Mechanical drying offers controlled temperature and humidity, ensuring uniform moisture removal from grains, which reduces spoilage and improves storage stability compared to sun drying. Sun drying depends on weather conditions, is time-consuming, and often exposes grains to contaminants, leading to potential quality degradation. Utilizing mechanical drying enhances efficiency and grain quality, making it a preferred method in modern post-harvest technology.

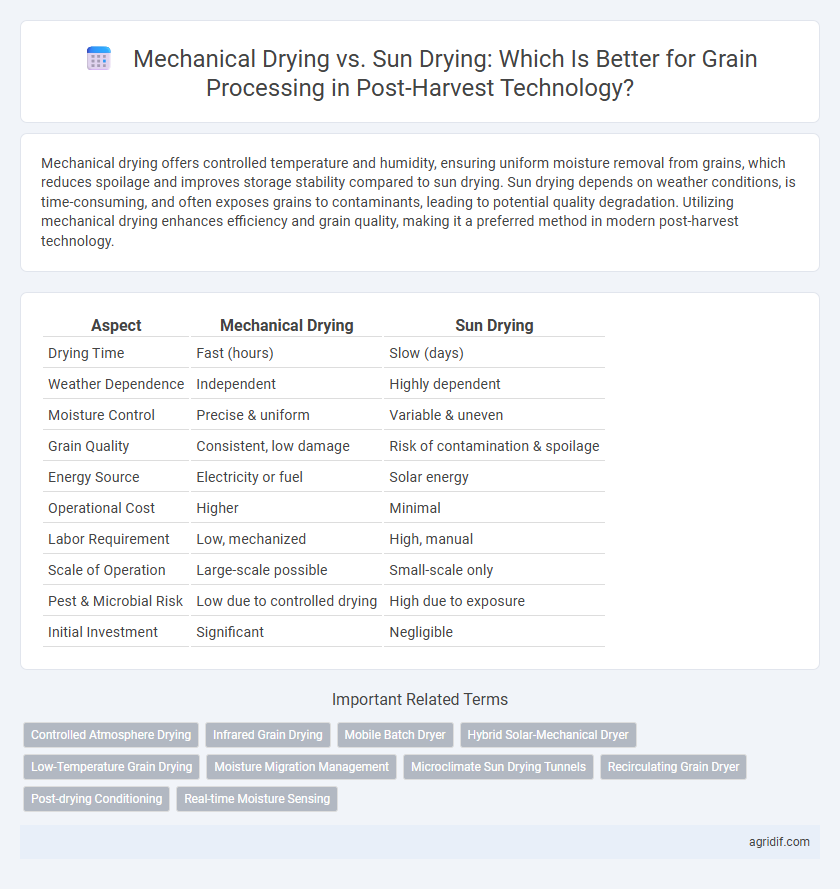

Table of Comparison

| Aspect | Mechanical Drying | Sun Drying |

|---|---|---|

| Drying Time | Fast (hours) | Slow (days) |

| Weather Dependence | Independent | Highly dependent |

| Moisture Control | Precise & uniform | Variable & uneven |

| Grain Quality | Consistent, low damage | Risk of contamination & spoilage |

| Energy Source | Electricity or fuel | Solar energy |

| Operational Cost | Higher | Minimal |

| Labor Requirement | Low, mechanized | High, manual |

| Scale of Operation | Large-scale possible | Small-scale only |

| Pest & Microbial Risk | Low due to controlled drying | High due to exposure |

| Initial Investment | Significant | Negligible |

Introduction to Post-Harvest Grain Drying Methods

Mechanical drying offers precise control over temperature and humidity, significantly reducing drying time compared to traditional sun drying, which relies on ambient conditions and exposes grains to potential contamination and weather risks. By utilizing forced air circulation and adjustable drying parameters, mechanical drying enhances grain quality preservation and minimizes post-harvest losses. Sun drying remains cost-effective but poses challenges such as uneven drying and susceptibility to insect infestation, making mechanical drying a preferred method in large-scale grain processing operations.

Overview of Mechanical Drying in Agriculture

Mechanical drying in agriculture offers a controlled environment to reduce moisture content in grains, enhancing storage life and minimizing spoilage. This technology uses heated air and advanced airflow systems to achieve uniform drying, significantly reducing drying time compared to traditional sun drying. By maintaining optimal temperature and humidity levels, mechanical drying preserves grain quality and reduces post-harvest losses effectively.

Sun Drying Techniques for Grain Processing

Sun drying techniques for grain processing utilize natural solar energy to reduce moisture content, preserving grain quality while minimizing energy costs. Traditional methods involve spreading grains thinly on clean surfaces, periodically turning to ensure uniform drying and prevent fungal growth. Optimizing sun drying duration and protecting grains from pests and contaminants are critical to maintaining food safety and extending storage life.

Efficiency Comparison: Mechanical vs Sun Drying

Mechanical drying offers precise control over temperature and humidity, resulting in faster moisture reduction and reduced risk of grain spoilage compared to sun drying. Sun drying, while cost-effective and energy-efficient, is highly dependent on weather conditions and slower, increasing the potential for contamination and uneven drying. Mechanical drying systems enhance post-harvest efficiency by ensuring consistent grain quality and minimizing losses during storage and transportation.

Impact on Grain Quality and Nutritional Value

Mechanical drying of grains provides controlled temperature and airflow, reducing moisture content efficiently while preserving essential nutrients such as proteins and vitamins. In contrast, sun drying exposes grains to fluctuating environmental conditions, increasing the risk of microbial contamination and nutrient degradation, particularly the loss of heat-sensitive compounds like vitamin E. Studies indicate that mechanical drying maintains higher grain quality and nutritional value by minimizing oxidative damage and enzymatic activity compared to traditional sun drying methods.

Cost Analysis: Mechanical Drying versus Sun Drying

Mechanical drying of grains incurs higher initial capital investment and operational costs due to energy consumption and equipment maintenance, contrasting with the virtually zero cost of sun drying which relies solely on natural solar radiation. While mechanical drying shortens drying time and reduces post-harvest losses by providing controlled drying conditions, the recurring energy expenses make its cost-effectiveness dependent on scale and market value of the grain. Economic assessments highlight that sun drying remains the most affordable method for small-scale farmers in developing regions, whereas mechanical drying offers cost advantages in large-scale commercial grain processing due to improved drying efficiency and product quality.

Labor and Time Requirements in Drying Methods

Mechanical drying significantly reduces labor intensity and drying time in grain processing compared to sun drying, which relies heavily on manual labor and extended exposure to weather conditions. Sun drying can take several days to weeks depending on climate, increasing the risk of spoilage and contamination, whereas mechanical dryers can complete drying within hours under controlled temperature and airflow. Efficient labor utilization and faster processing cycles in mechanical drying enhance productivity and minimize post-harvest losses in grain handling.

Environmental Considerations and Sustainability

Mechanical drying in grain processing offers controlled moisture removal, reducing the risk of spoilage and mycotoxin contamination while consuming significant energy, often derived from fossil fuels, which impacts carbon emissions. Sun drying is an environmentally sustainable option relying on natural solar energy, minimizing greenhouse gas emissions but is weather-dependent and slower, potentially increasing post-harvest losses. Integrating renewable energy sources with mechanical drying systems enhances sustainability by lowering environmental footprints and improving drying efficiency in grain post-harvest technology.

Challenges and Limitations of Each Drying Method

Mechanical drying in grain processing offers controlled temperature and humidity but faces challenges like high energy consumption and initial investment costs. Sun drying is cost-effective and eco-friendly, yet it is limited by weather dependency, prolonged drying times, and vulnerability to contamination and pest infestation. Both methods require careful management to minimize grain quality degradation and post-harvest losses.

Recommendations for Optimal Grain Drying Practices

Mechanical drying offers precise control over temperature and humidity, reducing drying time and minimizing grain quality deterioration compared to sun drying. Optimal grain drying practices recommend using mechanical dryers to achieve uniform moisture content, prevent mold growth, and maintain grain viability. Regular monitoring of moisture levels and avoiding excessive heat during mechanical drying are crucial to preserving nutritional value and seed germination rates.

Related Important Terms

Controlled Atmosphere Drying

Controlled Atmosphere Drying (CAD) offers precise regulation of temperature, humidity, and oxygen levels during grain processing, reducing drying time and minimizing quality degradation compared to traditional sun drying. Mechanical drying enhanced by CAD prevents biochemical losses and pest infestation by maintaining optimal conditions, ensuring higher grain quality and extended storage life.

Infrared Grain Drying

Infrared grain drying offers faster moisture removal and lower energy consumption compared to traditional sun drying, reducing post-harvest losses and preserving grain quality. Its controlled environment minimizes contamination risks and maintains nutritional value, making it a superior alternative in mechanical drying technologies for grain processing.

Mobile Batch Dryer

Mobile batch dryers provide precise temperature control and faster drying times compared to traditional sun drying, reducing grain moisture content effectively to prevent spoilage and mold growth. Their portability and energy efficiency enable post-harvest handlers to process grains quickly on-site, improving overall grain quality and minimizing losses.

Hybrid Solar-Mechanical Dryer

Hybrid solar-mechanical dryers combine the energy efficiency of solar drying with the reliability of mechanical systems, significantly reducing drying time and minimizing grain quality degradation compared to traditional sun drying. These systems optimize moisture removal under controlled temperature and airflow conditions, enhancing grain shelf-life and reducing post-harvest losses in various climatic conditions.

Low-Temperature Grain Drying

Low-temperature grain drying uses controlled mechanical systems to maintain optimal moisture reduction, preserving grain quality and reducing spoilage compared to traditional sun drying methods. Mechanical drying allows for consistent temperature regulation and faster processing times, enhancing the efficiency and safety of post-harvest grain preservation.

Moisture Migration Management

Mechanical drying offers precise moisture migration management by controlling temperature and airflow, ensuring uniform grain moisture reduction and minimizing quality loss. Sun drying, while cost-effective, results in uneven moisture migration due to fluctuating environmental conditions, increasing the risk of mold growth and reduced storage life.

Microclimate Sun Drying Tunnels

Microclimate sun drying tunnels enhance grain moisture reduction by creating controlled airflow and temperature conditions, significantly improving drying efficiency compared to traditional sun drying methods. These tunnels reduce grain spoilage and microbial growth by maintaining optimal microclimatic factors, offering a cost-effective alternative to mechanical drying with lower energy consumption.

Recirculating Grain Dryer

Recirculating grain dryers offer precise moisture control and reduced drying time compared to traditional sun drying, minimizing grain spoilage and quality loss. These mechanical dryers enhance uniform drying by continuously circulating heated air, which improves grain preservation and increases overall post-harvest efficiency.

Post-drying Conditioning

Mechanical drying ensures uniform moisture removal in grains, reducing the risk of mold and insect infestation during storage, while sun drying often leads to uneven drying and higher post-drying conditioning requirements to stabilize grain moisture content. Optimal post-drying conditioning after mechanical drying improves grain quality and prolongs shelf life by allowing moisture redistribution and temperature equilibration within the bulk.

Real-time Moisture Sensing

Mechanical drying in grain processing offers precise control over temperature and airflow, enhancing drying efficiency and grain quality by integrating real-time moisture sensing technology that continuously monitors moisture levels to prevent over-drying or mold growth. Sun drying lacks this real-time feedback mechanism, resulting in inconsistent moisture reduction and higher risk of grain spoilage due to unpredictable environmental conditions.

Mechanical drying vs sun drying for grain processing Infographic

agridif.com

agridif.com