Conveyor sorting relies on manual or mechanical separation to remove defects, offering simplicity and cost-effectiveness for small-scale operations. Optical sorting utilizes advanced sensors and machine learning algorithms to identify and eliminate defective produce with high precision and speed. Optical sorting significantly enhances efficiency and accuracy compared to conveyor sorting, reducing labor costs and improving product quality in post-harvest technology.

Table of Comparison

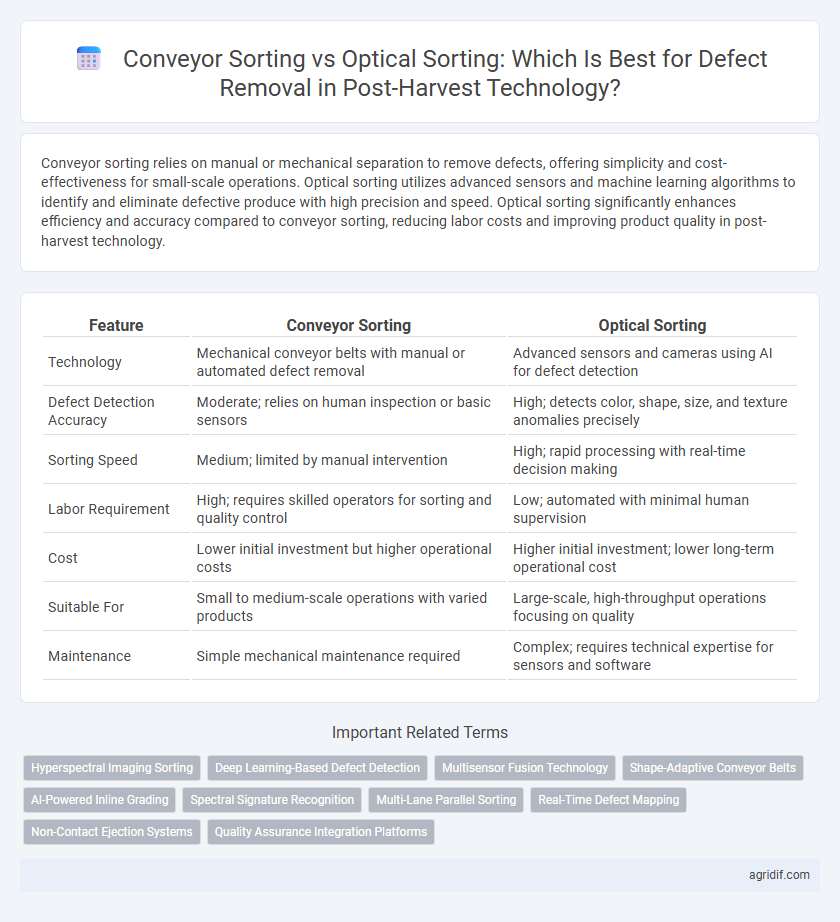

| Feature | Conveyor Sorting | Optical Sorting |

|---|---|---|

| Technology | Mechanical conveyor belts with manual or automated defect removal | Advanced sensors and cameras using AI for defect detection |

| Defect Detection Accuracy | Moderate; relies on human inspection or basic sensors | High; detects color, shape, size, and texture anomalies precisely |

| Sorting Speed | Medium; limited by manual intervention | High; rapid processing with real-time decision making |

| Labor Requirement | High; requires skilled operators for sorting and quality control | Low; automated with minimal human supervision |

| Cost | Lower initial investment but higher operational costs | Higher initial investment; lower long-term operational cost |

| Suitable For | Small to medium-scale operations with varied products | Large-scale, high-throughput operations focusing on quality |

| Maintenance | Simple mechanical maintenance required | Complex; requires technical expertise for sensors and software |

Introduction to Defect Removal in Post-Harvest Technology

Conveyor sorting and optical sorting are essential methods in post-harvest technology for efficient defect removal in agricultural produce. Conveyor sorting relies on manual or mechanical separation based on size, shape, and visible defects, while optical sorting employs advanced sensors and imaging technologies to detect and eliminate defective items with higher precision. Implementing these sorting techniques enhances product quality, reduces waste, and optimizes overall processing efficiency in the post-harvest supply chain.

Overview of Conveyor Sorting Systems

Conveyor sorting systems use mechanical methods to separate defective produce based on size, weight, and manual inspection, offering a cost-effective solution for small to medium-scale operations. These systems provide continuous product flow, enhancing processing efficiency but rely heavily on human labor for defect identification. While less precise than optical sorting, conveyor sorting offers straightforward maintenance and adaptability in post-harvest defect removal processes.

Fundamentals of Optical Sorting Technology

Optical sorting technology utilizes advanced sensors such as near-infrared (NIR), RGB cameras, and laser detection to identify and remove defects from harvested produce with high precision. This technology analyzes shape, size, color, and spectral signatures in real time, allowing it to distinguish subtle quality differences that traditional conveyor sorting cannot detect. By integrating artificial intelligence and machine learning algorithms, optical sorters enhance defect removal efficiency, reduce product waste, and improve overall post-harvest quality control.

Sorting Accuracy: Conveyor vs Optical Methods

Conveyor sorting relies on manual inspection or basic mechanical mechanisms resulting in moderate sorting accuracy for defect removal in post-harvest technology. Optical sorting employs advanced sensors and imaging systems to detect subtle variations in color, shape, and texture, achieving higher precision and consistency in identifying defective produce. Enhanced sorting accuracy of optical methods significantly reduces false positives and improves overall product quality compared to traditional conveyor sorting techniques.

Speed and Efficiency Comparison

Conveyor sorting systems offer rapid throughput with a continuous flow mechanism, ideal for handling large volumes of produce in post-harvest processing. Optical sorting leverages advanced imaging technology combined with AI algorithms, enabling precise defect detection at high speeds, often surpassing manual inspection rates. While conveyor sorting excels in volume capacity, optical sorting optimizes efficiency by minimizing false positives and ensuring higher accuracy in defect removal.

Labor Requirements and Automation Potential

Conveyor sorting in post-harvest technology demands significant manual labor for defect identification and removal, limiting throughput efficiency. Optical sorting systems leverage advanced imaging and sensor technologies to automate defect detection with minimal human intervention, increasing processing speed and consistency. Automation potential in optical sorting reduces labor costs and enhances scalability, making it ideal for large-scale operations focused on quality control.

Handling Delicate and High-Value Crops

Conveyor sorting offers gentle handling of delicate and high-value crops, minimizing mechanical stress and reducing bruising during defect removal. Optical sorting employs advanced imaging technology to detect and eliminate defects with high precision, ensuring quality standards without physical contact. Combining both methods can optimize throughput and product integrity while preserving the value of sensitive agricultural produce.

Implementation Costs and Return on Investment

Conveyor sorting systems typically involve lower initial implementation costs due to simpler mechanical setups, but their efficiency in defect removal is limited compared to optical sorting technologies. Optical sorting, though requiring higher upfront investment in sensors and software, offers superior accuracy and speed, leading to faster return on investment through reduced product waste and increased throughput. Long-term operational savings and enhanced product quality often justify the higher capital expenditure of optical sorting in post-harvest defect removal processes.

Impacts on Quality and Waste Reduction

Conveyor sorting provides efficient physical separation of defective produce based on size and weight, preserving overall product quality but may miss subtle defects. Optical sorting utilizes advanced sensors and imaging technology to identify and remove surface blemishes, discolorations, and internal defects, significantly enhancing quality consistency. Together, these technologies reduce waste by minimizing the inclusion of substandard items and maximizing yield from harvested crops.

Future Trends in Post-Harvest Sorting Technologies

Future trends in post-harvest sorting technologies emphasize integration of advanced AI and machine learning algorithms in optical sorting systems for enhanced defect detection and classification. Conveyor sorting, traditionally reliant on manual inspection, is increasingly complemented by sensor-based automation to improve throughput and accuracy. The convergence of hyperspectral imaging and real-time data analytics promises significant advancements in sorting efficiency, reducing waste and improving overall product quality in agricultural supply chains.

Related Important Terms

Hyperspectral Imaging Sorting

Hyperspectral imaging sorting in post-harvest technology offers superior defect detection by capturing detailed spectral information beyond visible wavelengths, enabling precise identification of internal and external produce defects that traditional conveyor sorting methods miss. This advanced optical sorting technique enhances quality control by reducing false positives and increasing throughput, making it a vital tool for efficient, high-accuracy defect removal in agricultural processing.

Deep Learning-Based Defect Detection

Deep learning-based defect detection in post-harvest technology significantly enhances optical sorting accuracy by automatically identifying and classifying subtle defects in produce, outperforming traditional conveyor sorting methods that rely on manual inspection or basic sensor inputs. Optical sorting integrated with advanced neural networks enables real-time analysis and precise defect removal, increasing throughput and reducing waste compared to conventional conveyor sorting systems.

Multisensor Fusion Technology

Multisensor fusion technology enhances defect removal by integrating data from conveyor sorting sensors and optical sorting systems, improving accuracy in identifying and separating defective produce. This combined approach leverages spectral, visual, and tactile sensor inputs to optimize sorting efficiency and reduce post-harvest losses.

Shape-Adaptive Conveyor Belts

Shape-adaptive conveyor belts enhance defect removal efficiency in post-harvest technology by physically adjusting to fruit contours for precise sorting, reducing mechanical damage and improving throughput compared to conventional conveyor sorting. Optical sorting, relying on multispectral imaging and machine learning algorithms, excels in identifying surface defects and color inconsistencies but cannot adapt physically to irregular shapes, which limits its effectiveness in sorting delicate or oddly shaped produce.

AI-Powered Inline Grading

AI-powered inline grading in optical sorting systems surpasses traditional conveyor sorting by utilizing advanced machine learning algorithms to accurately detect and classify defects in real-time. This technology enhances post-harvest quality control by increasing sorting precision, reducing human error, and enabling rapid processing of agricultural produce.

Spectral Signature Recognition

Conveyor sorting relies on mechanical and visual inspection to identify defects, while optical sorting utilizes spectral signature recognition to detect subtle differences in product quality based on specific wavelengths of reflected or transmitted light. Spectral signature recognition enhances defect removal accuracy by precisely identifying contaminants, discoloration, and internal defects that conventional conveyor sorting systems may overlook.

Multi-Lane Parallel Sorting

Multi-lane parallel sorting in conveyor systems enhances defect removal efficiency by increasing throughput and enabling simultaneous processing of multiple product streams, reducing sorting time per unit. Optical sorting leverages advanced imaging technology and real-time analysis to identify and eliminate defects with high precision, surpassing traditional conveyor sorting in accuracy and adaptability for complex criteria.

Real-Time Defect Mapping

Optical sorting utilizes advanced sensors and machine learning algorithms to perform precise real-time defect mapping, enhancing accuracy in identifying and removing damaged produce during post-harvest processing. Conveyor sorting relies on mechanical separation and manual inspection, offering lower resolution in defect detection and slower response times compared to optical systems.

Non-Contact Ejection Systems

Non-contact ejection systems in optical sorting utilize precise air jets or mechanical blowers to remove defective produce without physical contact, minimizing damage and maintaining product integrity. Conveyor sorting relies more on manual or mechanical means that can be less efficient in detecting subtle defects, leading to lower accuracy and potential fruit bruising.

Quality Assurance Integration Platforms

Conveyor sorting systems provide mechanical defect removal by physically separating damaged produce, ensuring consistent throughput and minimizing manual labor costs. Optical sorting leverages advanced sensors and machine learning algorithms within Quality Assurance Integration Platforms to detect and exclude subtle defects with higher precision, enhancing overall product quality and traceability.

Conveyor Sorting vs Optical Sorting for defect removal Infographic

agridif.com

agridif.com