Wax coating and edible coating are both effective methods for fruit preservation, but they differ in composition and benefits. Wax coatings create a protective barrier that reduces moisture loss and extends shelf life, while edible coatings, made from natural polymers, provide biodegradability and add nutritional value. Choosing between these coatings depends on factors such as desired fruit quality, consumer safety, and environmental impact.

Table of Comparison

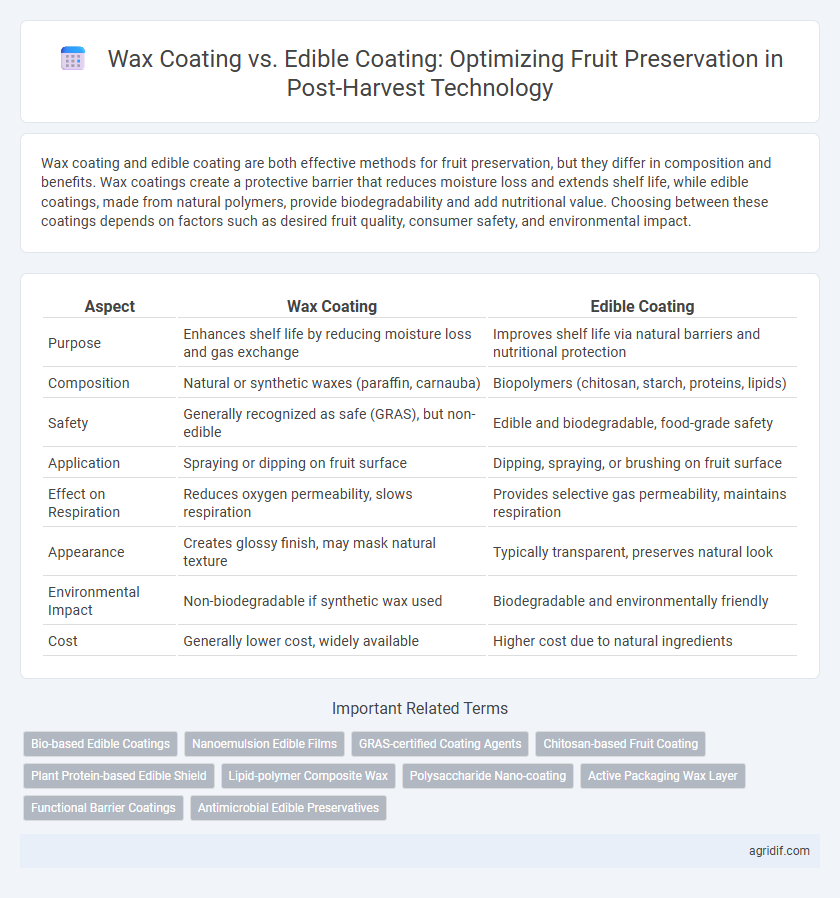

| Aspect | Wax Coating | Edible Coating |

|---|---|---|

| Purpose | Enhances shelf life by reducing moisture loss and gas exchange | Improves shelf life via natural barriers and nutritional protection |

| Composition | Natural or synthetic waxes (paraffin, carnauba) | Biopolymers (chitosan, starch, proteins, lipids) |

| Safety | Generally recognized as safe (GRAS), but non-edible | Edible and biodegradable, food-grade safety |

| Application | Spraying or dipping on fruit surface | Dipping, spraying, or brushing on fruit surface |

| Effect on Respiration | Reduces oxygen permeability, slows respiration | Provides selective gas permeability, maintains respiration |

| Appearance | Creates glossy finish, may mask natural texture | Typically transparent, preserves natural look |

| Environmental Impact | Non-biodegradable if synthetic wax used | Biodegradable and environmentally friendly |

| Cost | Generally lower cost, widely available | Higher cost due to natural ingredients |

Introduction to Fruit Preservation Technologies

Wax coating and edible coating are essential fruit preservation technologies that enhance shelf life by reducing moisture loss and delaying microbial spoilage. Wax coatings create a protective barrier on the fruit surface, improving firmness and visual appeal, while edible coatings, made from biopolymers like chitosan or alginate, offer biodegradable and safe alternatives that also provide antimicrobial properties. Both technologies play a crucial role in maintaining fruit quality during storage and transportation, reducing post-harvest losses and extending marketability.

Understanding Wax Coating: Materials and Application

Wax coating for fruit preservation primarily involves the use of natural or synthetic waxes such as carnauba, beeswax, or shellac, which create a protective barrier reducing moisture loss and delaying ripening. Application methods typically include dipping, spraying, or brushing the wax onto the fruit surface to enhance gloss, reduce shrinkage, and extend shelf life by minimizing respiration and microbial growth. Understanding the physicochemical properties of waxes and their interaction with fruit skin is crucial for optimizing coating thickness and uniformity to maintain fruit quality without compromising safety or taste.

Edible Coatings: Composition and Mechanisms

Edible coatings for fruit preservation are typically composed of polysaccharides, proteins, and lipids that form a semi-permeable barrier reducing moisture loss and gas exchange. These coatings enhance fruit shelf life by modulating respiration rates and limiting microbial growth while maintaining fruit quality and edibility. Natural biopolymers like chitosan, alginate, and starch are widely used due to their biodegradability and ability to carry antimicrobial agents for improved post-harvest protection.

Comparative Analysis: Effectiveness in Extending Shelf Life

Wax coating provides a strong barrier against moisture loss and gas exchange, significantly extending shelf life by reducing respiration rates and delaying ripening in fruits like apples and citrus. Edible coatings, composed of natural polymers such as chitosan or cellulose, not only enhance shelf life by forming semi-permeable films but also improve fruit quality by being biodegradable and sometimes providing antimicrobial properties. Comparative studies show that while wax coatings excel in moisture retention, edible coatings offer better environmental benefits and can enhance functional qualities like antioxidant activity, making the choice dependent on specific post-harvest goals and fruit types.

Impact on Fruit Quality and Sensory Properties

Wax coating enhances fruit shelf life by creating a moisture barrier, reducing weight loss and decay while maintaining firmness, but it may alter the natural appearance and aroma, potentially affecting consumer acceptance. Edible coatings, typically composed of biopolymers like chitosan or cellulose, improve gas exchange and retain sensory qualities such as flavor and texture without compromising the fruit's natural look. Studies show that edible coatings better preserve volatile compounds and reduce off-flavors, resulting in higher sensory scores compared to traditional wax coatings.

Safety, Regulations, and Consumer Acceptance

Wax coatings for fruit preservation are widely approved by food safety authorities and provide a durable barrier against moisture loss, but concerns about synthetic components can affect consumer acceptance. Edible coatings, often made from natural substances like chitosan or starch, offer safer alternatives with biodegradability and are increasingly favored in regulatory frameworks promoting minimal chemical use. Consumer preference is shifting towards edible coatings due to perceived health benefits and environmental sustainability, influencing market trends and labeling practices.

Environmental Sustainability: Wax vs Edible Coatings

Wax coatings, traditionally used for fruit preservation, provide a moisture barrier but often involve petrochemical-derived substances with limited biodegradability, raising environmental concerns. Edible coatings, made from natural polymers like chitosan, alginate, or cellulose, enhance sustainability by being biodegradable and reducing plastic waste in post-harvest handling. Incorporating edible coatings supports eco-friendly fruit preservation methods by minimizing environmental impact while maintaining fruit quality and shelf life.

Economic Considerations for Producers

Wax coating offers a cost-effective solution for fruit preservation due to its low application expenses and extended shelf life, making it attractive for large-scale producers aiming to maximize profit margins. Edible coatings, while generally more expensive to produce and apply, provide added value through enhanced consumer appeal and potential health benefits, justifying higher market prices. Producers must evaluate initial coating costs, potential price premiums, and shelf-life extension to optimize economic returns in post-harvest fruit management.

Emerging Innovations in Coating Technologies

Emerging innovations in wax coating and edible coating for fruit preservation are revolutionizing post-harvest technology by enhancing shelf life and maintaining fruit quality. Advanced formulations incorporating natural polymers, antimicrobial agents, and nanomaterials improve barrier properties against moisture loss and microbial contamination. Research into biodegradable and flavor-neutral edible coatings is expanding their application, providing sustainable and consumer-friendly alternatives to traditional wax coatings.

Future Trends and Recommendations in Fruit Preservation

Innovations in fruit preservation increasingly favor edible coatings derived from natural polymers such as chitosan, alginate, and cellulose, which enhance shelf life while maintaining safety and environmental sustainability, unlike conventional wax coatings that may involve synthetic additives. Emerging trends emphasize the integration of nanotechnology and bioactive compounds in edible coatings to improve antimicrobial properties and fruit respiration control, offering promising alternatives to traditional preservation methods. Future recommendations advocate for the development of multifunctional edible coatings that combine preservation efficacy with consumer health benefits and biodegradability to meet global sustainability goals.

Related Important Terms

Bio-based Edible Coatings

Bio-based edible coatings for fruit preservation enhance shelf life by creating a semi-permeable barrier that reduces moisture loss and gas exchange while maintaining fruit safety and edibility, unlike conventional wax coatings that may contain synthetic components. These natural polymer-based coatings, such as those derived from chitosan, alginate, and cellulose, also provide antimicrobial properties and improve fruit quality by preserving texture and nutritional value during storage and transportation.

Nanoemulsion Edible Films

Nanoemulsion edible films enhance fruit preservation by forming a breathable, biodegradable barrier that reduces moisture loss and oxidation more effectively than traditional wax coatings. Their nanoscale droplets improve film uniformity and bioactive compound delivery, extending shelf life while maintaining fruit quality and safety.

GRAS-certified Coating Agents

GRAS-certified coating agents such as carnauba wax and shellac are widely used in wax coating to extend fruit shelf life by reducing moisture loss and enhancing appearance. Edible coatings containing GRAS substances like cellulose, chitosan, and aloe vera not only provide effective moisture barriers but also offer antimicrobial properties, improving post-harvest fruit preservation and safety.

Chitosan-based Fruit Coating

Chitosan-based fruit coatings provide a biodegradable and antimicrobial alternative to traditional wax coatings, enhancing shelf life and reducing microbial spoilage in post-harvest fruit preservation. These edible coatings form a semi-permeable barrier that controls moisture loss and gas exchange, maintaining fruit freshness and quality without chemical residues.

Plant Protein-based Edible Shield

Plant protein-based edible coatings offer a sustainable alternative to traditional wax coatings by forming a biodegradable, breathable barrier that enhances fruit shelf life and maintains quality without harmful residues. These coatings improve moisture retention, reduce microbial decay, and preserve nutritional value, aligning with increasing consumer demand for natural and eco-friendly post-harvest preservation solutions.

Lipid-polymer Composite Wax

Lipid-polymer composite wax coatings enhance fruit preservation by providing a hydrophobic barrier that reduces moisture loss and respiration rates while maintaining fruit firmness and gloss. Compared to traditional edible coatings, these composite waxes offer superior durability, water resistance, and extended shelf life, making them ideal for commercial post-harvest applications.

Polysaccharide Nano-coating

Polysaccharide nano-coatings offer a biodegradable and edible alternative to traditional wax coatings, enhancing fruit preservation by improving gas permeability and moisture retention while providing antimicrobial properties. These nano-coatings, derived from natural polymers like chitosan and alginate, extend shelf life by reducing oxidative damage and maintaining fruit firmness without compromising safety or quality.

Active Packaging Wax Layer

Wax coating creates a moisture barrier that slows respiration and reduces weight loss in fruits, enhancing shelf life by preventing dehydration and oxidation. Active packaging wax layers infused with antimicrobial agents further inhibit microbial growth, offering improved fruit preservation compared to traditional edible coatings.

Functional Barrier Coatings

Wax coating provides a hydrophobic barrier that reduces moisture loss and gas exchange, effectively extending fruit shelf life by maintaining firmness and freshness. Edible coatings, often based on polysaccharides or proteins, create a multifunctional barrier that not only limits water vapor and oxygen permeability but also enhances fruit antioxidant capacity and microbial resistance, promoting longer and safer preservation.

Antimicrobial Edible Preservatives

Antimicrobial edible preservatives in edible coatings, such as chitosan and essential oils, offer enhanced fruit preservation by inhibiting microbial growth while maintaining fruit breathability and safety for consumption. Compared to traditional wax coatings, these bio-based edible coatings provide effective pathogen control and extend shelf life without compromising the fruit's natural texture or flavor.

Wax Coating vs Edible Coating for Fruit Preservation Infographic

agridif.com

agridif.com