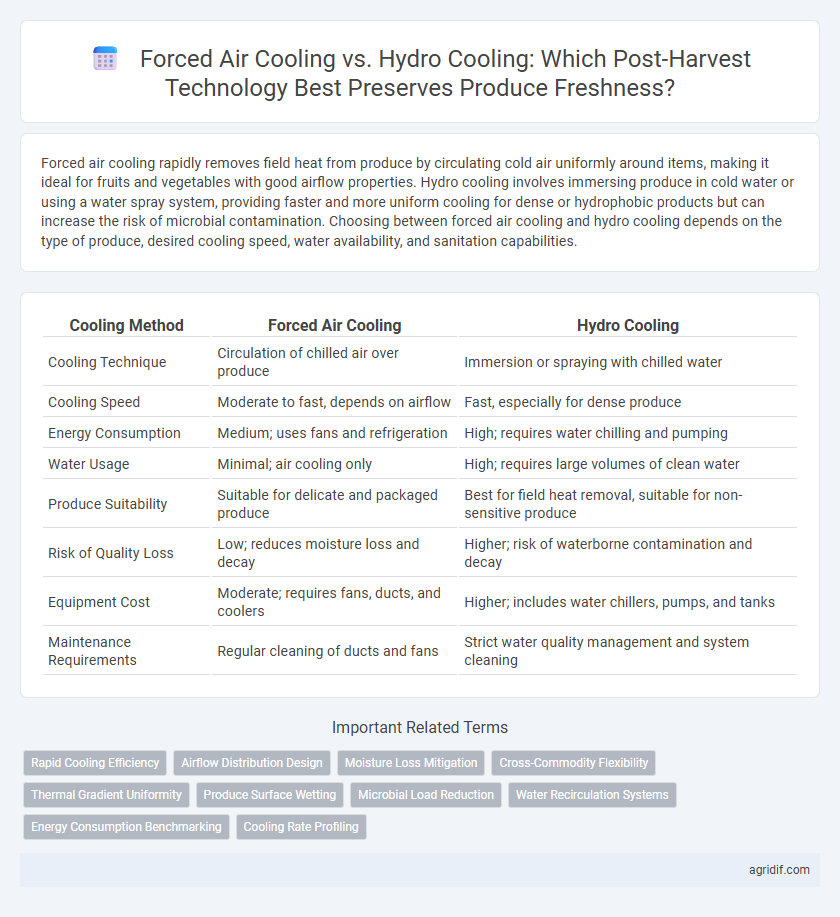

Forced air cooling rapidly removes field heat from produce by circulating cold air uniformly around items, making it ideal for fruits and vegetables with good airflow properties. Hydro cooling involves immersing produce in cold water or using a water spray system, providing faster and more uniform cooling for dense or hydrophobic products but can increase the risk of microbial contamination. Choosing between forced air cooling and hydro cooling depends on the type of produce, desired cooling speed, water availability, and sanitation capabilities.

Table of Comparison

| Cooling Method | Forced Air Cooling | Hydro Cooling |

|---|---|---|

| Cooling Technique | Circulation of chilled air over produce | Immersion or spraying with chilled water |

| Cooling Speed | Moderate to fast, depends on airflow | Fast, especially for dense produce |

| Energy Consumption | Medium; uses fans and refrigeration | High; requires water chilling and pumping |

| Water Usage | Minimal; air cooling only | High; requires large volumes of clean water |

| Produce Suitability | Suitable for delicate and packaged produce | Best for field heat removal, suitable for non-sensitive produce |

| Risk of Quality Loss | Low; reduces moisture loss and decay | Higher; risk of waterborne contamination and decay |

| Equipment Cost | Moderate; requires fans, ducts, and coolers | Higher; includes water chillers, pumps, and tanks |

| Maintenance Requirements | Regular cleaning of ducts and fans | Strict water quality management and system cleaning |

Introduction to Post-Harvest Cooling Methods

Forced air cooling rapidly reduces produce temperature by pushing cold air through packed commodities, enhancing shelf life and reducing respiration rates. Hydro cooling immerses or sprays produce with cold water, providing uniform temperature reduction and effective field heat removal, especially for leafy vegetables and fruits with high surface area. Both methods are crucial post-harvest cooling techniques that minimize microbial growth and maintain quality during storage and transportation.

Overview of Forced Air Cooling

Forced air cooling rapidly removes field heat from produce by circulating refrigerated air through stacked containers, optimizing airflow to ensure uniform temperature reduction. This method enhances shelf life and maintains quality by minimizing microbial growth and moisture loss. Forced air cooling is energy-efficient and widely used for leafy greens, berries, and other perishable fruits and vegetables requiring quick cooling after harvest.

Overview of Hydro Cooling

Hydro cooling rapidly reduces produce temperature by immersing or spraying fruits and vegetables with cold water, enhancing post-harvest shelf life and minimizing microbial growth. This method is especially effective for high-moisture produce like leafy greens, berries, and asparagus, offering uniform cooling and reducing moisture loss. Compared to forced air cooling, hydro cooling provides faster heat removal but requires careful water quality management to prevent contamination.

Mechanisms of Heat Removal: Air vs. Water

Forced air cooling removes heat from produce by circulating chilled air rapidly around the products, facilitating evaporative heat loss through increased airflow and thermal conduction from the produce surface to the air. Hydro cooling extracts heat more efficiently by immersing produce in cold water, enabling direct conductive heat transfer between the water and produce, which cools items faster due to water's higher heat capacity and thermal conductivity compared to air. The choice between air and water as cooling mediums impacts cooling rate, moisture retention, and energy consumption in post-harvest produce preservation.

Efficiency and Speed of Cooling

Forced air cooling rapidly removes field heat by circulating chilled air uniformly through produce pallets, achieving temperature reduction within 1-4 hours depending on produce type and packing density. Hydro cooling uses cold water immersion to extract heat quickly, often cooling certain fruits and vegetables in 30 minutes to 2 hours, but it is less energy-efficient and poses risks of water contamination. Forced air cooling offers greater efficiency in energy use and scalability for large-volume operations, while hydro cooling provides faster cooling times for smaller batches but demands higher water usage and sanitation measures.

Produce Suitability: Matching Crops to Methods

Forced air cooling is ideal for highly perishable fruits like berries, cherries, and leafy greens, as it rapidly removes field heat without causing excess moisture buildup. Hydro cooling suits produce such as broccoli, lettuce, and strawberries that tolerate or benefit from direct water contact, providing quick and uniform temperature reduction while maintaining product firmness. Selecting the appropriate cooling method based on crop sensitivity ensures optimal shelf life and quality preservation in post-harvest handling.

Energy and Water Consumption

Forced air cooling consumes less water compared to hydro cooling, making it a more water-efficient choice for produce cooling. Energy consumption varies depending on system design, but forced air cooling generally requires moderate electricity to operate fans and maintain airflow. Hydro cooling demands significant water use and energy for water circulation and chilling, which can increase operational costs and environmental impact.

Impact on Produce Quality and Shelf Life

Forced air cooling rapidly lowers produce temperature by circulating cold air through crates, minimizing moisture loss and fungal growth, which helps maintain firmness and extends shelf life by up to 14 days for leafy greens. Hydro cooling involves immersing produce in cold water, providing uniform cooling and reducing field heat more quickly, but excessive moisture uptake can promote decay and reduce shelf life for some fruits like berries. Choosing between forced air and hydro cooling depends on the specific crop's sensitivity to moisture and desired shelf life extension, with forced air preferred for high-respiration produce and hydro cooling ideal for densely packed items requiring rapid temperature reduction.

Cost Considerations and Infrastructure Needs

Forced air cooling requires significant investment in fans, ducts, and well-sealed storage rooms but offers energy-efficient rapid cooling suitable for large-scale operations. Hydro cooling involves substantial water usage, specialized water treatment systems, and drainage infrastructure, increasing operational costs especially where water is scarce or expensive. Choosing between these methods depends on the availability of capital, water resources, and the scale of post-harvest facilities to optimize cost-effectiveness and cooling efficiency.

Environmental and Food Safety Implications

Forced air cooling uses high-velocity fans to rapidly remove heat from produce, minimizing microbial growth while consuming less water, which supports environmental sustainability. Hydro cooling immerses produce in chilled water, effectively reducing field heat but posing risks of cross-contamination if water quality is not rigorously maintained. Prioritizing food safety, forced air cooling reduces pathogen transfer, whereas hydro cooling demands stringent sanitation protocols to prevent microbial proliferation and ensure produce quality.

Related Important Terms

Rapid Cooling Efficiency

Forced air cooling rapidly removes field heat by circulating chilled air through produce containers, achieving uniform temperature reduction within hours and enhancing shelf life. Hydro cooling uses cold water immersion for faster surface cooling but may lead to water consumption and potential cross-contamination, making forced air cooling more efficient for large-scale rapid cooling.

Airflow Distribution Design

Forced air cooling utilizes a carefully engineered airflow distribution system to ensure rapid and uniform temperature reduction by directing cold air through vented pallets or crates, optimizing cooling efficiency for perishable produce. In contrast, hydro cooling relies on direct water immersion or spraying, which does not require airflow distribution but emphasizes uniform water contact to quickly lower produce temperature and maintain quality.

Moisture Loss Mitigation

Forced air cooling effectively removes field heat from produce by circulating cold air, but can cause higher moisture loss due to direct air exposure. Hydro cooling submerges produce in chilled water, significantly reducing moisture loss and maintaining turgidity, making it optimal for moisture-sensitive fruits and vegetables.

Cross-Commodity Flexibility

Forced air cooling offers superior cross-commodity flexibility by efficiently cooling a wide range of produce types through controlled airflow, making it adaptable for diverse post-harvest handling environments. Hydro cooling, while highly effective for commodities like leafy greens and berries, is less versatile due to its water dependency and risk of pathogen spread, limiting its applicability across different produce categories.

Thermal Gradient Uniformity

Forced air cooling provides more uniform thermal gradient distribution within produce by circulating cold air evenly around the product, minimizing temperature variation and reducing spoilage risk. Hydro cooling rapidly decreases surface temperature but often results in less uniform internal cooling due to uneven water contact, causing greater thermal gradient inconsistencies.

Produce Surface Wetting

Forced air cooling minimizes produce surface wetting by circulating cold air rapidly, which reduces moisture accumulation and helps maintain optimal texture and shelf life. Hydro cooling submerges produce in chilled water, increasing surface wetting that can promote microbial growth and accelerate decay if drying is insufficient post-cooling.

Microbial Load Reduction

Forced air cooling rapidly reduces produce temperature, minimizing microbial growth by lowering surface moisture and oxygen availability, which inhibits bacterial proliferation. Hydro cooling effectively decreases field heat and surface microbes through direct water contact that washes away contaminants and lowers microbial load on fresh produce.

Water Recirculation Systems

Forced air cooling systems use ambient or chilled air circulated through produce to rapidly reduce temperature, while hydro cooling involves immersing produce in cold water, often requiring advanced water recirculation systems to maintain hygiene and minimize water usage. Water recirculation systems in hydro cooling optimize resource efficiency by filtering, chilling, and continuously reusing water, reducing contamination risks and operational costs in large-scale post-harvest produce handling.

Energy Consumption Benchmarking

Forced air cooling typically consumes less energy compared to hydro cooling due to its efficient airflow system that rapidly removes field heat from produce. Hydro cooling involves significant water pumping and chilling costs, resulting in higher overall energy consumption despite its faster cooling rates.

Cooling Rate Profiling

Forced air cooling rapidly reduces produce temperature by circulating chilled air around the product, achieving a uniform cooling rate that minimizes respiration and moisture loss. Hydro cooling offers faster heat transfer through direct water contact, providing efficient thermal conductivity, but may cause variable cooling rates and potential waterlogging depending on produce type and water temperature.

Forced Air Cooling vs Hydro Cooling for Produce Cooling Infographic

agridif.com

agridif.com