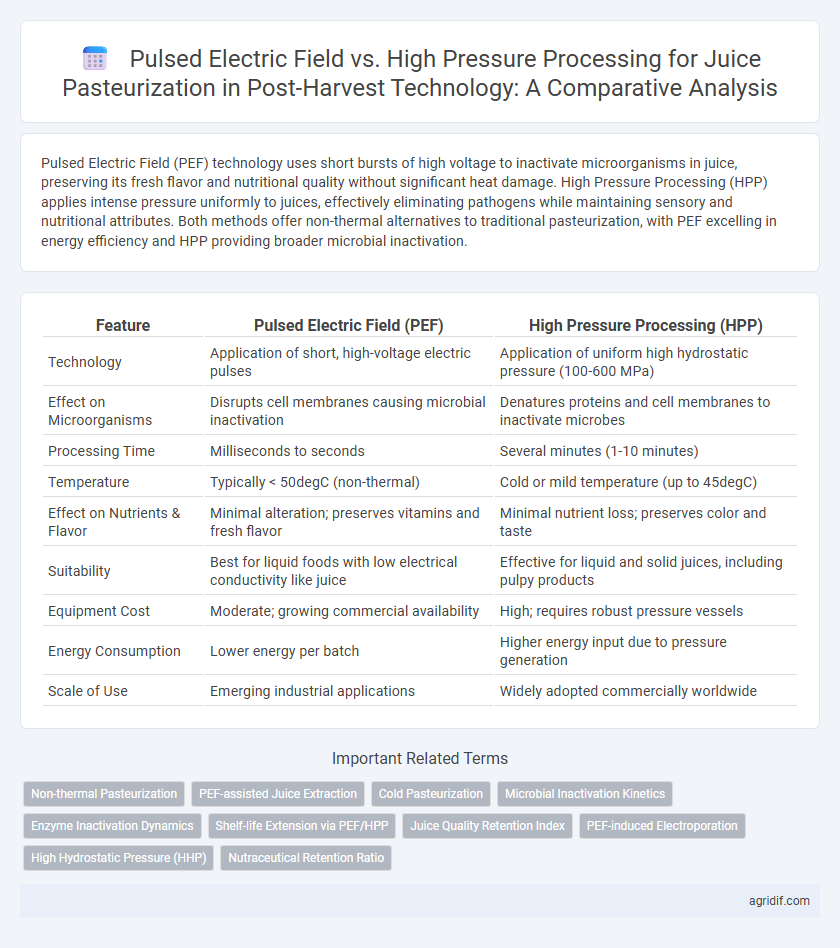

Pulsed Electric Field (PEF) technology uses short bursts of high voltage to inactivate microorganisms in juice, preserving its fresh flavor and nutritional quality without significant heat damage. High Pressure Processing (HPP) applies intense pressure uniformly to juices, effectively eliminating pathogens while maintaining sensory and nutritional attributes. Both methods offer non-thermal alternatives to traditional pasteurization, with PEF excelling in energy efficiency and HPP providing broader microbial inactivation.

Table of Comparison

| Feature | Pulsed Electric Field (PEF) | High Pressure Processing (HPP) |

|---|---|---|

| Technology | Application of short, high-voltage electric pulses | Application of uniform high hydrostatic pressure (100-600 MPa) |

| Effect on Microorganisms | Disrupts cell membranes causing microbial inactivation | Denatures proteins and cell membranes to inactivate microbes |

| Processing Time | Milliseconds to seconds | Several minutes (1-10 minutes) |

| Temperature | Typically < 50degC (non-thermal) | Cold or mild temperature (up to 45degC) |

| Effect on Nutrients & Flavor | Minimal alteration; preserves vitamins and fresh flavor | Minimal nutrient loss; preserves color and taste |

| Suitability | Best for liquid foods with low electrical conductivity like juice | Effective for liquid and solid juices, including pulpy products |

| Equipment Cost | Moderate; growing commercial availability | High; requires robust pressure vessels |

| Energy Consumption | Lower energy per batch | Higher energy input due to pressure generation |

| Scale of Use | Emerging industrial applications | Widely adopted commercially worldwide |

Introduction to Juice Pasteurization Technologies

Pulsed Electric Field (PEF) and High Pressure Processing (HPP) are two advanced non-thermal pasteurization technologies used in juice processing to enhance microbial safety while preserving nutritional quality. PEF uses short bursts of high voltage to inactivate microorganisms by disrupting cell membranes, maintaining fresh-like characteristics and vitamins. HPP applies intense hydrostatic pressure up to 600 MPa, effectively inactivating pathogens and spoilage organisms without significant heat, extending juice shelf life and preserving flavor and color.

Overview of Pulsed Electric Field (PEF) Processing

Pulsed Electric Field (PEF) processing uses short bursts of high voltage to inactivate microorganisms in juice, preserving nutritional and sensory qualities better than thermal methods. This non-thermal pasteurization technology maintains vitamin retention and flavor integrity by minimizing heat exposure. PEF is energy-efficient and tailored for treating heat-sensitive beverages, offering a promising alternative to High Pressure Processing (HPP) for juice preservation.

Fundamentals of High Pressure Processing (HPP)

High Pressure Processing (HPP) uses ultra-high hydrostatic pressures, typically between 400 and 600 MPa, to inactivate microorganisms and enzymes in juice, preserving sensory and nutritional quality. By applying isostatic pressure uniformly, HPP disrupts cellular membranes and protein structures without significant heat generation, maintaining vitamin content and flavor integrity. This non-thermal technique is widely recognized for extending shelf life while retaining fresh-like characteristics in fruit juices compared to conventional pasteurization methods.

Mechanisms of Microbial Inactivation in PEF and HPP

Pulsed Electric Field (PEF) pasteurization inactivates microbes by applying short bursts of high voltage that create pores in microbial cell membranes, leading to loss of cellular homeostasis and cell death. High Pressure Processing (HPP) disrupts microbial cells through the application of intense hydrostatic pressure, causing damage to cellular proteins, enzymes, and membrane structures, resulting in microbial inactivation. Both techniques maintain juice quality while effectively reducing pathogenic and spoilage microorganisms by targeting different cellular components and mechanisms.

Impact on Juice Nutritional Quality: PEF vs HPP

Pulsed Electric Field (PEF) technology preserves juice nutritional quality by minimizing thermal damage, maintaining higher levels of vitamins, antioxidants, and enzymes compared to traditional pasteurization. High Pressure Processing (HPP) effectively inactivates microorganisms while retaining nutrients but can cause slight changes in juice texture and bioactive compound stability. Both PEF and HPP demonstrate superior nutrient retention over thermal methods, with PEF showing a more pronounced advantage in preserving heat-sensitive vitamins such as vitamin C.

Effects on Juice Sensory Properties

Pulsed Electric Field (PEF) technology preserves the fresh-like flavor and vibrant color of juice by causing minimal thermal damage, maintaining volatile aroma compounds better than conventional methods. High Pressure Processing (HPP) enhances juice texture and clarity, often intensifying natural fruit flavors while retaining nutritional quality due to its non-thermal nature. Sensory evaluation studies indicate that PEF-treated juices exhibit higher consumer preference for taste and aroma, whereas HPP-treated juices receive higher scores for mouthfeel and visual appeal.

Energy Efficiency and Environmental Impact

Pulsed Electric Field (PEF) technology offers significant energy efficiency advantages over High Pressure Processing (HPP) by reducing processing time and lowering energy consumption during juice pasteurization. PEF operates at ambient temperatures, minimizing thermal damage and thereby decreasing the carbon footprint associated with energy-intensive heating in traditional methods. Environmental impact assessments highlight PEF's reduced water usage and minimal packaging waste compared to HPP, reinforcing PEF as a more sustainable option for high-quality juice preservation.

Cost-Effectiveness and Scalability in Commercial Juice Production

Pulsed Electric Field (PEF) technology offers cost-effective juice pasteurization with lower energy consumption and shorter processing times compared to High Pressure Processing (HPP), making it attractive for large-scale commercial production. While HPP provides superior microbial inactivation and shelf-life extension, its high equipment and operational costs limit scalability for small to medium-sized juice producers. PEF systems integrate more easily into continuous production lines, enhancing throughput and reducing downtime, thereby improving overall cost-efficiency in commercial juice manufacturing.

Safety and Regulatory Considerations

Pulsed Electric Field (PEF) and High Pressure Processing (HPP) offer non-thermal pasteurization methods that enhance juice safety by inactivating pathogenic microorganisms while preserving nutritional quality. Regulatory agencies such as the FDA and EFSA have approved both technologies, with HPP more widely accepted due to extensive validation and commercial use. Safety assessments emphasize validation of microbial inactivation, packaging integrity, and compliance with food contact materials regulations to ensure consumer protection.

Future Perspectives in Juice Pasteurization Technologies

Pulsed Electric Field (PEF) and High Pressure Processing (HPP) represent cutting-edge technologies reshaping juice pasteurization by enhancing microbial safety while preserving nutritional and sensory qualities. Future perspectives emphasize integrating PEF's energy-efficient microbial inactivation with HPP's ability to maintain bioactive compounds, potentially leading to hybrid systems for optimized juice quality and shelf life. Ongoing research explores scalable, cost-effective applications and real-time monitoring techniques to advance commercial adoption and meet increasing consumer demand for minimally processed, fresh-like juices.

Related Important Terms

Non-thermal Pasteurization

Pulsed Electric Field (PEF) and High Pressure Processing (HPP) are advanced non-thermal pasteurization methods preserving juice freshness by inactivating microorganisms without heat-induced nutrient loss. PEF utilizes short bursts of high voltage to disrupt microbial cell membranes, while HPP applies extreme pressure uniformly, maintaining sensory and nutritional quality during juice preservation.

PEF-assisted Juice Extraction

Pulsed Electric Field (PEF) technology enhances juice extraction by inducing electroporation in cell membranes, resulting in higher yield and improved retention of bioactive compounds compared to High Pressure Processing (HPP). PEF-assisted juice extraction operates at lower temperatures, preserving sensory attributes and nutritional quality while ensuring effective microbial inactivation for safer juice pasteurization.

Cold Pasteurization

Pulsed Electric Field (PEF) and High Pressure Processing (HPP) are advanced cold pasteurization technologies that preserve juice by inactivating microbes without heat, maintaining freshness and nutritional quality. PEF uses short bursts of high voltage to disrupt microbial cells, while HPP applies uniform high pressure to achieve microbial reduction, both extending shelf-life while retaining sensory attributes.

Microbial Inactivation Kinetics

Pulsed Electric Field (PEF) technology achieves microbial inactivation in juice by applying short, high-voltage pulses that disrupt cell membranes, demonstrating rapid kinetics with significant reduction of pathogenic and spoilage microorganisms while preserving sensory and nutritional qualities. High Pressure Processing (HPP) utilizes isostatic pressure up to 600 MPa, inducing cell membrane permeabilization and enzyme denaturation with a slightly slower but equally effective microbial inactivation rate, maintaining juice freshness and extending shelf life without thermal damage.

Enzyme Inactivation Dynamics

Pulsed Electric Field (PEF) technology offers rapid enzyme inactivation by disrupting cell membranes through short, high-voltage pulses, preserving juice sensory attributes and nutritional quality more effectively than High Pressure Processing (HPP). In contrast, HPP achieves enzyme inactivation primarily by applying uniform hydrostatic pressure, which may require longer processing times and potentially affects juice texture and flavor due to protein conformational changes.

Shelf-life Extension via PEF/HPP

Pulsed Electric Field (PEF) technology extends juice shelf-life by inactivating spoilage microorganisms with minimal heat, preserving nutritional and sensory qualities better than conventional methods. High Pressure Processing (HPP) achieves longer shelf-life by applying ultra-high pressure to destroy pathogens and enzymes, maintaining juice freshness and bioactive compounds while ensuring microbial safety.

Juice Quality Retention Index

Pulsed Electric Field (PEF) technology achieves a higher Juice Quality Retention Index by preserving sensory attributes and nutritional compounds such as vitamins and antioxidants more effectively than High Pressure Processing (HPP). PEF treatments minimize thermal degradation and maintain freshness, color, and flavor while ensuring microbial safety, making it superior for retaining juice quality post-pasteurization.

PEF-induced Electroporation

Pulsed Electric Field (PEF) technology enhances juice pasteurization by inducing electroporation, which disrupts microbial cell membranes through short, high-voltage pulses, preserving juice quality and nutrients more effectively than thermal methods. High Pressure Processing (HPP) inactivates pathogens via pressure-induced cell membrane deformation but lacks the selective permeability effects of PEF, making PEF a more energy-efficient method for maintaining fresh-like juice attributes.

High Hydrostatic Pressure (HHP)

High Hydrostatic Pressure (HHP) technology effectively inactivates spoilage microorganisms and enzymes in juice while preserving its nutritional and sensory qualities, making it a superior pasteurization method compared to Pulsed Electric Field. HHP operates by applying uniform pressure up to 600 MPa, ensuring microbial safety and extending shelf life without the heat-induced degradation typical of conventional pasteurization techniques.

Nutraceutical Retention Ratio

Pulsed Electric Field (PEF) technology demonstrates superior nutraceutical retention ratios compared to High Pressure Processing (HPP) during juice pasteurization, preserving higher levels of vitamins, antioxidants, and phenolic compounds. PEF's non-thermal mechanism minimizes nutrient degradation, maintaining the bioactive compound integrity crucial for functional beverage quality.

Pulsed Electric Field vs High Pressure Processing for juice pasteurization Infographic

agridif.com

agridif.com