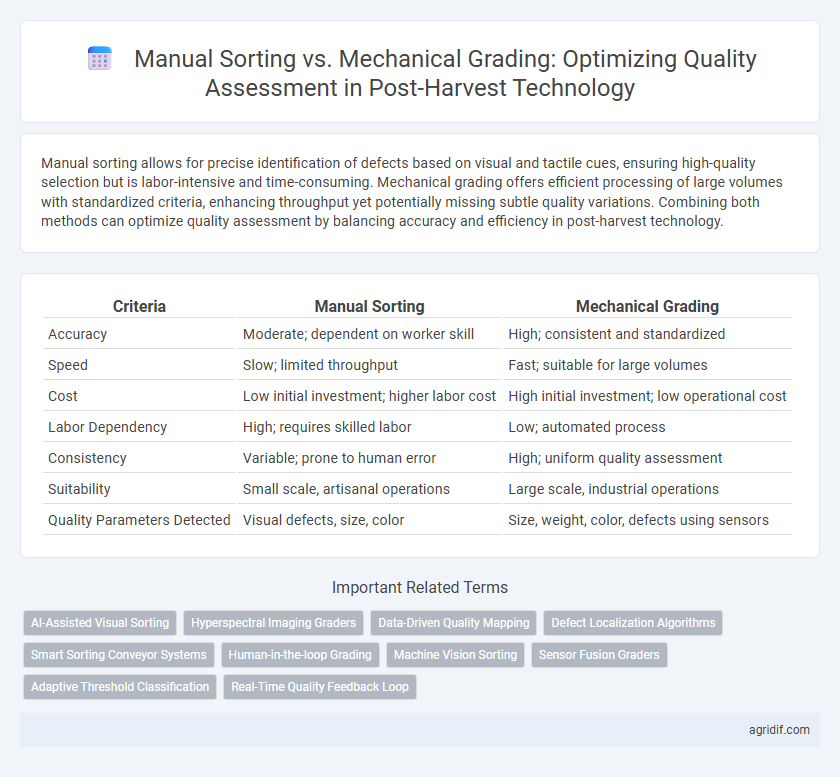

Manual sorting allows for precise identification of defects based on visual and tactile cues, ensuring high-quality selection but is labor-intensive and time-consuming. Mechanical grading offers efficient processing of large volumes with standardized criteria, enhancing throughput yet potentially missing subtle quality variations. Combining both methods can optimize quality assessment by balancing accuracy and efficiency in post-harvest technology.

Table of Comparison

| Criteria | Manual Sorting | Mechanical Grading |

|---|---|---|

| Accuracy | Moderate; dependent on worker skill | High; consistent and standardized |

| Speed | Slow; limited throughput | Fast; suitable for large volumes |

| Cost | Low initial investment; higher labor cost | High initial investment; low operational cost |

| Labor Dependency | High; requires skilled labor | Low; automated process |

| Consistency | Variable; prone to human error | High; uniform quality assessment |

| Suitability | Small scale, artisanal operations | Large scale, industrial operations |

| Quality Parameters Detected | Visual defects, size, color | Size, weight, color, defects using sensors |

Introduction to Post-Harvest Quality Assessment

Post-harvest quality assessment involves evaluating the physical and biochemical properties of agricultural products to ensure market standards and consumer satisfaction. Manual sorting relies on human inspection to identify defects, size, and color variations, offering flexibility but limited throughput and consistency. Mechanical grading utilizes automated systems with sensors and imaging technology to achieve higher precision, speed, and uniformity in sorting and grading processes.

Importance of Sorting and Grading in Agriculture

Sorting and grading in agriculture play a crucial role in enhancing product quality, reducing post-harvest losses, and improving market value. Manual sorting allows for careful selection based on visual inspection but is labor-intensive and subjective, while mechanical grading offers rapid, consistent assessment using advanced sensors and automation. Implementing efficient sorting and grading techniques ensures uniformity, meets quality standards, and supports supply chain optimization in post-harvest technology.

Overview of Manual Sorting Techniques

Manual sorting techniques in post-harvest quality assessment rely on visual inspection, tactile feedback, and experience to identify defects, size variations, and color differences in agricultural produce. Workers use handpicking, sieving, and simple tools to separate products based on quality standards, ensuring careful handling and minimizing damage. These techniques are labor-intensive but allow precise discrimination in small-scale operations where machinery may not be cost-effective.

Advancements in Mechanical Grading Systems

Advancements in mechanical grading systems have significantly enhanced the accuracy and speed of quality assessment in post-harvest technology, utilizing optical sensors and machine learning algorithms to detect defects and categorize produce consistently. These systems reduce human error and labor costs while increasing throughput, enabling large-scale operations to maintain high quality standards. Integration with real-time data analytics further optimizes sorting efficiency and supports traceability in supply chains.

Accuracy and Consistency: Manual vs Mechanical Methods

Mechanical grading systems deliver higher accuracy and consistency in quality assessment by minimizing human error and variability, ensuring uniformity in sorting based on objective parameters such as size, color, and weight. Manual sorting, while flexible and cost-effective for small-scale operations, often suffers from subjective judgment and fatigue, leading to inconsistent results and lower throughput. Advanced optical and electronic sensors in mechanical graders enhance precision in classifying produce, directly impacting post-harvest quality control and market value.

Labor Requirements and Operational Efficiency

Manual sorting in post-harvest technology demands high labor input, requiring skilled workers to inspect and separate produce, which can lead to inconsistencies and slower processing times. Mechanical grading enhances operational efficiency by automating quality assessment, enabling rapid, uniform sorting with reduced labor costs and minimal human error. Integrating advanced sensors and image processing in mechanical systems further optimizes throughput and accuracy compared to traditional manual methods.

Cost Analysis: Initial Investment and Long-term Savings

Manual sorting involves lower initial investment costs compared to mechanical grading systems, making it accessible for small-scale operations. Mechanical grading requires significant upfront capital but offers long-term savings through increased efficiency, reduced labor costs, and consistent quality assessment. Over time, the automated precision of mechanical graders enhances profitability by minimizing product loss and optimizing market value.

Effects on Product Quality and Market Value

Manual sorting enables precise selection based on visual and tactile cues, preserving product integrity and often resulting in higher market value for premium produce. Mechanical grading offers rapid, uniform classification but may increase the risk of product damage and inconsistent quality assessment, potentially lowering overall market price. Optimal post-harvest strategy balances manual inspection to ensure quality with mechanical grading for efficiency, maximizing product quality and profitability.

Challenges and Limitations of Each Method

Manual sorting in post-harvest technology faces challenges such as labor intensity, inconsistent accuracy, and susceptibility to human error, which can affect uniformity in quality assessment. Mechanical grading, while offering faster processing and standardized measurements, is limited by high initial costs, maintenance complexity, and difficulty in handling irregularly shaped or damaged produce. Both methods struggle with adaptability to diverse crop varieties, impacting the precision and efficiency of quality classification.

Future Trends in Sorting and Grading Technology

Emerging trends in post-harvest technology emphasize the integration of artificial intelligence and machine learning algorithms in mechanical grading systems to enhance accuracy and efficiency compared to manual sorting. Advancements in hyperspectral imaging and robotics enable real-time quality assessment, reducing human error and increasing throughput. Future sorting technologies prioritize sustainability by minimizing energy consumption and material waste while adapting to diverse crop varieties.

Related Important Terms

AI-Assisted Visual Sorting

AI-assisted visual sorting enhances post-harvest quality assessment by integrating machine learning algorithms with high-resolution imaging, enabling precise differentiation of produce based on color, size, and defects. This technology offers superior speed and accuracy compared to manual sorting and traditional mechanical grading, reducing human error and increasing throughput in agricultural processing.

Hyperspectral Imaging Graders

Hyperspectral imaging graders in post-harvest technology provide precise quality assessment by capturing detailed spectral data beyond visible wavelengths, enabling accurate detection of defects, ripeness, and contamination in produce. Unlike manual sorting, these graders offer high-speed, non-destructive analysis with consistent objectivity, significantly enhancing grading efficiency and reducing human error.

Data-Driven Quality Mapping

Manual sorting in post-harvest technology relies on human sensory judgment, offering flexibility but limited scalability and subjective quality assessment. Mechanical grading employs sensor-based data analysis such as imaging and spectroscopy to create precise, data-driven quality maps, enabling consistent and objective evaluation for enhanced supply chain efficiency.

Defect Localization Algorithms

Defect localization algorithms in post-harvest technology enhance manual sorting by enabling precise identification of quality issues on produce surfaces, yet mechanical grading systems utilize advanced imaging and sensor-based techniques for faster, consistent defect detection. Integration of machine learning models with defect localization algorithms improves accuracy in mechanical grading, reducing reliance on human visual inspection and increasing throughput in quality assessment.

Smart Sorting Conveyor Systems

Smart sorting conveyor systems revolutionize post-harvest quality assessment by integrating advanced sensors and machine learning algorithms to distinguish produce based on size, color, and defects with higher precision than manual sorting. These systems increase throughput, reduce labor costs, and maintain consistent grading standards, enhancing overall operational efficiency in agricultural processing.

Human-in-the-loop Grading

Human-in-the-loop grading combines manual sorting's sensory accuracy with mechanical grading's speed, enhancing post-harvest quality assessment by leveraging human expertise to identify subtle defects and ensure precise calibration of automated systems. This integrated approach maximizes accuracy in sorting fruits and vegetables, reducing post-harvest losses and improving overall supply chain efficiency.

Machine Vision Sorting

Machine vision sorting in post-harvest technology offers precise, high-throughput quality assessment by using advanced imaging and AI algorithms to detect defects, size, and color variations in produce, surpassing the consistency and speed of manual sorting. This technology enhances accuracy in grading, reduces labor costs, and minimizes human error, resulting in improved product uniformity and market value.

Sensor Fusion Graders

Sensor fusion graders in post-harvest technology combine data from multiple sensors such as RGB cameras, near-infrared spectroscopy, and laser scanners to enhance accuracy in quality assessment over traditional manual sorting and mechanical grading. This technology improves defect detection, texture analysis, and size categorization, leading to higher consistency and faster processing times in agricultural product evaluation.

Adaptive Threshold Classification

Adaptive threshold classification in post-harvest technology enhances manual sorting by enabling dynamic adjustment of quality parameters based on real-time data, improving accuracy in defect detection and grading consistency. Mechanical grading systems integrated with adaptive threshold algorithms optimize throughput and reduce human error by automatically categorizing produce according to size, color, and maturity levels with high precision.

Real-Time Quality Feedback Loop

Manual sorting in post-harvest technology allows for nuanced visual inspection, enabling immediate identification of defects and creating a real-time quality feedback loop essential for fine-tuning sorting criteria. Mechanical grading systems utilize sensors and automated algorithms to deliver consistent, data-driven quality assessments instantly, enhancing throughput while maintaining standardized quality control.

Manual Sorting vs Mechanical Grading for quality assessment Infographic

agridif.com

agridif.com