Clamshell packaging offers superior protection and ventilation for berries during shipment, reducing bruising and spoilage compared to polybag packaging. The rigid structure of clamshells minimizes fruit movement, while built-in vents maintain airflow to preserve freshness. In contrast, polybags trap moisture and often cause condensation, increasing the risk of mold and decay in post-harvest berry handling.

Table of Comparison

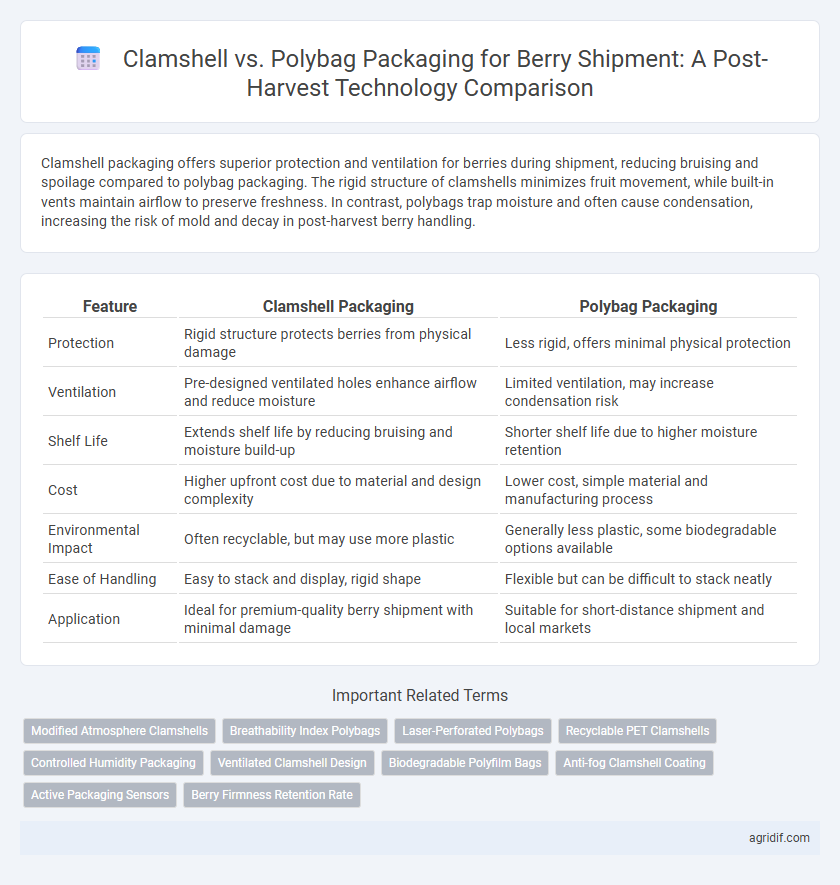

| Feature | Clamshell Packaging | Polybag Packaging |

|---|---|---|

| Protection | Rigid structure protects berries from physical damage | Less rigid, offers minimal physical protection |

| Ventilation | Pre-designed ventilated holes enhance airflow and reduce moisture | Limited ventilation, may increase condensation risk |

| Shelf Life | Extends shelf life by reducing bruising and moisture build-up | Shorter shelf life due to higher moisture retention |

| Cost | Higher upfront cost due to material and design complexity | Lower cost, simple material and manufacturing process |

| Environmental Impact | Often recyclable, but may use more plastic | Generally less plastic, some biodegradable options available |

| Ease of Handling | Easy to stack and display, rigid shape | Flexible but can be difficult to stack neatly |

| Application | Ideal for premium-quality berry shipment with minimal damage | Suitable for short-distance shipment and local markets |

Introduction to Berry Packaging Solutions

Clamshell packaging offers superior protection and ventilation for berries during shipment, reducing spoilage compared to traditional polybag packaging. Engineered with rigid plastic, clamshells minimize physical damage and allow air circulation, enhancing shelf life and maintaining berry quality. Polybags, while cost-effective and lightweight, often trap moisture and create anaerobic conditions that accelerate decay in berries.

Overview of Clamshell Packaging Design

Clamshell packaging for berry shipment features a rigid, transparent plastic container with hinged lids that securely enclose the fruit, providing optimal protection against mechanical damage and contamination. Its ventilated design promotes air circulation, reducing moisture buildup and extending berry shelf life during transit. This packaging enhances product visibility for consumers while maintaining the integrity and freshness of delicate berries throughout the supply chain.

Polybag Packaging: Features and Applications

Polybag packaging for berry shipment offers flexibility, lightweight design, and moisture protection, enhancing shelf life and reducing spoilage during transport. Its breathable material allows for adequate airflow, minimizing condensation and preserving freshness throughout distribution. Commonly used in large-volume shipping, polybags provide cost-efficiency and ease of handling, making them suitable for extended supply chains and retail display.

Protection and Preservation of Berries in Transit

Clamshell packaging provides superior protection for berries during transit by offering rigid support that minimizes crushing and bruising compared to polybag packaging. The ventilated design of clamshells enhances airflow, reducing moisture buildup and delaying spoilage, whereas polybags often trap humidity, accelerating decay. Clamshells also help maintain berry firmness and freshness, significantly extending shelf life through better preservation conditions.

Impact on Berry Shelf Life: Clamshells vs Polybags

Clamshell packaging significantly extends the shelf life of berries by providing rigid protection and better ventilation, reducing moisture buildup and mold growth compared to polybag packaging. Polybags tend to trap moisture and create an anaerobic environment, accelerating berry deterioration and spoilage. Studies indicate that clamshell-packaged berries maintain firmness and freshness up to 3-5 days longer than those stored in polybags, optimizing quality during shipment and retail display.

Cost Analysis: Clamshell vs Polybag Packaging

Clamshell packaging for berry shipment incurs higher initial costs due to its rigid structure and enhanced protection but reduces product loss by minimizing damage during transit. Polybag packaging offers a lower upfront cost, yet it frequently leads to increased spoilage and compression damage, raising overall expenses from product loss. Analyzing cost-effectiveness, clamshell packaging's reduction in waste and improved shelf life often outweighs its higher packaging expenditure compared to polybags.

Sustainability and Environmental Footprint

Clamshell packaging for berry shipment offers superior protection and is often made from recyclable PET, reducing environmental footprint through improved material recovery compared to polybags, which are typically single-use polyethylene and contribute significantly to plastic waste. Sustainable practices favor clamshells due to their potential for reusability and lower overall waste generation, aligning with industry goals to reduce post-harvest losses and minimize packaging-related pollution. Incorporating biodegradable or compostable clamshell alternatives further enhances sustainability by decreasing reliance on fossil-fuel-based plastics and promoting circular economy principles in berry supply chains.

Consumer Perception and Market Appeal

Clamshell packaging enhances consumer perception through its rigid, transparent structure that showcases berry freshness and minimizes damage, increasing purchase confidence. Polybag packaging offers cost-effectiveness but often compromises visual appeal and protection, potentially reducing market appeal for premium berries. Retailers favor clamshells for their reclosability and improved display, supporting higher price points and brand differentiation in competitive berry markets.

Packaging Efficiency: Handling and Logistics

Clamshell packaging offers superior packaging efficiency for berry shipment due to its rigid structure, which protects delicate berries from mechanical damage during handling and stacking. The ventilated design of clamshells enhances airflow, reducing moisture buildup and spoilage risk compared to polybag packaging that traps humidity. Polybags, while lightweight and inexpensive, present challenges in logistics, such as susceptibility to punctures and deformation, complicating transport and increasing product loss rates.

Future Trends in Berry Packaging Technologies

Clamshell packaging offers superior protection and breathability compared to polybag packaging, significantly reducing berry spoilage during transportation. Innovations are focused on incorporating biodegradable materials and smart sensors within clamshells to extend shelf life and monitor freshness in real-time. Future trends emphasize sustainable packaging solutions that enhance berry quality, reduce environmental impact, and improve supply chain efficiency in post-harvest technology.

Related Important Terms

Modified Atmosphere Clamshells

Modified atmosphere clamshell packaging significantly enhances the shelf life and quality of berries by reducing oxygen levels and increasing carbon dioxide concentration, which slows down respiration and microbial growth during shipment. Compared to polybag packaging, these clamshells provide better ventilation, physical protection, and humidity control, minimizing bruising and decay for fresher, market-ready fruit.

Breathability Index Polybags

Clamshell packaging offers moderate breathability with vented holes, maintaining berry freshness but sometimes leading to moisture buildup, while polybag packaging, particularly those with high Breathability Index, enhances air circulation significantly, reducing condensation and extending shelf life during shipment. Optimizing polybag breathability ensures controlled gas exchange, limiting microbial growth and preserving berry texture more effectively than standard clamshell containers.

Laser-Perforated Polybags

Laser-perforated polybags enhance berry shipment by providing optimal gas exchange and moisture control, reducing spoilage and extending shelf life compared to traditional clamshell packaging. This technology maintains berry freshness through precise micro-perforations that balance humidity and respiration rates, ensuring superior protection during transit.

Recyclable PET Clamshells

Recyclable PET Clamshells offer superior protection and ventilation for berry shipment compared to polybag packaging, reducing moisture accumulation and mechanical damage while extending shelf life. Their transparent design enhances product visibility and marketing appeal, and their recyclability aligns with sustainable post-harvest technology practices.

Controlled Humidity Packaging

Clamshell packaging offers superior controlled humidity for berry shipment by providing better ventilation and moisture regulation compared to polybag packaging, which often leads to excess condensation and accelerated berry spoilage. This precise humidity control in clamshell containers helps maintain berry freshness, extend shelf life, and reduce post-harvest losses during transportation.

Ventilated Clamshell Design

Ventilated clamshell packaging offers superior airflow and humidity control compared to traditional polybag packaging, significantly reducing berry spoilage during shipment. This design enhances freshness and extends shelf life by minimizing condensation and mechanical damage through its rigid, breathable structure.

Biodegradable Polyfilm Bags

Biodegradable polyfilm bags offer superior breathability and moisture control compared to traditional clamshell packaging, reducing berry spoilage during shipment. Their eco-friendly composition enhances sustainability in post-harvest technology by minimizing plastic waste while maintaining fruit quality.

Anti-fog Clamshell Coating

Anti-fog clamshell coating enhances breathability and moisture control in berry shipment, preventing condensation that accelerates spoilage compared to traditional polybag packaging. Clamshell packaging's rigid structure also reduces mechanical damage during transport, ensuring longer shelf life and better quality preservation for berries.

Active Packaging Sensors

Clamshell packaging integrated with active packaging sensors offers precise real-time monitoring of temperature, humidity, and oxygen levels, significantly reducing berry spoilage during shipment compared to traditional polybag packaging. Sensors embedded in clamshells enhance the preservation of berry freshness by providing dynamic environmental control and immediate data feedback to optimize post-harvest handling conditions.

Berry Firmness Retention Rate

Clamshell packaging improves berry firmness retention rate by providing better protection against mechanical damage and reducing moisture loss, extending shelf life during shipment. Polybag packaging, while cost-effective, often leads to higher bruising and faster firmness degradation due to limited ventilation and physical cushioning.

Clamshell packaging vs Polybag packaging for berry shipment Infographic

agridif.com

agridif.com