Controlled Atmosphere Storage (CAS) precisely regulates oxygen, carbon dioxide, and humidity levels to extend fruit shelf life by slowing respiration and delaying ripening. Modified Atmosphere Storage (MAS) involves altering the gas composition around the fruit, often through packaging, to reduce spoilage and maintain quality. CAS offers more dynamic environmental control compared to MAS, making it preferable for sensitive fruits requiring longer storage periods.

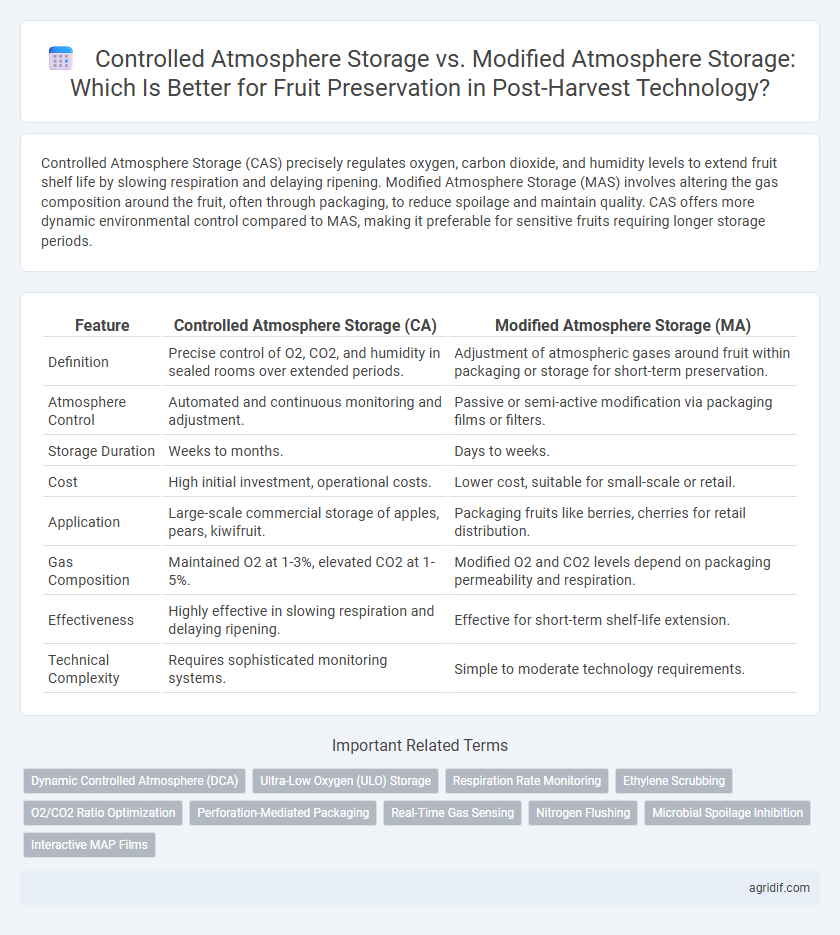

Table of Comparison

| Feature | Controlled Atmosphere Storage (CA) | Modified Atmosphere Storage (MA) |

|---|---|---|

| Definition | Precise control of O2, CO2, and humidity in sealed rooms over extended periods. | Adjustment of atmospheric gases around fruit within packaging or storage for short-term preservation. |

| Atmosphere Control | Automated and continuous monitoring and adjustment. | Passive or semi-active modification via packaging films or filters. |

| Storage Duration | Weeks to months. | Days to weeks. |

| Cost | High initial investment, operational costs. | Lower cost, suitable for small-scale or retail. |

| Application | Large-scale commercial storage of apples, pears, kiwifruit. | Packaging fruits like berries, cherries for retail distribution. |

| Gas Composition | Maintained O2 at 1-3%, elevated CO2 at 1-5%. | Modified O2 and CO2 levels depend on packaging permeability and respiration. |

| Effectiveness | Highly effective in slowing respiration and delaying ripening. | Effective for short-term shelf-life extension. |

| Technical Complexity | Requires sophisticated monitoring systems. | Simple to moderate technology requirements. |

Introduction to Post-Harvest Fruit Preservation

Controlled Atmosphere Storage (CA) maintains precise oxygen, carbon dioxide, and humidity levels to slow fruit respiration and delay ripening, extending shelf life significantly. Modified Atmosphere Storage (MA) involves altering the composition of gases surrounding the fruit, often using packaging films that adjust gas exchange rates to reduce spoilage and maintain quality. Both technologies are essential in post-harvest fruit preservation, improving marketability by reducing decay and maintaining texture and flavor during storage and transportation.

Overview of Controlled Atmosphere Storage (CA Storage)

Controlled Atmosphere Storage (CA Storage) is a post-harvest technology that regulates oxygen, carbon dioxide, and humidity levels to slow down fruit respiration and extend shelf life. This method maintains near-ideal gas concentrations, typically reducing oxygen to 1-3% and increasing carbon dioxide to 1-5%, effectively delaying ripening and microbial growth. Compared to Modified Atmosphere Storage (MA Storage), which modifies gas composition within packaging, CA Storage offers precise environmental control suitable for long-term preservation of apples, pears, and stone fruits.

Understanding Modified Atmosphere Storage (MA Storage)

Modified Atmosphere Storage (MA Storage) involves altering the composition of gases around fruits to slow respiration rates and delay ripening, primarily by reducing oxygen and increasing carbon dioxide levels. Unlike Controlled Atmosphere Storage, which maintains precise, automated control over environmental conditions, MA Storage typically relies on passive modification using film packaging or sealed containers. This technology effectively extends shelf life by minimizing oxidative stress and microbial growth while being more cost-effective for small-scale or short-term fruit preservation.

Key Differences between CA and MA Storage

Controlled Atmosphere (CA) storage maintains precise regulation of oxygen, carbon dioxide, and humidity levels within sealed environments, ensuring consistent conditions optimal for long-term fruit preservation. Modified Atmosphere (MA) storage involves altering the composition of gases surrounding the fruit passively or actively but lacks the stringent control seen in CA, often relying on packaging materials to achieve desired gas balances. Key differences lie in CA's continuous environment monitoring and adjustment, contrasted with MA's dependence on static or semi-passive atmospheric modifications, impacting storage duration and fruit quality retention.

Mechanisms of Gas Regulation in CA and MA Systems

Controlled Atmosphere (CA) storage regulates oxygen, carbon dioxide, and humidity through advanced monitoring and automated gas injection to maintain specific gas concentrations tailored for each fruit type, significantly slowing respiration and delaying ripening. Modified Atmosphere (MA) storage relies on the natural respiration of the fruit and the permeability of packaging materials to alter gas composition passively, creating a low oxygen and elevated carbon dioxide environment that reduces metabolic activity. The precise gas regulation in CA systems ensures optimal preservation conditions, while MA offers a cost-effective approach with less control over atmospheric composition.

Impact on Fruit Shelf Life and Quality

Controlled Atmosphere Storage (CAS) extends fruit shelf life by precisely regulating oxygen, carbon dioxide, and humidity levels, significantly slowing respiration and delaying ripening processes. Modified Atmosphere Storage (MAS) adjusts atmospheric composition within packaging, creating a microenvironment that reduces oxidative stress and microbial growth, but with less precise control than CAS. CAS generally provides superior maintenance of fruit firmness, color, and flavor over prolonged periods, while MAS is effective for shorter-term preservation and reducing post-harvest losses.

Cost and Infrastructure Comparison

Controlled Atmosphere Storage (CAS) requires significant investment in advanced monitoring systems and airtight chambers, resulting in higher initial infrastructure costs compared to Modified Atmosphere Storage (MAS), which employs simpler gas modifications often within flexible packaging or low-tech environments. CAS systems demand continuous operational expenses for specialized equipment and skilled personnel, whereas MAS typically incurs lower maintenance costs due to passive or semi-passive gas exchange methods. For large-scale fruit preservation, CAS offers precise environmental control but at elevated capital and operational expenses, while MAS provides a cost-effective alternative suitable for smaller producers with limited infrastructure.

Suitable Fruit Types for Each Technology

Controlled Atmosphere Storage (CA) is ideal for pome fruits like apples and pears, as well as some stone fruits such as cherries, due to its precise regulation of oxygen, carbon dioxide, and humidity levels that slow ripening and extend shelf life. Modified Atmosphere Storage (MA), often used for berries, leafy greens, and tropical fruits like mangoes and bananas, relies on the natural respiration of produce combined with packaging adjustments to create a low-oxygen environment suitable for shorter-term preservation. The selection between CA and MA depends on the fruit's respiration rate, sensitivity to gases, and desired storage duration.

Advantages and Limitations of CA and MA Storage

Controlled Atmosphere (CA) Storage optimizes fruit preservation through precise regulation of oxygen, carbon dioxide, and humidity levels, significantly extending shelf life and maintaining quality by slowing respiration and delaying ripening. Modified Atmosphere (MA) Storage, by contrast, alters the gas composition around fruits using packaging materials, offering flexibility and lower initial costs but less control over atmospheric conditions, which may lead to inconsistent results. CA Storage's advantages include enhanced longevity and uniformity, though it requires high investment and energy input; MA Storage is cost-effective and simpler but has limitations in maintaining stable atmospheres for long-term storage.

Future Trends and Innovations in Atmospheric Storage for Fruits

Emerging advancements in controlled atmosphere (CA) storage incorporate smart sensors and automation to precisely regulate oxygen, carbon dioxide, and humidity, extending the shelf life and quality of fruits with minimal human intervention. Innovations in modified atmosphere packaging (MAP) utilize bio-based, breathable films embedded with ethylene scavengers and antimicrobial agents to actively maintain optimal storage conditions and reduce post-harvest losses. Future trends emphasize integrating Internet of Things (IoT) technology and machine learning algorithms to dynamically adjust atmospheric parameters in real-time, ensuring customized preservation tailored to fruit type and maturity stage.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) storage enhances fruit preservation by continuously monitoring and adjusting oxygen and carbon dioxide levels to suppress respiration and delay ripening more effectively than Modified Atmosphere Storage (MAS), which relies on passive gas composition changes. DCA technology improves shelf life and reduces post-harvest losses by maintaining optimal atmospheric conditions tailored to fruit-specific metabolic rates.

Ultra-Low Oxygen (ULO) Storage

Ultra-Low Oxygen (ULO) Storage, a subset of Controlled Atmosphere (CA) Storage, maintains oxygen levels below 1% with precise control of carbon dioxide and humidity to extend fruit shelf life and reduce respiration rates. Unlike Modified Atmosphere Storage (MAS), which alters gases passively, ULO Storage actively regulates atmospheric composition, providing superior preservation for climacteric fruits such as apples and pears during long-term post-harvest storage.

Respiration Rate Monitoring

Controlled Atmosphere Storage (CA) precisely regulates oxygen, carbon dioxide, and humidity levels to significantly reduce fruit respiration rates and extend shelf life, enabling real-time monitoring and adjustment for optimal preservation. Modified Atmosphere Storage (MA) alters gas composition naturally through packaging, but offers less control over respiration rate variations, making it less effective for long-term storage compared to CA systems.

Ethylene Scrubbing

Controlled Atmosphere Storage incorporates ethylene scrubbing systems to effectively remove ethylene gas, significantly slowing fruit ripening and extending shelf life by reducing metabolic activity. Modified Atmosphere Storage relies on passive gas composition changes, offering limited ethylene removal, which can result in faster ripening and reduced preservation efficacy compared to controlled environments.

O2/CO2 Ratio Optimization

Controlled Atmosphere Storage maintains a precisely regulated O2/CO2 ratio to slow fruit respiration and extend shelf life, often achieving oxygen levels as low as 1-3% and carbon dioxide levels around 1-5%. Modified Atmosphere Storage alters the O2/CO2 ratio passively through packaging materials, resulting in less precise gas balance control but offering cost-effective preservation by reducing oxygen to 3-10% and increasing carbon dioxide to 3-10%.

Perforation-Mediated Packaging

Controlled Atmosphere Storage (CA) maintains precise gas concentrations, temperature, and humidity to extend fruit shelf life, while Modified Atmosphere Storage (MA) relies on perforation-mediated packaging to regulate gas exchange passively, enhancing fruit preservation by balancing oxygen and carbon dioxide levels. Perforation-mediated packaging in MA systems optimizes respiration rates and reduces spoilage by allowing dynamic gas movement, offering cost-effective and scalable solutions compared to the complex infrastructure of CA storage.

Real-Time Gas Sensing

Controlled Atmosphere Storage (CAS) utilizes precise regulation of oxygen, carbon dioxide, and humidity levels through integrated real-time gas sensing systems, enabling dynamic adjustments to optimize fruit preservation and reduce spoilage. Modified Atmosphere Storage (MAS), while also adjusting gas compositions, often relies on passive methods with limited real-time monitoring, resulting in less precise control over the storage environment and potentially shorter shelf life for perishable fruits.

Nitrogen Flushing

Controlled Atmosphere Storage (CAS) maintains low oxygen and high nitrogen levels through continuous monitoring and regulation, optimizing fruit respiration and extending shelf life, while Modified Atmosphere Storage (MAS) achieves elevated nitrogen concentrations primarily via nitrogen flushing, creating an oxygen-reduced environment that slows metabolic processes. Nitrogen flushing in MAS rapidly displaces oxygen around the fruit, reducing oxidative spoilage and microbial growth, but lacks the precise environmental control of CAS, impacting the consistency of preservation outcomes.

Microbial Spoilage Inhibition

Controlled Atmosphere Storage (CAS) maintains precise oxygen and carbon dioxide levels, effectively suppressing microbial growth and prolonging fruit shelf life by inhibiting aerobic spoilage organisms. Modified Atmosphere Storage (MAS) alters gas compositions passively or actively, reducing microbial spoilage but with less control over specific gas concentrations compared to CAS, leading to variable efficacy in inhibiting microbial spoilage.

Interactive MAP Films

Interactive MAP films enhance Modified Atmosphere Storage by actively regulating gas exchange and moisture levels, optimizing fruit preservation and extending shelf life compared to traditional Controlled Atmosphere Storage which relies on static gas composition. These advanced films respond dynamically to fruit respiration, reducing spoilage and maintaining firmness through precise oxygen and carbon dioxide control within the packaging environment.

Controlled Atmosphere Storage vs Modified Atmosphere Storage for fruit preservation Infographic

agridif.com

agridif.com