Chemical curing for root crops accelerates the healing process by applying synthetic agents that reduce moisture loss and inhibit microbial growth, leading to improved shelf life and reduced spoilage. Natural curing relies on controlled environmental conditions, such as temperature and humidity, to facilitate the formation of protective wound layers, preserving quality without chemical residues. Choosing between chemical and natural curing depends on factors like cost, safety, and desired storage duration.

Table of Comparison

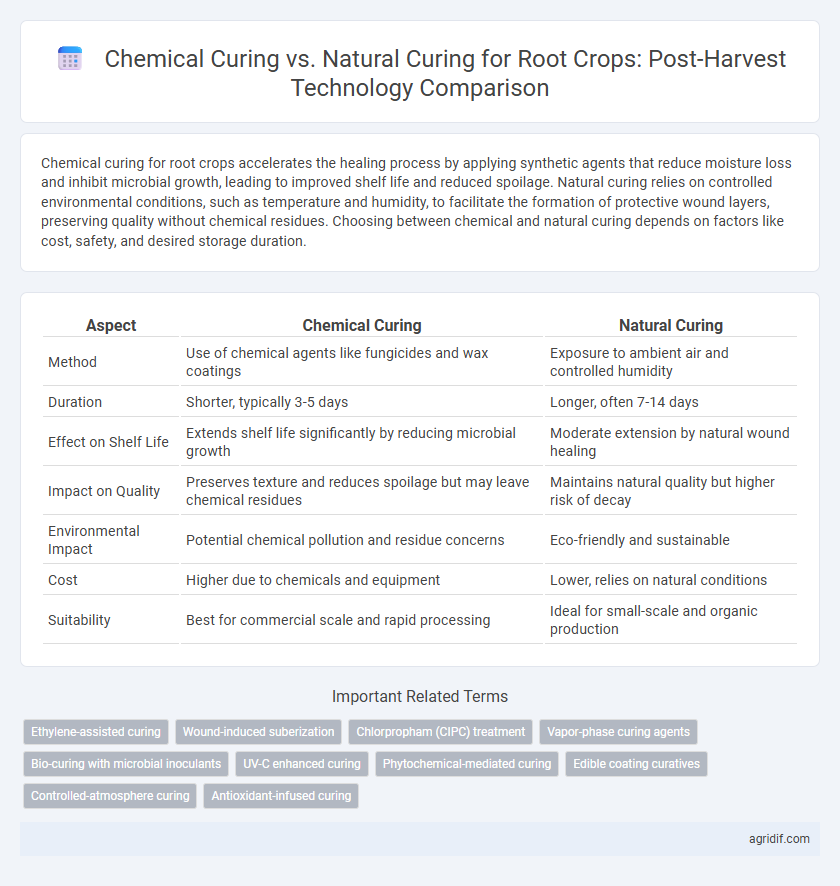

| Aspect | Chemical Curing | Natural Curing |

|---|---|---|

| Method | Use of chemical agents like fungicides and wax coatings | Exposure to ambient air and controlled humidity |

| Duration | Shorter, typically 3-5 days | Longer, often 7-14 days |

| Effect on Shelf Life | Extends shelf life significantly by reducing microbial growth | Moderate extension by natural wound healing |

| Impact on Quality | Preserves texture and reduces spoilage but may leave chemical residues | Maintains natural quality but higher risk of decay |

| Environmental Impact | Potential chemical pollution and residue concerns | Eco-friendly and sustainable |

| Cost | Higher due to chemicals and equipment | Lower, relies on natural conditions |

| Suitability | Best for commercial scale and rapid processing | Ideal for small-scale and organic production |

Introduction to Root Crop Curing Methods

Chemical curing of root crops involves using substances like fungicides and wax coatings to accelerate healing and prevent microbial decay, enhancing shelf life and marketability. Natural curing relies on controlled environmental conditions such as temperature, humidity, and ventilation to promote suberization and wound sealing in crops like sweet potatoes and yams. Both methods aim to reduce post-harvest losses by strengthening skin integrity and minimizing physiological deterioration during storage.

Overview of Chemical Curing Processes

Chemical curing of root crops involves the application of synthetic agents such as calcium carbide or ethylene-releasing compounds to accelerate the curing process, enhancing crop shelf life and reducing post-harvest losses. This method promotes rapid wound healing and starch-to-sugar conversion, improving root texture and flavor compared to natural curing, which relies solely on ambient environmental conditions. Chemical curing offers controlled and expedited results, optimizing storage conditions and market readiness for root crops like sweet potatoes and cassava.

Overview of Natural Curing Techniques

Natural curing techniques for root crops involve drying and aging the produce under controlled environmental conditions such as optimal temperature and humidity to enhance skin formation and heal minor injuries. These methods reduce post-harvest losses by strengthening the protective outer layer, improving shelf life without the use of synthetic chemicals. Common practices include field curing and ambient air curing, which leverage natural airflow and moisture regulation to achieve effective curing outcomes.

Comparative Effects on Crop Shelf Life

Chemical curing significantly extends the shelf life of root crops by accelerating wound healing and reducing microbial decay through applications of substances like calcium ammonium nitrate and fungicides. Natural curing relies on controlled environmental conditions such as temperature and humidity to promote suberization and lignification at wound sites, offering a chemical-free approach but generally resulting in a shorter shelf life compared to chemical methods. Studies indicate that chemical curing can increase shelf life by up to 50% over natural curing due to enhanced pathogen resistance and reduced moisture loss during storage.

Impact on Nutritional Quality and Flavor

Chemical curing of root crops accelerates the drying process and reduces post-harvest losses but may lead to a decline in certain heat-sensitive nutrients such as vitamin C and carotenoids. Natural curing preserves the nutritional quality more effectively by allowing gradual moisture reduction, which helps maintain flavor compounds and antioxidant levels. Studies indicate that naturally cured root crops retain higher sensory attributes and nutrient density compared to chemically cured counterparts.

Disease Control: Chemical vs Natural Approaches

Chemical curing of root crops utilizes fungicides and bactericides to effectively reduce post-harvest diseases, offering rapid and targeted control against pathogens such as Fusarium and Pythium species. Natural curing relies on controlled environmental conditions, like optimal temperature and humidity, to enhance wound healing and activate innate antimicrobial compounds, but may be less consistent in preventing infections. Integrated disease management combining chemical treatments with natural curing practices often yields superior control, minimizing post-harvest losses in crops like sweet potatoes and cassava.

Economic Considerations: Costs and Benefits

Chemical curing of root crops involves the application of synthetic agents that accelerate the curing process, reducing storage time and minimizing losses due to spoilage, which can lead to higher short-term costs but increased market value through improved produce quality. Natural curing relies on environmental factors such as temperature and humidity, incurring lower input costs but requiring longer storage periods and risking greater post-harvest losses that may affect overall profitability. Economic considerations balance the upfront expenses of chemicals against potential gains in shelf life and marketability, while natural curing offers cost savings at the risk of decreased product quality and yield.

Environmental Implications of Curing Methods

Chemical curing of root crops involves the use of synthetic agents like ethylene-releasing compounds, which can accelerate curing but contribute to environmental pollution through chemical residues and potential soil contamination. Natural curing relies on ambient conditions such as temperature and humidity, minimizing chemical inputs and reducing harmful emissions, making it a more sustainable option for maintaining ecological balance. However, natural curing requires longer periods and controlled environments, influencing energy use and overall carbon footprint depending on local climate conditions.

Adoption and Feasibility for Smallholder Farmers

Chemical curing of root crops offers faster disease control and uniform quality improvement but requires access to specialized chemicals and protective equipment, which may limit feasibility for smallholder farmers. Natural curing relies on traditional sun-drying and natural ventilation, making it more accessible and cost-effective for smallholders, though it demands longer time and favorable environmental conditions. Adoption rates among smallholder farmers tend to favor natural curing due to lower input costs and simpler implementation despite the potential benefits of chemical methods.

Future Trends in Root Crop Curing Technologies

Emerging trends in root crop curing technologies emphasize sustainable and efficient methods, with chemical curing offering rapid pathogen control while natural curing promotes eco-friendly and residue-free produce. Innovations in bio-based curing agents and controlled atmosphere storage are enhancing preservation quality and shelf life, reducing dependence on synthetic chemicals. Integration of sensor technologies for real-time monitoring is expected to optimize curing processes, ensuring better quality and reduced post-harvest losses.

Related Important Terms

Ethylene-assisted curing

Ethylene-assisted chemical curing accelerates the drying and toughening of root crop skins, enhancing shelf life and reducing rot compared to slower natural curing methods. Controlled ethylene exposure optimizes enzymatic activities that improve curing efficiency and storage quality in crops like sweet potatoes and yams.

Wound-induced suberization

Chemical curing accelerates wound-induced suberization in root crops by enhancing suberin deposition at injury sites, effectively reducing moisture loss and microbial infection. Natural curing relies on ambient conditions to promote gradual suberization, which may result in slower wound healing and increased susceptibility to post-harvest deterioration.

Chlorpropham (CIPC) treatment

Chlorpropham (CIPC) treatment in chemical curing effectively inhibits sprouting in root crops like potatoes, extending storage life and reducing post-harvest losses compared to natural curing methods. However, concerns over chemical residues and environmental impact have prompted exploration of alternative natural curing strategies that rely on controlled temperature and humidity to enhance shelf life without synthetic inputs.

Vapor-phase curing agents

Vapor-phase curing agents such as ethylene and allyl isothiocyanate provide effective chemical curing for root crops by reducing post-harvest diseases and enhancing storage life through controlled vapor exposure. Natural curing relies on ambient environmental conditions and microbial activity, often resulting in inconsistent disease control and variable shelf-life outcomes compared to the standardized efficacy of vapor-phase chemical treatments.

Bio-curing with microbial inoculants

Bio-curing using microbial inoculants in post-harvest technology enhances root crop quality by accelerating biochemical processes that reduce disease incidence and improve storage life, surpassing traditional chemical curing methods that rely on fungicides and synthetic agents. This sustainable approach leverages beneficial microbes to promote natural defense mechanisms and nutrient cycling, resulting in safer, eco-friendly, and more effective curing outcomes for root crops like cassava, sweet potato, and yam.

UV-C enhanced curing

Chemical curing methods for root crops typically involve fungicides and growth regulators to accelerate healing and reduce disease incidence, while natural curing relies on ambient conditions such as temperature, humidity, and airflow. UV-C enhanced curing promotes the synthesis of natural defense compounds in root crops, effectively reducing microbial decay and enhancing shelf life without chemical residues, thus offering a safer and more sustainable post-harvest technology.

Phytochemical-mediated curing

Chemical curing of root crops utilizes phytochemical agents like ethylene and calcium chloride to accelerate the curing process by enhancing enzymatic activities and reducing microbial decay, ensuring improved shelf life and quality. Natural curing relies on environmental factors such as temperature, humidity, and natural phytochemicals present in the crop, promoting gradual physiological changes and phytochemical stabilization essential for optimal storage and preservation.

Edible coating curatives

Edible coating curatives in post-harvest technology enhance the shelf life and quality of root crops by reducing moisture loss and microbial spoilage, proving more effective than chemical curing methods that may leave residues and pose health risks. Natural curing with edible coatings utilizes biopolymers like chitosan and aloe vera, offering eco-friendly preservation while improving root crop firmness and antioxidant retention.

Controlled-atmosphere curing

Controlled-atmosphere curing of root crops employs regulated oxygen, carbon dioxide, and humidity levels to enhance chemical curing effectiveness by accelerating lignin synthesis and reducing enzymatic browning, compared to slower natural curing processes. This method improves uniformity in skin set and extends shelf life by minimizing microbial decay and transpirational water loss under optimized atmospheric conditions.

Antioxidant-infused curing

Chemical curing for root crops enhances shelf life by applying antioxidant-infused solutions that reduce oxidative stress and inhibit microbial growth, resulting in improved post-harvest quality. Natural curing relies on controlled environmental conditions such as humidity and temperature to activate endogenous antioxidants, offering a residue-free method but often with less consistent efficacy compared to chemical treatments.

Chemical curing vs natural curing for root crops Infographic

agridif.com

agridif.com