Wax coating and edible coating both serve to extend the shelf life of perishable produce by creating a barrier against moisture loss and microbial contamination. Wax coatings are traditional, hydrophobic layers that prevent water evaporation but may hinder respiration, while edible coatings are often composed of natural polymers like proteins or lipids that are biodegradable and can enhance respiration rates. Edible coatings also allow for incorporation of antimicrobial agents, making them a more versatile and environmentally friendly option for post-harvest preservation.

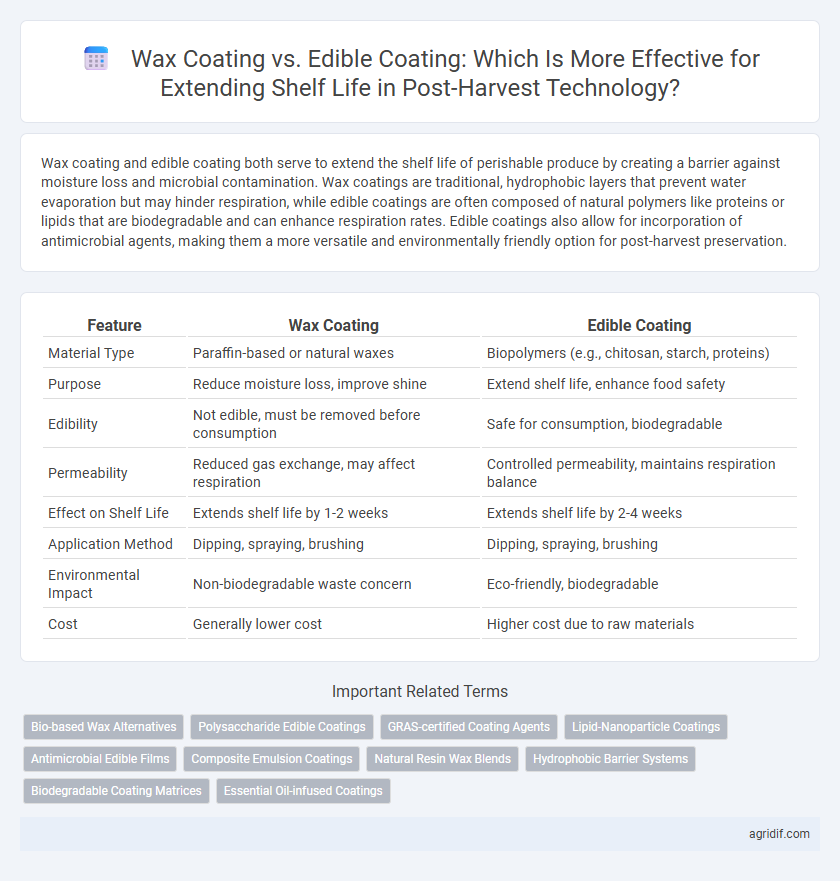

Table of Comparison

| Feature | Wax Coating | Edible Coating |

|---|---|---|

| Material Type | Paraffin-based or natural waxes | Biopolymers (e.g., chitosan, starch, proteins) |

| Purpose | Reduce moisture loss, improve shine | Extend shelf life, enhance food safety |

| Edibility | Not edible, must be removed before consumption | Safe for consumption, biodegradable |

| Permeability | Reduced gas exchange, may affect respiration | Controlled permeability, maintains respiration balance |

| Effect on Shelf Life | Extends shelf life by 1-2 weeks | Extends shelf life by 2-4 weeks |

| Application Method | Dipping, spraying, brushing | Dipping, spraying, brushing |

| Environmental Impact | Non-biodegradable waste concern | Eco-friendly, biodegradable |

| Cost | Generally lower cost | Higher cost due to raw materials |

Introduction to Post-Harvest Shelf Life Challenges

Post-harvest shelf life challenges stem from physiological, microbial, and environmental factors that accelerate deterioration in fruits and vegetables. Wax coatings primarily create a protective barrier against moisture loss and microbial invasion, enhancing shelf life by reducing respiration rates. Edible coatings, composed of biopolymers, not only act as moisture barriers but also improve gas exchange regulation and can carry antimicrobial compounds, offering a multifunctional approach to preserving freshness.

Overview of Wax Coating in Agriculture

Wax coating in agriculture is a widely used post-harvest technology that enhances the shelf life of fruits by creating a protective barrier against moisture loss, microbial invasion, and physical damage. Commonly applied on fruits such as citrus, apples, and cucumbers, wax coatings improve appearance and reduce respiration rates, thereby delaying ripening and spoilage. This method is cost-effective and supports extended storage and transportation periods while maintaining fruit quality.

Understanding Edible Coating Technologies

Edible coating technologies utilize natural, biodegradable materials such as polysaccharides, proteins, and lipids to create a semi-permeable barrier that reduces moisture loss, gas exchange, and microbial contamination, thereby extending the shelf life of fresh produce. Unlike traditional wax coatings, edible coatings enhance fruit and vegetable quality by maintaining texture, flavor, and nutritional value while being safe for direct consumption without washing. Advances in nanoemulsion and bioactive agent incorporation within edible coatings further improve their effectiveness by providing additional antimicrobial and antioxidant properties.

Mechanisms of Wax Coating for Shelf Life Extension

Wax coating extends shelf life by forming a thin, semi-permeable barrier on fruit surfaces that reduces moisture loss and slows respiration rates, thereby delaying ripening and spoilage. This coating modifies gas exchange, limiting oxygen influx and carbon dioxide efflux, which helps maintain firmness and reduces microbial growth. Through this physical barrier, wax coatings preserve quality and freshness without altering the fruit's natural appearance or flavor profile.

Benefits of Edible Coating for Fresh Produce

Edible coatings provide a biodegradable and non-toxic barrier that helps reduce moisture loss and gas exchange, thereby extending the shelf life of fresh produce without compromising safety. Unlike traditional wax coatings, edible coatings can incorporate natural antimicrobials and antioxidants, enhancing the preservation of fruit and vegetable quality while maintaining consumer health standards. These coatings improve texture and appearance, reduce post-harvest decay, and are compatible with organic and sustainable farming practices.

Comparative Analysis: Wax Coating vs Edible Coating

Wax coating provides a durable barrier against moisture loss and microbial contamination, effectively extending shelf life by reducing respiration rates in fruits and vegetables. Edible coatings, composed of natural polymers like chitosan and alginate, offer a biodegradable alternative that enhances gas exchange regulation and can carry antimicrobial agents, further preserving freshness. Comparative studies show that while wax coatings excel in mechanical protection and water retention, edible coatings improve product safety and consumer acceptance due to their non-toxic, consumable properties.

Safety and Regulatory Aspects of Coating Methods

Wax coatings are widely used in post-harvest technology for extending shelf life due to their effectiveness in moisture retention and surface protection but face regulatory scrutiny related to food-grade safety, with permissible wax types varying by country. Edible coatings, composed of natural biopolymers like chitosan, cellulose, and proteins, offer biocompatible, non-toxic alternatives that comply with stringent food safety regulations and provide additional functional benefits such as antimicrobial activity. Regulatory agencies, including the FDA and EFSA, emphasize the importance of ingredient transparency, allergen labeling, and migration limits, making edible coatings preferable for clean-label applications and markets with strict regulatory frameworks.

Impact on Quality, Taste, and Appearance

Wax coating provides a protective barrier that effectively reduces moisture loss and delays spoilage, preserving the fruit's firmness and extending shelf life but may slightly alter the natural appearance with a glossy finish. Edible coatings, composed of natural polymers like chitosan or alginate, enhance quality by maintaining moisture balance and allowing gas exchange, which helps retain the fresh taste and natural texture without compromising appearance. Both methods improve shelf life, but edible coatings are preferred for maintaining organoleptic properties and consumer acceptance due to their transparency and minimal impact on flavor.

Sustainability and Environmental Considerations

Wax coating provides an effective barrier against moisture loss and decay, but often relies on petroleum-based materials that raise concerns about environmental sustainability and biodegradability. Edible coatings, derived from natural sources such as proteins, lipids, and polysaccharides, offer a biodegradable and eco-friendly alternative that reduces reliance on synthetic chemicals while enhancing shelf life through antimicrobial and antioxidant properties. Sustainable post-harvest technology favors edible coatings due to their reduced environmental footprint and compatibility with organic produce standards.

Future Trends in Coating Technologies for Post-Harvest Preservation

Emerging trends in post-harvest technology emphasize biodegradable and nano-enabled edible coatings that enhance fruit and vegetable shelf life by reducing moisture loss and microbial growth more effectively than traditional wax coatings. Innovations in natural polysaccharide, protein, and lipid composites integrated with antimicrobial agents and antioxidants are expected to improve coating functionality while ensuring food safety and consumer acceptance. Future research prioritizes smart coatings with controlled release properties and compatibility with cold chain logistics to further extend post-harvest preservation and reduce food waste.

Related Important Terms

Bio-based Wax Alternatives

Bio-based wax alternatives in post-harvest technology provide a sustainable option for extending shelf life by reducing moisture loss and delaying ripening while maintaining fruit quality. Compared to traditional wax coatings, these edible coatings offer biodegradability, enhanced gas permeability, and incorporation of natural antimicrobials, improving preservation without compromising safety or environmental impact.

Polysaccharide Edible Coatings

Polysaccharide edible coatings, derived from natural biopolymers like chitosan, alginate, and starch, form a breathable barrier that reduces moisture loss and slows down respiration rates, effectively extending the shelf life of fresh produce while maintaining quality and safety. Unlike traditional wax coatings, polysaccharide coatings are biodegradable, non-toxic, and can be enriched with antimicrobial agents, enhancing preservation without altering the produce's sensory attributes.

GRAS-certified Coating Agents

GRAS-certified edible coatings, such as chitosan and alginate, offer biodegradable and non-toxic alternatives to traditional wax coatings for extending the shelf life of fresh produce by reducing moisture loss and microbial decay. These edible coatings enhance gas exchange control and maintain product quality without residues, making them preferable for consumer safety and regulatory compliance in post-harvest technology.

Lipid-Nanoparticle Coatings

Lipid-nanoparticle coatings offer superior efficiency in extending the shelf life of post-harvest fruits and vegetables by forming a thin, breathable, and biodegradable barrier that reduces moisture loss and microbial growth compared to traditional wax coatings. These edible coatings enhance gas exchange regulation and improve antioxidant delivery, contributing to better preservation of quality and nutritional value during storage and transportation.

Antimicrobial Edible Films

Antimicrobial edible films, often derived from biopolymers like chitosan and gelatin, provide an eco-friendly alternative to conventional wax coatings by forming a breathable barrier that not only reduces moisture loss but also inhibits microbial growth on fresh produce. These edible coatings enhance shelf life and safety by incorporating natural antimicrobial agents such as essential oils, organic acids, or enzymes, effectively controlling spoilage and pathogenic microorganisms without compromising fruit quality.

Composite Emulsion Coatings

Composite emulsion coatings, combining natural polymers and lipids, enhance post-harvest shelf life by improving moisture barrier properties and reducing respiration rates more effectively than conventional wax coatings, which primarily provide surface gloss and moderate protection. These edible coatings offer biocompatible, biodegradable advantages while maintaining fruit quality, texture, and safety during storage and transportation, making them a superior alternative for sustainable post-harvest technology.

Natural Resin Wax Blends

Natural resin wax blends in wax coating form create a hydrophobic barrier that significantly reduces moisture loss and delays respiration rates in post-harvest fruits, extending shelf life by maintaining firmness and freshness. Edible coatings, while biodegradable and sometimes nutrient-enhanced, generally offer less effective moisture barrier properties compared to resin wax blends, making the latter superior for long-term preservation in storage and transport.

Hydrophobic Barrier Systems

Hydrophobic barrier systems such as wax coatings provide a moisture-resistant layer that reduces water loss, thereby extending the shelf life of fresh produce by preserving firmness and weight. Edible coatings, composed of natural polymers like proteins and polysaccharides, not only create a hydrophobic barrier but also allow gas exchange, enhancing respiration control and maintaining quality during post-harvest storage.

Biodegradable Coating Matrices

Biodegradable coating matrices in post-harvest technology offer eco-friendly alternatives to traditional wax coatings by enhancing fruit and vegetable shelf life through natural polymers like chitosan, alginate, and cellulose, which provide effective moisture barriers and antimicrobial properties. Unlike synthetic wax coatings, edible coatings create semipermeable films that regulate gas exchange, reduce respiration rates, and maintain firmness, thereby significantly extending product freshness while minimizing environmental impact.

Essential Oil-infused Coatings

Essential oil-infused edible coatings offer a natural antimicrobial barrier that enhances fruit shelf life by reducing microbial decay and moisture loss more effectively than traditional wax coatings. These bioactive coatings improve gas exchange and antioxidant properties, maintaining freshness and extending post-harvest quality without compromising food safety.

Wax Coating vs Edible Coating for extending shelf life Infographic

agridif.com

agridif.com