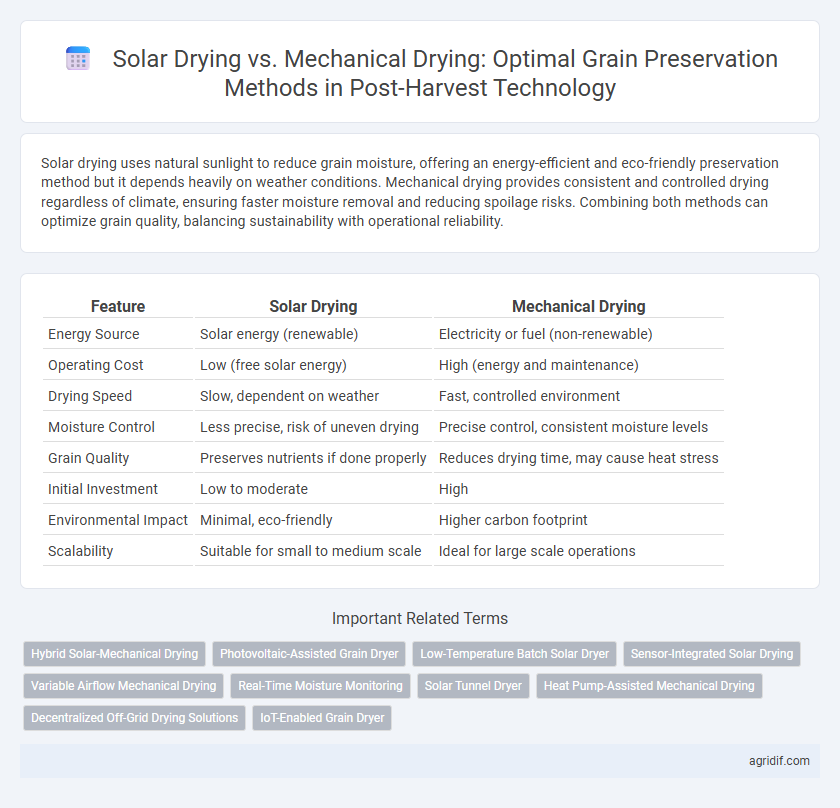

Solar drying uses natural sunlight to reduce grain moisture, offering an energy-efficient and eco-friendly preservation method but it depends heavily on weather conditions. Mechanical drying provides consistent and controlled drying regardless of climate, ensuring faster moisture removal and reducing spoilage risks. Combining both methods can optimize grain quality, balancing sustainability with operational reliability.

Table of Comparison

| Feature | Solar Drying | Mechanical Drying |

|---|---|---|

| Energy Source | Solar energy (renewable) | Electricity or fuel (non-renewable) |

| Operating Cost | Low (free solar energy) | High (energy and maintenance) |

| Drying Speed | Slow, dependent on weather | Fast, controlled environment |

| Moisture Control | Less precise, risk of uneven drying | Precise control, consistent moisture levels |

| Grain Quality | Preserves nutrients if done properly | Reduces drying time, may cause heat stress |

| Initial Investment | Low to moderate | High |

| Environmental Impact | Minimal, eco-friendly | Higher carbon footprint |

| Scalability | Suitable for small to medium scale | Ideal for large scale operations |

Introduction to Grain Preservation Challenges

Grain preservation faces significant challenges due to moisture content that promotes microbial growth and insect infestation, leading to substantial post-harvest losses. Solar drying offers an energy-efficient method using natural sunlight to reduce grain moisture, but its dependency on weather conditions limits consistency and drying speed. Mechanical drying provides controlled, rapid drying with the ability to maintain grain quality, yet it involves higher energy costs and initial investment.

Overview of Solar Drying Methods

Solar drying methods for grain preservation primarily utilize natural sunlight and ambient air to reduce moisture content, enhancing storage life and quality. Techniques vary from simple direct sun drying to improved solar dryers like cabinet or tunnel types, which offer controlled temperature and humidity conditions, reducing contamination and drying time. These methods are energy-efficient, environmentally friendly, and suitable for small to medium-scale farmers aiming to minimize post-harvest losses without high operational costs.

Overview of Mechanical Drying Technologies

Mechanical drying technologies for grain preservation include batch and continuous dryers using heated air to reduce moisture content efficiently. These systems offer precise control over drying temperature and airflow, minimizing grain damage and preventing fungal growth. Common mechanical dryers include rotary, fluidized bed, and column dryers, which are effective in maintaining grain quality during post-harvest storage.

Energy Efficiency: Solar vs Mechanical Drying

Solar drying utilizes renewable solar energy, significantly reducing operational costs and environmental impact compared to mechanical drying systems that rely on electricity or fossil fuels. Mechanical drying offers faster drying times and greater control over temperature and humidity, which can be essential for high-moisture grains but often results in higher energy consumption. Evaluating energy efficiency, solar drying is more sustainable for small-scale operations, whereas mechanical drying suits large-scale grain preservation due to its speed despite increased energy use.

Impact on Grain Quality and Nutritional Value

Solar drying preserves grain quality by reducing moisture content gradually, retaining essential nutrients and minimizing enzymatic degradation. Mechanical drying offers faster moisture removal but poses risks of overheating, which can degrade proteins, vitamins, and antioxidants in grains. Optimizing drying temperature and duration is critical to balance efficiency and maintain the nutritional value during post-harvest processing.

Cost Comparison: Initial Investment and Operational Expenses

Solar drying requires a significantly lower initial investment compared to mechanical drying systems, making it more accessible for small-scale farmers. Operational expenses for solar drying are minimal due to the reliance on natural sunlight, whereas mechanical drying involves higher ongoing costs from fuel, electricity, and maintenance. Despite the higher upfront and running costs, mechanical drying offers faster processing times and more consistent control over drying conditions.

Environmental Sustainability and Carbon Footprint

Solar drying significantly reduces carbon footprint by harnessing renewable solar energy, minimizing reliance on fossil fuels compared to mechanical drying systems. Mechanical drying consumes more electricity or fuel, resulting in higher greenhouse gas emissions and environmental degradation. Emphasizing solar drying enhances environmental sustainability by lowering energy consumption and promoting eco-friendly grain preservation methods.

Adaptability to Different Climates and Scales

Solar drying for grain preservation offers excellent adaptability in regions with abundant sunlight and warm climates, making it ideal for small-scale farmers due to low operational costs and minimal infrastructure requirements. Mechanical drying provides greater control over temperature and humidity, enabling consistent drying in diverse climates and large-scale operations, thus reducing post-harvest losses in variable weather conditions. Optimal grain preservation often involves selecting the drying method based on regional climate patterns, available resources, and intended production scale to maximize efficiency and product quality.

Maintenance Requirements and Durability

Solar drying systems for grain preservation demand minimal maintenance, primarily involving regular cleaning of solar panels and airflow channels, offering durability through passive components with fewer mechanical failures. Mechanical drying systems require consistent maintenance, including inspection and replacement of burners, fans, and moving parts, which increases operational costs but allows precise control over drying conditions. Durability of mechanical dryers depends on the quality of materials and maintenance frequency, often leading to shorter service life compared to low-maintenance, long-lasting solar dryers.

Future Trends in Grain Drying Technology

Future trends in grain drying technology emphasize the integration of renewable energy sources, with solar drying gaining traction due to its sustainability and low operational costs, particularly in regions with high solar insolation. Mechanical drying systems are advancing through the adoption of energy-efficient technologies, including hybrid drying methods that combine solar and mechanical processes to optimize drying rates and preserve grain quality. Innovations in sensor-based monitoring and automation are enhancing the precision and scalability of both solar and mechanical drying, contributing to reduced post-harvest losses and improved shelf-life of grains.

Related Important Terms

Hybrid Solar-Mechanical Drying

Hybrid solar-mechanical drying systems combine the energy efficiency of solar drying with the controlled environment of mechanical drying to enhance grain preservation by reducing moisture content rapidly while minimizing nutrient loss and fungal contamination. This integrated approach optimizes drying time and energy consumption, improving grain quality and extending shelf life compared to standalone solar or mechanical methods.

Photovoltaic-Assisted Grain Dryer

Photovoltaic-assisted grain dryers leverage solar energy through photovoltaic panels to power mechanical drying systems, offering an energy-efficient solution that reduces reliance on fossil fuels while maintaining controlled drying conditions essential for grain preservation. This technology enhances drying uniformity, minimizes post-harvest losses, and supports sustainable agricultural practices by integrating renewable energy into mechanical drying processes.

Low-Temperature Batch Solar Dryer

Low-temperature batch solar dryers offer an energy-efficient solution for grain preservation by harnessing solar radiation to achieve controlled drying conditions that minimize nutrient loss and prevent microbial growth. Compared to mechanical drying, these solar dryers reduce operating costs and environmental impact while maintaining grain quality through gentle drying at temperatures typically below 60degC.

Sensor-Integrated Solar Drying

Sensor-integrated solar drying for grain preservation enhances moisture control and reduces drying time by continuously monitoring temperature and humidity, optimizing drying conditions and minimizing quality loss. Compared to mechanical drying, this technology offers energy efficiency, lower operational costs, and sustainable post-harvest management while maintaining grain nutritional value and preventing microbial growth.

Variable Airflow Mechanical Drying

Variable Airflow Mechanical Drying offers precise control over temperature and humidity, significantly reducing drying time and minimizing nutrient loss in grain preservation compared to traditional solar drying. This technology enhances grain quality by preventing spoilage and microbial growth through uniform airflow distribution, ensuring higher market value and longer storage life.

Real-Time Moisture Monitoring

Solar drying relies on natural sunlight and ambient conditions, making real-time moisture monitoring essential to prevent over-drying or microbial growth, while mechanical drying offers precise control with automated sensors that continuously track moisture levels, ensuring optimal grain preservation and energy efficiency. Advanced moisture sensors integrated into mechanical dryers enhance drying uniformity and reduce post-harvest losses compared to the variable drying rates in solar systems.

Solar Tunnel Dryer

Solar tunnel dryers utilize renewable solar energy to reduce moisture content in grains efficiently, minimizing nutrient loss and microbial growth compared to conventional mechanical drying methods. Their cost-effectiveness and environmental sustainability make them ideal for smallholder farmers aiming for improved grain preservation with lower operational expenses.

Heat Pump-Assisted Mechanical Drying

Heat pump-assisted mechanical drying offers precise temperature and humidity control, reducing grain moisture content efficiently while preserving nutritional quality and minimizing energy consumption compared to traditional solar drying methods. This technology enables faster drying cycles and greater flexibility regardless of weather conditions, ensuring consistent grain preservation and extended shelf life.

Decentralized Off-Grid Drying Solutions

Solar drying offers a decentralized, off-grid solution for grain preservation by harnessing renewable solar energy, reducing operational costs and minimizing carbon emissions compared to mechanical drying systems. Mechanical drying provides faster moisture removal and higher processing capacity but relies on consistent energy supply, making solar drying more sustainable and accessible for rural post-harvest grain management.

IoT-Enabled Grain Dryer

IoT-enabled grain dryers enhance post-harvest technology by providing real-time monitoring and precise control over drying conditions, significantly reducing moisture content and minimizing spoilage compared to traditional solar drying methods. These smart mechanical dryers optimize energy use, maintain grain quality, and enable data-driven decision-making to improve overall grain preservation efficiency.

Solar Drying vs Mechanical Drying for grain preservation Infographic

agridif.com

agridif.com