Bulk packaging enhances transportation efficiency by maximizing space utilization and reducing packaging materials, leading to lower shipping costs and decreased environmental impact. Consumer packaging prioritizes product protection and individual portioning but often results in increased volume and higher transportation expenses. Optimizing the balance between bulk and consumer packaging is essential to streamline logistics while maintaining produce quality in post-harvest technology.

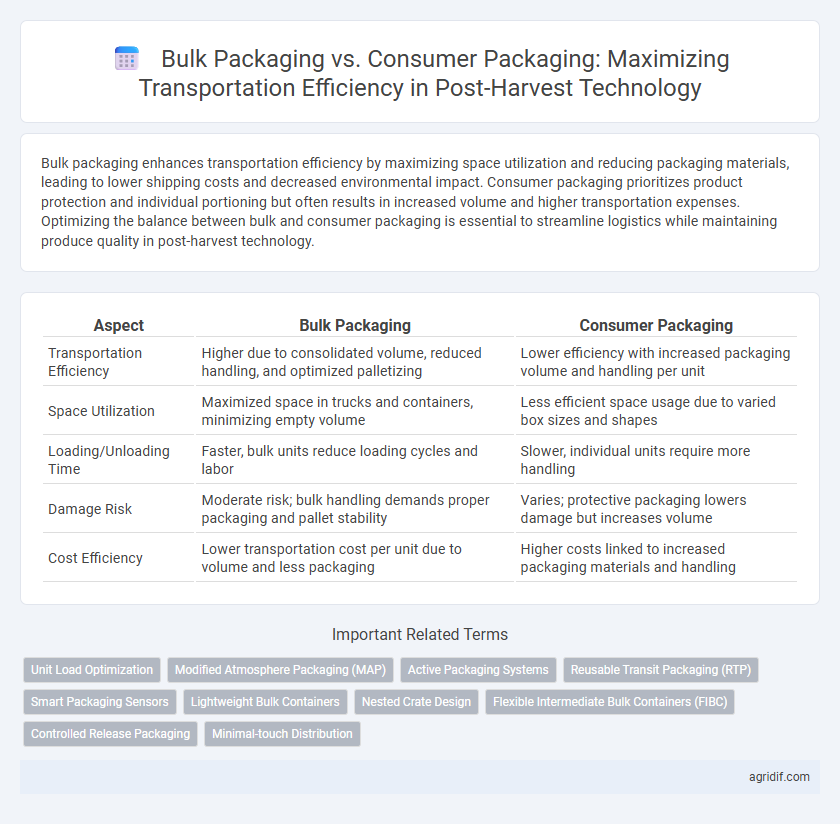

Table of Comparison

| Aspect | Bulk Packaging | Consumer Packaging |

|---|---|---|

| Transportation Efficiency | Higher due to consolidated volume, reduced handling, and optimized palletizing | Lower efficiency with increased packaging volume and handling per unit |

| Space Utilization | Maximized space in trucks and containers, minimizing empty volume | Less efficient space usage due to varied box sizes and shapes |

| Loading/Unloading Time | Faster, bulk units reduce loading cycles and labor | Slower, individual units require more handling |

| Damage Risk | Moderate risk; bulk handling demands proper packaging and pallet stability | Varies; protective packaging lowers damage but increases volume |

| Cost Efficiency | Lower transportation cost per unit due to volume and less packaging | Higher costs linked to increased packaging materials and handling |

Understanding Bulk vs Consumer Packaging in Post-Harvest Handling

Bulk packaging in post-harvest handling enhances transportation efficiency by maximizing volume utilization and reducing packaging costs, which is critical for large-scale produce movement. Consumer packaging, although less efficient for transport, offers advantages in product protection, branding, and convenience for retail distribution. Optimizing packaging methods based on supply chain stages ensures balance between transport efficiency and market-ready presentation of fresh produce.

Key Features of Bulk Packaging for Agricultural Produce

Bulk packaging for agricultural produce enhances transportation efficiency by maximizing load density and reducing packaging material per unit, leading to lower shipping costs and less environmental waste. It features robust containers designed to withstand mechanical handling, prevent produce damage, and facilitate stackability and uniform palletization. These attributes enable streamlined logistics, minimize handling times, and maintain post-harvest quality during long-distance transport.

Advantages of Consumer Packaging for End-User Distribution

Consumer packaging enhances transportation efficiency by reducing product damage and spoilage through improved protection and portion control. This packaging type facilitates easier handling, stacking, and display during end-user distribution, streamlining logistics and reducing labor costs. Moreover, consumer packaging supports accurate inventory management, leading to optimized supply chain flow and minimized waste.

Transportation Efficiency: Bulk vs Consumer Packaging Comparison

Bulk packaging significantly enhances transportation efficiency by maximizing space utilization and reducing packaging material per unit, leading to lower freight costs and carbon emissions. In contrast, consumer packaging, while designed for retail appeal and convenience, often results in increased volume and weight, decreasing load density and raising transportation expenses. Optimizing bulk packaging configurations can improve handling, minimize damage during transit, and streamline supply chain logistics in post-harvest technology.

Impact of Packaging Size on Logistics and Shipping Costs

Bulk packaging significantly reduces transportation costs by maximizing container utilization and minimizing packaging material per unit, leading to more efficient logistics operations. Consumer packaging, while enhancing product visibility and convenience, increases the volume and weight per shipment, thereby raising freight and handling expenses. Optimizing packaging size balances protection and cost-efficiency, critical for minimizing shipping costs in post-harvest technology supply chains.

Storage Optimization: Bulk Packaging vs Consumer Packaging

Bulk packaging enhances storage optimization by reducing packaging materials and maximizing space utilization, allowing more produce to be transported per shipment. Consumer packaging, while improving product presentation and individual portion control, often leads to increased volume and less efficient stacking, resulting in lower overall storage density. Efficient transportation relies on bulk packaging to minimize empty space in containers and reduce handling costs during post-harvest supply chain operations.

Product Quality and Damage Control in Different Packaging Methods

Bulk packaging in post-harvest transportation minimizes product handling and reduces the risk of mechanical damage but may increase exposure to environmental factors affecting product quality. Consumer packaging offers individual protection with cushioning and ventilation, enhancing damage control and preserving freshness during transit. Optimizing packaging methods involves balancing transport efficiency with maintaining product integrity to reduce post-harvest losses.

Environmental Implications: Bulk and Consumer Packaging

Bulk packaging reduces material usage and minimizes waste generation during transportation, significantly lowering the carbon footprint compared to consumer packaging. Consumer packaging, often made from mixed materials and smaller units, increases packaging waste and complicates recycling processes, leading to higher environmental impact. Efficient bulk packaging supports sustainable logistics by optimizing space and reducing emissions associated with transport and disposal.

Supply Chain Flexibility with Packaging Types

Bulk packaging enhances supply chain flexibility by allowing larger quantities of produce to be transported, reducing handling times and lowering transportation costs. In contrast, consumer packaging offers pre-portioned, retail-ready units that streamline distribution to end-users but may increase space requirements and handling complexity. Optimizing the balance between bulk and consumer packaging improves overall transportation efficiency by aligning packaging choices with specific supply chain demands and distribution channels.

Choosing the Right Packaging for Market Demands

Bulk packaging enhances transportation efficiency by maximizing load capacity and reducing per-unit packaging costs, making it ideal for large-scale distribution and wholesale markets. Consumer packaging, designed for retail appeal and convenience, often increases volume and weight but meets consumer preferences and regulatory requirements. Selecting the right packaging depends on balancing transportation efficiency with market demands, ensuring product protection while optimizing supply chain logistics.

Related Important Terms

Unit Load Optimization

Bulk packaging enhances transportation efficiency by maximizing unit load optimization, allowing for higher pallet density and reduced handling times compared to consumer packaging. This method minimizes packaging materials and space, leading to lower transportation costs and improved protection of perishable goods during transit.

Modified Atmosphere Packaging (MAP)

Bulk packaging in post-harvest technology enhances transportation efficiency by maximizing load capacity and reducing packaging waste, while Modified Atmosphere Packaging (MAP) within consumer packaging extends shelf life by controlling gas composition around the produce. MAP optimizes product freshness but increases packaging volume and handling complexity, contrasting with bulk packaging's focus on logistics and cost-effectiveness during transport.

Active Packaging Systems

Active packaging systems in bulk packaging enhance transportation efficiency by controlling gas exchange, moisture, and microbial growth, extending shelf life and reducing spoilage during transit. Consumer packaging with active technology offers tailored protection for individual units but generally results in higher material use and lower overall transportation efficiency compared to bulk solutions.

Reusable Transit Packaging (RTP)

Reusable Transit Packaging (RTP) significantly enhances transportation efficiency in bulk packaging by reducing packaging waste and lowering handling costs compared to single-use consumer packaging. RTP systems optimize space utilization, improve load stability during transit, and facilitate multiple reuse cycles, leading to sustainable logistics and cost savings in post-harvest supply chains.

Smart Packaging Sensors

Smart packaging sensors integrated into bulk packaging significantly enhance transportation efficiency by providing real-time monitoring of temperature, humidity, and gas levels, ensuring optimal conditions for fresh produce during transit. Consumer packaging, while tailored for individual retail display, often lacks the advanced sensor technology and scale benefits of bulk packaging that collectively reduce spoilage and logistical costs in large-scale post-harvest distribution.

Lightweight Bulk Containers

Lightweight bulk containers enhance transportation efficiency in post-harvest technology by reducing container weight, allowing for higher payload capacity and lower fuel consumption during transit. Compared to consumer packaging, these bulk containers minimize handling time and damage risks, optimizing logistics for bulk produce shipments.

Nested Crate Design

Nested crate design in post-harvest bulk packaging significantly enhances transportation efficiency by minimizing empty space and reducing volume during return logistics. This innovation lowers shipping costs, decreases carbon emissions, and improves handling convenience compared to traditional consumer packaging, which often lacks stackability and space optimization.

Flexible Intermediate Bulk Containers (FIBC)

Flexible Intermediate Bulk Containers (FIBCs) enhance transportation efficiency in post-harvest technology by enabling bulk packaging that maximizes space utilization and reduces handling time compared to consumer packaging. Their durability and reusability cut down logistical costs and minimize product damage during transit, proving superior for large-scale agricultural commodity transport.

Controlled Release Packaging

Controlled Release Packaging (CRP) enhances transportation efficiency by regulating gas exchange and moisture levels, extending shelf life and reducing spoilage in bulk packaging. Compared to consumer packaging, CRP in bulk formats optimizes space utilization and minimizes handling, leading to cost-effective logistics and diminished product losses during transit.

Minimal-touch Distribution

Bulk packaging significantly enhances transportation efficiency by reducing handling steps and optimizing space utilization during minimal-touch distribution. Consumer packaging, while tailored for retail, increases manual handling and warehouse labor, leading to higher costs and potential product damage in transit.

Bulk Packaging vs Consumer Packaging for transportation efficiency Infographic

agridif.com

agridif.com