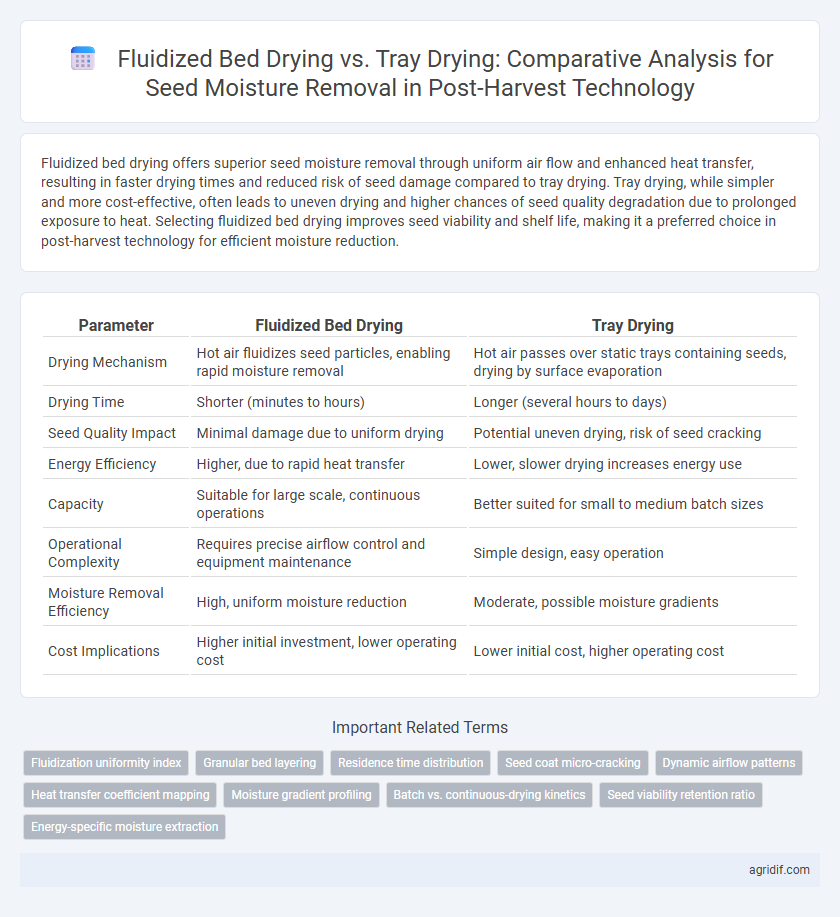

Fluidized bed drying offers superior seed moisture removal through uniform air flow and enhanced heat transfer, resulting in faster drying times and reduced risk of seed damage compared to tray drying. Tray drying, while simpler and more cost-effective, often leads to uneven drying and higher chances of seed quality degradation due to prolonged exposure to heat. Selecting fluidized bed drying improves seed viability and shelf life, making it a preferred choice in post-harvest technology for efficient moisture reduction.

Table of Comparison

| Parameter | Fluidized Bed Drying | Tray Drying |

|---|---|---|

| Drying Mechanism | Hot air fluidizes seed particles, enabling rapid moisture removal | Hot air passes over static trays containing seeds, drying by surface evaporation |

| Drying Time | Shorter (minutes to hours) | Longer (several hours to days) |

| Seed Quality Impact | Minimal damage due to uniform drying | Potential uneven drying, risk of seed cracking |

| Energy Efficiency | Higher, due to rapid heat transfer | Lower, slower drying increases energy use |

| Capacity | Suitable for large scale, continuous operations | Better suited for small to medium batch sizes |

| Operational Complexity | Requires precise airflow control and equipment maintenance | Simple design, easy operation |

| Moisture Removal Efficiency | High, uniform moisture reduction | Moderate, possible moisture gradients |

| Cost Implications | Higher initial investment, lower operating cost | Lower initial cost, higher operating cost |

Introduction to Seed Moisture Removal in Post-Harvest Technology

Effective seed moisture removal is crucial in post-harvest technology to prevent microbial growth and preserve seed viability. Fluidized bed drying offers uniform heat distribution and faster moisture reduction by suspending seeds in a hot air stream, enhancing drying efficiency. Tray drying, while simpler and cost-effective, often results in uneven drying and longer processing times, making it less suitable for large-scale or sensitive seed batches.

Principles of Fluidized Bed Drying in Agriculture

Fluidized bed drying in agriculture utilizes a heated air stream to suspend and circulate seeds, ensuring uniform moisture removal through intensive heat and mass transfer. This technique enhances drying efficiency by maximizing seed-to-air contact, reducing drying time compared to traditional tray drying which relies on static air exposure. The controlled fluidization minimizes seed damage and preserves quality, making it superior for moisture control in post-harvest seed processing.

Overview of Tray Drying Techniques for Seeds

Tray drying techniques for seeds involve spreading seeds evenly on perforated trays to allow hot air circulation, facilitating uniform moisture removal. This method is cost-effective, easy to operate, and suitable for small-scale seed drying operations, offering controlled temperature and drying time to preserve seed viability. Tray drying typically results in slower moisture reduction compared to fluidized bed drying but ensures minimal mechanical damage to seeds, making it ideal for delicate or high-value seed varieties.

Comparative Energy Efficiency: Fluidized Bed vs Tray Drying

Fluidized bed drying exhibits higher energy efficiency compared to tray drying due to enhanced heat and mass transfer rates that reduce drying time and energy consumption. Fluidized beds maintain uniform temperature distribution and better airflow, leading to consistent moisture removal with minimal thermal damage to seeds. Tray drying, while simpler, often consumes more energy due to longer drying cycles and less effective heat transfer mechanisms.

Impact on Seed Quality and Germination Rates

Fluidized bed drying offers uniform drying and precise temperature control, reducing seed damage and maintaining higher germination rates compared to tray drying. In contrast, tray drying often leads to uneven moisture removal and potential overheating, which can negatively impact seed vigor and viability. Studies indicate that seeds dried using fluidized beds retain better physiological quality, ensuring improved post-harvest seed performance.

Drying Time and Throughput Analysis

Fluidized bed drying offers significantly reduced drying time compared to tray drying due to enhanced heat and mass transfer, enabling uniform moisture removal from seeds at higher throughput rates. Tray drying, while simpler, often results in longer drying cycles and lower throughput because of limited airflow and batch processing constraints. The efficiency of fluidized bed dryers in maintaining seed quality during rapid drying makes them preferable for large-scale seed moisture removal operations.

Cost Implications in Large-Scale Seed Drying

Fluidized bed drying offers higher energy efficiency and faster moisture removal rates compared to tray drying, leading to lower operational costs in large-scale seed drying. Tray drying requires larger floor space and longer drying times, increasing labor and energy expenses significantly. Investment in fluidized bed dryers, although higher upfront, results in reduced total cost of ownership due to improved throughput and reduced drying duration.

Equipment Maintenance and Operational Complexity

Fluidized bed drying equipment requires regular maintenance of air distribution systems and vibration motors to ensure uniform seed drying and prevent mechanical failures, while tray drying systems involve simpler maintenance focused mainly on heating elements and tray cleaning. Operational complexity in fluidized bed dryers is higher due to the need for precise control of airflow and temperature to maintain seed quality, whereas tray drying operates with more straightforward temperature regulation but longer drying times. The choice impacts labor costs and downtime, with fluidized bed dryers demanding skilled operators and consistent monitoring compared to the relatively manual and less technical operation of tray dryers.

Suitability for Different Seed Types

Fluidized bed drying is highly efficient for small, round seeds such as mustard and sesame due to its uniform airflow and gentle handling, which minimizes seed damage and ensures consistent moisture removal. Tray drying is more suitable for larger, irregularly shaped seeds like sunflower and pumpkin, providing better control over drying conditions and preventing clumping. The choice between the two methods depends on seed size, shape, and sensitivity to heat, impacting drying speed, quality, and germination potential.

Future Trends in Seed Drying Technologies

Fluidized bed drying offers superior heat and mass transfer efficiency compared to tray drying, reducing seed drying time while preserving viability and nutritional quality. Advances in sensor integration and machine learning are driving the development of smart fluidized bed dryers that optimize drying parameters in real-time for uniform moisture removal. Future trends point toward energy-efficient, automated seed drying systems with improved control to enhance post-harvest seed quality and storage stability.

Related Important Terms

Fluidization uniformity index

Fluidized bed drying exhibits a superior fluidization uniformity index compared to tray drying, ensuring more consistent airflow distribution and enhanced moisture removal efficiency in seeds. This uniform fluidization minimizes variation in seed drying rates, reducing quality deterioration and improving overall post-harvest seed preservation.

Granular bed layering

Fluidized bed drying ensures uniform seed moisture removal by suspending seeds in a heated air stream, creating a granular bed layering that promotes efficient heat and mass transfer. In contrast, tray drying relies on static seed layers, leading to uneven moisture content due to limited air penetration and less effective granular bed dynamics.

Residence time distribution

Fluidized bed drying offers a more uniform residence time distribution compared to tray drying, resulting in consistent seed moisture removal and reduced risk of over-drying or under-drying. This enhanced flow dynamics in fluidized beds improve drying efficiency and preserve seed viability by minimizing moisture content variability.

Seed coat micro-cracking

Fluidized bed drying provides uniform airflow and rapid moisture removal, minimizing seed coat micro-cracking by reducing thermal and mechanical stress compared to tray drying. Tray drying often causes uneven temperature distribution and prolonged drying times, increasing the risk of seed coat damage and compromising seed viability.

Dynamic airflow patterns

Fluidized bed drying utilizes dynamic airflow patterns to suspend and uniformly dry seeds, enhancing moisture removal efficiency compared to the static airflow in tray drying. The continuous movement in fluidized beds prevents seed clumping and promotes even heat and mass transfer, resulting in faster drying rates and improved seed quality preservation.

Heat transfer coefficient mapping

Fluidized bed drying exhibits a significantly higher heat transfer coefficient, typically ranging from 50 to 200 W/m2K, compared to tray drying, which generally falls between 10 to 30 W/m2K, resulting in more efficient and uniform seed moisture removal. This enhanced heat transfer in fluidized beds promotes faster drying rates and reduced thermal gradients, minimizing seed damage and preserving germination quality.

Moisture gradient profiling

Fluidized bed drying ensures uniform heat and mass transfer, resulting in minimal moisture gradient profiling within seeds, which maintains seed viability and germination rates. Tray drying often leads to uneven moisture distribution due to limited air circulation, causing significant moisture gradients that can negatively impact seed quality.

Batch vs. continuous-drying kinetics

Fluidized bed drying offers faster and more uniform seed moisture removal due to enhanced heat and mass transfer in continuous operation, whereas tray drying operates primarily in batch mode with slower, less consistent drying kinetics. The continuous fluidized bed system optimizes drying time and energy efficiency, while tray drying's batch process leads to increased drying variability and longer processing periods.

Seed viability retention ratio

Fluidized bed drying enhances seed moisture removal efficiency while maintaining a higher seed viability retention ratio compared to tray drying, which often subjects seeds to uneven heat distribution and prolonged exposure that can reduce viability. Optimizing drying parameters in fluidized bed systems results in uniform temperature control and faster drying rates, preserving seed germination potential and extending seed storage life.

Energy-specific moisture extraction

Fluidized bed drying achieves higher energy-specific moisture extraction rates by enhancing heat and mass transfer through suspended seed particles, resulting in more uniform and faster moisture removal compared to tray drying. Tray drying exhibits lower energy efficiency due to limited air penetration and uneven drying, leading to longer drying times and higher energy consumption per unit moisture removed.

Fluidized Bed Drying vs Tray Drying for seed moisture removal Infographic

agridif.com

agridif.com