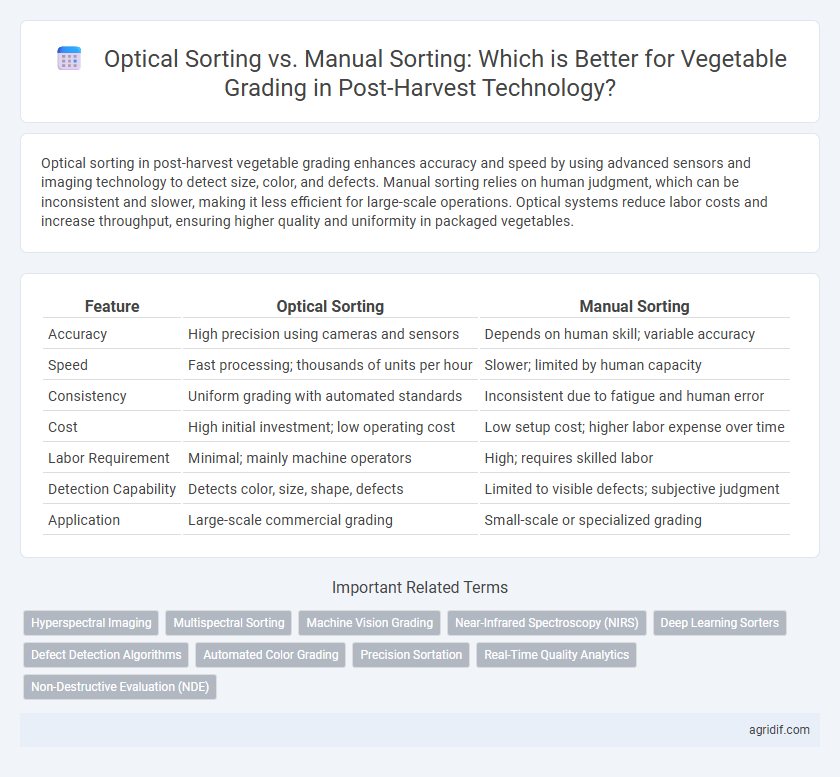

Optical sorting in post-harvest vegetable grading enhances accuracy and speed by using advanced sensors and imaging technology to detect size, color, and defects. Manual sorting relies on human judgment, which can be inconsistent and slower, making it less efficient for large-scale operations. Optical systems reduce labor costs and increase throughput, ensuring higher quality and uniformity in packaged vegetables.

Table of Comparison

| Feature | Optical Sorting | Manual Sorting |

|---|---|---|

| Accuracy | High precision using cameras and sensors | Depends on human skill; variable accuracy |

| Speed | Fast processing; thousands of units per hour | Slower; limited by human capacity |

| Consistency | Uniform grading with automated standards | Inconsistent due to fatigue and human error |

| Cost | High initial investment; low operating cost | Low setup cost; higher labor expense over time |

| Labor Requirement | Minimal; mainly machine operators | High; requires skilled labor |

| Detection Capability | Detects color, size, shape, defects | Limited to visible defects; subjective judgment |

| Application | Large-scale commercial grading | Small-scale or specialized grading |

Introduction to Vegetable Grading Methods

Optical sorting leverages advanced imaging technology and machine learning algorithms to rapidly and accurately classify vegetables based on size, color, and defects, greatly enhancing sorting efficiency and consistency compared to manual methods. Manual sorting relies on human operators to visually inspect and grade vegetables, which is labor-intensive, time-consuming, and prone to variability due to subjective judgment and fatigue. Integrating optical sorting into post-harvest technology streamlines vegetable grading processes, improves product quality, and reduces operational costs in commercial packing facilities.

Principles of Optical Sorting Technology

Optical sorting technology for vegetable grading relies on advanced imaging systems that analyze color, size, shape, and surface defects using cameras and sensors. This technology employs algorithms to rapidly differentiate and separate high-quality produce from defective items, enhancing accuracy and consistency compared to manual sorting. High-speed conveyors and real-time data processing ensure efficient sorting, reducing labor costs and post-harvest losses.

Manual Sorting: Processes and Limitations

Manual sorting in vegetable grading involves human inspectors visually assessing produce based on size, color, and defects to ensure quality standards. This process is labor-intensive, time-consuming, and prone to inconsistencies due to subjective judgment and operator fatigue. Limitations of manual sorting include lower throughput, reduced accuracy, and higher operational costs compared to automated optical sorting technologies.

Accuracy and Consistency in Grading Results

Optical sorting technology significantly enhances accuracy and consistency in vegetable grading compared to manual sorting by utilizing advanced imaging systems and artificial intelligence to detect defects, color variations, and size discrepancies with precision. Manual sorting, reliant on human judgment, often results in variable grading outcomes due to fatigue and subjective assessment. The integration of optical sorters reduces grading errors and ensures uniform quality control across large-scale post-harvest processing operations.

Labor Efficiency and Operational Costs

Optical sorting systems significantly enhance labor efficiency by automating the grading process, reducing the need for extensive manual labor and minimizing human error. These systems lower operational costs over time through faster processing speeds, consistent quality control, and decreased reliance on seasonal labor. In contrast, manual sorting requires higher labor input and is subject to variability, leading to increased operational expenses and lower throughput in post-harvest vegetable grading.

Impact on Product Quality and Safety

Optical sorting technology enhances product quality and safety by using advanced sensors and cameras to detect defects, contaminants, and foreign materials, ensuring consistent and precise vegetable grading. Manual sorting relies heavily on human judgment, which can lead to variability in quality assessment and increased risk of contamination or oversight of defective produce. Implementing optical sorting reduces post-harvest losses, improves hygiene by minimizing direct contact, and elevates overall food safety standards in vegetable processing.

Speed and Throughput Comparison

Optical sorting technology significantly outperforms manual sorting in speed and throughput, processing thousands of vegetables per minute with consistent accuracy. High-speed cameras and AI algorithms enable rapid identification and segregation of produce based on size, color, and defects, minimizing human error and fatigue. Manual sorting, limited by human speed and endurance, typically handles only a few hundred units per hour, leading to lower productivity and increased labor costs.

Adaptability to Different Vegetable Types

Optical sorting technology offers superior adaptability to different vegetable types by using advanced sensors and algorithms to detect size, color, and shape variations with high precision. Manual sorting relies heavily on human skill and experience, which can lead to inconsistent grading and slower processing times when handling diverse vegetable varieties. Implementing optical sorting improves efficiency, accuracy, and consistency in grading vegetables across multiple species.

Sustainability and Resource Utilization

Optical sorting enhances sustainability in vegetable grading by reducing food waste through precise defect detection and minimizing the use of water and energy compared to manual sorting. Automated systems improve resource utilization by increasing throughput and decreasing labor intensity, leading to more consistent quality control and lower overall operational costs. In contrast, manual sorting is labor-intensive, prone to human error, and less efficient in resource management, impacting both environmental and economic sustainability negatively.

Future Trends in Post-Harvest Sorting Technologies

Optical sorting technologies for vegetable grading leverage advanced machine learning algorithms and hyperspectral imaging to achieve higher accuracy and speed compared to traditional manual sorting. These automated systems reduce human error, increase throughput, and enable real-time quality assessment, crucial for meeting the growing demand for standardized produce in global markets. Future trends emphasize integrating AI-driven predictive analytics and robotics to enhance sorting capabilities, lower operational costs, and ensure consistent grading standards post-harvest.

Related Important Terms

Hyperspectral Imaging

Hyperspectral imaging in optical sorting enhances vegetable grading accuracy by capturing detailed spectral data beyond visible wavelengths, enabling precise identification of defects, ripeness, and contamination that manual sorting often misses. This technology accelerates processing speed and improves consistency, reducing human error and labor costs in post-harvest handling.

Multispectral Sorting

Multispectral sorting utilizes advanced imaging technology across multiple wavelengths to accurately differentiate vegetable quality attributes such as ripeness, defects, and contamination, significantly enhancing grading precision compared to traditional manual sorting. This optical sorting method increases throughput, reduces human error, and improves overall post-harvest quality management in vegetable processing.

Machine Vision Grading

Optical sorting using machine vision grading significantly enhances accuracy and speed compared to manual sorting by employing high-resolution cameras and artificial intelligence to detect defects, color inconsistencies, and size variations in vegetables. This technology reduces labor costs and minimizes human error, enabling consistent quality control and higher throughput in post-harvest vegetable processing.

Near-Infrared Spectroscopy (NIRS)

Optical sorting using Near-Infrared Spectroscopy (NIRS) enables precise, non-destructive assessment of vegetable quality by detecting internal attributes such as moisture content, sugar levels, and ripeness, outperforming manual sorting which relies heavily on external appearance and subjective human judgment. Implementing NIRS-equipped optical sorters accelerates grading efficiency, reduces labor costs, and enhances product consistency, crucial for meeting stringent quality standards in post-harvest vegetable processing.

Deep Learning Sorters

Deep learning-based optical sorting systems for vegetable grading enhance accuracy and efficiency by analyzing complex visual features beyond human capability, reducing sorting errors and labor costs compared to manual sorting. These advanced technologies integrate convolutional neural networks to detect size, color, texture, and defects in real time, optimizing post-harvest quality control and minimizing waste.

Defect Detection Algorithms

Optical sorting systems utilize advanced defect detection algorithms such as hyperspectral imaging and machine learning to identify and classify vegetable defects with high precision, outperforming manual sorting which relies on subjective human judgment. These algorithms analyze color, texture, and shape anomalies in real-time, enabling faster processing rates and consistent grading accuracy in post-harvest vegetable sorting operations.

Automated Color Grading

Automated color grading in optical sorting significantly enhances the accuracy and speed of vegetable grading by using advanced sensors and cameras to detect subtle color variations that indicate ripeness or defects, outperforming manual sorting's reliance on human perception. This technology reduces labor costs, minimizes sorting errors, and ensures consistent quality control, making it a crucial innovation in post-harvest technology.

Precision Sortation

Optical sorting in vegetable grading utilizes advanced imaging and sensor technologies to achieve high precision sortation, significantly reducing human error and variability compared to manual sorting methods. This technology enhances accuracy by detecting subtle differences in size, color, and defects, thereby improving overall product quality and consistency in post-harvest processing.

Real-Time Quality Analytics

Optical sorting systems utilize advanced sensors and machine learning algorithms to provide real-time quality analytics, enabling precise vegetable grading by detecting size, color, and defects with high accuracy. Manual sorting relies on human judgment, often leading to inconsistent grading and slower processing speeds, which limits the ability to perform immediate quality assessments during post-harvest handling.

Non-Destructive Evaluation (NDE)

Optical sorting utilizes advanced imaging technologies such as hyperspectral cameras and machine learning algorithms to non-destructively evaluate vegetable quality attributes like size, color, and surface defects with high precision and speed. In contrast, manual sorting relies on human visual inspection, which is subjective and less consistent, often leading to variability in grading accuracy and reduced throughput in post-harvest processing.

Optical Sorting vs Manual Sorting for vegetable grading Infographic

agridif.com

agridif.com