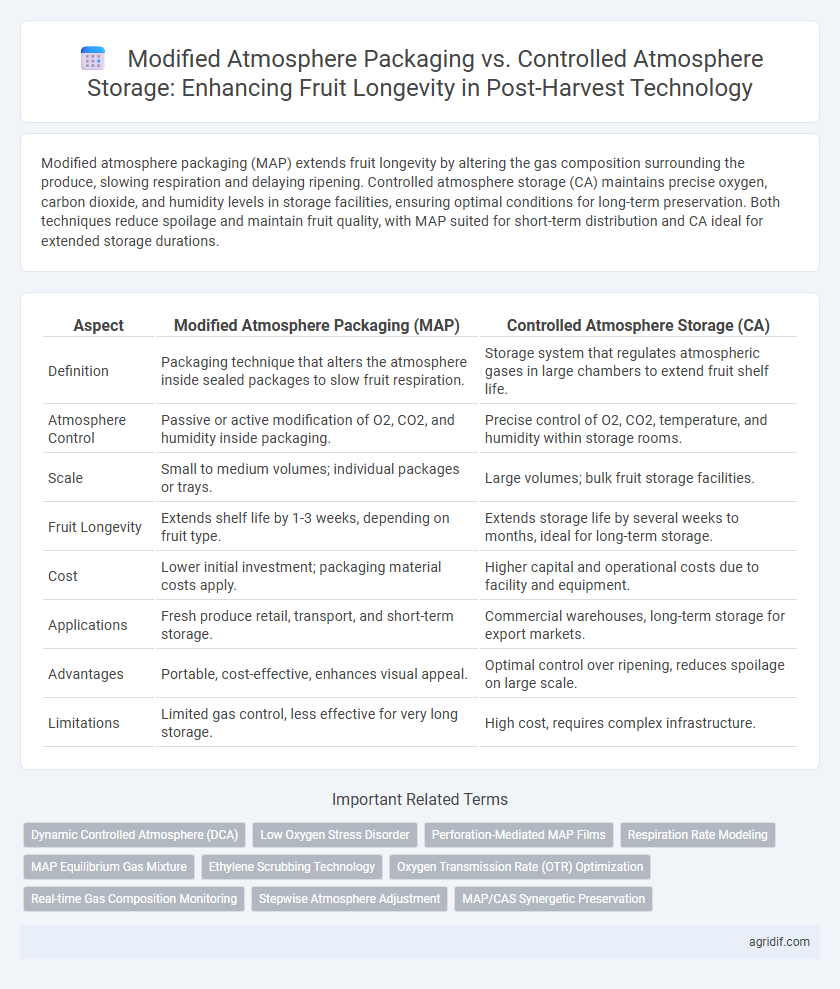

Modified atmosphere packaging (MAP) extends fruit longevity by altering the gas composition surrounding the produce, slowing respiration and delaying ripening. Controlled atmosphere storage (CA) maintains precise oxygen, carbon dioxide, and humidity levels in storage facilities, ensuring optimal conditions for long-term preservation. Both techniques reduce spoilage and maintain fruit quality, with MAP suited for short-term distribution and CA ideal for extended storage durations.

Table of Comparison

| Aspect | Modified Atmosphere Packaging (MAP) | Controlled Atmosphere Storage (CA) |

|---|---|---|

| Definition | Packaging technique that alters the atmosphere inside sealed packages to slow fruit respiration. | Storage system that regulates atmospheric gases in large chambers to extend fruit shelf life. |

| Atmosphere Control | Passive or active modification of O2, CO2, and humidity inside packaging. | Precise control of O2, CO2, temperature, and humidity within storage rooms. |

| Scale | Small to medium volumes; individual packages or trays. | Large volumes; bulk fruit storage facilities. |

| Fruit Longevity | Extends shelf life by 1-3 weeks, depending on fruit type. | Extends storage life by several weeks to months, ideal for long-term storage. |

| Cost | Lower initial investment; packaging material costs apply. | Higher capital and operational costs due to facility and equipment. |

| Applications | Fresh produce retail, transport, and short-term storage. | Commercial warehouses, long-term storage for export markets. |

| Advantages | Portable, cost-effective, enhances visual appeal. | Optimal control over ripening, reduces spoilage on large scale. |

| Limitations | Limited gas control, less effective for very long storage. | High cost, requires complex infrastructure. |

Introduction to Post-Harvest Fruit Preservation

Modified atmosphere packaging (MAP) and controlled atmosphere (CA) storage are essential post-harvest technologies for extending fruit longevity by regulating oxygen, carbon dioxide, and humidity levels to slow respiration and delay spoilage. MAP is typically used for retail packaging to maintain optimal gas composition around individual fruits, while CA storage involves large-scale controlled rooms managing atmospheric conditions for bulk storage. Both technologies significantly reduce enzymatic activity and microbial growth, preserving fruit quality and extending shelf life during distribution and storage.

Understanding Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) extends fruit longevity by altering the gas composition within packaging, typically reducing oxygen and increasing carbon dioxide levels to slow respiration and delay ripening. This technology contrasts with Controlled Atmosphere Storage (CAS), which regulates atmospheric conditions on a larger scale within storage facilities. MAP offers flexible, cost-effective protection tailored to individual fruit batches, enhancing shelf life while maintaining quality during distribution.

Exploring Controlled Atmosphere Storage (CAS)

Controlled Atmosphere Storage (CAS) enhances fruit longevity by precisely regulating oxygen, carbon dioxide, and humidity levels to slow metabolic processes and delay ripening. Compared to Modified Atmosphere Packaging (MAP), CAS provides a more stable and uniform environment, reducing the risk of anaerobic respiration and quality degradation over long storage periods. Advanced sensors and automation in CAS allow real-time monitoring and adjustment, optimizing fruit preservation and extending shelf life more effectively than passive MAP solutions.

Key Differences Between MAP and CAS

Modified Atmosphere Packaging (MAP) alters the gas composition inside sealed packages, typically reducing oxygen and increasing carbon dioxide levels to slow respiration and microbial growth in fruits, thereby extending shelf life primarily during transportation and retail display. Controlled Atmosphere Storage (CAS) maintains precisely regulated gas concentrations, temperature, and humidity in large storage rooms, offering long-term preservation by minimizing physiological deterioration and delaying ripening processes post-harvest. While MAP provides a cost-effective, scalable solution for short to medium-term fruit longevity, CAS requires advanced monitoring systems and infrastructure for optimal conditions over extended storage periods.

Mechanisms of Fruit Longevity in MAP

Modified atmosphere packaging (MAP) prolongs fruit longevity by altering the internal gas composition around the fruit, typically reducing oxygen levels and increasing carbon dioxide, which slows respiration rates and delays senescence. The modified environment in MAP inhibits ethylene production and microbial growth, crucial factors in fruit decay. This controlled microenvironment contrasts with controlled atmosphere storage, which maintains regulated gas concentrations on a larger scale but is often less adaptable for individual fruit batches.

Mechanisms of Fruit Longevity in CAS

Controlled atmosphere storage (CAS) extends fruit longevity by precisely regulating oxygen, carbon dioxide, and humidity levels to slow respiration rates and delay ripening. The low oxygen environment reduces ethylene production and oxidative stress, minimizing enzymatic activity that leads to senescence and decay. Additionally, elevated carbon dioxide levels inhibit microbial growth and maintain cell membrane integrity, preserving fruit quality throughout storage.

Advantages and Limitations of Modified Atmosphere Packaging

Modified Atmosphere Packaging (MAP) extends fruit longevity by altering the gas composition surrounding the produce, slowing respiration and microbial growth while maintaining freshness during transport and retail display. Advantages of MAP include cost-effectiveness, ease of implementation, and compatibility with existing supply chains, enabling tailored gas mixtures for different fruit types to optimize shelf life. Limitations involve inconsistent gas permeability in packaging materials, potential anaerobic respiration leading to off-flavors, and challenges in temperature control that can reduce efficacy compared to controlled atmosphere storage.

Advantages and Limitations of Controlled Atmosphere Storage

Controlled Atmosphere Storage (CAS) extends fruit longevity by precisely regulating oxygen, carbon dioxide, and humidity levels, significantly reducing respiration rates and delaying ripening compared to Modified Atmosphere Packaging (MAP). CAS offers superior scalability and consistency for large-scale storage but requires high initial investment and specialized infrastructure, limiting its accessibility for small producers. However, CAS can manage long-term storage effectively, while MAP is more suited for shorter durations and individual packaging needs.

Comparative Studies: MAP vs. CAS for Different Fruits

Comparative studies on modified atmosphere packaging (MAP) and controlled atmosphere storage (CAS) reveal distinct impacts on fruit longevity, with MAP offering flexible, small-scale solutions effective for berries and cherries, while CAS provides precise environmental control suited for apples and pears. Research indicates MAP maintains optimal oxygen and carbon dioxide levels within packaging, reducing respiration rates and delaying senescence, whereas CAS systems stabilize atmospheric gases in storage rooms to extend shelf life significantly. Species-specific outcomes show CAS excels in large-volume storage with consistent quality retention, whereas MAP is preferred for retail distribution requiring short-term preservation.

Future Trends in Atmospheric Control Technologies for Fruit Quality

Emerging atmospheric control technologies in post-harvest fruit storage emphasize precision in gas composition adjustments to extend shelf life and maintain quality. Modified atmosphere packaging (MAP) provides localized gas regulation around individual fruits, while controlled atmosphere storage (CAS) enables bulk storage environment management with dynamic monitoring systems utilizing oxygen, carbon dioxide, and humidity sensors. Future trends focus on integrating artificial intelligence (AI) and Internet of Things (IoT) for real-time atmospheric optimization, enhancing fruit longevity through tailored and adaptive respiration rate control.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology enhances fruit longevity by adjusting oxygen and carbon dioxide levels in real-time, preventing anaerobic respiration and maintaining optimal metabolic rates, unlike static Modified Atmosphere Packaging (MAP) which relies on preset gas compositions. In post-harvest technology, DCA outperforms traditional Controlled Atmosphere (CA) storage by dynamically adapting to fruit respiration changes, significantly reducing spoilage and extending shelf life for high-value fruits such as apples and pears.

Low Oxygen Stress Disorder

Modified atmosphere packaging (MAP) effectively reduces oxygen levels around fruit to slow respiration and delay ripening, but improper oxygen reduction can induce Low Oxygen Stress Disorder (LOSD), causing off-flavors and tissue damage. Controlled atmosphere (CA) storage maintains precise oxygen and carbon dioxide balance at ambient temperatures, minimizing LOSD risk by preventing hypoxic stress and extending fruit longevity with better physiological stability.

Perforation-Mediated MAP Films

Perforation-mediated modified atmosphere packaging (MAP) films enhance fruit longevity by allowing precise gas exchange, maintaining optimal oxygen and carbon dioxide levels that reduce respiration rate and delay ripening. Controlled atmosphere storage maintains a stable environment with specific gas concentrations but requires significant infrastructure, making MAP films a cost-effective alternative with adaptable perforation patterns to tailor atmospheres for different fruit types.

Respiration Rate Modeling

Modified atmosphere packaging (MAP) carefully adjusts oxygen and carbon dioxide levels around fruit to slow respiration rate, extending freshness by reducing metabolic activity and delaying senescence. Controlled atmosphere storage (CA) maintains precise gas compositions and temperature in large-scale facilities, enabling detailed respiration rate modeling to optimize storage duration and fruit quality over extended periods.

MAP Equilibrium Gas Mixture

Modified atmosphere packaging (MAP) maintains fruit longevity by creating an equilibrium gas mixture within the package that slows respiration and microbial growth, optimizing O2 and CO2 levels dynamically as the fruit consumes oxygen and produces carbon dioxide. Controlled atmosphere (CA) storage regulates gas composition externally at stable, low oxygen and elevated carbon dioxide concentrations, requiring specialized facilities, while MAP offers a cost-effective, scalable alternative by achieving a self-adjusting atmosphere around the produce.

Ethylene Scrubbing Technology

Modified atmosphere packaging (MAP) extends fruit longevity by creating a low-oxygen, high-carbon dioxide environment that slows respiration and ethylene production, while controlled atmosphere (CA) storage maintains precise gas concentrations to optimize shelf life. Ethylene scrubbing technology, integrated in CA storage, actively removes ethylene gas, significantly delaying ripening and senescence compared to passive ethylene management in MAP, resulting in superior fruit quality preservation.

Oxygen Transmission Rate (OTR) Optimization

Modified atmosphere packaging (MAP) extends fruit longevity by optimizing Oxygen Transmission Rate (OTR) through selective film permeability, balancing oxygen and carbon dioxide levels to slow respiration and delay ripening. Controlled atmosphere storage (CAS) achieves precise OTR control via regulated gaseous composition and temperature, allowing for more consistent extension of shelf life in large-scale fruit storage compared to MAP.

Real-time Gas Composition Monitoring

Modified atmosphere packaging (MAP) adjusts gas composition within the packaging to slow fruit respiration, while controlled atmosphere (CA) storage maintains precise gas levels in large storage facilities; real-time gas composition monitoring uses sensors to continuously track oxygen, carbon dioxide, and ethylene concentrations, optimizing conditions to extend fruit longevity. Advanced MAP systems with integrated gas sensors enable dynamic atmosphere adjustments, but CA storage's centralized monitoring allows for more consistent environment control across bulk fruit storage.

Stepwise Atmosphere Adjustment

Stepwise atmosphere adjustment in modified atmosphere packaging (MAP) gradually alters gas composition to reduce fruit respiration and delay senescence, optimizing shelf life without causing physiological stress. Controlled atmosphere (CA) storage maintains precise low oxygen and elevated carbon dioxide levels, extending fruit longevity through stable environmental regulation, but requires complex infrastructure compared to MAP's flexible packaging solutions.

MAP/CAS Synergetic Preservation

Modified atmosphere packaging (MAP) and controlled atmosphere storage (CAS) synergistically extend fruit longevity by optimizing gas compositions around produce; MAP adjusts O2 and CO2 levels in sealed packaging to slow respiration rates, while CAS maintains precise atmospheric conditions in storage facilities for consistent preservation. Combining MAP and CAS technologies enhances fruit quality retention, reduces spoilage, and prolongs shelf life by leveraging complementary gas control mechanisms during post-harvest handling.

Modified atmosphere packaging vs controlled atmosphere storage for fruit longevity Infographic

agridif.com

agridif.com