimizing human exposure to repetitive tasks and potential hazards. Manual sorting relies heavily on skilled laborers capable of discerning subtle quality differences, but it increases labor intensity and the risk of ergonomic injuries. Efficient post-harvest operations benefit from integrating mechanical systems with trained personnel to balance productivity, safety, and expertise.

Technological Advancements in Mechanical Sorting

Mechanical sorting in post-harvest technology has significantly advanced through the integration of optical sensors, machine learning algorithms, and automated conveyors, enabling precise and rapid grading of produce based on size, color, and quality parameters. These innovations reduce human error, increase throughput, and enhance consistency compared to manual sorting, which relies heavily on subjective visual inspection and labor intensity. Enhanced imaging systems and real-time data processing now allow mechanical sorters to detect defects and categorize fruits and vegetables with higher accuracy, optimizing supply chain efficiency and reducing post-harvest losses.

Sustainability and Future Trends in Produce Sorting

Mechanical sorting in post-harvest technology enhances sustainability by reducing labor intensity and minimizing produce waste through precise, automated grading systems that utilize optical sensors and AI algorithms. Manual sorting, while offering nuanced quality assessment, often results in higher labor costs and inconsistencies, limiting scalability for large-scale operations striving for eco-efficient practices. Future trends emphasize integrating AI-driven mechanical sorting with real-time data analytics to optimize supply chains, reduce carbon footprints, and promote circular economy principles in fresh produce management.

Related Important Terms

Hyperspectral Imaging Analysis

Mechanical sorting using hyperspectral imaging analysis enables rapid, non-destructive grading of produce by capturing detailed spectral data that reveals chemical composition and quality attributes, surpassing the speed and objectivity of manual sorting. This technology improves accuracy in detecting defects, ripeness, and contamination, enhancing overall post-harvest quality control and reducing labor costs.

Machine Vision Grading

Mechanical sorting using machine vision grading enhances accuracy and speed by employing advanced cameras and algorithms to assess produce attributes such as size, color, and surface defects, significantly reducing human error and labor costs. This technology enables consistent quality control and higher throughput compared to manual sorting, which relies on subjective human judgment and is slower and less scalable.

AI-Powered Sorting Systems

AI-powered mechanical sorting systems enhance accuracy and efficiency in grading produce by utilizing advanced image recognition and machine learning algorithms to identify size, color, and defects faster than manual sorting. These technologies reduce labor costs and improve consistency, enabling higher throughput and better quality control in post-harvest operations.

Defect Detection Algorithms

Mechanical sorting with advanced defect detection algorithms uses high-resolution imaging and machine learning to identify and classify produce imperfections more accurately and consistently than manual sorting, reducing human error and increasing throughput. These algorithms analyze color, texture, shape, and size variations to detect defects such as bruises, rot, and foreign matter, enhancing grading precision and ensuring better quality control in post-harvest technology.

Precision Optical Sorters

Precision optical sorters utilize advanced sensors and imaging technology to achieve higher accuracy and speed in grading produce compared to manual sorting, reducing human error and increasing throughput. These mechanical sorting systems enable consistent quality control by detecting color, size, shape, and defects with high precision, enhancing post-harvest efficiency and minimizing waste.

Human Sensory Calibration

Mechanical sorting offers consistent grading accuracy using calibrated sensors to evaluate produce characteristics such as color, size, and texture, reducing human error and increasing throughput. Manual sorting relies on human sensory calibration, where experienced workers assess produce quality through sight, touch, and smell, providing nuanced judgment but introducing variability and slower processing speeds.

Robotic Handling Automation

Robotic handling automation in mechanical sorting significantly enhances accuracy and efficiency by using AI-powered vision systems to grade produce based on size, color, and ripeness, reducing human error and labor costs. This technology enables high-throughput sorting with consistent quality control, outperforming manual sorting that relies on subjective human judgment and slower processing times.

Deep Learning Produce Classification

Mechanical sorting powered by deep learning produce classification improves accuracy and efficiency by analyzing visual features such as size, shape, and color with convolutional neural networks, outperforming traditional manual sorting. This technology enables real-time grading, reduces human error, and enhances throughput for large-scale post-harvest operations.

Variable Speed Conveyor Technology

Variable Speed Conveyor Technology enhances mechanical sorting by adjusting belt speeds to accommodate different sizes and weights of produce, improving grading accuracy and reducing damage compared to manual sorting. This technology enables precise control over throughput rates, optimizing efficiency and consistency in post-harvest grading processes.

Digital Twin Sorting Simulation

Digital Twin Sorting Simulation enhances mechanical sorting accuracy by replicating real-world grading scenarios, reducing errors and increasing efficiency compared to manual sorting. This technology enables precise calibration and optimization of sorting machines, minimizing post-harvest losses and improving overall produce quality consistency.

Mechanical Sorting vs Manual Sorting for grading produce Infographic

agridif.com

agridif.com