Moisture analyzers provide rapid and precise moisture content measurements, using infrared or halogen heating to quickly evaporate moisture and offer results in minutes. Oven drying methods, while considered the standard, require longer drying times and can be less efficient due to prolonged exposure to heat, which may degrade sensitive materials. Choosing a moisture analyzer improves throughput and accuracy, making it ideal for post-harvest technology applications where timely moisture assessment is critical for product quality.

Table of Comparison

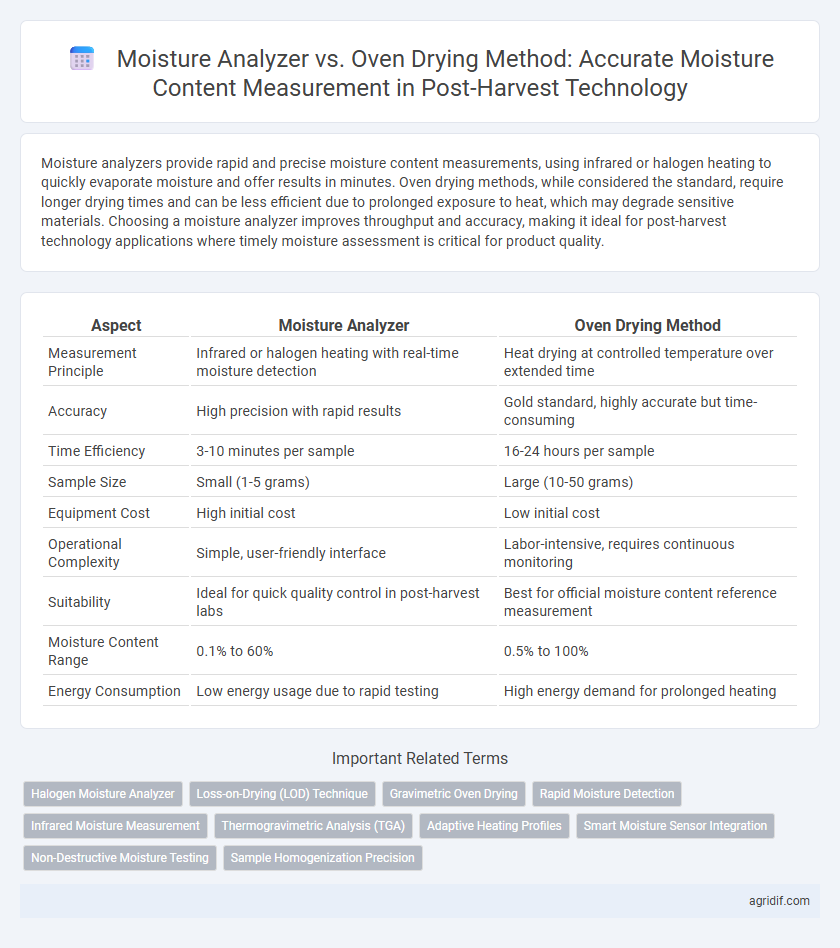

| Aspect | Moisture Analyzer | Oven Drying Method |

|---|---|---|

| Measurement Principle | Infrared or halogen heating with real-time moisture detection | Heat drying at controlled temperature over extended time |

| Accuracy | High precision with rapid results | Gold standard, highly accurate but time-consuming |

| Time Efficiency | 3-10 minutes per sample | 16-24 hours per sample |

| Sample Size | Small (1-5 grams) | Large (10-50 grams) |

| Equipment Cost | High initial cost | Low initial cost |

| Operational Complexity | Simple, user-friendly interface | Labor-intensive, requires continuous monitoring |

| Suitability | Ideal for quick quality control in post-harvest labs | Best for official moisture content reference measurement |

| Moisture Content Range | 0.1% to 60% | 0.5% to 100% |

| Energy Consumption | Low energy usage due to rapid testing | High energy demand for prolonged heating |

Introduction to Moisture Content Measurement in Agriculture

Moisture content measurement in agriculture is crucial for determining crop quality and storage conditions. Moisture analyzers provide rapid and accurate moisture quantification using infrared or microwave drying techniques, enabling real-time monitoring. Traditional oven drying methods, considered the standard, offer precise results through prolonged heating but require more time and labor, impacting efficiency in post-harvest handling.

Importance of Accurate Moisture Analysis Post-Harvest

Accurate moisture analysis in post-harvest technology is critical for preserving crop quality, preventing microbial growth, and minimizing post-harvest losses. Moisture analyzers provide rapid and precise moisture content measurements, enhancing decision-making during storage and processing compared to the traditional oven drying method, which can be time-consuming and less accurate. Reliable moisture data supports optimized drying protocols, maintaining commodity value and extending shelf life in agricultural supply chains.

Overview of Moisture Analyzer Technology

Moisture analyzers utilize advanced infrared or halogen heating elements combined with precise weight sensors to rapidly determine moisture content in agricultural products. This technology offers faster results compared to traditional oven drying methods by directly measuring weight loss in real-time during the drying process. The accuracy and efficiency of moisture analyzers enhance post-harvest quality control, enabling timely decisions to reduce spoilage and optimize storage conditions.

Principles of the Oven Drying Method

The oven drying method measures moisture content by heating a sample at a specific temperature until all moisture evaporates, allowing weight loss to indicate moisture percentage. This traditional approach relies on continuous temperature control and careful timing to avoid degradation of the sample. Its simplicity and accuracy make it a standard reference technique in post-harvest moisture analysis despite longer processing times compared to rapid moisture analyzers.

Comparative Accuracy: Moisture Analyzer vs Oven Drying

Moisture analyzers provide rapid and precise moisture content measurements by using infrared or halogen heating, offering greater accuracy for sensitive agricultural products compared to the traditional oven drying method that relies on prolonged heating and weigh loss calculation. Oven drying, while widely accepted, may introduce errors due to potential sample degradation or incomplete moisture removal during extended drying times, affecting its reliability in post-harvest analysis. The moisture analyzer's controlled heating and real-time results enhance consistency and reproducibility, making it superior for accuracy in moisture determination in grains and seeds.

Time Efficiency: Speed of Moisture Determination

Moisture analyzers provide rapid moisture content measurement, typically delivering results within 2 to 5 minutes, significantly faster than the traditional oven drying method that requires 12 to 24 hours for accurate analysis. This time efficiency enables increased throughput in post-harvest quality control and real-time decision-making. Accelerated moisture determination reduces storage delays and minimizes quality degradation risks associated with prolonged drying periods.

Sample Preparation and Handling Requirements

Moisture analyzers require minimal sample preparation, typically involving only a small, homogenous sample placed directly into the device, enabling rapid and accurate moisture content measurement. In contrast, the oven drying method demands thorough sample grinding and uniform spreading to ensure consistent drying and accurate results, often extending the preparation time. Proper handling in moisture analyzers reduces chances of contamination and moisture loss before measurement, while the oven method requires careful handling to avoid sample alteration during extended drying periods.

Cost Implications: Equipment and Operational Expenses

Moisture analyzers offer higher initial costs due to advanced sensors and digital displays, but they reduce operational expenses by delivering rapid, precise moisture content measurements with minimal sample preparation. Oven drying methods require lower upfront investment since ovens are basic equipment, but they incur higher operational costs over time due to longer processing times, increased energy consumption, and labor-intensive procedures. Considering the balance between equipment price and ongoing expenses, moisture analyzers often prove cost-effective for high-throughput post-harvest facilities seeking accurate moisture data.

Suitability for Different Crop Types and Products

Moisture analyzers offer rapid and precise moisture content measurement, making them highly suitable for sensitive crops like grains, fruits, and vegetables where timely data is crucial for quality control. Oven drying method, while more time-consuming and labor-intensive, provides reliable results for a wide range of crop types, especially those with complex matrices such as oilseeds and tubers. Selecting the appropriate method depends on the specific crop characteristics, required accuracy, and processing speed in post-harvest technology applications.

Best Practices and Recommendations for Farmers

Moisture analyzers provide rapid and accurate moisture content measurements essential for optimizing post-harvest quality, while the oven drying method, though reliable, is time-consuming and labor-intensive. Farmers are advised to use moisture analyzers for routine assessments to enable timely processing and storage decisions, reserving oven drying for calibration and validation purposes. Maintaining consistent sample sizes and calibration standards ensures accuracy across both methods, improving crop storage conditions and reducing post-harvest losses.

Related Important Terms

Halogen Moisture Analyzer

Halogen Moisture Analyzers provide rapid and accurate moisture content measurement by using infrared halogen heating combined with precision sensors, significantly reducing analysis time compared to the traditional Oven Drying Method, which requires prolonged heating to reach constant weight. This technology ensures enhanced efficiency in post-harvest quality control by minimizing sample degradation and improving repeatability for a wide range of agricultural products.

Loss-on-Drying (LOD) Technique

The Loss-on-Drying (LOD) technique utilizes both Moisture Analyzers and Oven Drying Method to determine moisture content, where Moisture Analyzers provide rapid, precise results by measuring weight loss during controlled heating, while Oven Drying offers a traditional, standardized approach through prolonged exposure to elevated temperatures. Moisture Analyzers optimize efficiency in post-harvest quality control by significantly reducing analysis time compared to the Oven Drying Method, which, despite its accuracy, requires several hours to yield results.

Gravimetric Oven Drying

Gravimetric oven drying remains the gold standard for moisture content measurement in post-harvest technology due to its accuracy and reliability, where samples are weighed before and after drying at a controlled temperature to determine moisture loss. In contrast, moisture analyzers offer faster results through infrared or halogen heating but may lack the precision required for regulatory compliance and quality control in agricultural products.

Rapid Moisture Detection

Moisture analyzers provide rapid moisture detection by using infrared heating and precise weight measurements, delivering results within minutes compared to the several hours required by the traditional oven drying method. This speed enhances post-harvest technology by enabling timely decisions in crop processing and storage, reducing losses due to over-drying or microbial growth.

Infrared Moisture Measurement

Infrared moisture analyzers provide rapid and accurate moisture content measurement by detecting water molecules' absorption of infrared radiation, enabling precise monitoring during post-harvest processing. Compared to the traditional oven drying method, infrared technology significantly reduces analysis time while maintaining reliability, enhancing efficiency in grain and produce moisture management.

Thermogravimetric Analysis (TGA)

Thermogravimetric Analysis (TGA) offers precise moisture content measurement by continuously monitoring weight changes under controlled temperature conditions, providing real-time data for post-harvest quality control. Compared to traditional oven drying methods, TGA delivers faster results with higher sensitivity, reducing errors caused by volatile compound loss during prolonged heating.

Adaptive Heating Profiles

Moisture analyzers with adaptive heating profiles offer precise control over drying temperatures, minimizing sample degradation and reducing measurement time compared to the conventional oven drying method. This technology adjusts heating rates based on real-time moisture levels, enhancing accuracy and efficiency in post-harvest moisture content determination.

Smart Moisture Sensor Integration

Smart moisture sensor integration offers precise, real-time moisture content measurement in post-harvest technology, enhancing efficiency and accuracy compared to the traditional oven drying method, which is time-consuming and labor-intensive. Advanced moisture analyzers with embedded smart sensors provide rapid, non-destructive testing, enabling better quality control and reducing post-harvest losses.

Non-Destructive Moisture Testing

Moisture analyzers offer rapid, accurate, and non-destructive moisture content measurement by using near-infrared or microwave technology, preserving the sample's integrity for further analysis. Unlike traditional oven drying methods, which require extended drying times and cause sample destruction, moisture analyzers enable continuous monitoring and real-time adjustments in post-harvest processes to optimize product quality and storage longevity.

Sample Homogenization Precision

Moisture analyzers provide higher precision in sample homogenization by rapidly heating and evenly distributing temperature, ensuring uniform moisture content measurement. Oven drying methods can result in uneven drying due to prolonged heat exposure and sample heterogeneity, leading to less consistent moisture content data in post-harvest quality assessments.

Moisture Analyzer vs Oven Drying Method for moisture content measurement Infographic

agridif.com

agridif.com