Controlled Atmosphere Storage (CAS) precisely regulates oxygen, carbon dioxide, and humidity levels to significantly extend the shelf life of perishable products by slowing respiration and delaying ripening. Modified Atmosphere Storage (MAS) alters the gas composition within packaging, optimizing conditions to reduce decay and maintain freshness, but typically offers shorter-term preservation compared to CAS. Both techniques enhance post-harvest quality, with CAS providing more stable, long-term control and MAS offering flexible, cost-effective solutions suitable for varying supply chain needs.

Table of Comparison

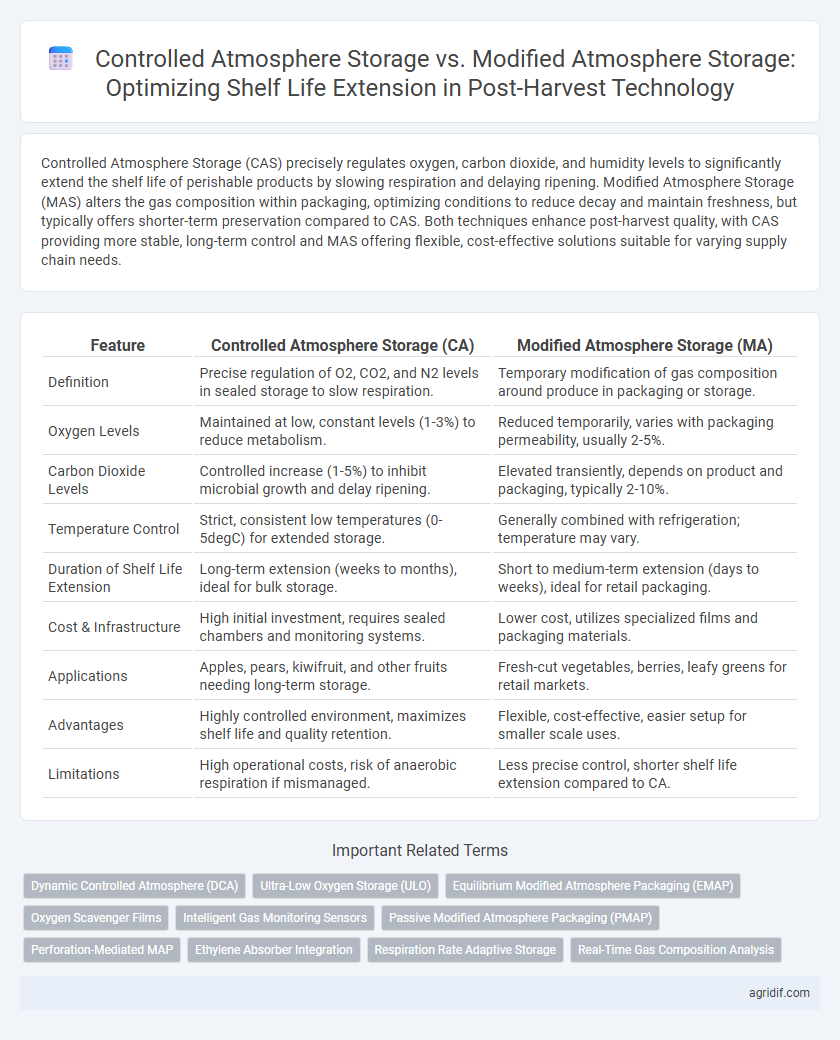

| Feature | Controlled Atmosphere Storage (CA) | Modified Atmosphere Storage (MA) |

|---|---|---|

| Definition | Precise regulation of O2, CO2, and N2 levels in sealed storage to slow respiration. | Temporary modification of gas composition around produce in packaging or storage. |

| Oxygen Levels | Maintained at low, constant levels (1-3%) to reduce metabolism. | Reduced temporarily, varies with packaging permeability, usually 2-5%. |

| Carbon Dioxide Levels | Controlled increase (1-5%) to inhibit microbial growth and delay ripening. | Elevated transiently, depends on product and packaging, typically 2-10%. |

| Temperature Control | Strict, consistent low temperatures (0-5degC) for extended storage. | Generally combined with refrigeration; temperature may vary. |

| Duration of Shelf Life Extension | Long-term extension (weeks to months), ideal for bulk storage. | Short to medium-term extension (days to weeks), ideal for retail packaging. |

| Cost & Infrastructure | High initial investment, requires sealed chambers and monitoring systems. | Lower cost, utilizes specialized films and packaging materials. |

| Applications | Apples, pears, kiwifruit, and other fruits needing long-term storage. | Fresh-cut vegetables, berries, leafy greens for retail markets. |

| Advantages | Highly controlled environment, maximizes shelf life and quality retention. | Flexible, cost-effective, easier setup for smaller scale uses. |

| Limitations | High operational costs, risk of anaerobic respiration if mismanaged. | Less precise control, shorter shelf life extension compared to CA. |

Introduction to Post-Harvest Technology in Agriculture

Controlled Atmosphere Storage (CA) and Modified Atmosphere Storage (MA) are critical techniques in post-harvest technology aimed at extending the shelf life of agricultural produce by regulating the composition of gases such as oxygen, carbon dioxide, and nitrogen around the product. CA involves a continuous and precise control of gas levels using sophisticated monitoring systems, whereas MA relies on passive modification of the atmosphere through packaging materials or produce respiration. Both methods reduce metabolic rates and delay ripening and spoilage, thereby maintaining quality and reducing post-harvest losses in fruits and vegetables.

Understanding Controlled Atmosphere Storage (CA Storage)

Controlled Atmosphere Storage (CA Storage) regulates oxygen, carbon dioxide, and humidity levels within sealed environments to slow down respiration and delay ripening in perishable produce. Precise monitoring and adjustment of gas compositions, typically reducing oxygen to 1-3% and increasing carbon dioxide to 3-5%, significantly extend shelf life by minimizing microbial growth and oxidative damage. CA Storage offers superior control compared to Modified Atmosphere Storage by maintaining consistent atmospheric conditions, making it ideal for long-term preservation of fruits like apples, pears, and cherries.

Exploring Modified Atmosphere Storage (MA Storage)

Modified Atmosphere Storage (MA Storage) extends the shelf life of perishable products by altering the composition of gases surrounding the produce, typically reducing oxygen and increasing carbon dioxide levels to slow down respiration and microbial growth. Unlike Controlled Atmosphere Storage, which precisely regulates gas concentrations and temperature through complex monitoring systems, MA Storage relies on passive or semi-active packaging techniques that modify the internal atmosphere naturally or with minimal intervention. This cost-effective approach is widely used for fruits like apples, berries, and leafy greens, preserving quality and freshness while minimizing energy consumption and infrastructure requirements.

Key Differences Between CA and MA Storage Systems

Controlled Atmosphere (CA) storage maintains a precisely regulated gas mixture, including oxygen, carbon dioxide, and nitrogen levels, to significantly slow down the respiration and ripening processes of stored produce. Modified Atmosphere (MA) storage relies on passive changes in gas composition within sealed packaging, influenced by the produce's respiration and package permeability, to extend shelf life. Key differences between CA and MA include the level of control over atmospheric conditions, with CA providing active monitoring and adjustment, whereas MA depends on passive equilibrium, impacting scalability, cost, and effectiveness in shelf life extension.

Mechanisms of Shelf Life Extension in CA and MA Storage

Controlled Atmosphere (CA) storage extends shelf life by precisely regulating oxygen, carbon dioxide, and humidity levels, slowing respiration and delaying ripening and senescence in fruits and vegetables. Modified Atmosphere (MA) storage alters the gas composition around the produce through packaging materials that balance gas permeability, reducing oxygen and increasing carbon dioxide to suppress microbial growth and enzymatic activity. The key mechanism in CA storage is active atmosphere control ensuring consistent gas concentrations, while MA relies on passive atmosphere modification achieved by produce respiration and film permeability.

Impact on Quality and Nutritional Value of Produce

Controlled Atmosphere Storage (CAS) maintains low oxygen and elevated carbon dioxide levels through precise gas regulation, effectively preserving the firmness, color, and nutrient content of fruits like apples and pears over extended periods. Modified Atmosphere Storage (MAS) relies on passive alteration of gas composition within packaging, which can slow respiration but may result in less consistent quality retention and variable effects on vitamins and antioxidants. CAS demonstrates superior control in minimizing enzymatic browning and nutrient degradation, thereby extending shelf life while maintaining higher nutritional value compared to MAS.

Suitability for Different Crop Types

Controlled Atmosphere Storage (CAS) offers precise regulation of oxygen, carbon dioxide, and humidity levels, making it ideal for high-value fruits like apples and pears that require long-term storage under stable conditions. Modified Atmosphere Storage (MAS) modifies the gaseous environment primarily through packaging films and is more suitable for perishable vegetables and berries that benefit from shorter-term freshness preservation. Crop-specific respiration rates and sensitivity to gas compositions dictate the choice between CAS and MAS for optimal shelf life extension.

Cost, Infrastructure, and Operational Considerations

Controlled Atmosphere Storage (CA) involves precise regulation of oxygen, carbon dioxide, and humidity levels, requiring significant investment in advanced infrastructure and continuous monitoring systems, making it cost-intensive but highly effective for long-term shelf life extension. Modified Atmosphere Storage (MA), often achieved through packaging adjustments or gas flushing, offers a lower-cost alternative with simpler infrastructure, suitable for short to medium-term storage but less precise atmosphere control. Operational considerations favor CA for large-scale, long-duration storage where consistent quality is critical, whereas MA suits smaller operations seeking affordable, flexible solutions with reduced capital expenditure.

Sustainability and Environmental Implications

Controlled Atmosphere Storage (CAS) optimizes oxygen, carbon dioxide, and humidity levels, significantly extending shelf life while minimizing spoilage and reducing food waste, thus supporting sustainability goals. Modified Atmosphere Storage (MAS) alters the packaging gas composition but typically requires frequent monitoring and generates disposable materials, impacting environmental footprints. CAS demonstrates greater potential for long-term sustainability due to its energy-efficient systems and reduced reliance on single-use plastics, aligning with eco-friendly agricultural practices.

Future Trends in Atmosphere Storage Technologies

Emerging trends in Controlled Atmosphere Storage (CAS) and Modified Atmosphere Storage (MAS) emphasize precision gas modulation using advanced sensor technologies and AI-driven monitoring systems to optimize oxygen, carbon dioxide, and humidity levels, significantly extending the shelf life of horticultural products. Integration of nanotechnology for packaging materials that dynamically adjust permeability and incorporate antimicrobial properties offers promising enhancements in MAS, reducing spoilage and maintaining product quality. Future developments also explore carbon footprint reduction through energy-efficient storage solutions and smart logistics, aligning post-harvest technology with sustainability goals in global supply chains.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology adjusts oxygen and carbon dioxide levels in real-time, optimizing fruit respiration rates and significantly extending shelf life compared to static Controlled Atmosphere (CA) and Modified Atmosphere Storage (MAS) methods. DCA enhances post-harvest quality by reducing physiological disorders and delaying ripening, resulting in improved freshness and marketability of stored produce.

Ultra-Low Oxygen Storage (ULO)

Ultra-Low Oxygen Storage (ULO) within Controlled Atmosphere Storage precisely regulates oxygen levels below 1%, significantly delaying respiration and ethylene production to extend the shelf life of perishable commodities. Unlike Modified Atmosphere Storage, ULO relies on advanced technology to maintain consistent ultra-low oxygen environments, enhancing quality preservation and reducing spoilage in fruits and vegetables during prolonged storage.

Equilibrium Modified Atmosphere Packaging (EMAP)

Equilibrium Modified Atmosphere Packaging (EMAP) maintains a stable gas composition by balancing the respiration rate of produce with gas permeability of packaging materials, effectively extending shelf life while preserving quality. Unlike Controlled Atmosphere Storage (CAS), which requires expensive infrastructure to regulate oxygen, carbon dioxide, and humidity levels, EMAP offers a cost-effective, scalable solution ideal for perishables like fruits and vegetables in retail environments.

Oxygen Scavenger Films

Oxygen scavenger films used in modified atmosphere storage (MAS) actively reduce residual oxygen levels, enhancing shelf life by inhibiting aerobic microbial growth and oxidative degradation in fresh produce. Controlled atmosphere storage (CAS) typically regulates oxygen and carbon dioxide concentrations in bulk storage environments, but MAS with oxygen scavenger films offers precise, localized atmospheric control, optimizing freshness and quality retention at the package level.

Intelligent Gas Monitoring Sensors

Intelligent gas monitoring sensors enhance Controlled Atmosphere Storage by providing precise and real-time data on oxygen, carbon dioxide, and ethylene levels, enabling optimal environmental conditions for extended shelf life. Modified Atmosphere Storage benefits from these sensors' ability to dynamically adjust gas compositions, reducing spoilage and maintaining produce quality during storage and transportation.

Passive Modified Atmosphere Packaging (PMAP)

Controlled Atmosphere Storage (CAS) precisely regulates oxygen, carbon dioxide, and humidity to extend shelf life of fruits and vegetables, whereas Passive Modified Atmosphere Packaging (PMAP) relies on the respiration of produce to modify the internal gas composition naturally without external gas flushing. PMAP offers a cost-effective, scalable solution for shelf life extension by maintaining optimal gas balance within sealed packaging, reducing oxidative stress and microbial growth during post-harvest storage.

Perforation-Mediated MAP

Perforation-mediated Modified Atmosphere Packaging (MAP) enhances shelf life by regulating gas exchange through micro-perforations, optimizing oxygen and carbon dioxide levels to slow respiration and delay ripening. Compared to Controlled Atmosphere Storage (CAS), this technology offers greater flexibility and cost-efficiency for perishable produce storage at ambient temperatures while maintaining quality and reducing post-harvest losses.

Ethylene Absorber Integration

Controlled Atmosphere Storage (CAS) utilizes precise regulation of oxygen, carbon dioxide, and humidity levels to slow respiration and delay ripening, while Modified Atmosphere Storage (MAS) modifies the gas composition around the produce through packaging or enclosure. Integrating ethylene absorbers in both CAS and MAS systems effectively reduces ethylene concentration, significantly enhancing shelf life extension by inhibiting ethylene-induced ripening and senescence in fruits and vegetables.

Respiration Rate Adaptive Storage

Controlled Atmosphere Storage precisely regulates oxygen, carbon dioxide, and humidity to slow respiration rates, significantly extending the shelf life of perishable produce by minimizing metabolic activity. Modified Atmosphere Storage adapts packaging gas composition dynamically to match respiration rate changes, optimizing the internal environment and reducing spoilage while maintaining product quality during distribution and retail.

Real-Time Gas Composition Analysis

Controlled Atmosphere Storage (CA) maintains a precisely regulated gas composition, typically low oxygen and elevated carbon dioxide levels, to significantly extend shelf life by slowing respiration and microbial growth in produce. Real-time gas composition analysis in CA ensures optimal atmospheric conditions are consistently maintained, whereas Modified Atmosphere Storage (MA) relies on passive gas modifications that fluctuate, making real-time monitoring less critical but often less precise for shelf life extension.

Controlled Atmosphere Storage vs Modified Atmosphere Storage for Shelf Life Extension Infographic

agridif.com

agridif.com