Controlled Atmosphere Storage (CAS) maintains fruit quality by regulating oxygen, carbon dioxide, and humidity levels in a sealed environment for long-term preservation. Modified Atmosphere Packaging (MAP) extends shelf life by altering gas composition within packaging to slow respiration and delay ripening. Both technologies optimize fruit freshness, but CAS is better suited for bulk storage, while MAP is ideal for retail distribution.

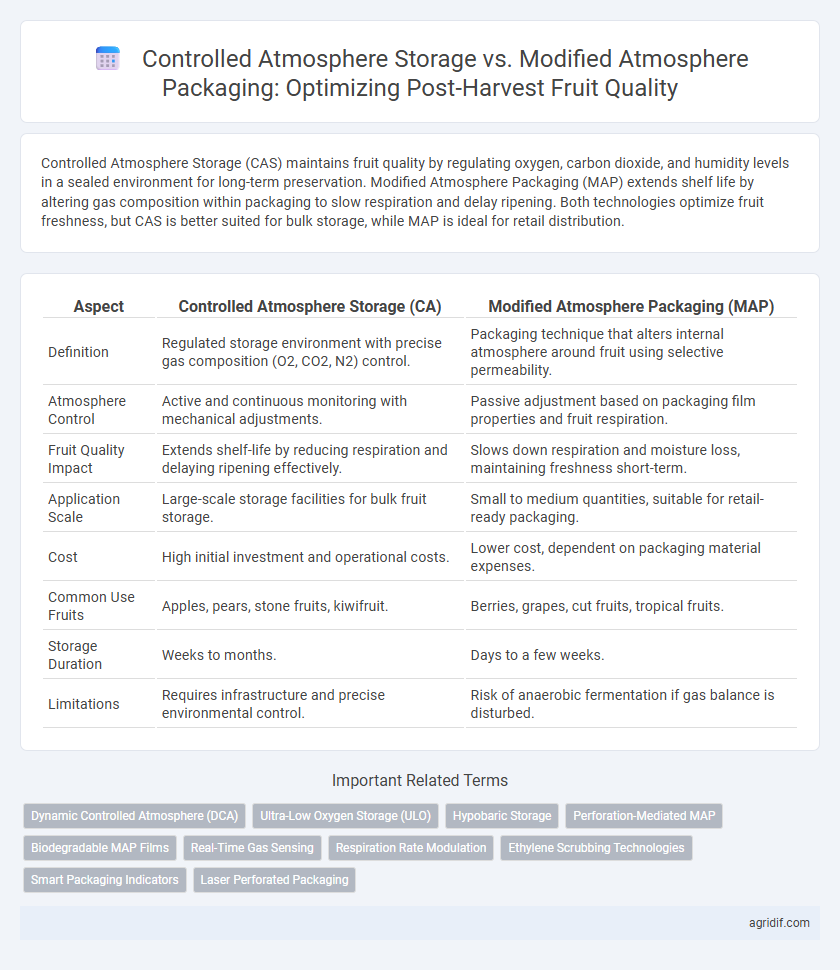

Table of Comparison

| Aspect | Controlled Atmosphere Storage (CA) | Modified Atmosphere Packaging (MAP) |

|---|---|---|

| Definition | Regulated storage environment with precise gas composition (O2, CO2, N2) control. | Packaging technique that alters internal atmosphere around fruit using selective permeability. |

| Atmosphere Control | Active and continuous monitoring with mechanical adjustments. | Passive adjustment based on packaging film properties and fruit respiration. |

| Fruit Quality Impact | Extends shelf-life by reducing respiration and delaying ripening effectively. | Slows down respiration and moisture loss, maintaining freshness short-term. |

| Application Scale | Large-scale storage facilities for bulk fruit storage. | Small to medium quantities, suitable for retail-ready packaging. |

| Cost | High initial investment and operational costs. | Lower cost, dependent on packaging material expenses. |

| Common Use Fruits | Apples, pears, stone fruits, kiwifruit. | Berries, grapes, cut fruits, tropical fruits. |

| Storage Duration | Weeks to months. | Days to a few weeks. |

| Limitations | Requires infrastructure and precise environmental control. | Risk of anaerobic fermentation if gas balance is disturbed. |

Introduction: Importance of Atmosphere Control in Post-Harvest Fruit Storage

Controlling the atmosphere during post-harvest storage is crucial for maintaining fruit quality by slowing respiration and delaying ripening. Controlled Atmosphere Storage (CAS) regulates oxygen, carbon dioxide, and humidity levels in storage rooms to extend shelf life of fruits such as apples and pears. Modified Atmosphere Packaging (MAP) modifies gas composition within packaging, providing benefits for smaller fruit batches by preserving freshness and reducing microbial growth.

Defining Controlled Atmosphere Storage (CAS)

Controlled Atmosphere Storage (CAS) is a post-harvest technology that manipulates oxygen, carbon dioxide, and humidity levels within storage environments to slow down fruit respiration and delay ripening, thereby extending shelf life. CAS maintains precise atmospheric conditions over extended periods, typically in large storage rooms or chambers, ensuring consistent quality and reducing spoilage. Unlike Modified Atmosphere Packaging (MAP), which alters the gas composition inside sealed packages, CAS provides a stable external atmosphere for bulk fruit storage.

Understanding Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) enhances fruit quality by altering the gas composition surrounding the product, typically reducing oxygen and increasing carbon dioxide levels to slow respiration and delay ripening. Unlike Controlled Atmosphere Storage (CAS), which regulates the entire storage environment for large quantities of fruit, MAP is applied directly at the packaging level, offering flexibility for smaller batches and retail distribution. This technique extends shelf life while maintaining firmness, color, and nutritional value, making it a cost-effective solution in post-harvest technology.

Key Principles and Technologies behind CAS

Controlled Atmosphere Storage (CAS) maintains fruit quality by precisely regulating oxygen, carbon dioxide, and humidity levels within specialized storage chambers to slow respiration and delay ripening. Key technologies in CAS include advanced gas monitoring and control systems, along with temperature and humidity sensors that create an optimal environment to extend shelf life and preserve texture and flavor. Unlike Modified Atmosphere Packaging (MAP), which alters gas composition within sealed packages, CAS adjusts the entire storage environment for consistent, long-term preservation of various fruit types.

MAP Approaches: Passive vs Active Systems

Modified Atmosphere Packaging (MAP) enhances fruit quality by regulating gas compositions around produce, with passive MAP relying on the natural respiration of fruit to alter internal atmosphere, while active MAP uses gas flushing or adsorption technologies for precise control of oxygen, carbon dioxide, and humidity levels. Passive MAP is cost-effective and simple but may not maintain optimal conditions for highly respiring fruits, whereas active MAP offers tailored environments that better extend shelf life and reduce spoilage, particularly for sensitive or high-value fruits. Effective implementation of MAP approaches depends on factors like fruit type, respiration rate, and storage duration, making the choice between passive and active systems critical for optimizing post-harvest quality.

Comparative Impact on Fruit Shelf Life and Quality

Controlled Atmosphere Storage (CAS) extends fruit shelf life by maintaining low oxygen (1-3%) and elevated carbon dioxide (3-5%) conditions, significantly slowing respiration and delaying ripening processes. Modified Atmosphere Packaging (MAP) alters gas composition within sealed packaging, typically reducing oxygen to 2-5% and increasing carbon dioxide to 5-10%, effectively controlling moisture loss and microbial growth while being more suited for short-term storage and retail distribution. CAS provides superior long-term preservation and quality retention for climacteric fruits like apples and pears, whereas MAP offers flexible and cost-effective solutions primarily for perishable fruits such as berries and stone fruits during transportation and retail display.

Effects on Nutritional Value and Sensory Properties

Controlled Atmosphere Storage (CAS) maintains fruit quality by regulating oxygen, carbon dioxide, and humidity levels, effectively slowing respiration and delaying ripening, which preserves nutritional content such as vitamins C and antioxidants. Modified Atmosphere Packaging (MAP) alters the gaseous environment around the fruit within sealed packs, maintaining freshness and sensory attributes like texture, flavor, and aroma but may vary in effectiveness depending on packaging permeability. CAS generally offers more uniform control over internal atmospheres, resulting in better preservation of nutritional value and sensory properties during long-term storage compared to MAP, which is more suitable for short-term freshness maintenance.

Cost, Scalability, and Practical Considerations

Controlled Atmosphere Storage (CAS) offers superior long-term preservation of fruit quality by regulating oxygen, carbon dioxide, and humidity levels but requires high initial investment and complex infrastructure, making it less scalable for small-scale operations. Modified Atmosphere Packaging (MAP) is more cost-effective and scalable, utilizing specialized films to alter the internal gas composition around the fruit, suitable for short to medium-term storage and retail distribution. Practical considerations favor MAP for flexibility and lower operational complexity, while CAS demands continuous monitoring and energy consumption, which affects overall cost-efficiency and applicability depending on the scale and duration of storage needed.

Suitability for Different Fruit Types

Controlled atmosphere storage (CA) is highly suitable for long-term preservation of fruits such as apples, pears, and kiwifruit, as it regulates oxygen, carbon dioxide, and humidity levels to slow respiration and ripening processes. Modified atmosphere packaging (MAP), involving altering gas composition within packaged fruit, is more appropriate for short-term storage and transportation of delicate fruits like berries, grapes, and stone fruits, maintaining freshness while allowing for easier handling. The choice between CA and MAP depends on fruit respiration rate, shelf life requirements, and storage duration, with CA offering extended storage for hardy fruits and MAP providing flexibility for perishable and soft-textured varieties.

Future Trends in Atmospheric Storage Innovations

Emerging advancements in post-harvest technology emphasize integrating nanotechnology and smart sensors within Controlled Atmosphere Storage (CAS) to precisely monitor and adjust oxygen and carbon dioxide levels, ensuring optimal fruit quality. Modified Atmosphere Packaging (MAP) innovations are moving towards biodegradable films embedded with oxygen-scavenging compounds that extend shelf life while reducing environmental impact. Future trends also explore combining CAS and MAP techniques with artificial intelligence to predict fruit respiration rates and dynamically control storage atmospheres, enhancing freshness and reducing spoilage.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology optimizes fruit quality by continuously adjusting oxygen and carbon dioxide levels to slow respiration and delay ripening, outperforming traditional Controlled Atmosphere Storage and Modified Atmosphere Packaging methods. DCA effectively maintains firmness, color, and nutritional value, reducing spoilage and extending shelf life for various fruit types.

Ultra-Low Oxygen Storage (ULO)

Ultra-Low Oxygen Storage (ULO) within Controlled Atmosphere Storage (CA) maintains fruit quality by reducing oxygen levels to 0.5% or lower, thereby slowing respiration and delaying ripening more effectively than Modified Atmosphere Packaging (MAP). ULO's precise regulation of oxygen, carbon dioxide, and humidity ensures extended shelf life and better preservation of firmness, flavor, and nutritional content in fruits like apples and avocados.

Hypobaric Storage

Controlled Atmosphere Storage (CAS) maintains specific gas concentrations and low oxygen environments, effectively preserving fruit quality by slowing respiration and delaying ripening, whereas Modified Atmosphere Packaging (MAP) adjusts gas composition within packaging but offers less precise control. Hypobaric Storage, a subset of CAS involving reduced pressure environments, enhances fruit shelf life by lowering oxygen partial pressure and minimizing decay, making it superior for long-term preservation compared to conventional MAP.

Perforation-Mediated MAP

Controlled Atmosphere Storage (CAS) maintains fruit quality by regulating oxygen, carbon dioxide, and humidity levels in large sealed environments, while Perforation-Mediated Modified Atmosphere Packaging (PM-MAP) uses film micro-perforations to balance gas exchange, reducing anaerobic respiration and extending shelf life in small-scale packaging. PM-MAP optimizes fruit firmness, color retention, and reduces decay by precisely controlling internal atmosphere, making it suitable for delicate fruits requiring high respiratory rates.

Biodegradable MAP Films

Controlled Atmosphere Storage (CA) maintains fruit quality by regulating oxygen, carbon dioxide, and humidity levels over extended periods, while Modified Atmosphere Packaging (MAP) uses biodegradable films to alter gas composition at the microenvironment level, enhancing sustainability and reducing plastic waste. Biodegradable MAP films, made from materials like polylactic acid (PLA) or starch-based polymers, optimize gas permeability and moisture retention, effectively extending shelf life and preserving fruit firmness, color, and nutritional value compared to conventional non-biodegradable films.

Real-Time Gas Sensing

Controlled Atmosphere Storage (CAS) utilizes real-time gas sensing technology to maintain optimal oxygen and carbon dioxide levels, effectively slowing fruit respiration and extending shelf life while preserving flavor and texture. Modified Atmosphere Packaging (MAP) relies on initial gas composition adjustments without continuous monitoring, which may result in less precise environmental control and variable fruit quality outcomes during storage.

Respiration Rate Modulation

Controlled Atmosphere Storage effectively reduces respiration rates by maintaining low oxygen and elevated carbon dioxide levels, thus prolonging fruit shelf life and preserving firmness. Modified Atmosphere Packaging alters gas composition locally around the fruit, moderately slowing respiration but offering less consistent control compared to the precise environmental regulation in Controlled Atmosphere Storage.

Ethylene Scrubbing Technologies

Controlled Atmosphere Storage employs ethylene scrubbing technologies that maintain low oxygen and elevated CO2 levels to significantly slow fruit respiration and delay ripening, preserving quality over extended periods. Modified Atmosphere Packaging incorporates selective permeability films combined with ethylene absorbers to regulate gas composition within packaging, effectively reducing ethylene concentrations and maintaining firmness and freshness during shorter-term storage and distribution.

Smart Packaging Indicators

Controlled Atmosphere Storage (CA) maintains fruit quality by regulating oxygen, carbon dioxide, and humidity levels in large storage environments, while Modified Atmosphere Packaging (MAP) adjusts gas composition within sealed packaging to extend shelf life. Smart Packaging Indicators in MAP provide real-time visual cues on fruit freshness and respiration rates, enabling precise monitoring of quality changes during transportation and retail display.

Laser Perforated Packaging

Laser Perforated Packaging (LPP) enhances Modified Atmosphere Packaging (MAP) by precisely regulating gas exchange to maintain optimal oxygen and carbon dioxide levels, effectively preserving fruit firmness, flavor, and shelf life compared to Controlled Atmosphere (CA) Storage. This technology offers scalable, cost-efficient storage solutions with improved moisture retention and reduced fungal decay, making it ideal for extending post-harvest quality in high-respiration fruits like berries and stone fruits.

Controlled Atmosphere Storage vs Modified Atmosphere Packaging for fruit quality Infographic

agridif.com

agridif.com