Waxing and coating both enhance fruit shelf life by creating barriers that reduce moisture loss and delay ripening. Waxing typically involves applying a thin layer of natural or synthetic wax that improves gloss and water retention, while coatings often use edible polymers that provide more controlled gas exchange and can include antimicrobial properties. Choosing between waxing and coating depends on the specific fruit type, desired shelf life, and consumer preferences for natural or synthetic treatments.

Table of Comparison

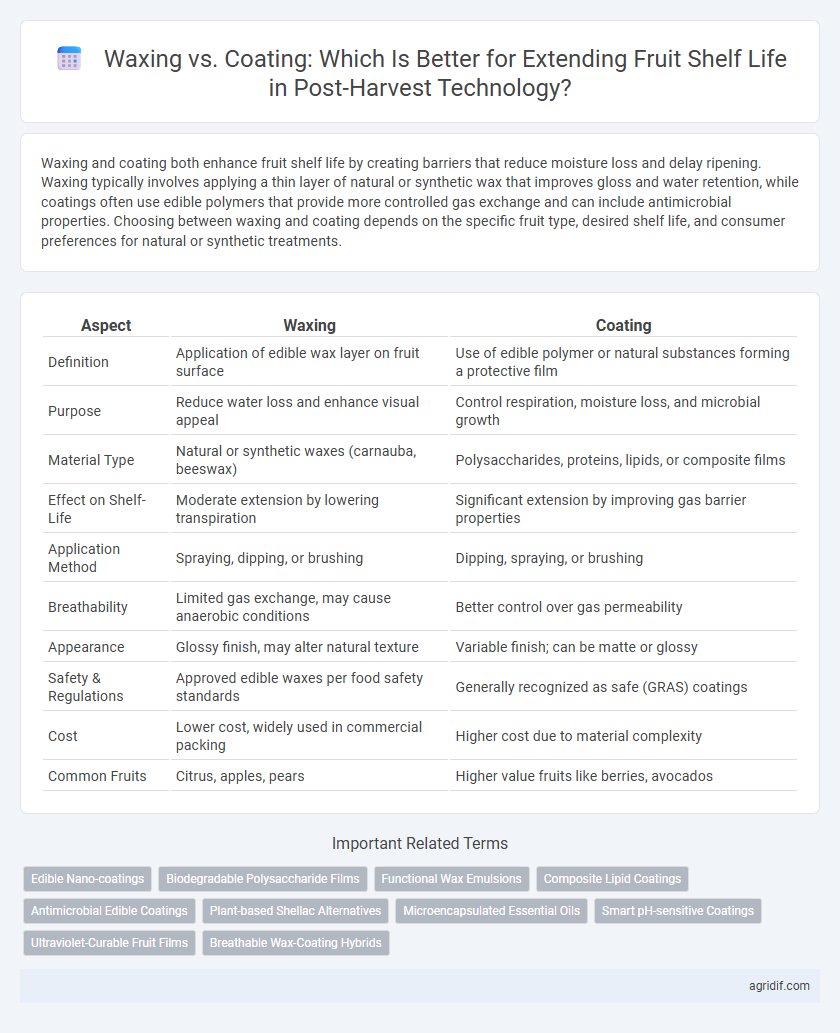

| Aspect | Waxing | Coating |

|---|---|---|

| Definition | Application of edible wax layer on fruit surface | Use of edible polymer or natural substances forming a protective film |

| Purpose | Reduce water loss and enhance visual appeal | Control respiration, moisture loss, and microbial growth |

| Material Type | Natural or synthetic waxes (carnauba, beeswax) | Polysaccharides, proteins, lipids, or composite films |

| Effect on Shelf-Life | Moderate extension by lowering transpiration | Significant extension by improving gas barrier properties |

| Application Method | Spraying, dipping, or brushing | Dipping, spraying, or brushing |

| Breathability | Limited gas exchange, may cause anaerobic conditions | Better control over gas permeability |

| Appearance | Glossy finish, may alter natural texture | Variable finish; can be matte or glossy |

| Safety & Regulations | Approved edible waxes per food safety standards | Generally recognized as safe (GRAS) coatings |

| Cost | Lower cost, widely used in commercial packing | Higher cost due to material complexity |

| Common Fruits | Citrus, apples, pears | Higher value fruits like berries, avocados |

Introduction to Post-Harvest Fruit Preservation

Waxing and coating are essential techniques in post-harvest technology aimed at extending fruit shelf-life by reducing moisture loss and slowing down respiration rates. Waxing involves applying a thin layer of natural or synthetic wax to create a moisture barrier, while coatings can include edible films formulated with polymers, lipids, or proteins that provide additional protection and sometimes incorporate antimicrobial agents. Both methods optimize fruit quality maintenance during storage and transportation, crucial for reducing post-harvest losses and ensuring market value.

Understanding Waxing: Methods and Materials

Waxing involves applying a thin layer of natural or synthetic waxes like carnauba, beeswax, or shellac to fruit surfaces to reduce moisture loss and slow respiration rates, thereby extending shelf life. Common methods include brushing, dipping, or spraying, ensuring uniform coverage while maintaining fruit permeability to gases. Material selection depends on fruit type and regulatory standards, aiming to balance barrier properties with consumer safety and product appearance.

Exploring Edible Coatings for Fruit Shelf-Life

Edible coatings for fruit shelf-life extension offer a biodegradable and safe alternative to traditional waxing, enhancing fruit quality by reducing moisture loss, delaying ripening, and minimizing microbial spoilage. These coatings, often composed of natural polymers like chitosan, starch, or alginate, create a semi-permeable barrier that regulates gas exchange, thereby maintaining firmness and freshness longer. Research demonstrates that edible coatings improve post-harvest performance while meeting consumer demand for environmentally friendly and health-conscious packaging solutions.

Comparative Efficacy: Waxing vs Coating

Waxing creates a semi-permeable barrier on fruit surfaces that reduces moisture loss and gas exchange, effectively extending shelf life by maintaining firmness and inhibiting microbial growth. Coatings, often composed of natural polymers like chitosan or polysaccharides, provide a tailored protective layer that can include antifungal agents and improve gas exchange regulation, enhancing fruit quality and longevity. Comparative studies show coatings generally offer superior efficacy over waxing by combining physical protection with bioactive functions that better preserve post-harvest fruit attributes.

Impact on Fruit Quality and Appearance

Waxing and coating treatments significantly influence fruit shelf-life extension by enhancing surface protection and reducing moisture loss. Waxing forms a thin, uniform layer that preserves natural gloss and firmness, maintaining the fruit's fresh appearance and texture. Coatings, often composed of edible polymers or natural extracts, create a barrier that can also improve gas exchange control, but may alter surface shine and occasionally affect flavor, requiring careful formulation to balance quality and visual appeal.

Moisture Loss Reduction Mechanisms

Waxing and coating both serve to reduce moisture loss in fruits by creating a semi-permeable barrier that slows down water vapor diffusion. Waxing typically forms a thin, hydrophobic layer that fills surface pores, effectively minimizing transpiration and maintaining fruit turgidity. Coating involves applying edible films composed of polysaccharides, lipids, or proteins, which control moisture loss by adjusting permeability and enhancing the fruit's natural protective barrier.

Effects on Nutrient Retention and Flavor

Waxing fruits creates a thin, moisture-retentive barrier that slows respiration and helps preserve vitamin C and antioxidants, but may slightly alter flavor by trapping volatile compounds. Coating techniques, often using edible substances like chitosan or aloe vera, enhance nutrient retention by reducing oxidative stress and microbial spoilage while maintaining more natural fruit aroma and taste profiles. Both methods effectively extend shelf life, but coatings tend to better preserve flavor intensity and overall nutritional quality compared to traditional waxing.

Safety and Regulatory Considerations

Waxing and coating technologies both play crucial roles in extending fruit shelf-life by reducing moisture loss and delaying spoilage, with regulatory agencies like the FDA and EFSA approving specific edible waxes and coatings based on safety assessments. Waxing materials, typically composed of carnauba, shellac, or beeswax, must meet stringent purity and residue limits to prevent toxicological hazards, while coatings often incorporate biopolymers and antimicrobial agents subject to ongoing regulatory evaluation. Ensuring compliance with international standards such as Codex Alimentarius is essential for market access and consumer safety, as residues beyond permissible levels can lead to trade restrictions and health risks.

Consumer Perceptions and Market Trends

Waxing enhances fruit shelf-life by creating a moisture barrier while maintaining natural appearance, appealing to consumers seeking minimal processing. Coating technologies, often made from edible polymers, offer advanced protection against spoilage and can be tailored with antimicrobial properties, attracting health-conscious buyers. Market trends indicate a growing preference for biodegradable and organic coatings as consumers increasingly demand sustainable and clean-label fruit preservation methods.

Future Prospects in Fruit Shelf-Life Extension

Future prospects in fruit shelf-life extension emphasize advanced edible coatings integrated with natural antimicrobial agents and nanomaterials, surpassing traditional waxing methods in preserving freshness and reducing spoilage. Innovations in biodegradable polymers and smart coatings capable of responding to environmental changes offer targeted protection, extending shelf-life while maintaining fruit quality. Ongoing research prioritizes sustainable solutions that enhance post-harvest protection with minimal environmental impact, supporting global food security efforts.

Related Important Terms

Edible Nano-coatings

Edible nano-coatings utilize nanoparticles to create a thin, breathable film on fruit surfaces that significantly reduces moisture loss and delays ripening, outperforming traditional waxing methods in extending shelf life. These coatings enhance gas exchange, provide antimicrobial properties, and improve fruit quality by maintaining firmness and reducing microbial spoilage during storage.

Biodegradable Polysaccharide Films

Biodegradable polysaccharide films improve fruit shelf-life by forming an edible, semi-permeable barrier that reduces moisture loss and gas exchange, thereby maintaining post-harvest quality better than conventional wax coatings. These films, derived from natural sources such as chitosan, alginate, and cellulose, enhance biodegradability and reduce environmental impact while providing antimicrobial properties that further protect fruit during storage.

Functional Wax Emulsions

Functional wax emulsions enhance fruit shelf-life by creating a breathable barrier that reduces moisture loss and slows respiration, maintaining firmness and freshness. Unlike traditional coatings, these emulsions offer superior adhesion and compatibility with various fruit surfaces, optimizing protection without compromising gas exchange essential for fruit quality.

Composite Lipid Coatings

Composite lipid coatings significantly enhance fruit shelf-life by creating a semi-permeable barrier that regulates moisture loss and gas exchange, effectively reducing respiration and delaying ripening. Compared to traditional waxing, these coatings offer improved biodegradability and compatibility with fruit surfaces, promoting better preservation of texture and nutritional quality during storage.

Antimicrobial Edible Coatings

Antimicrobial edible coatings enhance fruit shelf-life by forming a protective barrier that reduces microbial growth, moisture loss, and oxidation, outperforming traditional waxing methods that mainly provide a physical surface seal. These coatings often incorporate natural antimicrobial agents like essential oils or chitosan, improving preservation while maintaining fruit quality and safety.

Plant-based Shellac Alternatives

Plant-based shellac alternatives such as carnauba wax and candelilla wax offer sustainable, biodegradable options for fruit waxing, enhancing shelf-life by reducing moisture loss and delaying ripening while minimizing environmental impact. These natural coatings provide effective barriers against microbial infection and oxidative damage, extending post-harvest quality without chemical residues associated with synthetic coatings.

Microencapsulated Essential Oils

Microencapsulated essential oils integrated into fruit coatings provide a controlled release of natural antimicrobials, significantly extending shelf life by reducing microbial growth and oxidative damage compared to traditional waxing methods. Coatings incorporating these bioactive compounds enhance fruit quality preservation while offering an eco-friendly alternative to synthetic preservatives.

Smart pH-sensitive Coatings

Smart pH-sensitive coatings enhance fruit shelf-life by dynamically responding to changes in fruit surface acidity, thereby providing targeted antimicrobial and antioxidant protection compared to traditional waxing methods. These advanced coatings improve gas exchange and moisture retention, reducing spoilage and maintaining fruit quality during post-harvest storage.

Ultraviolet-Curable Fruit Films

Ultraviolet-Curable (UV-Curable) fruit films offer a superior alternative to traditional waxing by creating a thin, transparent barrier that enhances fruit shelf-life through improved gas exchange regulation and microbial resistance. These coatings cure rapidly under UV light, forming durable, eco-friendly films that minimize spoilage and maintain fruit quality without the drawbacks of conventional wax residues.

Breathable Wax-Coating Hybrids

Breathable wax-coating hybrids enhance fruit shelf-life by combining the moisture retention properties of wax with selective gas permeability, improving respiration rates and reducing decay. These advanced coatings create a protective barrier that maintains fruit firmness and freshness longer than traditional waxes or synthetic coatings alone.

Waxing vs Coating for fruit shelf-life extension Infographic

agridif.com

agridif.com