Wet sterilization effectively controls grain pests by using steam or hot water, ensuring deep penetration and rapid microbial elimination while preserving grain quality. Dry sterilization employs high temperatures without moisture, reducing insect infestation risk but may cause grain moisture loss and potential damage. Selecting the appropriate method depends on grain type, pest severity, and post-treatment storage conditions to maximize disinfestation efficacy and maintain grain viability.

Table of Comparison

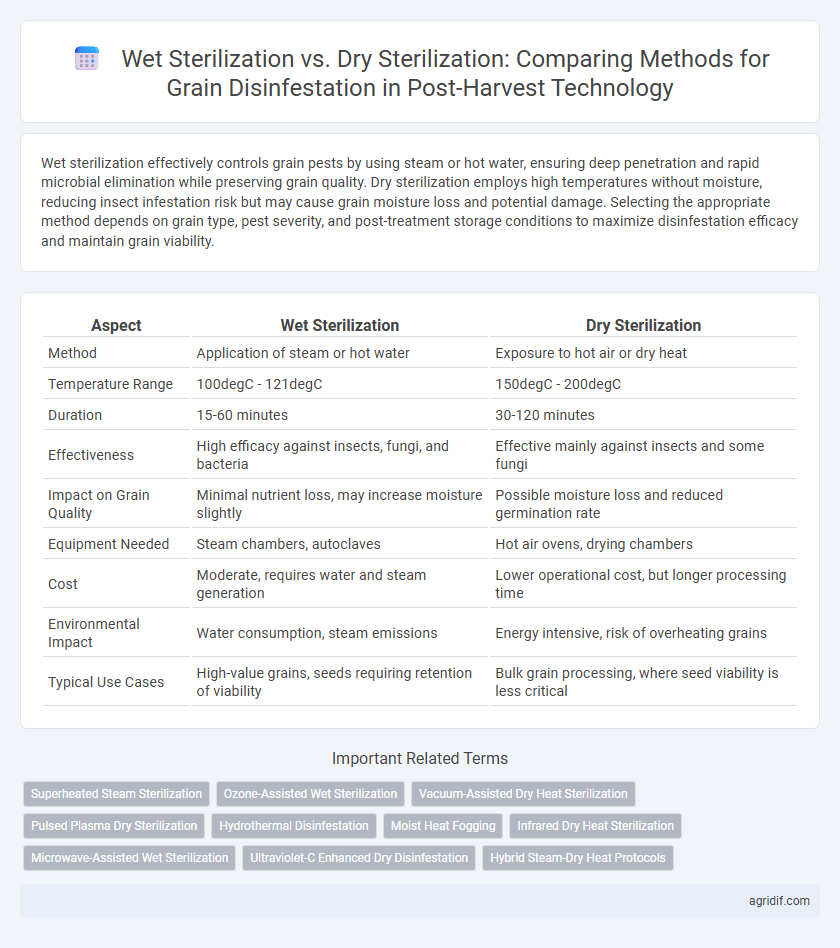

| Aspect | Wet Sterilization | Dry Sterilization |

|---|---|---|

| Method | Application of steam or hot water | Exposure to hot air or dry heat |

| Temperature Range | 100degC - 121degC | 150degC - 200degC |

| Duration | 15-60 minutes | 30-120 minutes |

| Effectiveness | High efficacy against insects, fungi, and bacteria | Effective mainly against insects and some fungi |

| Impact on Grain Quality | Minimal nutrient loss, may increase moisture slightly | Possible moisture loss and reduced germination rate |

| Equipment Needed | Steam chambers, autoclaves | Hot air ovens, drying chambers |

| Cost | Moderate, requires water and steam generation | Lower operational cost, but longer processing time |

| Environmental Impact | Water consumption, steam emissions | Energy intensive, risk of overheating grains |

| Typical Use Cases | High-value grains, seeds requiring retention of viability | Bulk grain processing, where seed viability is less critical |

Introduction to Grain Disinfestation Techniques

Grain disinfestation techniques include wet sterilization and dry sterilization, each targeting the elimination of pests and microorganisms in stored grains. Wet sterilization involves the use of steam or hot water to penetrate grain masses, effectively reducing insect infestation and microbial contamination while preserving grain quality. Dry sterilization employs high-temperature dry heat or controlled atmospheres, minimizing moisture-related damage and ensuring long-term grain storage stability.

Overview of Wet Sterilization Methods in Agriculture

Wet sterilization methods in agriculture involve the use of steam or hot water treatments to eliminate pests and pathogens from stored grains, ensuring disinfestation while preserving grain quality. These techniques offer precise temperature control, typically ranging from 60degC to 100degC, which effectively targets insects and microbial contaminants without causing thermal degradation of the grains. Wet sterilization is widely preferred for its efficiency in penetrating grain masses and reducing post-harvest losses in storage facilities.

Dry Sterilization: Principles and Practices

Dry sterilization in grain disinfestation utilizes high temperatures, typically between 130-160degC, to destroy insect pests without moisture, ensuring the grain's structural integrity and quality. This method relies on conduction and convection heat transfer principles, applying controlled exposure times to effectively eliminate insects while minimizing damage to the grain. Practical implementation includes specialized dry heat chambers or hot air ovens designed to maintain uniform temperature distribution, making it an energy-efficient and residue-free alternative to chemical fumigation.

Comparative Effectiveness: Wet vs Dry Sterilization

Wet sterilization, involving steam or hot water, achieves rapid microbial inactivation and effective grain disinfestation by penetrating kernels and reaching microbial spores. Dry sterilization relies on high temperature or radiation with limited penetration depth, often requiring longer exposure times for comparable efficacy. Studies demonstrate wet sterilization offers superior effectiveness in reducing insect pests and fungal contamination, preserving grain quality with minimal nutrient degradation.

Impact on Grain Quality and Nutritional Value

Wet sterilization for grain disinfestation involves steam or hot water treatment, which effectively reduces microbial contamination but may cause slight loss of water-soluble vitamins and affect grain texture. Dry sterilization uses hot air or infrared radiation, preserving nutritional quality better by minimizing nutrient leaching, though it may be less effective against certain pests. Both methods impact grain quality differently, with wet sterilization potentially altering moisture content and dry sterilization maintaining structural integrity but requiring precise temperature control to avoid nutrient degradation.

Residue and Safety Concerns in Sterilization Methods

Wet sterilization for grain disinfestation often involves steam or chemical treatments, which can leave moisture residues that promote mold growth and pose safety risks during storage. In contrast, dry sterilization techniques like heat or irradiation minimize residue accumulation, thereby reducing contamination and enhancing long-term grain safety. Selecting appropriate sterilization methods depends on balancing residue impact and safety to maintain grain quality and prevent post-harvest losses.

Equipment and Technology Requirements

Wet sterilization for grain disinfestation requires equipment capable of applying controlled steam or hot water vapor, such as steam chambers or autoclaves, ensuring uniform moisture and temperature distribution. Dry sterilization relies on high-temperature ovens or hot air chambers with precise airflow control, designed to prevent grain moisture increase and maintain quality. The choice between these technologies depends on available infrastructure, required throughput, and grain moisture sensitivity, influencing equipment complexity and energy consumption.

Cost Analysis: Wet vs Dry Sterilization

Wet sterilization for grain disinfestation incurs higher operational costs due to the need for water, increased energy consumption for heating, and extended drying times post-treatment, while dry sterilization methods, such as infrared or microwave treatments, offer lower energy usage and faster processing times, reducing overall expenses. Equipment investment for wet sterilization includes corrosion-resistant machinery and water treatment systems, contributing to higher capital costs compared to typically simpler dry sterilization setups. Cost efficiency in large-scale grain storage is generally more favorable with dry sterilization, especially in regions facing water scarcity or high utility prices.

Environmental and Regulatory Considerations

Wet sterilization for grain disinfestation typically generates wastewater containing chemical residues, necessitating strict adherence to environmental discharge regulations and effective treatment systems. Dry sterilization methods, such as heat or irradiation, produce minimal liquid waste but require compliance with air quality standards and safety protocols to limit emissions and occupational exposure. Regulatory frameworks often favor dry sterilization due to its lower environmental impact, though local policies may mandate specific controls for both techniques to ensure sustainable post-harvest management.

Future Directions in Grain Sterilization Technology

Emerging advancements in grain sterilization technology emphasize integrating wet sterilization methods with precision moisture control to enhance efficacy against pests while minimizing grain quality degradation. Innovations in dry sterilization leverage pulsed electric fields and low-temperature plasma to achieve effective disinfestation without chemical residues. Future research prioritizes hybrid approaches combining wet and dry sterilization techniques, optimizing energy efficiency, and incorporating real-time monitoring systems for improved grain safety and shelf life.

Related Important Terms

Superheated Steam Sterilization

Superheated steam sterilization offers a highly effective wet sterilization method for grain disinfestation by penetrating grain moisture to eliminate pests and microbial contaminants without chemical residues. Compared to dry sterilization, superheated steam provides uniform heat distribution and reduces treatment time, enhancing post-harvest grain quality and storage longevity.

Ozone-Assisted Wet Sterilization

Ozone-assisted wet sterilization enhances grain disinfestation by utilizing ozone's strong oxidative properties to effectively eliminate pests and pathogens without chemical residues, improving grain quality and storage life. Compared to traditional dry sterilization, this method offers superior penetration and faster microbial reduction, reducing treatment time and preserving grain moisture content.

Vacuum-Assisted Dry Heat Sterilization

Vacuum-Assisted Dry Heat Sterilization enhances grain disinfestation by combining high temperature with reduced pressure, enabling deeper heat penetration and rapid moisture removal without damaging grain quality. This method outperforms traditional wet sterilization by minimizing thermal degradation and preventing moisture-induced spoilage, ensuring prolonged storage stability and maintaining germination capacity.

Pulsed Plasma Dry Sterilization

Pulsed Plasma Dry Sterilization offers an advanced, chemical-free method for grain disinfestation by generating reactive species that effectively eliminate pests and pathogens without moisture, preserving grain quality compared to traditional wet sterilization techniques. This dry sterilization process enhances post-harvest grain preservation by minimizing spoilage risks associated with moisture while ensuring efficient microbial and insect control through plasma-induced oxidative damage.

Hydrothermal Disinfestation

Hydrothermal disinfestation utilizes controlled moisture and heat to effectively eliminate pests from stored grains, preserving grain quality better than dry sterilization methods that rely solely on high temperatures. This wet sterilization approach ensures uniform pest eradication while minimizing grain damage by maintaining optimal humidity and temperature conditions during the treatment process.

Moist Heat Fogging

Moist heat fogging in post-harvest grain disinfestation leverages wet sterilization to penetrate deeply and eliminate pests effectively by generating fine droplets of hot steam, ensuring uniform coverage and rapid microbial inactivation. Compared to dry sterilization methods, which primarily rely on high temperature without moisture, moist heat fogging enhances pest mortality rates while minimizing grain quality degradation and moisture imbalance.

Infrared Dry Heat Sterilization

Infrared dry heat sterilization offers precise temperature control and rapid heating for effective grain disinfestation, minimizing moisture absorption and preserving grain quality compared to wet sterilization methods. This technique utilizes infrared radiation to penetrate grains deeply, ensuring thorough microbial inactivation while reducing energy consumption and processing time.

Microwave-Assisted Wet Sterilization

Microwave-assisted wet sterilization for grain disinfestation leverages rapid dielectric heating to effectively eliminate pests and pathogens while preserving grain quality by minimizing thermal damage compared to traditional dry sterilization methods. This technology enhances moisture uniformity and penetrative heating, resulting in improved disinfestation efficacy and reduced energy consumption in post-harvest grain management.

Ultraviolet-C Enhanced Dry Disinfestation

Ultraviolet-C enhanced dry disinfestation offers a non-chemical, residue-free alternative to traditional wet and dry sterilization methods for grain preservation, effectively reducing insect pests while maintaining grain quality. This method leverages UVC radiation's germicidal properties, ensuring rapid microbial inactivation and minimal moisture alteration compared to conventional wet sterilization, which often risks grain spoilage.

Hybrid Steam-Dry Heat Protocols

Hybrid steam-dry heat protocols combine the efficiency of wet sterilization in penetrating grain masses with the surface-level desiccation benefits of dry heat, enhancing grain disinfestation by targeting pests at multiple moisture and temperature thresholds. These protocols optimize preservation of grain quality while achieving superior eradication of insects and pathogens compared to singular wet or dry sterilization methods.

Wet sterilization vs Dry sterilization for grain disinfestation Infographic

agridif.com

agridif.com