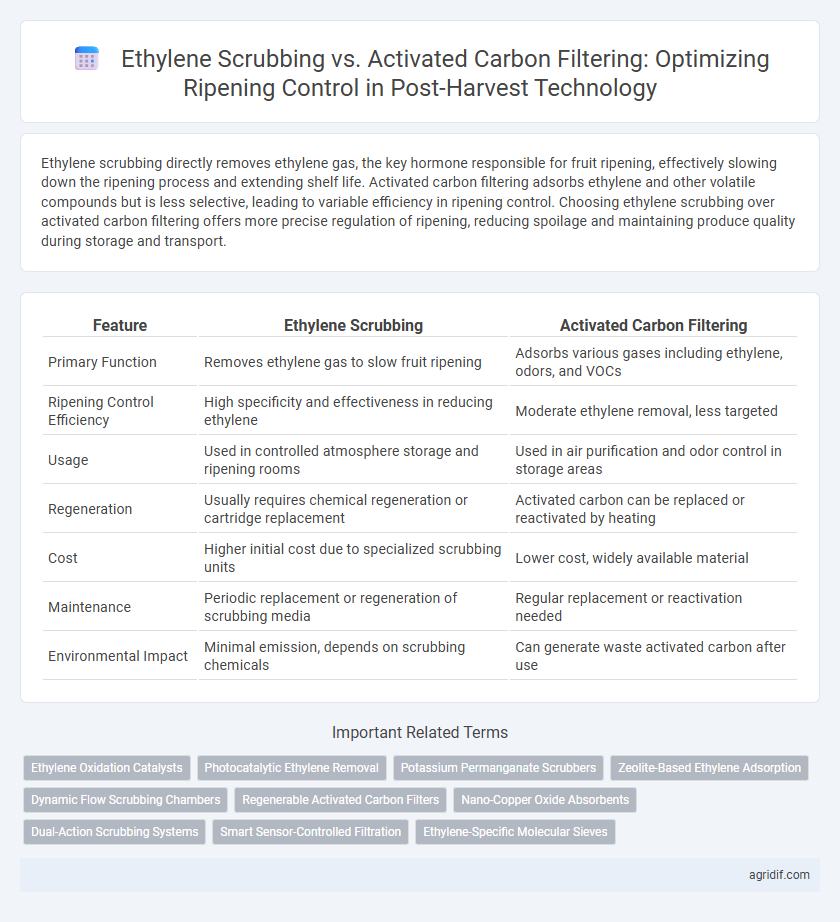

Ethylene scrubbing directly removes ethylene gas, the key hormone responsible for fruit ripening, effectively slowing down the ripening process and extending shelf life. Activated carbon filtering adsorbs ethylene and other volatile compounds but is less selective, leading to variable efficiency in ripening control. Choosing ethylene scrubbing over activated carbon filtering offers more precise regulation of ripening, reducing spoilage and maintaining produce quality during storage and transport.

Table of Comparison

| Feature | Ethylene Scrubbing | Activated Carbon Filtering |

|---|---|---|

| Primary Function | Removes ethylene gas to slow fruit ripening | Adsorbs various gases including ethylene, odors, and VOCs |

| Ripening Control Efficiency | High specificity and effectiveness in reducing ethylene | Moderate ethylene removal, less targeted |

| Usage | Used in controlled atmosphere storage and ripening rooms | Used in air purification and odor control in storage areas |

| Regeneration | Usually requires chemical regeneration or cartridge replacement | Activated carbon can be replaced or reactivated by heating |

| Cost | Higher initial cost due to specialized scrubbing units | Lower cost, widely available material |

| Maintenance | Periodic replacement or regeneration of scrubbing media | Regular replacement or reactivation needed |

| Environmental Impact | Minimal emission, depends on scrubbing chemicals | Can generate waste activated carbon after use |

Overview of Ethylene in Post-Harvest Ripening

Ethylene is a key plant hormone involved in the ripening process, accelerating fruit softening, color change, and sugar accumulation. Controlling ethylene concentration through scrubbing methods directly impacts reducing over-ripening and extending shelf life. Ethylene scrubbing, using potassium permanganate or catalytic converters, chemically removes ethylene gas, while activated carbon filtering adsorbs ethylene molecules, each varying in efficiency and regeneration capacity for post-harvest storage systems.

Importance of Ripening Control in Fresh Produce Storage

Effective ripening control in fresh produce storage is critical to maintain quality, extend shelf life, and reduce post-harvest losses. Ethylene scrubbing actively removes ethylene gas, which accelerates ripening, allowing precise regulation of fruit maturation. Activated carbon filtering adsorbs ethylene molecules but with lower specificity, making ethylene scrubbing a more targeted and efficient method for controlling ripening in storage environments.

Ethylene Scrubbing: Principles and Methods

Ethylene scrubbing in post-harvest technology involves the removal of ethylene gas, a natural plant hormone responsible for fruit ripening, through chemical or catalytic processes to delay senescence and extend shelf life. Common methods include using potassium permanganate-coated filters, catalytic oxidation with noble metal catalysts, and molecular sieve adsorption, each targeting the breakdown or absorption of ethylene molecules. These techniques enable precise ripening control by maintaining optimal atmospheric conditions in storage and transportation environments.

Activated Carbon Filtering: Mechanisms and Applications

Activated carbon filtering in post-harvest technology functions by adsorbing ethylene gas, a natural plant hormone responsible for fruit ripening, thus effectively controlling the ripening process. The porous structure and large surface area of activated carbon enable it to trap ethylene molecules, preventing premature ripening and extending shelf life. This method is widely applied in storage facilities and transportation to maintain fruit quality and reduce post-harvest losses.

Comparative Efficiency: Ethylene Scrubbing vs Activated Carbon Filtering

Ethylene scrubbing demonstrates higher efficiency in ripening control by actively removing ethylene gas, which directly delays fruit senescence and extends shelf life, while activated carbon filtering primarily adsorbs ethylene and other volatiles but with limited specificity and capacity. Studies show ethylene scrubbers reduce ethylene concentration to near-zero levels faster than activated carbon filters, enhancing post-harvest storage quality and marketability. The targeted mechanism of ethylene scrubbing results in improved uniformity of ripening and reduces spoilage compared to the broader but less effective adsorption properties of activated carbon.

Impact on Shelf Life and Fruit Quality

Ethylene scrubbing effectively reduces ethylene concentrations, slowing the ripening process and extending shelf life for fruits like bananas and tomatoes, while maintaining firmness and flavor quality. Activated carbon filtering adsorbs ethylene along with other volatile compounds but may not provide as targeted ripening control, potentially leading to inconsistent fruit quality. Studies show ethylene scrubbing offers superior control in commercial storage, preserving sensory attributes and reducing spoilage compared to activated carbon filtering.

Cost Analysis and Scalability in Commercial Operations

Ethylene scrubbing systems typically require higher initial capital investment but offer precise control over ripening processes, making them cost-effective in large-scale commercial operations due to reduced product loss and enhanced shelf life. Activated carbon filtering presents a lower upfront cost and simpler scalability but may incur higher operational expenses over time due to frequent media replacement and less selective ethylene removal. For extensive post-harvest facilities, ethylene scrubbing provides superior long-term value despite greater complexity, while activated carbon remains suitable for smaller or budget-constrained operations.

Environmental Considerations and Sustainability

Ethylene scrubbing effectively reduces ethylene concentrations in storage environments, enhancing fruit shelf life with minimal chemical residues, supporting eco-friendly post-harvest management. Activated carbon filtering absorbs ethylene gas through porous materials but requires frequent replacement, generating waste and higher environmental impact. Ethylene scrubbing offers a more sustainable approach due to lower waste production and greater efficiency in maintaining optimal ripening conditions.

Recent Advances and Technological Innovations

Recent advances in ethylene scrubbing have enhanced selective removal of ethylene gas using potassium permanganate and photocatalytic oxidation, improving ripening control in storage facilities. Technological innovations in activated carbon filtering include the development of modified activated carbons with increased adsorption capacity and regeneration ability for sustained ethylene capture. Integration of sensor-based monitoring systems with both technologies enables precise environmental control, optimizing fruit shelf life and reducing post-harvest losses.

Future Trends in Controlled Ripening Technologies

Ethylene scrubbing and activated carbon filtering represent critical advancements in post-harvest fruit ripening control, with ongoing research focusing on enhancing selectivity and efficiency for ethylene gas removal. Future trends emphasize integration of smart sensors and AI-driven automation to optimize ripening parameters dynamically, reducing post-harvest losses and extending shelf life. Innovations in nanomaterials and bio-based adsorbents aim to improve the environmental sustainability and cost-effectiveness of ethylene management technologies.

Related Important Terms

Ethylene Oxidation Catalysts

Ethylene oxidation catalysts offer a precise method for accelerating or inhibiting fruit ripening by chemically converting ethylene into harmless byproducts, enhancing control over post-harvest shelf life. This technology surpasses activated carbon filtering by actively degrading ethylene molecules rather than merely adsorbing them, resulting in more efficient and sustained ripening management.

Photocatalytic Ethylene Removal

Photocatalytic ethylene removal utilizes titanium dioxide catalysts under UV light to effectively break down ethylene molecules, significantly enhancing ripening control compared to traditional activated carbon filtering. This advanced ethylene scrubbing method not only reduces ethylene concentration more efficiently but also prevents fruit overripening and extends shelf life in post-harvest storage environments.

Potassium Permanganate Scrubbers

Potassium permanganate scrubbers are highly effective in ethylene scrubbing by oxidizing ethylene gas, thus delaying fruit ripening and extending shelf life during post-harvest storage. Unlike activated carbon filters that primarily adsorb ethylene, potassium permanganate chemically removes it, offering more consistent control over ripening in fruits like bananas and tomatoes.

Zeolite-Based Ethylene Adsorption

Zeolite-based ethylene adsorption offers superior selectivity and capacity for ethylene scrubbing compared to activated carbon filtering, enhancing precision in ripening control during post-harvest storage. Its molecular sieve properties enable efficient removal of ethylene gas, reducing spoilage and extending the shelf life of fruits and vegetables.

Dynamic Flow Scrubbing Chambers

Dynamic flow scrubbing chambers in ethylene scrubbing provide precise control over gas concentrations, enhancing the regulation of fruit ripening by continuously removing ethylene from storage environments. Compared to activated carbon filtering, these chambers offer higher efficiency and faster response times in maintaining optimal atmospheric conditions for extending post-harvest shelf life.

Regenerable Activated Carbon Filters

Regenerable activated carbon filters offer an efficient, sustainable method for ethylene scrubbing in post-harvest technology by adsorbing ethylene gas released during fruit ripening and enabling repeated use through thermal regeneration, thereby reducing operational costs and environmental impact. Compared to single-use activated carbon and less selective ethylene scrubbers, regenerable filters provide consistent ripening control and prolonged service life, enhancing fruit shelf-life and quality in storage and transport environments.

Nano-Copper Oxide Absorbents

Nano-copper oxide absorbents in ethylene scrubbing offer higher reactivity and longer lifespan compared to activated carbon filtering, enabling more precise ripening control in post-harvest technology. Their enhanced catalytic properties rapidly degrade ethylene gas, reducing spoilage and extending shelf life of perishable produce.

Dual-Action Scrubbing Systems

Dual-action ethylene scrubbing systems combine catalytic oxidation and activated carbon filtering to enhance ripening control by effectively reducing ethylene concentration and adsorbing volatile organic compounds in post-harvest environments. These integrated systems improve fruit shelf life and quality by maintaining optimal atmospheric conditions, outperforming single-method scrubbing techniques.

Smart Sensor-Controlled Filtration

Smart sensor-controlled ethylene scrubbing systems precisely monitor and regulate ethylene gas levels, accelerating or delaying fruit ripening with higher accuracy compared to activated carbon filtering, which passively adsorbs ethylene but lacks real-time gas concentration feedback. Integration of advanced sensors enables dynamic adjustment of filtration intensity, optimizing post-harvest quality and reducing waste by maintaining ideal atmospheres in storage environments.

Ethylene-Specific Molecular Sieves

Ethylene-specific molecular sieves offer targeted removal of ethylene gas, effectively slowing fruit ripening and extending shelf life by adsorbing only ethylene molecules without affecting humidity or other gases. Compared to activated carbon filtering, which nonspecifically adsorbs a broader range of organic compounds, molecular sieves provide higher selectivity and regeneration efficiency, making them optimal for precise ripening control in post-harvest technology.

Ethylene Scrubbing vs Activated Carbon Filtering for ripening control Infographic

agridif.com

agridif.com