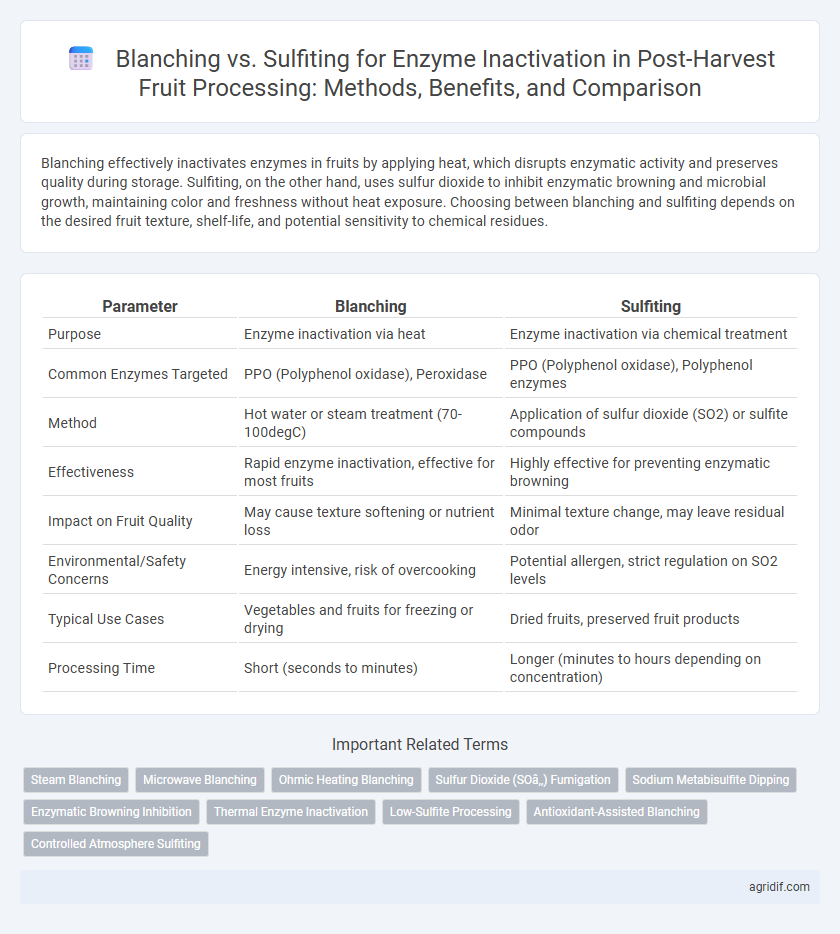

Blanching effectively inactivates enzymes in fruits by applying heat, which disrupts enzymatic activity and preserves quality during storage. Sulfiting, on the other hand, uses sulfur dioxide to inhibit enzymatic browning and microbial growth, maintaining color and freshness without heat exposure. Choosing between blanching and sulfiting depends on the desired fruit texture, shelf-life, and potential sensitivity to chemical residues.

Table of Comparison

| Parameter | Blanching | Sulfiting |

|---|---|---|

| Purpose | Enzyme inactivation via heat | Enzyme inactivation via chemical treatment |

| Common Enzymes Targeted | PPO (Polyphenol oxidase), Peroxidase | PPO (Polyphenol oxidase), Polyphenol enzymes |

| Method | Hot water or steam treatment (70-100degC) | Application of sulfur dioxide (SO2) or sulfite compounds |

| Effectiveness | Rapid enzyme inactivation, effective for most fruits | Highly effective for preventing enzymatic browning |

| Impact on Fruit Quality | May cause texture softening or nutrient loss | Minimal texture change, may leave residual odor |

| Environmental/Safety Concerns | Energy intensive, risk of overcooking | Potential allergen, strict regulation on SO2 levels |

| Typical Use Cases | Vegetables and fruits for freezing or drying | Dried fruits, preserved fruit products |

| Processing Time | Short (seconds to minutes) | Longer (minutes to hours depending on concentration) |

Introduction to Post-Harvest Enzyme Inactivation

Post-harvest enzyme inactivation is critical for maintaining fruit quality by preventing enzymatic browning and texture degradation. Blanching involves briefly exposing fruits to hot water or steam, effectively denaturing enzymes like polyphenol oxidase, while sulfiting uses sulfur dioxide to inhibit enzymatic activity and microbial growth. Both methods aim to preserve color, flavor, and nutritional value during storage and processing, with selection depending on fruit type and desired shelf life.

The Role of Enzymes in Fruit Spoilage

Enzymes such as polyphenol oxidase and peroxidase play a critical role in fruit spoilage by catalyzing browning and degradation reactions after harvest. Blanching inactivates these enzymes through heat treatment, effectively reducing enzymatic browning and microbial growth in fruits. Sulfiting inhibits enzyme activity by chemically binding to enzyme active sites, preventing oxidation and preserving fruit quality during storage.

Blanching: Mechanism and Process Overview

Blanching in post-harvest technology involves briefly heating fruits in hot water or steam to inactivate enzymes like polyphenol oxidase and peroxidase, preventing browning and spoilage. The process denatures enzyme proteins by disrupting their tertiary and quaternary structures through thermal energy, effectively halting enzymatic reactions. This technique is widely used due to its simplicity, effectiveness, and minimal impact on fruit texture and nutritional quality compared to chemical methods like sulfiting.

Sulfiting: Chemical-Based Enzyme Inactivation

Sulfiting is a chemical-based method widely used for enzyme inactivation in post-harvest fruit processing, effectively inhibiting polyphenol oxidase and peroxidase enzymes responsible for browning. The addition of sulfur dioxide or sulfite salts disrupts enzymatic activity, preserving fruit color, flavor, and nutritional quality during storage and processing. Compared to blanching, sulfiting offers a lower thermal impact, maintaining fruit texture and reducing energy consumption while ensuring microbial stability.

Comparative Efficacy: Blanching vs Sulfiting

Blanching effectively inactivates enzymes in fruits by applying high-temperature steam or hot water, rapidly denaturing enzymes such as polyphenol oxidase and peroxidase, which prevents browning and preserves color. Sulfiting, using sulfur dioxide or sulfite salts, inhibits enzymatic activity chemically by binding to the active sites of enzymes, but may leave residues affecting flavor and generating regulatory concerns. Comparative studies indicate blanching offers superior enzyme inactivation and minimal impact on sensory quality, while sulfiting provides partial inhibition but with potential health risks and consumer sensitivity issues.

Impact on Fruit Quality and Nutritional Value

Blanching effectively inactivates enzymes such as polyphenol oxidase and peroxidase, preserving fruit color and texture while minimizing nutrient loss, particularly vitamin C and carotenoids. Sulfiting inhibits enzymatic browning by targeting sulfite-sensitive enzymes but may negatively affect flavor, cause allergenic reactions, and reduce nutritional quality due to sulfite residues. The choice between blanching and sulfiting depends on balancing enzyme inactivation efficiency with the preservation of fruit sensory attributes and nutritional integrity.

Health and Safety Considerations

Blanching effectively inactivates enzymes in fruits by applying heat, ensuring microbial safety without chemical residues, which makes it a safer option for health-conscious consumers. Sulfiting utilizes sulfur dioxide to inhibit enzymatic browning and microbial growth but poses risks of allergic reactions and respiratory issues, particularly for sensitive individuals. Careful regulation and labeling are essential when using sulfiting agents to mitigate potential health hazards in post-harvest fruit processing.

Environmental and Economic Factors

Blanching and sulfiting are key methods for enzyme inactivation in post-harvest fruit processing with distinct environmental and economic impacts. Blanching, involving heat treatment, often requires significant energy consumption and water usage, raising operational costs and environmental footprint. Sulfiting uses sulfur dioxide, which is more cost-effective and energy-efficient but poses environmental and health concerns due to chemical residues and potential allergenicity.

Application Suitability for Different Fruits

Blanching effectively inactivates enzymes like polyphenol oxidase in fruits such as apples, potatoes, and peaches by applying high-temperature steam or hot water, making it suitable for heat-tolerant produce. Sulfiting, using sulfur dioxide, is preferred for delicate fruits like grapes and apricots where thermal treatment may cause texture or flavor degradation. Selecting between blanching and sulfiting depends on fruit sensitivity, enzyme activity levels, and the desired retention of sensory qualities during post-harvest processing.

Future Trends in Fruit Enzyme Inactivation Techniques

Emerging trends in fruit enzyme inactivation emphasize eco-friendly and non-thermal methods surpassing traditional blanching and sulfiting techniques. Advanced technologies such as pulsed electric fields and cold plasma offer precise enzyme control with minimal nutrient loss and improved sensory quality. Ongoing research prioritizes sustainability and consumer safety while enhancing shelf life and maintaining fruit freshness without sulfite residues.

Related Important Terms

Steam Blanching

Steam blanching effectively inactivates polyphenol oxidase and peroxidase enzymes in fruits by applying high-temperature steam, preserving texture and nutrient content without significant leaching of water-soluble vitamins. Compared to sulfiting, steam blanching avoids chemical residues and potential allergenic reactions while maintaining enzymatic stability crucial for extended shelf life in post-harvest processing.

Microwave Blanching

Microwave blanching offers rapid and uniform enzyme inactivation in fruits, preserving texture, color, and nutrient retention more effectively than traditional sulfiting methods, which rely on chemical inhibition and may leave residual sulfur compounds. This non-thermal technique minimizes enzyme activity such as polyphenol oxidase and peroxidase without compromising fruit quality or introducing chemical additives.

Ohmic Heating Blanching

Ohmic heating blanching offers rapid and uniform enzyme inactivation in fruits by passing electrical current through the product, minimizing thermal damage compared to traditional sulfiting methods that rely on chemical inhibition and pose potential health risks. This innovative post-harvest technology enhances microbial safety and preserves sensory and nutritional quality while avoiding sulfite residues often associated with allergies and regulatory restrictions.

Sulfur Dioxide (SO₂) Fumigation

Sulfur Dioxide (SO2) fumigation effectively inactivates polyphenol oxidase enzymes in fruits, preventing enzymatic browning and preserving quality during post-harvest storage. Compared to blanching, SO2 treatment maintains better texture and nutritional value while providing antimicrobial properties and extending shelf life.

Sodium Metabisulfite Dipping

Sodium metabisulfite dipping effectively inactivates polyphenol oxidase enzymes in fruits, preventing enzymatic browning and maintaining color quality during post-harvest handling. Compared to blanching, sulfiting preserves texture and nutritional content by avoiding heat-induced cellular damage.

Enzymatic Browning Inhibition

Blanching rapidly inactivates polyphenol oxidase enzymes in fruits, effectively preventing enzymatic browning by denaturing proteins through heat. Sulfiting inhibits enzymatic browning by chemically interacting with quinones, but carries potential health risks and regulatory restrictions compared to the thermal method of blanching.

Thermal Enzyme Inactivation

Blanching effectively inactivates enzymes in fruits through controlled heating, usually between 70-100degC for short durations, which denatures proteins and halts enzymatic browning. Sulfiting, by contrast, inhibits enzyme activity chemically via sulfur dioxide but does not apply thermal energy, making blanching more suitable for thermal enzyme inactivation in post-harvest fruit processing.

Low-Sulfite Processing

Low-sulfite processing effectively inactivates polyphenol oxidase enzymes in fruits while minimizing sulfite residues, preserving sensory quality and meeting regulatory limits for consumer safety. Blanching controls enzymatic browning through thermal denaturation but may cause texture and nutrient loss, making low-sulfite methods a preferred alternative for delicate fruits.

Antioxidant-Assisted Blanching

Antioxidant-assisted blanching enhances enzyme inactivation in fruits more effectively than traditional sulfiting by preserving phenolic compounds and reducing enzymatic browning. This method leverages natural antioxidants to stabilize color and nutritional quality, optimizing post-harvest shelf life and fruit quality.

Controlled Atmosphere Sulfiting

Controlled Atmosphere Sulfiting effectively inhibits polyphenol oxidase activity in fruits, preserving color and texture by generating sulfur dioxide within a sealed environment. Compared to blanching, this method offers superior enzyme inactivation while minimizing heat damage and nutrient loss during post-harvest processing.

Blanching vs Sulfiting for enzyme inactivation in fruits Infographic

agridif.com

agridif.com