Sulphur dioxide fumigation effectively controls microbial growth and preserves post-harvest quality by inhibiting enzymatic browning on fruits and vegetables. Ozone treatment offers a chemical-free alternative with strong oxidizing properties that deactivate pathogens and extend shelf life without leaving harmful residues. Both methods enhance food safety, but ozone treatment is increasingly favored for its environmental benefits and reduced impact on produce sensory attributes.

Table of Comparison

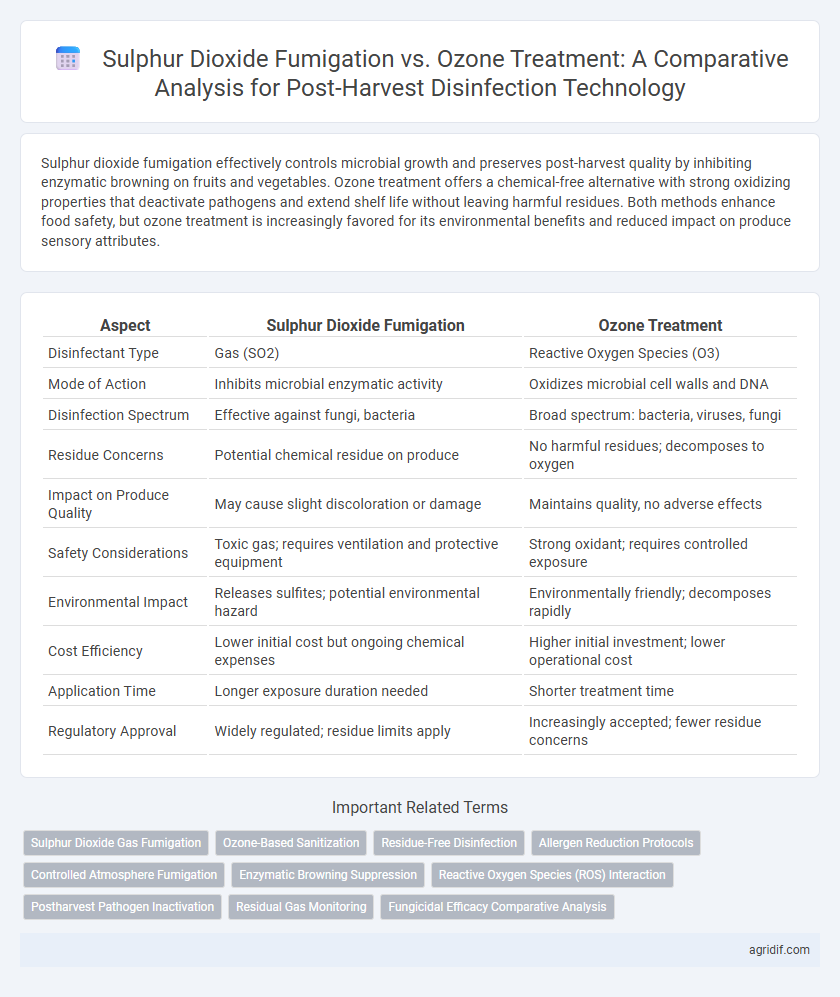

| Aspect | Sulphur Dioxide Fumigation | Ozone Treatment |

|---|---|---|

| Disinfectant Type | Gas (SO2) | Reactive Oxygen Species (O3) |

| Mode of Action | Inhibits microbial enzymatic activity | Oxidizes microbial cell walls and DNA |

| Disinfection Spectrum | Effective against fungi, bacteria | Broad spectrum: bacteria, viruses, fungi |

| Residue Concerns | Potential chemical residue on produce | No harmful residues; decomposes to oxygen |

| Impact on Produce Quality | May cause slight discoloration or damage | Maintains quality, no adverse effects |

| Safety Considerations | Toxic gas; requires ventilation and protective equipment | Strong oxidant; requires controlled exposure |

| Environmental Impact | Releases sulfites; potential environmental hazard | Environmentally friendly; decomposes rapidly |

| Cost Efficiency | Lower initial cost but ongoing chemical expenses | Higher initial investment; lower operational cost |

| Application Time | Longer exposure duration needed | Shorter treatment time |

| Regulatory Approval | Widely regulated; residue limits apply | Increasingly accepted; fewer residue concerns |

Introduction to Post-Harvest Disinfection Methods

Post-harvest disinfection methods such as Sulphur Dioxide (SO2) fumigation and Ozone treatment play critical roles in extending the shelf life of fruits and vegetables by controlling microbial spoilage and phytopathogens. Sulphur Dioxide fumigation is widely used for its strong antimicrobial properties and ability to prevent enzymatic browning, especially in dried fruits, while Ozone treatment offers an eco-friendly alternative with powerful oxidizing capacity that decomposes into oxygen without harmful residues. The choice between SO2 fumigation and Ozone treatment depends on factors such as product sensitivity, regulatory limits, and target pathogens, making an informed selection essential for effective post-harvest disinfection.

Overview of Sulphur Dioxide Fumigation

Sulphur dioxide fumigation is a widely used post-harvest treatment in fruit and vegetable storage to control fungal growth and insect infestation. This chemical method acts as a potent antimicrobial agent, effectively preventing decay and prolonging shelf life, especially in dried fruits such as apricots and grapes. However, due to potential health risks and residue concerns, its application is regulated, prompting a growing interest in alternative methods like ozone treatment.

Ozone Treatment: Mechanism and Applications

Ozone treatment in post-harvest technology operates through strong oxidative reactions that disrupt cell membranes of pathogens, leading to effective microbial disinfection without leaving harmful residues. This method improves shelf life and maintains produce quality by reducing spoilage microorganisms on fruits, vegetables, and grains. Widely applied in cold storage facilities and packaging processes, ozone treatment offers an eco-friendly alternative to sulphur dioxide fumigation by minimizing chemical exposure and environmental impact.

Comparative Efficacy Against Common Post-Harvest Pathogens

Sulphur dioxide fumigation effectively inhibits a broad spectrum of common post-harvest pathogens, including Penicillium and Botrytis species, by disrupting cellular metabolism and enzymatic activity. Ozone treatment demonstrates potent antimicrobial properties through oxidative damage to microbial cell walls, offering rapid pathogen inactivation with minimal residue. Comparative studies indicate that ozone treatment provides superior efficacy in reducing microbial load while minimizing chemical residues, positioning it as a safer alternative to sulphur dioxide for post-harvest disinfection.

Impact on Shelf Life and Produce Quality

Sulphur Dioxide fumigation effectively controls microbial growth and extends shelf life but may leave residual sulfur compounds affecting produce flavor and causing potential allergic reactions. Ozone treatment offers strong oxidative disinfection without chemical residues, maintaining produce quality and freshness while enhancing shelf life through pathogen reduction and ethylene degradation. Comparative studies highlight ozone's advantage in preserving texture and nutritional content over sulphur dioxide, making it a preferable choice for sensitive and organic produce.

Chemical Residues and Food Safety Considerations

Sulphur dioxide fumigation leaves chemical residues that can pose health risks such as respiratory irritation and allergic reactions, necessitating strict regulatory limits to ensure food safety. In contrast, ozone treatment decomposes into oxygen, leaving no harmful residues, making it a safer alternative for disinfecting fresh produce. Both methods require controlled applications to maintain microbial control while minimizing potential impacts on food quality and consumer health.

Environmental and Worker Safety Concerns

Sulphur dioxide fumigation, while effective for post-harvest disinfection, poses significant environmental risks due to its contribution to acid rain and air pollution, alongside respiratory hazards for workers exposed to high concentrations. In contrast, ozone treatment offers a safer alternative by decomposing quickly into oxygen, minimizing residual environmental impact and reducing occupational health risks. However, ozone's oxidative properties require careful monitoring to prevent worker exposure to harmful concentrations during application.

Regulatory Status and Compliance Requirements

Sulphur dioxide fumigation remains widely regulated with strict maximum residue limits (MRLs) established by agencies such as the USDA and EU to ensure food safety during post-harvest treatment. Ozone treatment, classified as Generally Recognized As Safe (GRAS) by the FDA, faces fewer regulatory hurdles, promoting its acceptance for organic produce disinfection. Compliance with regulatory standards for sulphur dioxide demands continuous monitoring of residue levels, whereas ozone requires adherence to exposure limits to prevent product quality degradation and ensure worker safety.

Cost Analysis: Sulphur Dioxide vs Ozone Treatment

Sulphur dioxide fumigation typically incurs lower initial setup costs compared to ozone treatment equipment, making it a cost-effective choice for small to medium-scale post-harvest operations. However, ongoing expenses for sulphur dioxide include frequent chemical procurement and potential regulatory compliance costs due to its hazardous nature. In contrast, ozone treatment involves higher upfront investment in ozone generators but benefits from reduced chemical costs and lower environmental impact, offering long-term savings and sustainability advantages in large-scale disinfection processes.

Future Trends in Post-Harvest Disinfection Technologies

Emerging post-harvest disinfection technologies prioritize sustainability, favoring ozone treatment over sulphur dioxide fumigation due to ozone's rapid degradation into oxygen, eliminating toxic residues. Advanced ozone systems integrated with smart sensors enable precise control, optimizing microbial inactivation while preserving produce quality and extending shelf life. Research trends focus on combining ozone with other non-thermal methods such as UV-C and plasma treatments to enhance efficacy and reduce chemical reliance in fresh produce preservation.

Related Important Terms

Sulphur Dioxide Gas Fumigation

Sulphur Dioxide Gas Fumigation is a widely used post-harvest technology for disinfection due to its strong antimicrobial properties that effectively inhibit fungal growth and preserve the quality of fruits and vegetables during storage. This method offers cost-effective control of post-harvest decay, although concerns about residue safety and environmental impact promote ongoing research into alternative treatments such as ozone.

Ozone-Based Sanitization

Ozone-based sanitization offers a powerful alternative to sulphur dioxide fumigation for post-harvest disinfection by effectively eliminating bacteria, fungi, and viruses without leaving harmful residues. Ozone's strong oxidative properties enable rapid microbial inactivation while preserving the quality and shelf life of fruits and vegetables under controlled post-harvest conditions.

Residue-Free Disinfection

Ozone treatment offers a residue-free disinfection method in post-harvest technology by decomposing into oxygen, eliminating concerns related to chemical residues common with sulphur dioxide fumigation. Sulphur dioxide fumigation, while effective against microbial contamination, often leaves sulfur residues that can affect commodity quality and consumer health.

Allergen Reduction Protocols

Sulphur dioxide fumigation effectively reduces microbial contamination but poses allergen risks due to residual sulfites, necessitating caution in allergen-sensitive environments. Ozone treatment offers a powerful, residue-free disinfection method that significantly diminishes allergen presence by oxidizing proteins without chemical residues, enhancing post-harvest allergen reduction protocols.

Controlled Atmosphere Fumigation

Sulphur dioxide fumigation effectively controls microbial growth and preserves post-harvest quality in controlled atmosphere fumigation by maintaining specific gas concentrations that inhibit spoilage organisms. Ozone treatment offers a chemical-free alternative with strong oxidizing properties that rapidly disinfects produce while minimizing residue and environmental impact in controlled atmosphere systems.

Enzymatic Browning Suppression

Sulphur Dioxide fumigation effectively suppresses enzymatic browning in post-harvest fruits by inhibiting polyphenol oxidase activity and reducing oxidation of phenolic compounds, while ozone treatment offers a chemical-free alternative that deactivates enzymes through strong oxidative reactions but may require precise control to prevent produce damage. Both methods enhance shelf life and maintain visual quality, yet Sulphur Dioxide remains more widely used for rapid enzymatic browning control due to its potent antimicrobial and antioxidant properties.

Reactive Oxygen Species (ROS) Interaction

Sulphur dioxide fumigation primarily disrupts microbial cells through the generation of sulfurous acid, whereas ozone treatment produces reactive oxygen species (ROS) like hydroxyl radicals that induce oxidative damage to cellular components. The interaction of ROS in ozone treatment enhances microbial inactivation by targeting lipids, proteins, and nucleic acids, offering a broader and more effective disinfection mechanism compared to sulphur dioxide fumigation.

Postharvest Pathogen Inactivation

Sulphur dioxide fumigation effectively controls postharvest pathogens like Penicillium expansum but poses risks of residue toxicity and produce damage. Ozone treatment offers a residue-free alternative with broad-spectrum antimicrobial activity, enhancing pathogen inactivation while preserving fruit quality in postharvest storage.

Residual Gas Monitoring

Sulphur dioxide fumigation requires precise residual gas monitoring to prevent toxic residues on produce, ensuring safety and compliance with regulatory limits. Ozone treatment leaves no harmful residues, as it rapidly decomposes into oxygen, reducing the need for extensive post-treatment gas monitoring.

Fungicidal Efficacy Comparative Analysis

Sulphur dioxide fumigation demonstrates strong fungicidal efficacy by effectively inhibiting post-harvest fungal pathogens such as Botrytis cinerea and Penicillium spp., reducing spoilage in fruits and vegetables. Ozone treatment offers comparable disinfection by oxidizing fungal cell walls and spores, with added benefits of residue-free sanitization and broad-spectrum antimicrobial activity under optimized exposure conditions.

Sulphur Dioxide Fumigation vs Ozone Treatment for Disinfection Infographic

agridif.com

agridif.com