Cold chain logistics ensures the preservation of fresh produce quality by maintaining optimal low temperatures, significantly reducing spoilage and extending shelf life during transportation and storage. Ambient storage, while more cost-effective, often leads to faster deterioration and higher waste rates due to exposure to fluctuating temperatures and humidity. Implementing cold chain systems in post-harvest technology is essential for maintaining freshness, nutritional value, and marketability of perishable fruits and vegetables.

Table of Comparison

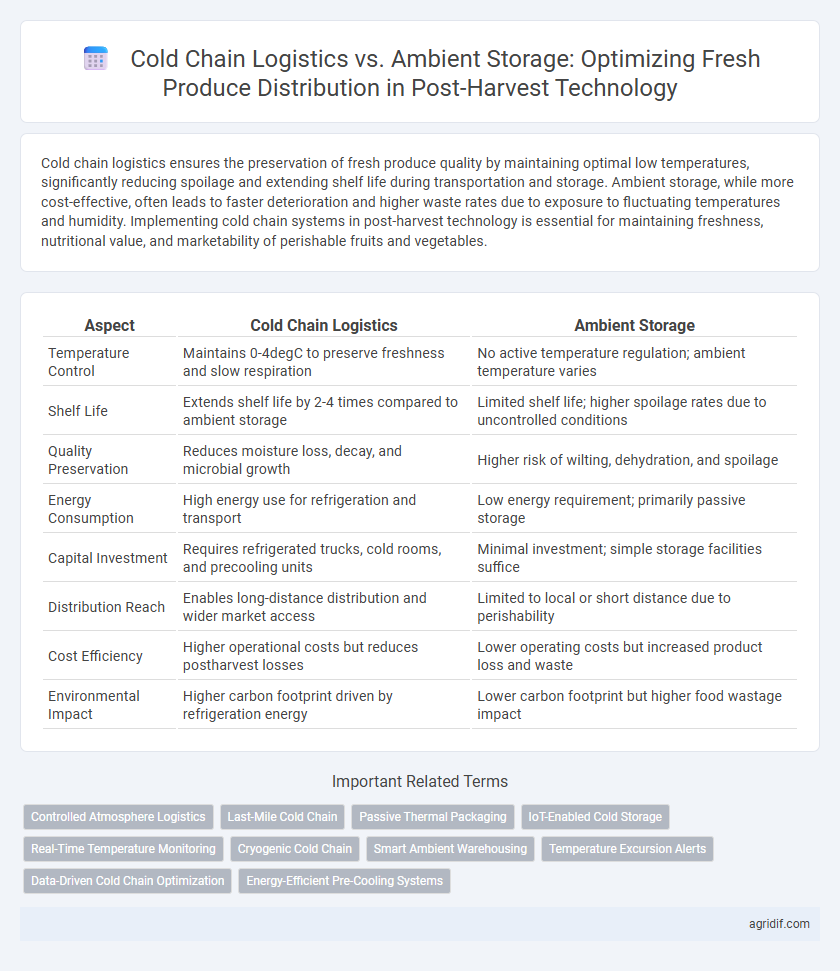

| Aspect | Cold Chain Logistics | Ambient Storage |

|---|---|---|

| Temperature Control | Maintains 0-4degC to preserve freshness and slow respiration | No active temperature regulation; ambient temperature varies |

| Shelf Life | Extends shelf life by 2-4 times compared to ambient storage | Limited shelf life; higher spoilage rates due to uncontrolled conditions |

| Quality Preservation | Reduces moisture loss, decay, and microbial growth | Higher risk of wilting, dehydration, and spoilage |

| Energy Consumption | High energy use for refrigeration and transport | Low energy requirement; primarily passive storage |

| Capital Investment | Requires refrigerated trucks, cold rooms, and precooling units | Minimal investment; simple storage facilities suffice |

| Distribution Reach | Enables long-distance distribution and wider market access | Limited to local or short distance due to perishability |

| Cost Efficiency | Higher operational costs but reduces postharvest losses | Lower operating costs but increased product loss and waste |

| Environmental Impact | Higher carbon footprint driven by refrigeration energy | Lower carbon footprint but higher food wastage impact |

Introduction: The Importance of Post-Harvest Storage Methods

Effective post-harvest storage methods are crucial for maintaining the quality and extending the shelf life of fresh produce during distribution. Cold chain logistics employs temperature-controlled environments to significantly reduce spoilage and microbial growth, preserving nutritional value and freshness. In contrast, ambient storage, though more cost-effective, often leads to faster deterioration and increased post-harvest losses, highlighting the importance of optimized storage solutions in the supply chain.

Understanding Cold Chain Logistics in Fresh Produce Distribution

Cold chain logistics in fresh produce distribution ensures temperature-controlled environments from harvest to retail, preserving quality and extending shelf life by preventing microbial growth and enzymatic decay. It requires refrigerated transportation, cold storage facilities, and real-time temperature monitoring systems to maintain produce freshness and reduce post-harvest losses. Implementing an effective cold chain reduces spoilage rates by up to 30%, crucial for perishable items like berries, leafy greens, and tomatoes.

Overview of Ambient Storage in Agriculture

Ambient storage in agriculture involves maintaining fresh produce at natural, uncontrolled temperatures to extend shelf life without refrigeration. This method relies on proper ventilation, humidity control, and timely handling to reduce spoilage and microbial growth. While more cost-effective than cold chain logistics, ambient storage is best suited for crops with inherent tolerance to temperature fluctuations and shorter distribution distances.

Temperature Management: Cold Chain vs Ambient Conditions

Cold chain logistics ensures precise temperature control between 0degC and 4degC, minimizing enzymatic activity and microbial growth to extend the shelf life of fresh produce. In contrast, ambient storage exposes produce to fluctuating temperatures, accelerating ripening and deterioration while increasing food waste. Effective temperature management through cold chain systems enhances quality preservation, reduces post-harvest losses, and supports global distribution of perishable goods.

Impact on Freshness and Shelf Life of Produce

Cold chain logistics significantly extend the shelf life of fresh produce by maintaining optimal low temperatures that slow down respiration and microbial growth, preserving freshness and nutritional quality. In contrast, ambient storage exposes produce to fluctuating temperatures and humidity levels, accelerating spoilage and reducing marketability. Implementing cold chain systems reduces post-harvest losses and ensures consistent quality during distribution, crucial for high-value fruits and vegetables with short shelf lives.

Cost Considerations: Investment and Operational Expenses

Cold chain logistics for fresh produce distribution involve higher initial investment in refrigeration equipment, insulated transport vehicles, and temperature-controlled storage facilities compared to ambient storage systems. Operational expenses in cold chain logistics include energy consumption, maintenance of cooling systems, and specialized handling, which substantially increase the overall cost. Ambient storage offers lower capital and operational costs but often leads to higher product loss and reduced shelf life, impacting the cost-efficiency in long-term fresh produce distribution.

Infrastructure and Technology Requirements

Cold chain logistics for fresh produce distribution demands advanced refrigeration systems, insulated transport vehicles, and temperature monitoring technologies to maintain product quality and extend shelf life. Ambient storage relies primarily on controlled environmental conditions such as humidity and ventilation but lacks active cooling, making it less suitable for highly perishable items. Investments in infrastructure like refrigerated warehouses, GPS-enabled cold trucks, and IoT sensors differentiate cold chain solutions from simpler ambient storage setups, impacting overall post-harvest losses and market reach.

Food Safety and Quality Preservation

Cold chain logistics maintains fresh produce at consistently low temperatures, effectively slowing microbial growth and enzymatic activity, which preserves food safety and extends shelf life compared to ambient storage. Ambient storage exposes produce to fluctuating temperatures that increase the risk of spoilage and contamination, compromising quality and safety. Implementing cold chain systems reduces post-harvest losses and maintains nutritional value, ensuring higher quality produce throughout the distribution process.

Environmental and Energy Implications

Cold chain logistics for fresh produce distribution significantly reduces spoilage by maintaining optimal low temperatures but demands substantial energy consumption, often relying on fossil fuels that increase carbon footprint. Ambient storage involves lower energy use and greenhouse gas emissions but risks higher product loss due to temperature fluctuations and accelerated spoilage. Evaluating environmental impact requires balancing energy intensity of refrigeration systems against losses in product quality and quantity during ambient storage.

Choosing the Right Storage Method for Different Crops

Cold chain logistics ensures optimal temperature control, significantly extending the shelf life of temperature-sensitive crops like berries, leafy greens, and tropical fruits by minimizing spoilage and maintaining freshness. Ambient storage is suitable for more resilient produce such as potatoes, onions, and garlic, which tolerate fluctuating temperatures without rapid quality degradation. Selecting the appropriate storage method depends on crop-specific factors including ethylene sensitivity, respiration rate, and moisture requirements to preserve post-harvest quality and reduce losses.

Related Important Terms

Controlled Atmosphere Logistics

Controlled Atmosphere Logistics within Cold Chain Logistics significantly extends the shelf life of fresh produce by precisely regulating oxygen, carbon dioxide, and humidity levels, reducing respiration rates and delaying ripening. Unlike ambient storage, this method minimizes quality degradation and spoilage during distribution, ensuring fresher produce reaches consumers with optimal nutritional and sensory attributes.

Last-Mile Cold Chain

Last-mile cold chain logistics ensure the preservation of freshness and nutritional quality in perishable produce by maintaining optimal temperature control during final delivery stages, reducing spoilage and extending shelf life significantly compared to ambient storage. Efficient use of refrigerated transport, temperature-monitored packaging, and real-time tracking systems in last-mile cold chain solutions minimizes microbial growth and oxidative damage, enhancing consumer satisfaction and reducing food waste in fresh produce distribution.

Passive Thermal Packaging

Passive thermal packaging in cold chain logistics effectively maintains optimal temperature for fresh produce during transportation, significantly reducing spoilage compared to ambient storage. This method leverages insulated materials and phase-change materials to preserve freshness, extend shelf life, and minimize reliance on active refrigeration systems.

IoT-Enabled Cold Storage

IoT-enabled cold storage revolutionizes fresh produce distribution by maintaining precise temperature and humidity control throughout the supply chain, significantly reducing spoilage compared to ambient storage. Real-time sensor data and predictive analytics enhance cold chain logistics, ensuring optimal freshness and extended shelf life in fruit and vegetable shipments.

Real-Time Temperature Monitoring

Real-time temperature monitoring enhances cold chain logistics by ensuring consistent optimal temperatures during fresh produce distribution, reducing spoilage and maintaining quality. Ambient storage lacks this precise control, increasing risks of temperature fluctuations that accelerate degradation and decrease shelf life.

Cryogenic Cold Chain

Cryogenic cold chain logistics utilizes ultra-low temperature storage with liquid nitrogen or carbon dioxide to preserve the freshness and nutritional quality of perishable produce, significantly reducing respiration rates and microbial growth compared to ambient storage. This advanced post-harvest technology ensures prolonged shelf life and minimizes spoilage during distribution, outperforming conventional ambient storage methods by maintaining optimal freshness throughout the supply chain.

Smart Ambient Warehousing

Smart ambient warehousing enhances the distribution of fresh produce by optimizing temperature, humidity, and airflow control without the energy costs associated with cold chain logistics. This technology leverages IoT sensors and AI-driven data analytics to maintain produce quality, reduce spoilage, and extend shelf life while supporting sustainable supply chain practices.

Temperature Excursion Alerts

Cold chain logistics for fresh produce distribution employs continuous temperature monitoring systems that trigger instant temperature excursion alerts to prevent spoilage and maintain quality. Ambient storage lacks such precise temperature control, increasing the risk of unnoticed thermal deviations that compromise shelf life and safety.

Data-Driven Cold Chain Optimization

Data-driven cold chain optimization enhances fresh produce distribution by maintaining precise temperature control, reducing spoilage rates by up to 30% compared to ambient storage. Real-time sensor data and predictive analytics enable dynamic adjustments in cold chain logistics, ensuring optimal freshness and extending shelf life throughout transportation and retail stages.

Energy-Efficient Pre-Cooling Systems

Energy-efficient pre-cooling systems in cold chain logistics significantly reduce temperature fluctuations and extend the shelf life of fresh produce by rapidly lowering produce temperature after harvest, minimizing respiration rates and moisture loss. In contrast, ambient storage lacks active cooling, resulting in higher energy consumption during transportation and increased spoilage rates, highlighting the superiority of cold chain systems for preserving produce quality and reducing overall energy demand.

Cold Chain Logistics vs Ambient Storage for fresh produce distribution Infographic

agridif.com

agridif.com