Forced air cooling rapidly reduces fruit temperature by circulating cold air around the produce, effectively slowing metabolic processes and extending shelf life. Hydro cooling immerses fruits in cold water, providing uniform cooling and reducing field heat faster than air methods, which helps maintain freshness and firmness. Both techniques enhance post-harvest quality, but hydro cooling is generally more suitable for dense or large-volume fruits, while forced air cooling is energy-efficient and ideal for delicate products.

Table of Comparison

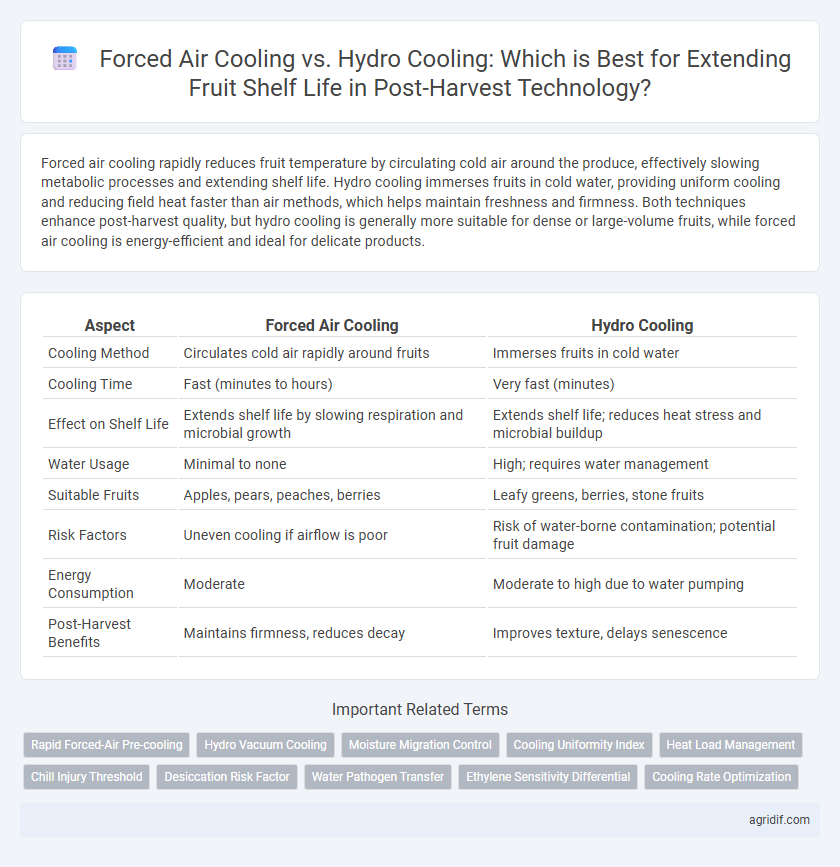

| Aspect | Forced Air Cooling | Hydro Cooling |

|---|---|---|

| Cooling Method | Circulates cold air rapidly around fruits | Immerses fruits in cold water |

| Cooling Time | Fast (minutes to hours) | Very fast (minutes) |

| Effect on Shelf Life | Extends shelf life by slowing respiration and microbial growth | Extends shelf life; reduces heat stress and microbial buildup |

| Water Usage | Minimal to none | High; requires water management |

| Suitable Fruits | Apples, pears, peaches, berries | Leafy greens, berries, stone fruits |

| Risk Factors | Uneven cooling if airflow is poor | Risk of water-borne contamination; potential fruit damage |

| Energy Consumption | Moderate | Moderate to high due to water pumping |

| Post-Harvest Benefits | Maintains firmness, reduces decay | Improves texture, delays senescence |

Introduction to Post-Harvest Cooling Techniques

Forced air cooling and hydro cooling are essential post-harvest techniques designed to rapidly reduce the temperature of fruits, minimizing respiration rates and delaying spoilage. Forced air cooling utilizes chilled air circulated around the produce, offering uniform cooling suitable for large-scale operations, while hydro cooling immerses fruits in cold water, providing faster cooling but requiring careful water management to prevent contamination. Both methods significantly extend fruit shelf life by slowing metabolic processes, with the choice depending on fruit type, cost considerations, and infrastructure availability.

Forced Air Cooling: Principles and Process

Forced air cooling utilizes the rapid circulation of refrigerated air through ventilated fruit pallets to remove field heat efficiently, reducing the temperature to optimal storage levels within hours. This technique ensures uniform cooling by directing cold air across all fruit surfaces, minimizing moisture loss and delaying senescence, thereby extending shelf life significantly. The controlled airflow rate and temperature parameters in forced air cooling optimize respiration rates and inhibit microbial growth, preserving fruit freshness during post-harvest storage.

Understanding Hydro Cooling Technology

Hydro cooling technology rapidly reduces the temperature of harvested fruits by immersing or spraying them with cold water, which efficiently removes field heat and slows metabolic processes that cause spoilage. Unlike forced air cooling that circulates chilled air through the produce, hydro cooling offers higher heat transfer rates, resulting in quicker cooling times and extended shelf life for fruits such as berries, cherries, and stone fruits. Proper management of water temperature, flow rate, and sanitation is critical to maximize hydro cooling effectiveness and prevent cross-contamination during post-harvest handling.

Comparative Analysis: Cooling Efficiency

Forced air cooling rapidly decreases fruit temperature by circulating cold air around produce, achieving uniform cooling and reducing respiration rates effectively. Hydro cooling submerges fruits in cold water, offering faster heat removal for dense or large-sized fruits but posing higher risks of microbial contamination. Studies indicate forced air cooling provides better temperature control and energy efficiency, while hydro cooling excels in cooling speed but demands strict hygiene management to maintain optimal shelf life.

Impact on Fruit Shelf Life and Quality

Forced air cooling rapidly removes field heat by circulating cold air through stacked fruit, significantly extending shelf life and maintaining firmness and color. Hydro cooling immerses fruit in cold water, providing uniform temperature reduction and reducing water stress, which helps preserve fruit freshness and weight. Both methods effectively slow respiration rate and microbial growth, but forced air cooling offers more consistency for long-term storage and transportation.

Energy Consumption and Operational Costs

Forced air cooling typically consumes less energy compared to hydro cooling due to its lower water usage and simpler infrastructure, making it cost-effective for large-scale fruit storage. Hydro cooling, while faster at reducing fruit temperature, incurs higher operational costs from water treatment and energy-intensive pumping systems. Choosing between methods depends on balancing quicker cooling benefits against long-term energy savings and cost efficiency in fruit shelf life management.

Suitability for Different Fruit Types

Forced air cooling is highly suitable for fruits with firm skins and uniform shapes, such as apples and pears, as it quickly removes field heat without causing surface moisture buildup. Hydro cooling excels with fruits that tolerate water contact, like cherries and berries, by rapidly reducing temperature and maintaining firmness but may increase the risk of microbial growth if not properly managed. Choosing between forced air and hydro cooling depends on the fruit's permeability and sensitivity to moisture to optimize shelf life and quality.

Hygiene and Food Safety Considerations

Forced air cooling enhances hygiene by minimizing direct water contact, reducing risks of microbial contamination on fruit surfaces during post-harvest handling. Hydro cooling, while effective for rapid temperature reduction, requires stringent water quality management and frequent sanitation of cooling systems to prevent cross-contamination and pathogen proliferation. Maintaining optimal sanitation protocols in both methods is critical to ensuring food safety and extending fruit shelf life.

Environmental Sustainability of Cooling Methods

Forced air cooling significantly reduces water consumption compared to hydro cooling, making it a more environmentally sustainable method for preserving fruit shelf life. Hydro cooling, while effective in rapidly lowering fruit temperature, often leads to increased water use and potential wastewater management challenges. Implementing forced air systems can decrease energy use and water waste, contributing to lower environmental impacts in post-harvest fruit handling.

Choosing the Optimal Cooling Method for Your Produce

Forced air cooling rapidly removes field heat by circulating chilled air through packaged fruits, effectively reducing respiration rates and delaying spoilage. Hydro cooling submerges fruits in cold water, providing uniform temperature reduction and minimizing weight loss, ideal for high-density produce like berries and leafy greens. Selecting the optimal cooling method depends on fruit type, packaging, and post-harvest handling infrastructure to maximize shelf life and maintain quality.

Related Important Terms

Rapid Forced-Air Pre-cooling

Rapid forced-air pre-cooling significantly extends fruit shelf life by quickly reducing field heat through high-velocity air circulation, minimizing microbial growth and physiological deterioration. Compared to hydro cooling, forced-air cooling offers uniform temperature reduction without the risk of waterborne pathogens or excess moisture, making it ideal for sensitive fruits requiring extended freshness.

Hydro Vacuum Cooling

Hydro vacuum cooling rapidly reduces fruit temperature by combining vacuum pressure with cold water immersion, significantly extending shelf life compared to forced air cooling, which relies solely on cooled air circulation and is less efficient in heat transfer. This advanced hydro vacuum technology improves moisture retention and reduces respiration rates, resulting in fresher fruit with prolonged marketability.

Moisture Migration Control

Forced air cooling accelerates cooling by circulating cold air rapidly around fruits, effectively reducing field heat and limiting moisture migration, which helps maintain firmness and extends shelf life. Hydro cooling immerses fruits in chilled water, providing uniform and rapid cooling that minimizes moisture loss and reduces respiration rates, crucial for preserving freshness and delaying spoilage.

Cooling Uniformity Index

Forced air cooling achieves a higher Cooling Uniformity Index compared to hydro cooling by evenly distributing cold air through stacked fruit layers, reducing temperature gradients and minimizing spoilage. Hydro cooling, while effective for surface chilling, often results in uneven internal temperatures, leading to variable shelf life and increased risk of microbial growth.

Heat Load Management

Forced air cooling effectively manages heat load in fruit storage by rapidly removing field heat through high-velocity airflow, enhancing shelf life by reducing respiration rates and delaying ripening. Hydro cooling achieves heat load reduction by immersing fruits in chilled water, providing uniform cooling that minimizes surface dehydration and maintains firmness, thereby extending post-harvest freshness.

Chill Injury Threshold

Forced air cooling reduces fruit temperature rapidly by circulating cold air, minimizing chill injury risk by maintaining temperature above the threshold for sensitive fruits. Hydro cooling utilizes cold water immersion to quickly remove field heat but can cause uneven cooling, increasing susceptibility to chill injury if fruit temperature drops below the critical threshold.

Desiccation Risk Factor

Forced air cooling reduces fruit temperature rapidly by circulating cold air, but it increases the desiccation risk due to moisture loss from the fruit surface. Hydro cooling minimizes desiccation by immersing fruit in cold water, maintaining higher humidity levels that preserve shelf life and reduce weight loss.

Water Pathogen Transfer

Forced air cooling minimizes water pathogen transfer by rapidly reducing produce temperature through cold air circulation without direct contact, preserving fruit shelf life more effectively. Hydro cooling, while efficient in cooling, increases the risk of cross-contamination and waterborne pathogen spread, potentially shortening fruit shelf life.

Ethylene Sensitivity Differential

Forced air cooling rapidly lowers fruit temperature by circulating cold air, effectively reducing ethylene production and slowing respiration in ethylene-sensitive fruits like mangoes and avocados. Hydro cooling, involving immersion in cold water, is more suitable for less ethylene-sensitive fruits such as berries, as it provides uniform cooling but may increase ethylene-induced spoilage in sensitive varieties due to prolonged moisture exposure.

Cooling Rate Optimization

Forced air cooling accelerates the removal of field heat by circulating cold air rapidly around the fruit, optimizing cooling rates to significantly extend shelf life through reduced respiration and microbial growth. Hydro cooling leverages direct water contact to achieve faster heat transfer, but excessive moisture can promote decay, making precise control of cooling rate essential to maintain fruit quality and prolong shelf life.

Forced Air Cooling vs Hydro Cooling for fruit shelf life Infographic

agridif.com

agridif.com