Solar drying offers an energy-efficient and cost-effective method for grain dehydration, utilizing natural sunlight to reduce moisture content while preserving grain quality. Mechanical drying provides faster and more controlled drying conditions, minimizing the risk of microbial growth but often involves higher operational costs and energy consumption. Selecting the optimal drying technique depends on factors such as available resources, scale of operation, and desired grain quality.

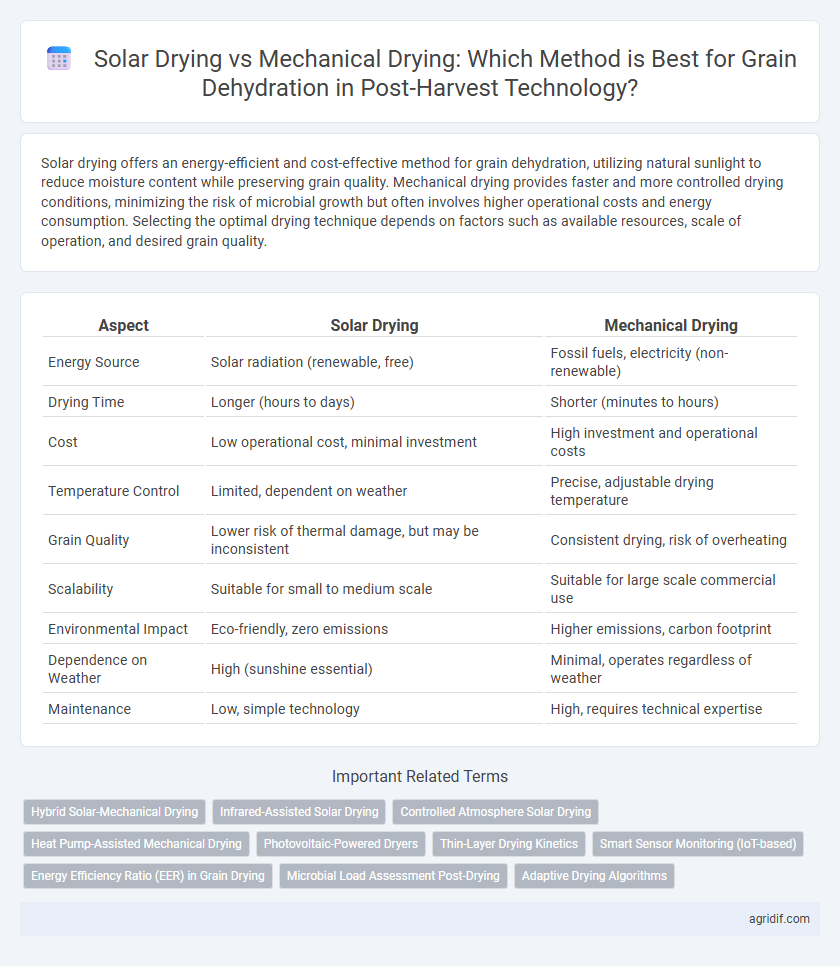

Table of Comparison

| Aspect | Solar Drying | Mechanical Drying |

|---|---|---|

| Energy Source | Solar radiation (renewable, free) | Fossil fuels, electricity (non-renewable) |

| Drying Time | Longer (hours to days) | Shorter (minutes to hours) |

| Cost | Low operational cost, minimal investment | High investment and operational costs |

| Temperature Control | Limited, dependent on weather | Precise, adjustable drying temperature |

| Grain Quality | Lower risk of thermal damage, but may be inconsistent | Consistent drying, risk of overheating |

| Scalability | Suitable for small to medium scale | Suitable for large scale commercial use |

| Environmental Impact | Eco-friendly, zero emissions | Higher emissions, carbon footprint |

| Dependence on Weather | High (sunshine essential) | Minimal, operates regardless of weather |

| Maintenance | Low, simple technology | High, requires technical expertise |

Introduction to Grain Dehydration Methods

Solar drying utilizes natural sunlight and ambient air to reduce moisture content in grains, offering an energy-efficient and cost-effective method ideal for small-scale farmers in tropical regions. Mechanical drying employs controlled heated air and advanced equipment to achieve precise moisture removal, ensuring uniform grain quality and reduced drying time suitable for large-scale commercial operations. Both methods aim to prevent spoilage, optimize storage life, and maintain grain nutritional value, with choice influenced by factors such as climate, grain type, and available resources.

Overview of Solar Drying in Post-Harvest Processing

Solar drying in post-harvest processing utilizes solar energy to reduce grain moisture content, offering an eco-friendly and cost-effective alternative to mechanical drying. This method enhances grain preservation by inhibiting microbial growth and enzymatic activity, thereby extending shelf life and maintaining nutritional quality. Solar dryers, including direct, indirect, and mixed-mode types, optimize drying efficiency by controlling temperature and airflow without relying on fossil fuels.

Mechanical Drying: Principles and Technologies

Mechanical drying for grain dehydration operates on the principle of transferring heat through forced air circulation to remove moisture efficiently, using technologies such as batch and continuous flow dryers. These systems employ controlled temperature, airflow, and humidity settings to optimize drying rates while minimizing quality loss and grain damage. Advanced mechanical dryers integrate sensors and automated controls to ensure uniform drying, reduce energy consumption, and enhance post-harvest grain preservation.

Comparative Efficiency: Solar vs. Mechanical Drying

Solar drying utilizes natural sunlight and ambient air, resulting in lower operational costs and energy consumption but slower dehydration rates and susceptibility to weather conditions. Mechanical drying employs controlled temperature and airflow, offering faster and more consistent grain moisture reduction, crucial for timely post-harvest processing. Efficiency comparison highlights that mechanical drying achieves higher throughput and uniformity, while solar drying remains cost-effective and sustainable for small-scale operations.

Impact on Grain Quality and Nutrient Retention

Solar drying preserves grain quality and nutrient content by using low temperatures, reducing the risk of thermal damage and nutrient degradation common in mechanical drying. Mechanical drying, while faster and controllable, often exposes grains to higher temperatures that can lead to nutrient loss, color changes, and reduced germination rates. Optimal drying methods balance efficiency and grain integrity, prioritizing nutrient retention and minimizing quality deterioration in post-harvest grain management.

Energy Consumption and Sustainability Considerations

Solar drying for grain dehydration significantly reduces energy consumption by harnessing renewable solar energy, making it highly sustainable and cost-effective for small-scale farmers. Mechanical drying relies on fossil fuels or electricity, resulting in higher energy usage and greenhouse gas emissions, which can contribute to environmental degradation. Choosing solar drying supports sustainable agriculture by lowering carbon footprints and promoting energy efficiency in post-harvest grain processing.

Cost Analysis: Installation and Operational Expenses

Solar drying presents a lower installation cost compared to mechanical drying, leveraging natural sunlight and reducing the need for expensive equipment. Operational expenses for solar drying are significantly minimized as it relies on free solar energy, while mechanical drying incurs continuous costs due to electricity or fuel consumption. Evaluating long-term feasibility, mechanical drying offers faster dehydration but at a higher energy expenditure, making solar drying more cost-effective for small to medium-scale grain farmers.

Scalability for Smallholder and Commercial Farms

Solar drying offers smallholder farms an affordable, energy-efficient solution for grain dehydration, leveraging natural sunlight with minimal infrastructure costs. Mechanical drying, while requiring higher initial investment and operational energy, provides commercial farms with scalable throughput, precise moisture control, and year-round drying capacity essential for large-scale grain processing. The choice between solar and mechanical drying largely depends on farm size, capital availability, and the need for rapid, consistent drying performance in post-harvest grain management.

Environmental Implications of Drying Technologies

Solar drying reduces carbon emissions significantly compared to mechanical drying, as it relies on renewable solar energy instead of fossil fuels. Mechanical drying consumes substantial electricity or fuel, leading to higher greenhouse gas emissions and increased environmental pollution. Solar drying also minimizes the risk of heat-induced nutrient loss, promoting sustainable grain preservation with a lower ecological footprint.

Future Trends and Innovations in Grain Drying

Emerging trends in grain drying emphasize integrating solar drying with advanced control systems to enhance energy efficiency and reduce carbon footprints compared to traditional mechanical drying. Innovations include hybrid solar-mechanical dryers featuring automated moisture sensors and IoT-enabled monitoring for real-time data analytics, boosting drying precision and grain quality preservation. Future developments are expected to focus on scalable solar drying technologies combined with AI-driven process optimization to meet sustainable agriculture goals and adapt to climate variability.

Related Important Terms

Hybrid Solar-Mechanical Drying

Hybrid solar-mechanical drying integrates solar energy with mechanical systems to optimize grain dehydration by reducing drying time and energy consumption compared to standalone methods. This approach enhances drying uniformity and quality, minimizing nutrient loss and microbial growth while improving overall post-harvest grain preservation efficiency.

Infrared-Assisted Solar Drying

Infrared-assisted solar drying enhances grain dehydration by accelerating moisture removal through infrared radiation, improving efficiency compared to traditional solar drying methods. This technique reduces drying time and energy consumption while preserving grain quality better than conventional mechanical drying systems.

Controlled Atmosphere Solar Drying

Controlled Atmosphere Solar Drying enhances grain dehydration by regulating temperature, humidity, and airflow within solar dryers, minimizing microbial growth and preserving nutritional quality compared to traditional Mechanical Drying methods that rely on higher energy consumption and often cause uneven moisture reduction. This energy-efficient technique leverages solar radiation with controlled environmental parameters to achieve uniform drying, reducing post-harvest losses and improving grain shelf life sustainably.

Heat Pump-Assisted Mechanical Drying

Heat pump-assisted mechanical drying offers precise temperature and humidity control, enhancing grain quality by reducing nutrient loss and fungal contamination compared to traditional solar drying methods. This technology achieves higher energy efficiency and faster dehydration rates, making it a cost-effective solution for post-harvest grain preservation.

Photovoltaic-Powered Dryers

Photovoltaic-powered dryers utilize solar energy to drive grain dehydration, offering a sustainable alternative to mechanical drying that relies on fossil fuels and electricity. These dryers enhance drying efficiency by converting solar radiation into electrical energy, reducing operational costs and greenhouse gas emissions while maintaining grain quality through controlled temperature and humidity.

Thin-Layer Drying Kinetics

Solar drying of grains using thin-layer drying kinetics offers energy-efficient dehydration by harnessing natural solar radiation, resulting in moderate drying rates dependent on ambient temperature and humidity. Mechanical drying, conversely, provides controlled thin-layer drying with higher and consistent drying rates through regulated temperature and airflow, reducing moisture content more rapidly but requiring greater energy input.

Smart Sensor Monitoring (IoT-based)

Smart sensor monitoring in solar drying systems utilizes IoT-based technology to optimize grain dehydration by continuously tracking temperature, humidity, and moisture levels, ensuring efficient drying while minimizing energy consumption. Mechanical drying with integrated IoT sensors provides real-time data for precise control of drying parameters, reducing drying time and preventing grain spoilage through dynamic adjustments in airflow and temperature.

Energy Efficiency Ratio (EER) in Grain Drying

Solar drying for grain dehydration often achieves a higher Energy Efficiency Ratio (EER) by utilizing renewable solar energy, reducing reliance on external power sources and minimizing operational costs. Mechanical drying systems, while faster and more controllable, typically exhibit lower EER due to significant energy consumption from fuel or electricity, impacting overall sustainability in post-harvest technology.

Microbial Load Assessment Post-Drying

Solar drying reduces microbial load in grains primarily through natural UV exposure and gradual moisture reduction, whereas mechanical drying achieves rapid dehydration with controlled temperature and airflow, effectively minimizing microbial proliferation. Comparative assessments reveal mechanical drying often results in lower residual microbial counts, enhancing grain safety and storage longevity post-harvest.

Adaptive Drying Algorithms

Adaptive drying algorithms in solar drying systems optimize moisture removal by adjusting drying parameters based on real-time environmental data, enhancing energy efficiency and grain quality retention. Mechanical drying employs adaptive control systems to regulate temperature and airflow, minimizing over-drying and preserving grain integrity while reducing energy consumption.

Solar Drying vs Mechanical Drying for grain dehydration Infographic

agridif.com

agridif.com