Vacuum packaging removes air from the package, significantly reducing oxygen exposure and slowing down microbial growth, which extends the shelf life of fresh produce. Modified Atmosphere Packaging (MAP) adjusts the gas composition inside the package by balancing oxygen, carbon dioxide, and nitrogen levels to maintain optimal respiration rates and freshness. While vacuum packaging is effective for highly perishable items, MAP is preferred for fruits and vegetables that require controlled atmospheres to retain texture and flavor.

Table of Comparison

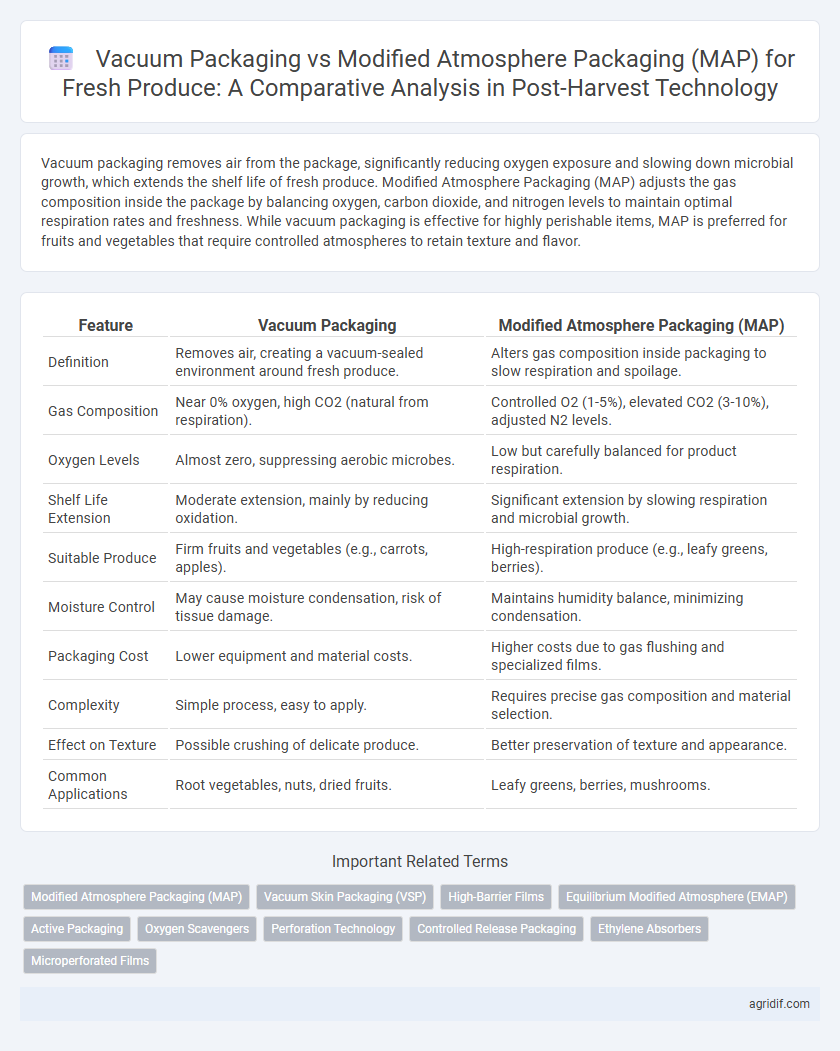

| Feature | Vacuum Packaging | Modified Atmosphere Packaging (MAP) |

|---|---|---|

| Definition | Removes air, creating a vacuum-sealed environment around fresh produce. | Alters gas composition inside packaging to slow respiration and spoilage. |

| Gas Composition | Near 0% oxygen, high CO2 (natural from respiration). | Controlled O2 (1-5%), elevated CO2 (3-10%), adjusted N2 levels. |

| Oxygen Levels | Almost zero, suppressing aerobic microbes. | Low but carefully balanced for product respiration. |

| Shelf Life Extension | Moderate extension, mainly by reducing oxidation. | Significant extension by slowing respiration and microbial growth. |

| Suitable Produce | Firm fruits and vegetables (e.g., carrots, apples). | High-respiration produce (e.g., leafy greens, berries). |

| Moisture Control | May cause moisture condensation, risk of tissue damage. | Maintains humidity balance, minimizing condensation. |

| Packaging Cost | Lower equipment and material costs. | Higher costs due to gas flushing and specialized films. |

| Complexity | Simple process, easy to apply. | Requires precise gas composition and material selection. |

| Effect on Texture | Possible crushing of delicate produce. | Better preservation of texture and appearance. |

| Common Applications | Root vegetables, nuts, dried fruits. | Leafy greens, berries, mushrooms. |

Introduction to Post-Harvest Packaging Technologies

Vacuum packaging removes air from the package, significantly reducing oxygen levels to inhibit microbial growth and enzymatic reactions in fresh produce, thereby extending shelf life. Modified Atmosphere Packaging (MAP) involves altering the gas composition inside the package, typically increasing carbon dioxide and reducing oxygen, to slow respiration rates and maintain produce freshness. Both technologies are essential post-harvest packaging methods that enhance product quality, reduce spoilage, and optimize supply chain efficiency for fruits and vegetables.

Understanding Vacuum Packaging: Principles and Applications

Vacuum packaging removes air from the packaging environment to reduce oxygen levels, slowing down the respiration rate and microbial growth in fresh produce. This technology extends the shelf life by maintaining product freshness, texture, and nutritional quality under controlled low-oxygen conditions. Commonly applied to fruits, vegetables, and leafy greens, vacuum packaging also minimizes moisture loss and prevents oxidative damage, making it crucial in post-harvest preservation.

Modified Atmosphere Packaging (MAP): How It Works

Modified Atmosphere Packaging (MAP) extends the shelf life of fresh produce by altering the gas composition inside the packaging to slow down respiration and microbial growth. By selectively controlling oxygen, carbon dioxide, and nitrogen levels, MAP creates an optimal environment that preserves freshness, color, and texture. This precise gas regulation enhances post-harvest quality compared to vacuum packaging, which primarily removes air but does not customize atmospheric conditions.

Key Differences Between Vacuum and MAP Packaging

Vacuum packaging removes all air from the package to create an anaerobic environment, significantly extending shelf life by slowing oxidation and microbial growth in fresh produce. Modified Atmosphere Packaging (MAP) replaces air with a specific gas mixture, such as increased carbon dioxide and reduced oxygen, to optimize respiration rates and maintain freshness without deformation. Key differences include vacuum packaging's potential to cause product compression versus MAP's ability to preserve shape and texture, alongside MAP's adjustable gas formulations tailored to different produce types.

Impact on Shelf Life of Fresh Produce

Vacuum packaging significantly extends the shelf life of fresh produce by removing air, thereby reducing oxidation and microbial growth, which slows spoilage. Modified atmosphere packaging (MAP) adjusts the gas composition around the produce, typically lowering oxygen and increasing carbon dioxide levels, to inhibit respiration and ethylene production, further preserving freshness. Compared to vacuum packaging, MAP offers more precise control over the storage environment, making it especially effective for maintaining the quality of fruits and vegetables with high respiration rates.

Effects on Nutritional Quality and Freshness

Vacuum packaging effectively extends the shelf life of fresh produce by reducing oxygen exposure, thereby minimizing oxidation and preserving key nutrients such as vitamins C and E. Modified Atmosphere Packaging (MAP) adjusts gas composition inside the package to slow respiration and microbial growth, maintaining freshness and nutrient retention, particularly for ethylene-sensitive fruits and vegetables. Both technologies enhance post-harvest quality, but MAP offers superior control over atmospheric conditions, resulting in better preservation of texture and antioxidant levels in fresh produce.

Cost Comparison: Vacuum Packaging vs MAP

Vacuum packaging typically involves lower initial equipment costs but may incur higher maintenance expenses compared to Modified Atmosphere Packaging (MAP), which requires advanced gas-mixing technology and controlled atmosphere systems. MAP packaging often results in higher material costs due to specialized films and gas mixtures but can extend shelf life more effectively, potentially reducing overall product loss and associated costs. Analyzing total cost of ownership reveals that MAP's higher upfront investment may be offset by improved freshness preservation and reduced waste in large-scale fresh produce operations.

Environmental Sustainability Considerations

Vacuum packaging reduces oxygen levels, extending shelf life of fresh produce while minimizing spoilage and waste, contributing to lower environmental impact. Modified Atmosphere Packaging (MAP) precisely controls gas composition inside the package, maintaining product freshness and reducing the need for preservatives, but often employs multi-layer plastics that challenge recyclability. Selecting sustainable materials and optimizing packaging design in both vacuum and MAP systems is critical to balancing post-harvest quality preservation with environmental sustainability goals.

Suitability for Different Types of Fresh Produce

Vacuum packaging effectively extends shelf life for firm, low-respiration fresh produce such as root vegetables, mushrooms, and hard fruits by removing air and reducing microbial growth. Modified Atmosphere Packaging (MAP) suits highly perishable, high-respiration products like leafy greens, berries, and soft fruits, as it adjusts oxygen and carbon dioxide levels to slow metabolism. Selecting the right packaging technique depends on the specific respiration rate, moisture content, and sensitivity of the fresh produce to anaerobic conditions.

Future Trends in Post-Harvest Packaging Technologies

Vacuum packaging enhances shelf life by removing air, reducing oxidation and microbial growth, while MAP (Modified Atmosphere Packaging) fine-tunes gas composition inside packages to optimize freshness based on produce type. Future trends emphasize smart packaging integrating sensors for real-time quality monitoring and adaptive atmosphere adjustment, leveraging IoT and AI technologies to extend freshness and reduce food waste. Biodegradable, sustainable materials combined with advanced gas control mechanisms are also driving innovations in post-harvest packaging solutions for fresh produce.

Related Important Terms

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) for fresh produce involves altering the gas composition inside the package, typically reducing oxygen levels and increasing carbon dioxide, to slow down respiration and microbial growth, thereby extending shelf life. Compared to vacuum packaging, MAP maintains the product's shape and texture better by preventing package collapse and allows for selective gas mixtures tailored to specific produce types, optimizing freshness and quality retention.

Vacuum Skin Packaging (VSP)

Vacuum Skin Packaging (VSP) creates an airtight barrier closely conforming to the surface of fresh produce, significantly extending shelf life by reducing oxygen exposure and moisture loss compared to standard Vacuum Packaging. Modified Atmosphere Packaging (MAP) adjusts the gas composition inside the package to slow respiration rates and microbial growth, but VSP offers superior protection against physical damage and oxidation due to its custom-fit, durable barrier film.

High-Barrier Films

High-barrier films in vacuum packaging effectively reduce oxygen transmission rates to extend the shelf life of fresh produce by minimizing oxidation and microbial growth. Modified Atmosphere Packaging (MAP) using these films strategically alters the gas composition around the produce, balancing oxygen, carbon dioxide, and humidity levels to maintain freshness and delay ripening.

Equilibrium Modified Atmosphere (EMAP)

Vacuum packaging removes air to create a low-oxygen environment that slows respiration and microbial growth in fresh produce, whereas Equilibrium Modified Atmosphere Packaging (EMAP) relies on the produce's own respiration to establish a gas balance within the package, optimizing oxygen and carbon dioxide levels for extended shelf life. EMAP maintains a stable atmospheric composition without external gas flushing, enhancing freshness retention and reducing package deformation compared to traditional Modified Atmosphere Packaging (MAP).

Active Packaging

Vacuum packaging removes air to reduce oxygen levels and slow microbial growth, while Modified Atmosphere Packaging (MAP) actively controls and adjusts gas compositions, such as oxygen, carbon dioxide, and nitrogen, to extend the shelf life of fresh produce. Active packaging technologies in MAP integrate oxygen scavengers and moisture regulators, enhancing freshness by maintaining optimal environmental conditions during storage and transportation.

Oxygen Scavengers

Vacuum packaging effectively reduces oxygen levels by creating an anaerobic environment, while Modified Atmosphere Packaging (MAP) often incorporates oxygen scavengers to further control residual oxygen and extend the shelf life of fresh produce. Oxygen scavengers in MAP actively absorb oxygen, preventing enzymatic browning and microbial growth, thus maintaining quality and freshness longer compared to vacuum packaging alone.

Perforation Technology

Vacuum packaging combined with precision perforation technology enhances gas exchange, preventing anaerobic conditions and extending the shelf life of fresh produce by maintaining optimal respiration rates. Modified Atmosphere Packaging (MAP) relies on micro-perforations to regulate internal gas composition, balancing oxygen and carbon dioxide levels to reduce spoilage and preserve freshness during storage and transportation.

Controlled Release Packaging

Vacuum packaging extends the shelf life of fresh produce by removing air to inhibit microbial growth, while Modified Atmosphere Packaging (MAP) utilizes controlled release technology to optimize gas composition, balancing oxygen and carbon dioxide levels to maintain freshness and reduce spoilage. Controlled Release Packaging enhances MAP by regulating internal gases through selective permeability, ensuring an ideal atmosphere that slows respiration rates and preserves texture, flavor, and nutritional quality.

Ethylene Absorbers

Vacuum packaging reduces oxygen levels to slow respiration rates and delay ripening in fresh produce, but Modified Atmosphere Packaging (MAP) combined with ethylene absorbers more effectively controls ethylene concentration, extending shelf life by preventing premature spoilage. Ethylene absorbers in MAP target the hormone responsible for fruit ripening, providing a superior solution for maintaining freshness compared to vacuum packaging alone.

Microperforated Films

Microperforated films in Modified Atmosphere Packaging (MAP) regulate gas exchange by allowing selective permeability, which helps maintain optimal oxygen and carbon dioxide levels to extend the shelf life of fresh produce. Vacuum packaging removes air entirely, slowing microbial growth but may cause anaerobic conditions harmful to some fruits and vegetables, making microperforated MAP films more suitable for preserving freshness and texture.

Vacuum Packaging vs MAP Packaging for Fresh Produce Infographic

agridif.com

agridif.com