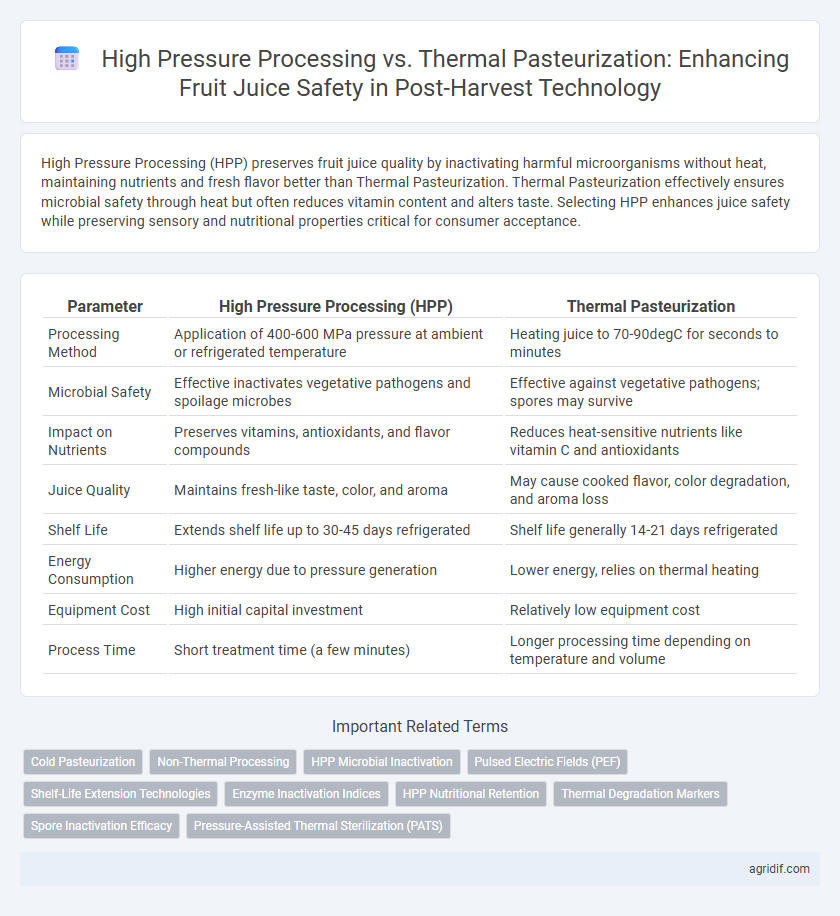

High Pressure Processing (HPP) preserves fruit juice quality by inactivating harmful microorganisms without heat, maintaining nutrients and fresh flavor better than Thermal Pasteurization. Thermal Pasteurization effectively ensures microbial safety through heat but often reduces vitamin content and alters taste. Selecting HPP enhances juice safety while preserving sensory and nutritional properties critical for consumer acceptance.

Table of Comparison

| Parameter | High Pressure Processing (HPP) | Thermal Pasteurization |

|---|---|---|

| Processing Method | Application of 400-600 MPa pressure at ambient or refrigerated temperature | Heating juice to 70-90degC for seconds to minutes |

| Microbial Safety | Effective inactivates vegetative pathogens and spoilage microbes | Effective against vegetative pathogens; spores may survive |

| Impact on Nutrients | Preserves vitamins, antioxidants, and flavor compounds | Reduces heat-sensitive nutrients like vitamin C and antioxidants |

| Juice Quality | Maintains fresh-like taste, color, and aroma | May cause cooked flavor, color degradation, and aroma loss |

| Shelf Life | Extends shelf life up to 30-45 days refrigerated | Shelf life generally 14-21 days refrigerated |

| Energy Consumption | Higher energy due to pressure generation | Lower energy, relies on thermal heating |

| Equipment Cost | High initial capital investment | Relatively low equipment cost |

| Process Time | Short treatment time (a few minutes) | Longer processing time depending on temperature and volume |

Introduction to Post-Harvest Technology in Fruit Juice Processing

High Pressure Processing (HPP) offers a non-thermal alternative to conventional Thermal Pasteurization, enhancing fruit juice safety by inactivating pathogens while preserving nutritional and sensory qualities. Post-harvest technology prioritizes minimal quality degradation, where HPP maintains bioactive compounds and fresh flavor profiles better than heat treatments. Implementing HPP in fruit juice processing supports extended shelf life and consumer demand for minimally processed, nutritious beverages.

Overview of Fruit Juice Safety Concerns

Fruit juice safety concerns primarily involve microbial contamination, enzymatic activity, and chemical hazards that can compromise product quality and consumer health. High Pressure Processing (HPP) effectively inactivates pathogens such as E. coli, Salmonella, and Listeria without significant loss of sensory or nutritional attributes by applying pressures up to 600 MPa. Thermal pasteurization uses heat treatment to achieve microbial safety but often leads to nutrient degradation and altered flavor profiles, making HPP a preferred non-thermal alternative for maintaining fruit juice safety and quality.

Understanding High Pressure Processing (HPP)

High Pressure Processing (HPP) preserves fruit juice safety by applying intense pressure up to 600 MPa, inactivating pathogens and spoilage microorganisms without heat. This non-thermal method retains nutritional value, flavor, and color better than thermal pasteurization, preventing quality degradation. HPP extends shelf life while maintaining sensory attributes, making it a superior alternative for juice preservation in post-harvest technology.

Fundamentals of Thermal Pasteurization

Thermal pasteurization in fruit juice safety relies on the application of controlled heat to inactivate spoilage microorganisms and pathogens by denaturing proteins and disrupting cellular membranes. This method operates typically at temperatures between 60degC and 85degC for a specific duration, ensuring microbial lethality while preserving juice quality. Understanding the kinetic parameters such as D-value and Z-value is essential to optimize thermal treatment and maintain nutritional and sensory attributes during pasteurization.

Comparative Efficacy: Microbial Inactivation

High Pressure Processing (HPP) achieves microbial inactivation in fruit juices at pressures up to 600 MPa, effectively targeting pathogens such as Escherichia coli and Listeria monocytogenes while preserving nutritional and sensory qualities. Thermal pasteurization utilizes temperatures typically between 71-85degC for 15-30 seconds, ensuring microbial safety by denaturing enzymes and proteins, but often causes nutrient degradation and flavor loss. Comparative studies demonstrate that HPP offers superior retention of bioactive compounds with equivalent or greater reduction of microbial loads compared to conventional thermal methods.

Impact on Nutritional Quality and Sensory Attributes

High Pressure Processing (HPP) effectively preserves fruit juice by inactivating pathogens while retaining higher levels of vitamins, antioxidants, and natural flavors compared to Thermal Pasteurization, which often leads to nutrient degradation and altered taste. Studies show that HPP maintains the juice's fresh sensory attributes, including color and aroma, better than heat treatments that can cause cooked notes and color darkening. This makes HPP a superior method for ensuring safety without compromising the nutritional quality and sensory appeal of fruit juices.

Shelf Life Enhancement: HPP vs Thermal Pasteurization

High Pressure Processing (HPP) significantly extends the shelf life of fruit juices by inactivating spoilage microorganisms and enzymes without compromising flavor or nutrient content, often doubling the storage time compared to traditional thermal pasteurization. Thermal pasteurization, although effective in microbial reduction, tends to degrade heat-sensitive vitamins and alters sensory qualities, resulting in a shorter shelf life. HPP maintains juice quality and freshness for up to 30-45 days under refrigeration, whereas thermal pasteurized juices typically last 14-21 days.

Energy Consumption and Environmental Considerations

High Pressure Processing (HPP) of fruit juice significantly reduces energy consumption compared to Thermal Pasteurization by eliminating prolonged heating phases, thereby minimizing carbon emissions. Thermal Pasteurization relies on continuous heat application, leading to higher fuel use and increased environmental impact due to greenhouse gas generation. Implementing HPP supports sustainable fruit juice production with lower overall ecological footprint and enhanced juice quality retention.

Economic Feasibility for Commercial Juice Production

High Pressure Processing (HPP) for fruit juice safety demonstrates higher initial capital investment compared to Thermal Pasteurization but offers reduced operational costs and extended shelf life, driving greater economic feasibility in large-scale commercial juice production. Thermal Pasteurization requires lower upfront costs yet incurs higher ongoing energy expenses and potential quality degradation, impacting market value and long-term profitability. The choice between HPP and Thermal Pasteurization hinges on balancing equipment investment against operational savings and product quality premium in commercial juice processing.

Future Trends and Innovations in Juice Pasteurization Technologies

Emerging advancements in fruit juice pasteurization emphasize High Pressure Processing (HPP) due to its superior preservation of nutritional quality and sensory attributes compared to traditional thermal pasteurization. Innovations in HPP equipment are enhancing scalability and cost-efficiency, addressing previous limitations in commercial adoption. Future trends also explore combining HPP with mild thermal treatments or pulsed electric fields to achieve synergistic microbial inactivation while minimizing quality degradation.

Related Important Terms

Cold Pasteurization

High Pressure Processing (HPP) offers a cold pasteurization method that effectively inactivates pathogens and spoilage microorganisms in fruit juices without compromising nutritional quality or flavor, unlike traditional thermal pasteurization which relies on heat and can degrade sensitive vitamins and volatile compounds. HPP maintains maximum freshness and extends shelf life by applying pressures up to 600 MPa, ensuring microbial safety while preserving the sensory and nutritional attributes crucial for consumer acceptance.

Non-Thermal Processing

High Pressure Processing (HPP) preserves fruit juice safety by inactivating pathogens and spoilage microorganisms through isostatic pressure without heat, maintaining nutritional quality and sensory attributes better than Thermal Pasteurization. Non-thermal processing like HPP reduces thermal degradation of vitamins and flavor compounds, ensuring extended shelf life while retaining fresh-like characteristics in fruit juices.

HPP Microbial Inactivation

High Pressure Processing (HPP) inactivates pathogenic microorganisms in fruit juice by applying pressures above 600 MPa, disrupting cellular functions without compromising nutritional and sensory quality. Unlike Thermal Pasteurization, which uses heat to kill microbes but can degrade vitamins and alter flavor, HPP ensures effective microbial inactivation while preserving the juice's fresh attributes.

Pulsed Electric Fields (PEF)

High Pressure Processing (HPP) and Thermal Pasteurization are traditional methods for ensuring fruit juice safety, but Pulsed Electric Fields (PEF) provide a non-thermal alternative that preserves nutritional quality while effectively inactivating microorganisms. PEF utilizes short bursts of high voltage to disrupt microbial cell membranes, maintaining flavor and vitamin content better than heat-based treatments.

Shelf-Life Extension Technologies

High Pressure Processing (HPP) preserves fruit juice by inactivating pathogens and spoilage microorganisms at low temperatures, maintaining nutritional quality and sensory attributes, thereby significantly extending shelf life compared to Thermal Pasteurization. Thermal Pasteurization, which relies on heat, often compromises flavor and nutritional content while providing shorter shelf stability due to thermal degradation and potential loss of bioactive compounds.

Enzyme Inactivation Indices

High Pressure Processing (HPP) achieves superior enzyme inactivation indices in fruit juice, preserving nutritional quality while effectively reducing enzymes like polyphenol oxidase and pectin methylesterase, which cause spoilage. Thermal pasteurization often results in lower enzyme inactivation efficiency and can degrade sensitive nutrients, impacting juice freshness and shelf life.

HPP Nutritional Retention

High Pressure Processing (HPP) preserves fruit juice nutritional quality by inactivating pathogens without heat, maintaining vitamin C, antioxidants, and flavor compounds more effectively than Thermal Pasteurization. Unlike heat-based methods that degrade nutrients, HPP extends shelf life while retaining the juice's fresh-like sensory and health benefits.

Thermal Degradation Markers

High Pressure Processing preserves fruit juice safety by inactivating pathogens without causing significant thermal degradation markers such as furfural, hydroxymethylfurfural (HMF), and Maillard reaction products. Thermal pasteurization, while effective for microbial control, often increases these degradation markers, leading to reduced nutritional and sensory quality of fruit juices.

Spore Inactivation Efficacy

High Pressure Processing (HPP) demonstrates superior spore inactivation efficacy compared to thermal pasteurization, effectively inactivating Bacillus and Clostridium spores without compromising fruit juice quality. Thermal pasteurization requires higher temperatures and longer exposure, often leading to nutrient loss and altered sensory properties, whereas HPP maintains freshness while ensuring microbial safety.

Pressure-Assisted Thermal Sterilization (PATS)

Pressure-Assisted Thermal Sterilization (PATS) combines high-pressure processing with moderate heat to achieve microbial inactivation in fruit juice, maintaining nutritional quality and sensory attributes better than traditional thermal pasteurization. This technology enables effective elimination of pathogens such as Escherichia coli and Listeria monocytogenes while preserving vitamins and flavor compounds that typically degrade under conventional heat treatment.

High Pressure Processing vs Thermal Pasteurization for fruit juice safety Infographic

agridif.com

agridif.com