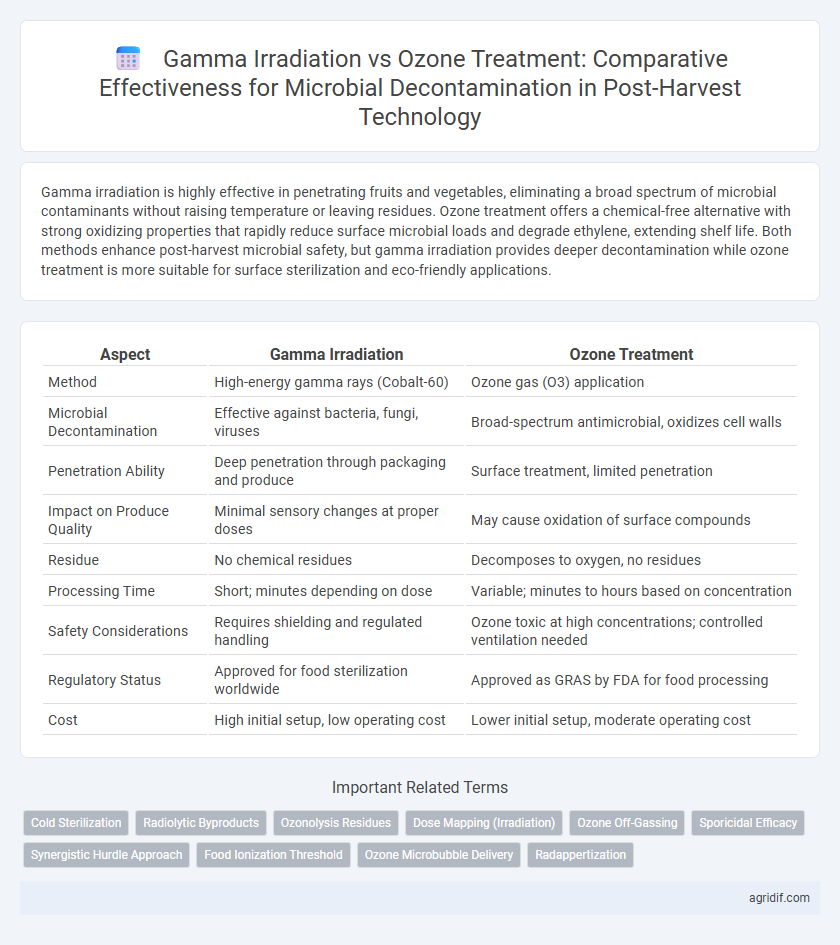

Gamma irradiation is highly effective in penetrating fruits and vegetables, eliminating a broad spectrum of microbial contaminants without raising temperature or leaving residues. Ozone treatment offers a chemical-free alternative with strong oxidizing properties that rapidly reduce surface microbial loads and degrade ethylene, extending shelf life. Both methods enhance post-harvest microbial safety, but gamma irradiation provides deeper decontamination while ozone treatment is more suitable for surface sterilization and eco-friendly applications.

Table of Comparison

| Aspect | Gamma Irradiation | Ozone Treatment |

|---|---|---|

| Method | High-energy gamma rays (Cobalt-60) | Ozone gas (O3) application |

| Microbial Decontamination | Effective against bacteria, fungi, viruses | Broad-spectrum antimicrobial, oxidizes cell walls |

| Penetration Ability | Deep penetration through packaging and produce | Surface treatment, limited penetration |

| Impact on Produce Quality | Minimal sensory changes at proper doses | May cause oxidation of surface compounds |

| Residue | No chemical residues | Decomposes to oxygen, no residues |

| Processing Time | Short; minutes depending on dose | Variable; minutes to hours based on concentration |

| Safety Considerations | Requires shielding and regulated handling | Ozone toxic at high concentrations; controlled ventilation needed |

| Regulatory Status | Approved for food sterilization worldwide | Approved as GRAS by FDA for food processing |

| Cost | High initial setup, low operating cost | Lower initial setup, moderate operating cost |

Overview of Gamma Irradiation and Ozone Treatment

Gamma irradiation utilizes high-energy gamma rays to penetrate and disrupt microbial DNA, effectively reducing microbial load on post-harvest produce without significantly affecting nutritional quality. Ozone treatment employs ozone gas, a strong oxidizing agent, to oxidize and destroy microbial cell walls on fruits and vegetables, offering a residue-free and environmentally friendly alternative. Both methods enhance shelf life and safety, with gamma irradiation providing deeper penetration and ozone treatment allowing rapid, surface-level decontamination.

Mechanisms of Microbial Decontamination

Gamma irradiation eliminates microbial contamination by generating ionizing radiation that disrupts microbial DNA, leading to cellular damage and death. Ozone treatment acts as a powerful oxidizing agent, oxidizing cell walls and membrane lipids, causing permeability loss and microbial cell lysis. Both methods effectively inactivate bacteria, fungi, and viruses, but gamma irradiation penetrates deeper, while ozone's efficacy depends on surface exposure and concentration levels.

Effectiveness Against Common Agricultural Pathogens

Gamma irradiation effectively reduces microbial load by damaging the DNA of pathogens like Salmonella, E. coli, and Listeria, ensuring extended shelf life and food safety in agricultural products. Ozone treatment offers strong oxidative properties that eliminate bacteria, fungi, and viruses on fresh produce surfaces without chemical residues. Both methods demonstrate high efficacy, but gamma irradiation provides deeper penetration while ozone excels in rapid surface sterilization of common agricultural pathogens.

Impact on Nutrient Composition and Food Quality

Gamma irradiation effectively reduces microbial load in post-harvest products while maintaining key nutrient levels such as vitamins A and C with minimal degradation. Ozone treatment offers rapid microbial decontamination but can cause oxidative stress, potentially reducing antioxidants like ascorbic acid and altering sensory qualities. Both technologies influence food quality parameters differently, with gamma irradiation preserving texture and color more consistently compared to ozone's potential to induce surface oxidation.

Residual Effects and Food Safety Considerations

Gamma irradiation effectively reduces microbial load on post-harvest produce with minimal residual impact, preserving food quality and extending shelf life. Ozone treatment offers rapid microbial decontamination but may lead to potential oxidative damage, necessitating careful dosage control to maintain food safety. Both methods require stringent monitoring to prevent chemical residues and ensure compliance with food safety regulations.

Cost-Effectiveness and Operational Efficiency

Gamma irradiation offers high microbial decontamination efficacy but involves significant initial capital investment and regulatory compliance costs, making it less cost-effective for small-scale post-harvest operations. Ozone treatment provides a more affordable and energy-efficient alternative with rapid microbial inactivation and lower maintenance expenses, enhancing operational efficiency in large batch processing. However, ozone's effectiveness can vary with produce type and storage conditions, requiring tailored system design for optimal results.

Regulatory Approvals and Global Acceptance

Gamma irradiation for microbial decontamination in post-harvest technology has widespread regulatory approvals from agencies such as the FDA, WHO, and USDA, enabling its global acceptance for treating fruits, vegetables, and spices. Ozone treatment, recognized for its residue-free antimicrobial properties, has gained regulatory clearance in regions including the US, EU, and Japan, but faces variable acceptance due to differences in national standards and limited standardized protocols. Both technologies are increasingly integrated into post-harvest management systems, with regulatory frameworks continuing to evolve to address efficacy, safety, and environmental impact considerations.

Environmental Impacts and Sustainability

Gamma irradiation and ozone treatment both serve as effective microbial decontamination methods in post-harvest technology, but they differ significantly in environmental impacts and sustainability. Gamma irradiation relies on radioactive sources, posing challenges in waste management and potential radiation hazards, while ozone treatment utilizes ozone gas, which decomposes rapidly into oxygen, leaving no chemical residues and reducing environmental risks. Ozone's lower energy requirements and minimal ecological footprint make it a more sustainable choice for post-harvest microbial control compared to gamma irradiation.

Consumer Perception and Market Trends

Gamma irradiation and ozone treatment effectively reduce microbial contamination in post-harvest produce, yet consumer perception significantly influences market adoption. Consumers often express greater apprehension about gamma irradiation due to fears of radiation exposure, despite its proven safety and efficacy, whereas ozone treatment is viewed more favorably as a chemical-free, residue-free method. Market trends reveal a growing preference for ozone treatment, driven by increasing demand for natural preservation techniques and clean-label products.

Future Prospects in Post-Harvest Decontamination

Gamma irradiation demonstrates high efficacy in microbial decontamination with deep penetration capability, making it suitable for bulk post-harvest treatment. Ozone treatment offers a chemical-free, residue-free alternative with strong oxidation potential but limited penetration depth, ideal for surface sterilization. Future prospects involve combining both technologies to enhance microbial control, improve shelf life, and meet safety standards in the post-harvest supply chain.

Related Important Terms

Cold Sterilization

Gamma irradiation and ozone treatment are advanced cold sterilization methods for microbial decontamination in post-harvest technology, effectively eliminating pathogens without heat exposure. Gamma irradiation uses ionizing radiation to disrupt microbial DNA, while ozone treatment relies on strong oxidative properties to oxidize cell components, both preserving produce quality and extending shelf life.

Radiolytic Byproducts

Gamma irradiation effectively eliminates microbial contaminants in post-harvest produce but generates radiolytic byproducts such as free radicals and organic compounds that may affect food safety and quality. In contrast, ozone treatment offers microbial decontamination without forming persistent byproducts, making it a cleaner alternative, though its oxidative potential requires careful application to prevent produce damage.

Ozonolysis Residues

Ozone treatment effectively reduces microbial contamination on post-harvest produce without leaving harmful ozonolysis residues, as ozone rapidly decomposes into oxygen, ensuring residue-free sanitization. In contrast, gamma irradiation may generate residual free radicals that require additional time to dissipate, raising concerns about prolonged microbial inactivation but potential chemical residues.

Dose Mapping (Irradiation)

Dose mapping in gamma irradiation ensures uniform microbial decontamination by precisely measuring and controlling radiation doses across the produce, preventing under- or over-exposure that can compromise quality. Ozone treatment relies on controlled concentration and exposure time to inactivate microbes, but lacks the detailed spatial dose distribution analysis inherent in gamma irradiation dose mapping.

Ozone Off-Gassing

Ozone treatment for microbial decontamination in post-harvest technology generates ozone off-gassing, which necessitates controlled ventilation to prevent toxicity and ensure worker safety. Unlike gamma irradiation, ozone off-gassing can lead to residual ozone exposure, requiring monitoring systems to maintain safe atmospheric ozone concentrations during and after treatment.

Sporicidal Efficacy

Gamma irradiation demonstrates superior sporicidal efficacy compared to ozone treatment, effectively disrupting bacterial spores through ionizing radiation that penetrates produce surfaces. Ozone treatment, while antimicrobial, exhibits limited sporicidal action due to its lower penetration power and reliance on oxidative stress, making gamma irradiation a more robust choice for post-harvest microbial decontamination.

Synergistic Hurdle Approach

Gamma irradiation and ozone treatment both serve as effective microbial decontamination methods in post-harvest technology, with gamma irradiation providing deep penetration and ozone offering strong oxidative disinfection. Employing a synergistic hurdle approach leverages the complementary mechanisms of action, enhancing microbial inactivation while minimizing chemical residues and preserving produce quality.

Food Ionization Threshold

Gamma irradiation surpasses ozone treatment in microbial decontamination due to its higher ionization threshold, effectively penetrating food matrices to eliminate pathogens without compromising nutritional quality. While ozone treatment offers surface-level disinfection, gamma rays achieve deeper ionization, ensuring comprehensive microbial reduction in post-harvest food preservation.

Ozone Microbubble Delivery

Ozone microbubble delivery enhances microbial decontamination by increasing ozone solubility and contact efficiency compared to conventional gamma irradiation, reducing microbial load on post-harvest produce without chemical residues. This method improves shelf life and safety by generating reactive oxygen species that disrupt microbial cell membranes more effectively than gamma irradiation's ionizing radiation.

Radappertization

Gamma irradiation achieves Radappertization by applying high doses of ionizing radiation to eliminate microbial pathogens in post-harvest produce, ensuring extended shelf life and safety without compromising quality. Ozone treatment offers an alternative by generating reactive oxygen species that disrupt microbial cells, but it typically does not reach the sterilization levels required for complete Radappertization.

Gamma Irradiation vs Ozone Treatment for microbial decontamination Infographic

agridif.com

agridif.com