Osmotic dehydration effectively reduces moisture content in sugar-rich products by immersing them in hypertonic solutions, preserving flavor and texture while minimizing nutrient loss. Vacuum drying, on the other hand, removes water at low pressures and temperatures, retaining color and bioactive compounds but potentially causing shrinkage and texture changes. Selecting between these methods depends on product characteristics and desired quality attributes, with osmotic dehydration often preferred for delicate, sugar-rich fruits and vacuum drying suited for enhancing shelf life with minimal thermal damage.

Table of Comparison

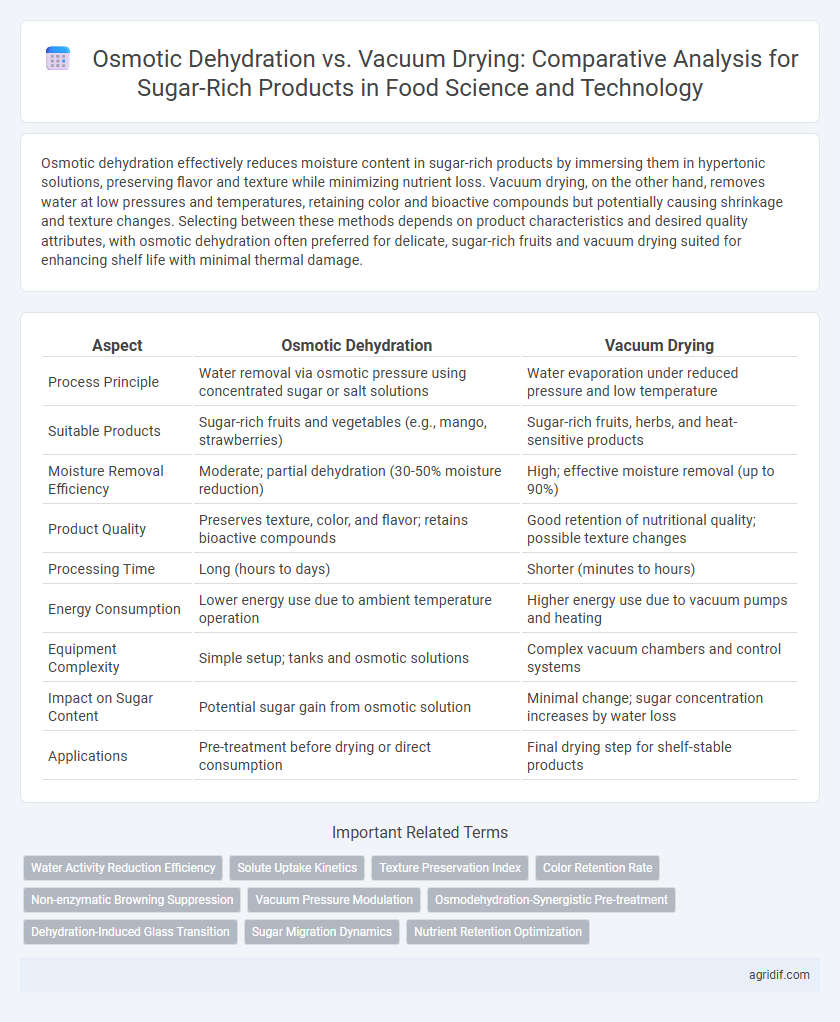

| Aspect | Osmotic Dehydration | Vacuum Drying |

|---|---|---|

| Process Principle | Water removal via osmotic pressure using concentrated sugar or salt solutions | Water evaporation under reduced pressure and low temperature |

| Suitable Products | Sugar-rich fruits and vegetables (e.g., mango, strawberries) | Sugar-rich fruits, herbs, and heat-sensitive products |

| Moisture Removal Efficiency | Moderate; partial dehydration (30-50% moisture reduction) | High; effective moisture removal (up to 90%) |

| Product Quality | Preserves texture, color, and flavor; retains bioactive compounds | Good retention of nutritional quality; possible texture changes |

| Processing Time | Long (hours to days) | Shorter (minutes to hours) |

| Energy Consumption | Lower energy use due to ambient temperature operation | Higher energy use due to vacuum pumps and heating |

| Equipment Complexity | Simple setup; tanks and osmotic solutions | Complex vacuum chambers and control systems |

| Impact on Sugar Content | Potential sugar gain from osmotic solution | Minimal change; sugar concentration increases by water loss |

| Applications | Pre-treatment before drying or direct consumption | Final drying step for shelf-stable products |

Introduction to Sugar-Rich Product Preservation

Sugar-rich product preservation relies heavily on osmotic dehydration and vacuum drying due to their efficiency in moisture removal and quality retention. Osmotic dehydration utilizes concentrated sugar or salt solutions to induce water loss via osmosis, minimizing thermal damage and preserving texture and flavor in fruits like mangoes and cherries. Vacuum drying complements this by lowering boiling points to dry products gently, enhancing shelf life while maintaining sensory and nutritional qualities crucial for high-sugar content foods.

Principles of Osmotic Dehydration

Osmotic dehydration leverages osmotic pressure gradients to remove water from sugar-rich products by immersing them in hypertonic sugar or salt solutions, which draws out moisture while minimizing thermal damage. This principle preserves product texture, flavor, and nutritional quality better than vacuum drying, which relies on reduced pressure and temperature to evaporate water. Controlling solute concentration, temperature, and immersion time is critical for optimizing water removal efficiency and sugar uptake during osmotic dehydration.

Principles of Vacuum Drying

Vacuum drying operates by reducing atmospheric pressure to lower the boiling point of water, enabling moisture removal from sugar-rich products at lower temperatures, which preserves their nutritional and sensory qualities. The reduced pressure accelerates water vaporization while minimizing thermal degradation and Maillard browning reactions typical in high-sugar matrices. This method is advantageous for maintaining product integrity and enhancing shelf life compared to conventional osmotic dehydration techniques.

Comparative Analysis of Moisture Removal Efficiency

Osmotic dehydration exploits osmotic pressure differences to remove moisture from sugar-rich products, achieving water loss of up to 40-60% while retaining structural integrity and sugars. Vacuum drying enhances moisture removal efficiency by reducing boiling point under low pressure, enabling rapid dehydration that can reach moisture content below 10% but may cause texture alteration. Comparative analysis reveals osmotic dehydration is energy-efficient and preserves product quality, whereas vacuum drying provides faster drying rates and lower residual moisture, crucial for shelf stability.

Impact on Nutritional Quality

Osmotic dehydration preserves nutritional quality in sugar-rich products by reducing water content through solute diffusion, minimizing thermal degradation of vitamins and antioxidants. Vacuum drying operates under low pressure and temperature, which effectively retains heat-sensitive nutrients but may cause more structural damage than osmotic dehydration. Both methods impact nutrient retention differently, with osmotic dehydration offering superior preservation of bioactive compounds and vacuum drying ensuring faster drying times with moderate nutrient loss.

Effect on Sensory Attributes: Color, Taste, and Texture

Osmotic dehydration preserves the natural color and flavor of sugar-rich products by reducing water content through solute diffusion, resulting in a sweeter taste and firmer texture. Vacuum drying minimizes thermal degradation and oxidation, maintaining vibrant color and enhanced aroma while creating a porous, crisp texture. Comparing both methods, osmotic dehydration often yields a softer final product with intensified sweetness, whereas vacuum drying produces a drier texture with concentrated flavors and better color retention.

Energy Consumption and Cost Considerations

Osmotic dehydration significantly reduces energy consumption compared to vacuum drying by utilizing lower temperatures and leveraging osmotic pressure to remove water from sugar-rich products, resulting in energy savings of up to 40%. The lower operational temperatures also minimize thermal damage, preserving product quality while reducing costs associated with heat energy and equipment maintenance. Conversely, vacuum drying requires higher energy inputs due to the need for creating and maintaining low-pressure environments, leading to increased operational expenses despite faster drying rates.

Suitability for Different Sugar-Rich Foods

Osmotic dehydration is highly suitable for sugar-rich fruits like mangoes and pineapples, as it effectively reduces water content while preserving texture and enhancing sweetness through solute uptake. Vacuum drying excels in processing sugar-rich products such as berries and grapes by enabling low-temperature moisture removal, which minimizes thermal degradation and maintains flavor integrity. Both methods offer distinct advantages depending on the specific sugar composition and structural characteristics of the food matrix.

Quality Retention during Storage

Osmotic dehydration preserves the sensory and nutritional quality of sugar-rich products better than vacuum drying by minimizing thermal degradation and moisture loss during storage. The elevated sugar concentration from osmotic processes creates a natural barrier against microbial growth, enhancing shelf life and maintaining firmness and color stability. In contrast, vacuum drying can cause product shrinkage and nutrient loss, leading to inferior quality retention over extended storage periods.

Future Trends in Dehydration Technologies for Sugar-Rich Products

Emerging dehydration technologies for sugar-rich products emphasize energy efficiency and preservation of nutritional quality, with osmotic dehydration gaining popularity due to its ability to reduce water activity while retaining flavor and bioactive compounds. Vacuum drying is evolving through integration with combined techniques like microwave vacuum drying, enhancing drying rates and minimizing thermal damage to sensitive sugars. Future research focuses on optimizing process parameters and developing hybrid methods that balance osmotic dehydration's gentle moisture removal with vacuum drying's speed and uniformity to achieve superior product stability and sensory attributes.

Related Important Terms

Water Activity Reduction Efficiency

Osmotic dehydration achieves superior water activity reduction in sugar-rich products by leveraging high solute concentrations to draw out water, effectively inhibiting microbial growth and enzymatic browning. Vacuum drying rapidly removes residual moisture under low pressure, enhancing water activity reduction efficiency while preserving product quality and extending shelf life.

Solute Uptake Kinetics

Osmotic dehydration of sugar-rich products involves rapid solute uptake kinetics driven by high osmotic pressure gradients, enhancing water removal while preserving product quality. In contrast, vacuum drying exhibits slower solute diffusion due to reduced pressure and temperature conditions, resulting in diminished solute uptake but improved retention of heat-sensitive nutrients.

Texture Preservation Index

Osmotic dehydration exhibits a higher Texture Preservation Index for sugar-rich products due to its gentle water removal process that minimizes cellular structure damage compared to vacuum drying. Vacuum drying often leads to tougher textures as rapid moisture extraction causes cell collapse and shrinkage, reducing overall product quality.

Color Retention Rate

Osmotic dehydration preserves color better in sugar-rich products by reducing enzymatic browning and pigment degradation through controlled water loss and sugar infusion. Vacuum drying, while efficient for moisture removal, often leads to greater color deterioration due to higher temperatures accelerating Maillard reactions.

Non-enzymatic Browning Suppression

Osmotic dehydration effectively suppresses non-enzymatic browning in sugar-rich products by reducing water activity and limiting Maillard reaction substrates, whereas vacuum drying can accelerate browning due to higher temperature exposure despite reduced oxygen levels. Optimizing osmotic dehydration parameters such as solute concentration and immersion time enhances color retention and flavor stability by minimizing caramelization and Maillard reaction pathways.

Vacuum Pressure Modulation

Vacuum pressure modulation in vacuum drying significantly enhances the retention of sensory and nutritional qualities in sugar-rich products by reducing oxidation and thermal degradation. Compared to osmotic dehydration, this technique offers greater control over moisture removal rates, leading to improved texture and color stability in food science and technology applications.

Osmodehydration-Synergistic Pre-treatment

Osmodehydration synergistic pre-treatment enhances moisture removal in sugar-rich products by leveraging osmotic pressure gradients, improving texture and flavor retention compared to vacuum drying alone. This combined approach reduces drying time and energy consumption while minimizing thermal degradation of sensitive compounds.

Dehydration-Induced Glass Transition

Osmotic dehydration preserves the quality of sugar-rich products by gently reducing water content through solute diffusion, minimizing structural collapse related to dehydration-induced glass transition. Vacuum drying accelerates moisture removal under reduced pressure, inducing faster glass transition but potentially causing textural changes and nutrient loss due to rapid dehydration.

Sugar Migration Dynamics

Osmotic dehydration exploits concentration gradients to drive water out and sugar inward, preserving product texture by controlling sugar migration dynamics. Vacuum drying accelerates moisture removal under reduced pressure, minimizing thermal degradation but can cause uneven sugar distribution due to rapid moisture loss.

Nutrient Retention Optimization

Osmotic dehydration preserves vitamins and antioxidants in sugar-rich products by gently removing water through osmotic pressure, minimizing thermal degradation compared to vacuum drying. Vacuum drying achieves faster moisture removal but may cause greater loss of heat-sensitive nutrients due to higher temperature exposure.

Osmotic dehydration vs vacuum drying for sugar-rich products Infographic

agridif.com

agridif.com