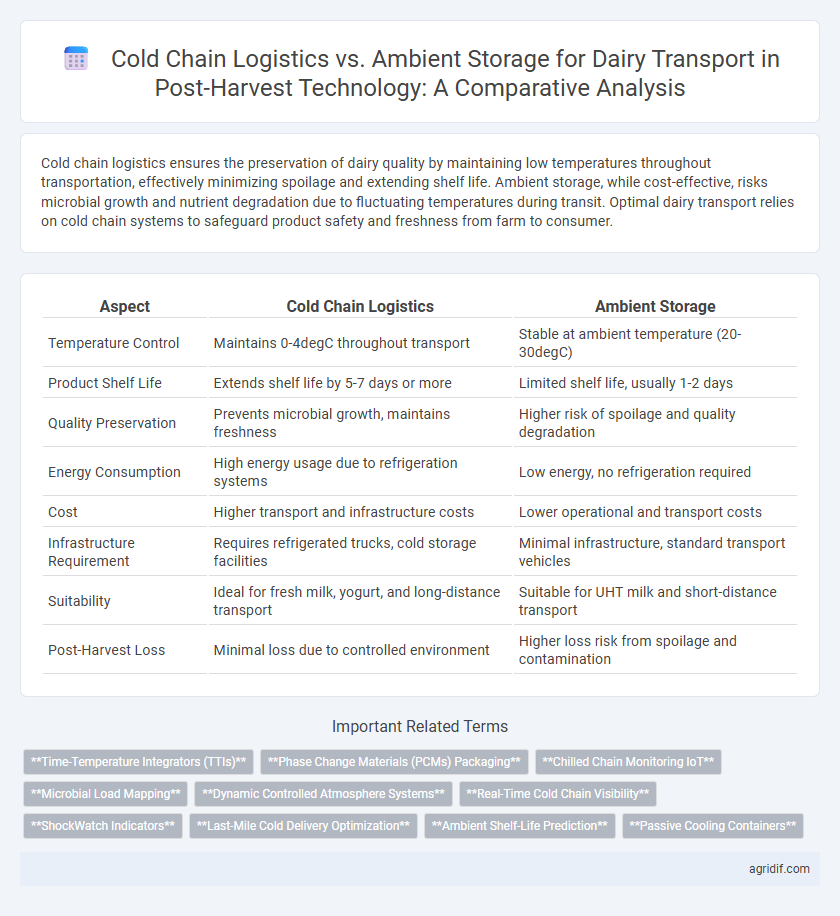

Cold chain logistics ensures the preservation of dairy quality by maintaining low temperatures throughout transportation, effectively minimizing spoilage and extending shelf life. Ambient storage, while cost-effective, risks microbial growth and nutrient degradation due to fluctuating temperatures during transit. Optimal dairy transport relies on cold chain systems to safeguard product safety and freshness from farm to consumer.

Table of Comparison

| Aspect | Cold Chain Logistics | Ambient Storage |

|---|---|---|

| Temperature Control | Maintains 0-4degC throughout transport | Stable at ambient temperature (20-30degC) |

| Product Shelf Life | Extends shelf life by 5-7 days or more | Limited shelf life, usually 1-2 days |

| Quality Preservation | Prevents microbial growth, maintains freshness | Higher risk of spoilage and quality degradation |

| Energy Consumption | High energy usage due to refrigeration systems | Low energy, no refrigeration required |

| Cost | Higher transport and infrastructure costs | Lower operational and transport costs |

| Infrastructure Requirement | Requires refrigerated trucks, cold storage facilities | Minimal infrastructure, standard transport vehicles |

| Suitability | Ideal for fresh milk, yogurt, and long-distance transport | Suitable for UHT milk and short-distance transport |

| Post-Harvest Loss | Minimal loss due to controlled environment | Higher loss risk from spoilage and contamination |

Introduction to Dairy Transport Methods

Cold chain logistics ensures the continuous refrigeration of dairy products from farm to consumer, preserving freshness and preventing microbial spoilage. Ambient storage relies on controlling storage duration and packaging to maintain product quality without refrigeration, suitable for shelf-stable dairy items like UHT milk and certain cheeses. Understanding the distinct temperature requirements and infrastructure demands for each method is crucial for optimizing dairy transport efficiency and product safety.

Understanding Cold Chain Logistics in Dairy

Cold chain logistics in dairy transport involves maintaining a consistent temperature range, typically between 1degC to 4degC, throughout the supply chain to preserve milk quality and prevent microbial growth. In contrast, ambient storage allows dairy products to be stored at room temperature, increasing the risk of spoilage and nutrient degradation. Effective cold chain management reduces spoilage rates by up to 30%, ensuring longer shelf life and maintaining the nutritional and sensory properties of dairy products during transport.

Ambient Storage: Definition and Application

Ambient storage for dairy transport refers to the practice of storing and transporting dairy products at room temperature without refrigeration. This method is commonly applied in regions with limited cold chain infrastructure, relying on shelf-stable dairy products like UHT milk, powdered milk, and certain fermented products designed to withstand ambient conditions. While ambient storage reduces energy costs and logistical complexity, it requires rigorous quality control and packaging technologies to maintain product safety and extend shelf life.

Temperature Sensitivity of Dairy Products

Dairy products require strict temperature control during transport to maintain quality and safety, making cold chain logistics essential for preventing spoilage and microbial growth. Ambient storage exposes dairy products to temperature fluctuations, accelerating deterioration and increasing the risk of contamination. Cold chain systems preserve the freshness and extend the shelf life of milk, cheese, and yogurt by maintaining temperatures typically between 0degC and 4degC.

Impact on Shelf Life and Product Quality

Cold chain logistics for dairy transport significantly extends shelf life by maintaining consistent temperatures between 0-4degC, preventing microbial growth and enzymatic spoilage. Ambient storage exposes dairy products to fluctuating temperatures, accelerating spoilage and reducing quality through increased bacterial proliferation and nutrient degradation. The controlled environment in cold chain logistics preserves sensory attributes and nutritional value, ensuring optimal product quality throughout distribution.

Cost Comparison: Cold Chain vs Ambient Storage

Cold chain logistics for dairy transport demands higher initial investment and operational expenses due to refrigeration equipment, energy consumption, and temperature monitoring. Ambient storage incurs lower costs by eliminating refrigeration needs but increases spoilage risks and limits shelf life, potentially raising product loss expenses. Cost-effectiveness depends on factors like transport duration, product sensitivity, and market requirements, with cold chain offering superior quality preservation despite higher costs.

Energy Consumption and Environmental Considerations

Cold chain logistics for dairy transport demands significantly higher energy consumption due to continuous refrigeration requirements, increasing carbon emissions compared to ambient storage methods. Ambient storage, while less energy-intensive, poses risks of spoilage and reduced shelf life, potentially leading to higher food waste and indirect environmental impacts. Balancing energy efficiency and environmental sustainability requires optimizing refrigeration technologies and exploring hybrid storage systems to minimize overall ecological footprint.

Infrastructure Requirements for Both Systems

Cold chain logistics for dairy transport demands specialized infrastructure such as refrigerated trucks, temperature-controlled warehouses, and insulated packaging to maintain product quality and safety. In contrast, ambient storage requires minimal cooling facilities but needs well-ventilated, humidity-controlled environments to prevent spoilage. Investment in reliable power supply and monitoring systems is critical for cold chain operations, while ambient storage emphasizes robust packaging and timely transportation to mitigate temperature fluctuations.

Risks of Spoilage and Contamination

Cold chain logistics for dairy transport significantly reduces the risks of spoilage and contamination by maintaining consistent low temperatures that inhibit microbial growth and enzymatic activity. Ambient storage exposes dairy products to fluctuating temperatures and humidity, increasing the likelihood of bacterial proliferation, quality degradation, and shorter shelf life. Maintaining an unbroken cold chain from farm to consumer is essential for preserving milk freshness, nutrient content, and food safety in the dairy supply chain.

Future Trends in Dairy Transportation Logistics

Future trends in dairy transportation logistics emphasize the integration of advanced cold chain technologies to maintain optimal temperature control, ensuring milk quality and extending shelf life. Innovations such as IoT-enabled smart sensors and real-time temperature monitoring are revolutionizing cold chain logistics, reducing spoilage and enhancing traceability. Despite the energy efficiency of ambient storage, the industry's shift toward sustainable, low-carbon cold chain solutions is shaping the future of dairy transport.

Related Important Terms

Time-Temperature Integrators (TTIs)

Time-Temperature Integrators (TTIs) provide crucial real-time monitoring of dairy products during cold chain logistics, ensuring the temperature-sensitive quality and safety are maintained from farm to consumer. In contrast, ambient storage lacks continuous temperature control, increasing the risk of spoilage and product degradation, making TTIs essential for validating cold chain efficacy in dairy transport.

Phase Change Materials (PCMs) Packaging

Phase Change Materials (PCMs) packaging in cold chain logistics for dairy transport maintains precise temperature control by absorbing and releasing latent heat, significantly reducing spoilage compared to ambient storage. This technology ensures extended freshness and safety of dairy products by stabilizing temperatures during transit, outperforming conventional storage methods that rely solely on ambient conditions.

Chilled Chain Monitoring IoT

Chilled Chain Monitoring IoT enhances cold chain logistics in dairy transport by providing real-time temperature tracking, ensuring optimal freshness and reducing spoilage compared to ambient storage. This technology integrates sensors and data analytics to maintain precise cooling conditions throughout transit, improving product quality and extending shelf life.

Microbial Load Mapping

Cold chain logistics significantly reduces microbial load in dairy transport by maintaining temperatures below 4degC, inhibiting bacterial growth and preserving product safety and quality. In contrast, ambient storage allows rapid microbial proliferation, increasing the risk of spoilage and foodborne illnesses due to lack of temperature control during transit.

Dynamic Controlled Atmosphere Systems

Dynamic Controlled Atmosphere (DCA) systems enhance cold chain logistics for dairy transport by precisely regulating temperature, humidity, and gas composition to maintain product freshness and extend shelf life compared to traditional ambient storage. These systems minimize microbial growth and enzymatic activity, ensuring superior quality and reducing spoilage during transit in the dairy supply chain.

Real-Time Cold Chain Visibility

Real-time cold chain visibility in dairy transport ensures continuous monitoring of temperature and humidity levels, preventing spoilage and maintaining product quality during transit. Unlike ambient storage, this technology enables immediate corrective actions and data-driven decision-making, enhancing supply chain transparency and reducing dairy losses significantly.

ShockWatch Indicators

ShockWatch indicators play a critical role in cold chain logistics by providing real-time monitoring of impact and temperature fluctuations during dairy transport, ensuring product integrity and reducing spoilage risk. Ambient storage lacks this precise monitoring capability, increasing the likelihood of quality degradation in dairy products due to unnoticed exposure to adverse conditions.

Last-Mile Cold Delivery Optimization

Last-mile cold delivery optimization in dairy transport enhances product quality by minimizing temperature fluctuations through insulated packaging and real-time temperature monitoring devices, ensuring freshness from collection to retailer. Implementing cold chain logistics outperforms ambient storage by reducing spoilage rates and extending shelf life, crucial for maintaining dairy safety and consumer satisfaction during transit.

Ambient Shelf-Life Prediction

Ambient shelf-life prediction in dairy transport relies on advanced modeling of temperature fluctuations and microbial growth under non-refrigerated conditions to optimize product quality without continuous cooling. Accurate prediction algorithms integrate intrinsic factors like pH and water activity with extrinsic parameters such as ambient temperature and humidity to forecast spoilage timelines, enabling better risk management compared to traditional cold chain logistics.

Passive Cooling Containers

Passive cooling containers in cold chain logistics significantly enhance the preservation of dairy products by maintaining consistent low temperatures without external energy sources, reducing spoilage and extending shelf life. Unlike ambient storage, which exposes dairy to temperature fluctuations and microbial growth, passive cooling containers leverage insulated materials and phase change materials to stabilize conditions during transport, ensuring product quality and safety.

Cold chain logistics vs Ambient storage for dairy transport Infographic

agridif.com

agridif.com