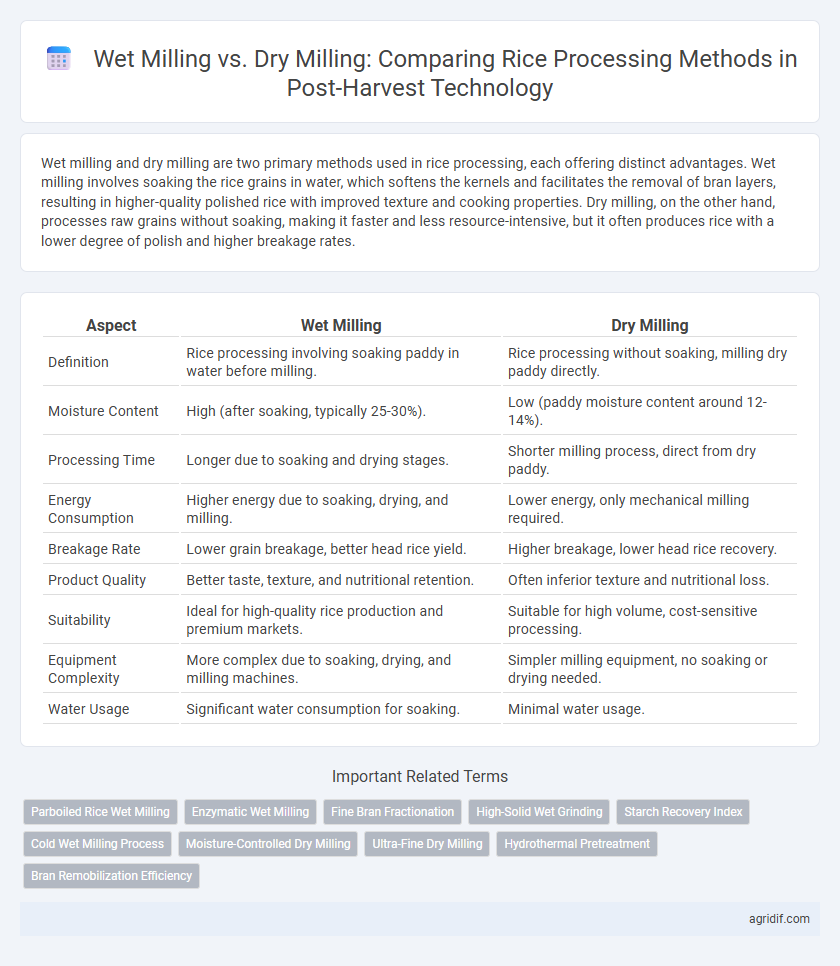

Wet milling and dry milling are two primary methods used in rice processing, each offering distinct advantages. Wet milling involves soaking the rice grains in water, which softens the kernels and facilitates the removal of bran layers, resulting in higher-quality polished rice with improved texture and cooking properties. Dry milling, on the other hand, processes raw grains without soaking, making it faster and less resource-intensive, but it often produces rice with a lower degree of polish and higher breakage rates.

Table of Comparison

| Aspect | Wet Milling | Dry Milling |

|---|---|---|

| Definition | Rice processing involving soaking paddy in water before milling. | Rice processing without soaking, milling dry paddy directly. |

| Moisture Content | High (after soaking, typically 25-30%). | Low (paddy moisture content around 12-14%). |

| Processing Time | Longer due to soaking and drying stages. | Shorter milling process, direct from dry paddy. |

| Energy Consumption | Higher energy due to soaking, drying, and milling. | Lower energy, only mechanical milling required. |

| Breakage Rate | Lower grain breakage, better head rice yield. | Higher breakage, lower head rice recovery. |

| Product Quality | Better taste, texture, and nutritional retention. | Often inferior texture and nutritional loss. |

| Suitability | Ideal for high-quality rice production and premium markets. | Suitable for high volume, cost-sensitive processing. |

| Equipment Complexity | More complex due to soaking, drying, and milling machines. | Simpler milling equipment, no soaking or drying needed. |

| Water Usage | Significant water consumption for soaking. | Minimal water usage. |

Introduction to Rice Milling: Wet vs Dry Methods

Wet milling and dry milling represent two core rice processing methods with distinct impacts on rice quality and yield. Wet milling involves soaking paddy rice in water to soften the grains, resulting in higher head rice recovery and improved bran removal, whereas dry milling processes paddy rice without soaking, focusing on rapid moisture reduction before husk removal. Understanding these methods helps optimize post-harvest efficiency by balancing moisture content, milling quality, and energy consumption in rice production.

Overview of Post-Harvest Rice Processing

Wet milling and dry milling are two primary post-harvest rice processing methods that impact rice quality and yield significantly. Wet milling involves soaking paddy rice to soften the grains, enhancing bran removal and producing higher milling recovery with improved texture and aroma. Dry milling uses mechanical friction to remove husk and bran without soaking, offering faster processing but often resulting in slightly lower yield and increased broken grains.

Principles and Process Flow of Wet Milling

Wet milling of rice involves soaking paddy in water to soften the grain and facilitate the removal of the husk and bran layers, resulting in polished white rice. The process flow includes soaking, dehusking, milling, and polishing stages, where water acts as a medium to reduce friction and prevent heat build-up, preserving rice quality and nutritional content. This method contrasts with dry milling, which relies on mechanical abrasion without water, often leading to higher breakage and reduced starch integrity.

Principles and Process Flow of Dry Milling

Dry milling for rice processing involves mechanically removing the husk and bran layers from paddy rice without using water, preserving the grain's natural moisture content. The process flow includes cleaning, dehusking, separating bran from the brown rice using abrasive or friction methods, and polishing the grains to obtain white rice. This method is energy-efficient, reduces microbial growth, and is particularly suited for regions with water scarcity or where controlling moisture content is critical for rice quality.

Equipment Used in Wet and Dry Rice Milling

Wet milling of rice involves equipment such as water soaking tanks, attrition scrubbers, and centrifugal separators to remove husks and bran layers efficiently while preserving grain integrity. Dry milling, on the other hand, utilizes machines like hulling machines, rubber roll shellers, and abrasive polishers designed to process the grain without water, focusing on mechanical removal of outer layers. The choice of equipment impacts milling yield, rice quality, and energy consumption significantly in post-harvest rice processing.

Quality and Yield: Comparing Wet and Dry Milling

Wet milling of rice typically results in higher quality grains with better texture, aroma, and reduced bran contamination, enhancing consumer appeal. This method also achieves higher yield by minimizing broken kernels and improving whole grain recovery compared to dry milling. Dry milling, while faster and less water-intensive, often produces lower milling yield and more bran residues, affecting both quality and commercial value.

Energy Consumption and Environmental Impact

Wet milling in rice processing consumes significantly more energy due to the need for soaking, steaming, and drying, leading to higher water usage and wastewater generation that impacts the environment. Dry milling requires less energy as it involves mechanical processes without soaking, reducing water consumption and minimizing wastewater production, thus lowering the overall environmental footprint. Choosing dry milling can enhance energy efficiency and promote sustainable rice processing by reducing both resource use and pollution.

Suitability for Different Rice Varieties

Wet milling is particularly suitable for starch-rich rice varieties as it enhances starch extraction and yield, making it ideal for producing rice flour and starch-based products. Dry milling works better for harder, low-starch rice varieties by preserving the grain's structural integrity and minimizing broken grains during processing. Selecting between wet milling and dry milling depends on the rice variety's moisture content, starch composition, and desired end product quality.

Economic Considerations: Cost and Efficiency

Wet milling of rice involves higher initial capital investment and increased water usage, leading to elevated operational costs compared to dry milling. However, wet milling yields higher quality rice with less broken grains, which can command premium market prices and improve profitability. Dry milling is more cost-efficient for large-scale operations due to lower water requirements and simpler machinery, but it typically results in higher breakage rates, potentially reducing overall economic returns.

Future Trends in Rice Milling Technologies

Future trends in rice milling technologies emphasize the integration of advanced sensors and automation in both wet milling and dry milling processes to enhance yield and reduce grain breakage. Innovations in moisture control and real-time quality assessment are expected to optimize the efficiency and sustainability of rice processing. The adoption of AI-driven predictive maintenance and IoT-enabled equipment will further transform the rice milling industry by minimizing downtime and improving product consistency.

Related Important Terms

Parboiled Rice Wet Milling

Wet milling for parboiled rice processing enhances grain quality by improving hydration and gelatinization, resulting in higher head rice yield and reduced breakage compared to dry milling. This method retains more nutrients and produces rice with better texture and longer shelf life, making it a preferred technique in post-harvest rice technology.

Enzymatic Wet Milling

Enzymatic wet milling in rice processing utilizes specific enzymes to break down starches and proteins, enhancing yield and improving the functional properties of rice flour compared to traditional dry milling methods. This technique increases starch recovery, reduces energy consumption, and generates higher-quality rice fractions suitable for diverse food applications.

Fine Bran Fractionation

Wet milling of rice enhances fine bran fractionation by facilitating the separation of bran layers with higher precision and reduced nutrient loss compared to dry milling. The aqueous environment in wet milling softens the bran, enabling efficient extraction of fine bran particles rich in bioactive compounds like antioxidants and dietary fibers.

High-Solid Wet Grinding

High-solid wet grinding in wet milling enhances rice processing efficiency by retaining bran layers and improving starch gelatinization, resulting in higher yield and better nutritional quality compared to dry milling. Unlike dry milling, wet milling minimizes heat generation and reduces milling losses, making it the preferred method for producing superior rice flour with finer particle size and enhanced functional properties.

Starch Recovery Index

Wet milling in rice processing achieves a higher Starch Recovery Index compared to dry milling, due to its ability to efficiently separate starch granules from rice bran and husk. The controlled hydration and grinding conditions in wet milling enhance starch yield and purity, making it preferable for industrial applications requiring maximum starch extraction.

Cold Wet Milling Process

Cold wet milling in rice processing involves soaking paddy grains in water to soften the outer husk and bran layers, facilitating efficient removal and reducing heat generation compared to dry milling. This method enhances rice yield and quality by minimizing grain breakage and preserving nutritional components such as vitamins and minerals.

Moisture-Controlled Dry Milling

Moisture-controlled dry milling in rice processing optimizes grain texture and milling yield by maintaining precise kernel moisture levels between 12-14%, minimizing breakage and enhancing starch quality. Compared to wet milling, this method reduces water usage and drying time, resulting in cost savings and improved environmental sustainability without compromising rice quality.

Ultra-Fine Dry Milling

Ultra-fine dry milling in rice processing offers superior particle size reduction and enhanced flour quality without moisture addition, preserving shelf life and reducing microbial risks compared to wet milling. This method produces finer rice flour with better functionality for diverse food applications, making it a preferred technique in modern post-harvest technology.

Hydrothermal Pretreatment

Wet milling in rice processing involves hydrothermal pretreatment, which enhances starch gelatinization and improves milling yield by softening the rice kernels, while dry milling skips this step, often resulting in higher bran breakage and lower starch quality. Hydrothermal pretreatment optimizes moisture content and temperature, facilitating easier bran removal and producing higher quality polished rice compared to dry milling methods.

Bran Remobilization Efficiency

Wet milling enhances bran remobilization efficiency in rice processing by soaking grains to soften the outer layers, facilitating more effective separation of bran from the endosperm compared to dry milling. This method reduces bran loss and improves yield quality, optimizing nutrient retention and overall product value.

Wet Milling vs Dry Milling for rice processing Infographic

agridif.com

agridif.com