Ethylene scrubbers effectively remove ethylene gas from storage environments, slowing down fruit ripening and extending shelf life by preventing premature spoilage. Ozone generators oxidize ethylene and other microbial contaminants, offering both ripening control and sanitation benefits, but require careful dosage management to avoid crop damage. Comparing both, ethylene scrubbers provide a targeted approach to ripening control, while ozone generators offer broader antimicrobial effects but with increased operational complexity.

Table of Comparison

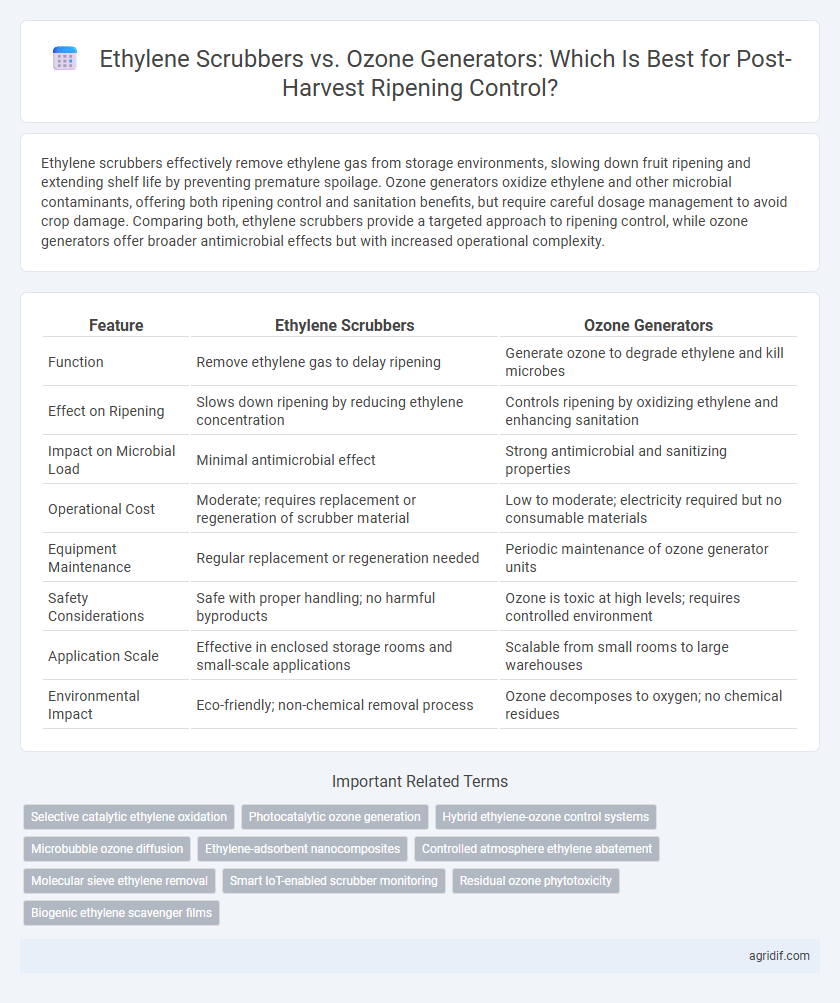

| Feature | Ethylene Scrubbers | Ozone Generators |

|---|---|---|

| Function | Remove ethylene gas to delay ripening | Generate ozone to degrade ethylene and kill microbes |

| Effect on Ripening | Slows down ripening by reducing ethylene concentration | Controls ripening by oxidizing ethylene and enhancing sanitation |

| Impact on Microbial Load | Minimal antimicrobial effect | Strong antimicrobial and sanitizing properties |

| Operational Cost | Moderate; requires replacement or regeneration of scrubber material | Low to moderate; electricity required but no consumable materials |

| Equipment Maintenance | Regular replacement or regeneration needed | Periodic maintenance of ozone generator units |

| Safety Considerations | Safe with proper handling; no harmful byproducts | Ozone is toxic at high levels; requires controlled environment |

| Application Scale | Effective in enclosed storage rooms and small-scale applications | Scalable from small rooms to large warehouses |

| Environmental Impact | Eco-friendly; non-chemical removal process | Ozone decomposes to oxygen; no chemical residues |

Understanding Ethylene's Role in Post-Harvest Ripening

Ethylene is a critical plant hormone that regulates fruit ripening and senescence during post-harvest storage, influencing quality, texture, and shelf life. Ethylene scrubbers efficiently remove ethylene gas from storage environments, slowing down ripening and reducing spoilage, while ozone generators oxidize ethylene along with microbial contaminants, offering dual benefits. Understanding the concentration and effects of ethylene enables optimized use of ethylene scrubbers and ozone generators to maintain produce freshness and extend marketability.

Ethylene Scrubbers: Mechanism and Applications

Ethylene scrubbers remove ethylene gas by chemically absorbing or catalytically breaking down the molecule, effectively slowing down the ripening and senescence processes in harvested fruits and vegetables. These systems use materials such as potassium permanganate or activated carbon impregnated with catalytic agents to maintain low ethylene concentration within storage environments. Common applications include cold storage facilities, shipping containers, and controlled atmosphere rooms to extend shelf life and preserve quality in produce like apples, bananas, and tomatoes.

Ozone Generators: Functionality in Ripening Control

Ozone generators function in ripening control by breaking down ethylene gas, a key hormone responsible for fruit maturation, thereby slowing down the ripening process and extending shelf life. Ozone's strong oxidizing properties enable it to effectively neutralize ethylene molecules in storage environments, reducing spoilage and maintaining fruit quality. These generators also exhibit antimicrobial effects, lowering the risk of fungal growth and decay during post-harvest storage.

Comparative Effectiveness of Ethylene Scrubbers vs. Ozone Generators

Ethylene scrubbers effectively reduce ethylene concentration in storage environments by chemically adsorbing ethylene molecules, directly slowing down fruit ripening and decay. Ozone generators control post-harvest ripening by oxidizing ethylene and degrading microbial populations, but their oxidative strength can sometimes cause surface damage to delicate produce. Comparative studies show ethylene scrubbers provide more consistent control over ripening rates with minimal produce quality impact, whereas ozone generators offer broader antimicrobial benefits at the risk of potential phytotoxicity.

Impact on Shelf Life and Fruit Quality

Ethylene scrubbers effectively reduce ethylene concentration, delaying ripening and extending shelf life of fruits while maintaining firmness and color. Ozone generators oxidize ethylene and microbial contaminants, also prolonging shelf life but may cause oxidative stress, potentially affecting fruit texture and flavor. Balancing ethylene removal efficacy and oxidative impact is crucial for optimizing post-harvest fruit quality and marketability.

Safety Considerations for Ethylene and Ozone Technologies

Ethylene scrubbers effectively reduce ethylene gas levels to delay fruit ripening without introducing harmful residues, ensuring safe air quality for storage environments. Ozone generators provide antimicrobial benefits and ethylene degradation but require careful concentration control due to ozone's oxidative properties, which can pose respiratory risks to workers and damage produce at high levels. Implementing proper ventilation, monitoring systems, and adherence to safety guidelines is critical when using ozone technologies, while ethylene scrubbers generally offer a lower-risk alternative for maintaining post-harvest quality.

Energy Consumption and Operational Costs

Ethylene scrubbers typically consume less energy compared to ozone generators, making them more cost-effective for long-term post-harvest ripening control. Operational costs for ethylene scrubbers are generally lower due to simpler maintenance and fewer consumables, whereas ozone generators require higher energy input and regular replacement of ozone-producing components. Selecting ethylene scrubbers can lead to significant savings in electricity bills and reduced equipment downtime in commercial storage facilities.

Suitability for Different Crops and Storage Environments

Ethylene scrubbers effectively extend shelf life for climacteric fruits like bananas, tomatoes, and avocados by selectively removing ethylene gas without altering storage atmosphere composition. Ozone generators offer broader antimicrobial benefits, suitable for fruits and vegetables prone to microbial spoilage, but their oxidizing nature requires careful control to prevent damage in sensitive crops like leafy greens. Storage environments with high humidity and varying temperatures favor ethylene scrubbers, while ozone generators perform well in controlled, low-humidity cold storage facilities.

Environmental Implications of Post-Harvest Technologies

Ethylene scrubbers reduce post-harvest fruit spoilage by selectively removing ethylene gas, minimizing chemical residues and lowering energy consumption compared to ozone generators. Ozone generators effectively degrade ethylene and pathogens but produce reactive oxygen species that can impact worker safety and require careful ventilation to prevent environmental ozone pollution. Choosing between these technologies depends on balancing ethylene management efficiency with environmental and health considerations in storage facilities.

Future Trends in Ripening Control Systems

Ethylene scrubbers and ozone generators represent advancing technologies in post-harvest ripening control, with future trends emphasizing integration of smart sensors and automation for precise atmospheric regulation. Ethylene scrubbers effectively remove ethylene gas to delay ripening, while ozone generators oxidize ethylene molecules, offering antimicrobial benefits and extended shelf life. Emerging systems leverage AI-driven monitoring and energy-efficient designs to optimize fruit quality, reduce waste, and enhance supply chain sustainability.

Related Important Terms

Selective catalytic ethylene oxidation

Selective catalytic ethylene oxidation using ethylene scrubbers effectively reduces ethylene concentration in storage environments, slowing fruit ripening and extending shelf life by targeting ethylene molecules without producing harmful byproducts. Ozone generators oxidize ethylene non-selectively, potentially causing oxidative damage to produce and creating residues, making ethylene scrubbers a more precise and safer option for post-harvest ripening control.

Photocatalytic ozone generation

Photocatalytic ozone generation using titanium dioxide catalysts in ozone generators provides a targeted approach to degrade ethylene, reducing fruit ripening and spoilage by breaking down ethylene molecules more efficiently than traditional ethylene scrubbers. This method minimizes chemical residues and offers a sustainable, energy-efficient solution to extend post-harvest shelf life while maintaining produce quality.

Hybrid ethylene-ozone control systems

Hybrid ethylene-ozone control systems combine ethylene scrubbers and ozone generators to enhance post-harvest ripening management by simultaneously removing ethylene gas and oxidizing organic compounds responsible for decay. These integrated systems optimize fruit quality preservation, reduce spoilage rates, and extend shelf life by regulating the atmospheric composition within storage environments more effectively than single-method approaches.

Microbubble ozone diffusion

Microbubble ozone diffusion in ozone generators enhances the oxidation of ethylene, effectively slowing fruit ripening and extending shelf life compared to traditional ethylene scrubbers that primarily absorb ethylene gas. The increased surface area and reactivity of microbubbles improve ozone solubility and contact efficiency, making ozone systems more efficient for post-harvest ripening control in storage environments.

Ethylene-adsorbent nanocomposites

Ethylene-adsorbent nanocomposites in ethylene scrubbers effectively reduce ethylene concentration, prolonging shelf life and controlling ripening in post-harvest fruits. Compared to ozone generators, these nanocomposites offer selective ethylene adsorption without oxidative damage, ensuring better fruit quality and safer storage environments.

Controlled atmosphere ethylene abatement

Ethylene scrubbers effectively remove ethylene gas in controlled atmosphere storage, slowing fruit ripening and extending shelf life by adsorbing or chemically neutralizing ethylene molecules. Ozone generators oxidize ethylene but pose risks of phytotoxicity and require precise concentration control, making ethylene scrubbers more reliable for maintaining optimal ripening conditions in post-harvest technology.

Molecular sieve ethylene removal

Molecular sieve ethylene removal in ethylene scrubbers efficiently adsorbs ethylene gas, slowing fruit ripening and extending shelf life by reducing ethylene concentration in storage environments. Compared to ozone generators, molecular sieve ethylene scrubbers offer selective ethylene removal without producing oxidative byproducts, minimizing fruit damage and maintaining post-harvest quality.

Smart IoT-enabled scrubber monitoring

Smart IoT-enabled ethylene scrubbers provide precise, real-time monitoring and regulation of ethylene concentrations, enhancing post-harvest ripening control by reducing spoilage and extending shelf life. Compared to ozone generators, these ethylene scrubbers offer targeted gas removal without oxidative damage, ensuring optimal fruit quality and energy-efficient operation through predictive analytics and remote system management.

Residual ozone phytotoxicity

Ethylene scrubbers effectively reduce ethylene concentrations without generating harmful byproducts, preventing residual ozone phytotoxicity that can cause oxidative damage to fruits and vegetables during post-harvest ripening. In contrast, ozone generators produce ozone gas that, while controlling microbial growth and ethylene, may leave residual ozone leading to tissue injury, discoloration, and compromised crop quality.

Biogenic ethylene scavenger films

Biogenic ethylene scavenger films offer a sustainable alternative to ethylene scrubbers and ozone generators by actively absorbing ethylene gas, delaying ripening and extending shelf life in post-harvest storage. These films enhance fruit quality without the oxidative stress associated with ozone generators, providing a targeted, eco-friendly solution for ethylene management in supply chains.

Ethylene scrubbers vs Ozone generators for post-harvest ripening control Infographic

agridif.com

agridif.com