Mechanical sorting in post-harvest technology offers rapid and consistent fruit grading by utilizing sensors and automated systems to assess size, color, and texture, reducing human error and labor costs. Manual sorting, while more flexible in handling irregularities and subtle defects, is labor-intensive, time-consuming, and prone to subjective decisions that may affect grading accuracy. Integrating mechanical sorting with manual inspection can optimize fruit quality assessment, enhancing efficiency and market value.

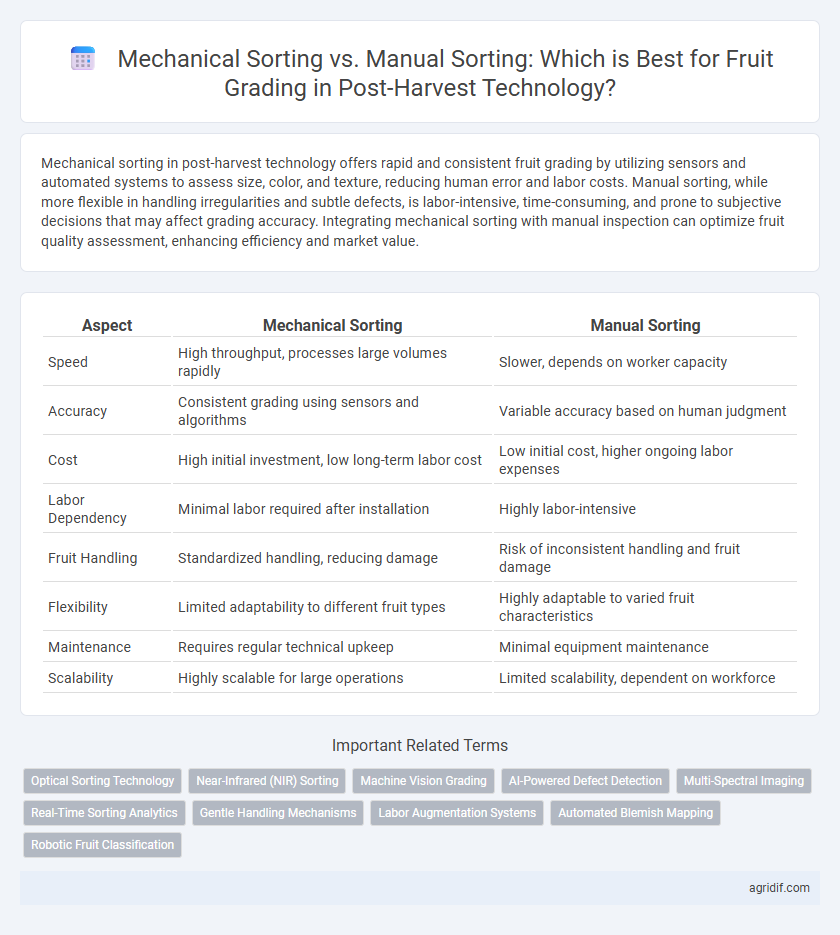

Table of Comparison

| Aspect | Mechanical Sorting | Manual Sorting |

|---|---|---|

| Speed | High throughput, processes large volumes rapidly | Slower, depends on worker capacity |

| Accuracy | Consistent grading using sensors and algorithms | Variable accuracy based on human judgment |

| Cost | High initial investment, low long-term labor cost | Low initial cost, higher ongoing labor expenses |

| Labor Dependency | Minimal labor required after installation | Highly labor-intensive |

| Fruit Handling | Standardized handling, reducing damage | Risk of inconsistent handling and fruit damage |

| Flexibility | Limited adaptability to different fruit types | Highly adaptable to varied fruit characteristics |

| Maintenance | Requires regular technical upkeep | Minimal equipment maintenance |

| Scalability | Highly scalable for large operations | Limited scalability, dependent on workforce |

Introduction to Fruit Grading in Post-Harvest Technology

Mechanical sorting in post-harvest technology enhances fruit grading efficiency by employing sensors and automated systems to classify fruits based on size, color, and firmness. Manual sorting relies on human judgment for selecting quality fruit, which can be subjective and slower but allows for nuanced assessment of defects. Integrating advanced mechanical sorting technologies improves accuracy, throughput, and consistency in fruit grading, essential for maintaining market standards and reducing post-harvest losses.

Overview of Mechanical Sorting Systems

Mechanical sorting systems for fruit grading utilize advanced sensors such as near-infrared, color cameras, and laser scanners to assess size, color, and quality with high precision. Automated conveyors and robotic arms enable rapid, consistent sorting, reducing human error and increasing throughput compared to manual methods. These systems enhance post-harvest efficiency by minimizing fruit damage and enabling real-time quality control data integration.

Manual Sorting Techniques in Fruit Grading

Manual sorting techniques in fruit grading rely on skilled labor to assess fruit quality based on visual and tactile cues such as color, size, texture, and defects. These methods enable precise selection of premium fruits by identifying subtle imperfections that machines might overlook, ensuring higher quality standards. However, manual sorting is labor-intensive and slower compared to mechanical sorting, impacting overall efficiency in large-scale operations.

Efficiency Comparison: Mechanical vs Manual Sorting

Mechanical sorting for fruit grading significantly enhances efficiency by processing thousands of fruits per hour through automated sensors and conveyor systems, reducing labor costs and minimizing human error. Manual sorting, although offering greater flexibility in handling delicate or irregular fruits, is considerably slower and more labor-intensive, leading to lower throughput and higher operational expenses. The integration of advanced machine learning algorithms in mechanical sorters improves accuracy in defect detection and grade classification, making it the preferred choice for large-scale post-harvest operations focused on maximizing efficiency.

Impact on Fruit Quality and Consistency

Mechanical sorting enhances fruit quality and consistency by using precise sensors and calibrated machinery to detect size, color, and defects, reducing human error and variability. Manual sorting, while allowing for nuanced judgment in assessing fruit quality, often results in inconsistent grading due to fatigue and subjective evaluation. The adoption of mechanical sorting systems leads to improved uniformity in fruit batches, higher throughput, and minimized damage, ultimately optimizing post-harvest handling efficiency.

Labor and Cost Implications

Mechanical sorting reduces labor costs significantly by automating the grading process, enabling higher throughput and consistent quality assessment compared to manual sorting. Manual sorting requires intensive labor input, resulting in increased operational expenses and variability due to human error and fatigue. Investment in mechanical sorting systems involves upfront capital expenditure but offers long-term savings by minimizing labor dependency and improving efficiency in post-harvest fruit grading.

Technology Adaptation in Small and Large Farms

Mechanical sorting technology enhances fruit grading efficiency and consistency, especially in large farms where high throughput is critical. Manual sorting remains prevalent in small farms due to lower capital costs and flexibility in handling diverse fruit varieties. Adapting sorting technology involves balancing investment capacity, labor availability, and the scale of fruit production to optimize post-harvest operations.

Error Rates and Accuracy in Sorting Methods

Mechanical sorting in fruit grading significantly reduces error rates by utilizing advanced sensors and algorithms, achieving accuracy levels above 95%. Manual sorting, while flexible, often shows higher variability and a greater error rate, typically ranging between 15-25% due to human fatigue and subjective judgment. Integration of machine vision systems enhances mechanical sorting precision by detecting subtle defects that are frequently missed during manual inspection.

Environmental and Sustainability Considerations

Mechanical sorting in post-harvest fruit grading significantly reduces labor intensity and enhances throughput while minimizing organic waste through precise defect detection, leading to lower environmental impact compared to manual sorting. Manual sorting relies heavily on human labor, often resulting in inconsistent grading and higher waste due to subjective judgment, which can lead to increased resource consumption and reduced sustainability. Implementing automated mechanical sorting systems supports sustainable agricultural practices by optimizing energy use, decreasing water consumption for cleaning, and enabling better waste management through accurate segregation of fruit quality.

Future Trends in Fruit Grading Technologies

Future trends in fruit grading technologies emphasize automation and precision, with mechanical sorting systems integrating advanced sensors and AI-driven image analysis to enhance accuracy and throughput. These innovations reduce reliance on manual sorting, which is labor-intensive and variable in consistency, enabling scalability for large-scale operations. Ongoing developments in hyperspectral imaging and machine learning algorithms promise to further refine defect detection and quality assessment, driving more sustainable and cost-effective post-harvest processes.

Related Important Terms

Optical Sorting Technology

Optical sorting technology in fruit grading significantly enhances accuracy and efficiency compared to traditional manual sorting by using advanced sensors and imaging systems to detect color, size, shape, and defects at high speeds. This mechanical sorting method reduces labor costs, minimizes human error, and ensures consistent quality while enabling rapid processing of large quantities of harvested fruit.

Near-Infrared (NIR) Sorting

Near-Infrared (NIR) sorting enhances mechanical fruit grading by detecting internal quality attributes such as sugar content and firmness, surpassing the limitations of manual sorting which relies primarily on external appearance. This technology improves sorting accuracy, increases throughput, and reduces labor costs, making it a superior choice for post-harvest quality control in the fruit industry.

Machine Vision Grading

Machine vision grading in post-harvest fruit sorting enables precise, consistent evaluation of size, color, and surface defects, outperforming manual sorting in speed and objectivity. Advanced image processing algorithms facilitate high-throughput grading, reducing human error and increasing overall packing efficiency in fruit processing lines.

AI-Powered Defect Detection

AI-powered defect detection in mechanical sorting systems significantly enhances fruit grading accuracy by rapidly identifying bruises, discoloration, and size inconsistencies that manual sorting often overlooks. This technology improves throughput and consistency while reducing labor costs and human error in post-harvest fruit quality assessment.

Multi-Spectral Imaging

Multi-spectral imaging enhances mechanical sorting by enabling precise, non-destructive analysis of fruit quality attributes such as ripeness, defects, and contamination, outperforming manual sorting in speed and consistency. This advanced technology integrates spectral data across multiple wavelengths to improve grading accuracy and reduce labor costs in post-harvest fruit processing.

Real-Time Sorting Analytics

Mechanical sorting for fruit grading leverages advanced sensors and machine learning algorithms to provide real-time sorting analytics, ensuring rapid and accurate classification based on size, color, and defects. Manual sorting lacks real-time data integration, resulting in slower processing times and less consistent quality control compared to automated mechanical systems optimized for high-throughput fruit grading.

Gentle Handling Mechanisms

Mechanical sorting utilizes advanced sensors and soft-touch robotic arms to gently handle fruit, minimizing bruising and maintaining quality during grading. Manual sorting relies on trained workers to carefully inspect and select fruit, allowing for delicate handling but at a slower and less consistent pace compared to automated systems.

Labor Augmentation Systems

Mechanical sorting systems significantly enhance efficiency and accuracy in fruit grading by utilizing advanced sensors and automation technologies, reducing reliance on manual labor and minimizing human error. Labor augmentation systems integrate robotic arms and AI-driven vision systems to support workers, improving throughput and ensuring consistent quality control in post-harvest fruit processing.

Automated Blemish Mapping

Automated blemish mapping in mechanical sorting utilizes advanced imaging technology and machine learning algorithms to detect and grade fruit based on surface defects with higher accuracy and speed compared to manual sorting. This technology reduces human error and labor costs while enabling consistent quality control and improved post-harvest handling efficiency.

Robotic Fruit Classification

Robotic fruit classification in mechanical sorting leverages advanced sensors and AI algorithms to achieve high precision and consistency in fruit grading, significantly reducing human error compared to manual sorting. This technology enhances throughput efficiency and ensures uniform quality standards in post-harvest fruit processing.

Mechanical sorting vs Manual sorting for fruit grading Infographic

agridif.com

agridif.com