Mechanical drying offers precise control over temperature and humidity, significantly reducing drying time and minimizing microbial contamination compared to sun drying. Sun drying depends heavily on weather conditions, often leading to uneven moisture removal and increased risk of spoilage. Implementing mechanical drying enhances product quality and shelf life by ensuring consistent post-harvest dehydration.

Table of Comparison

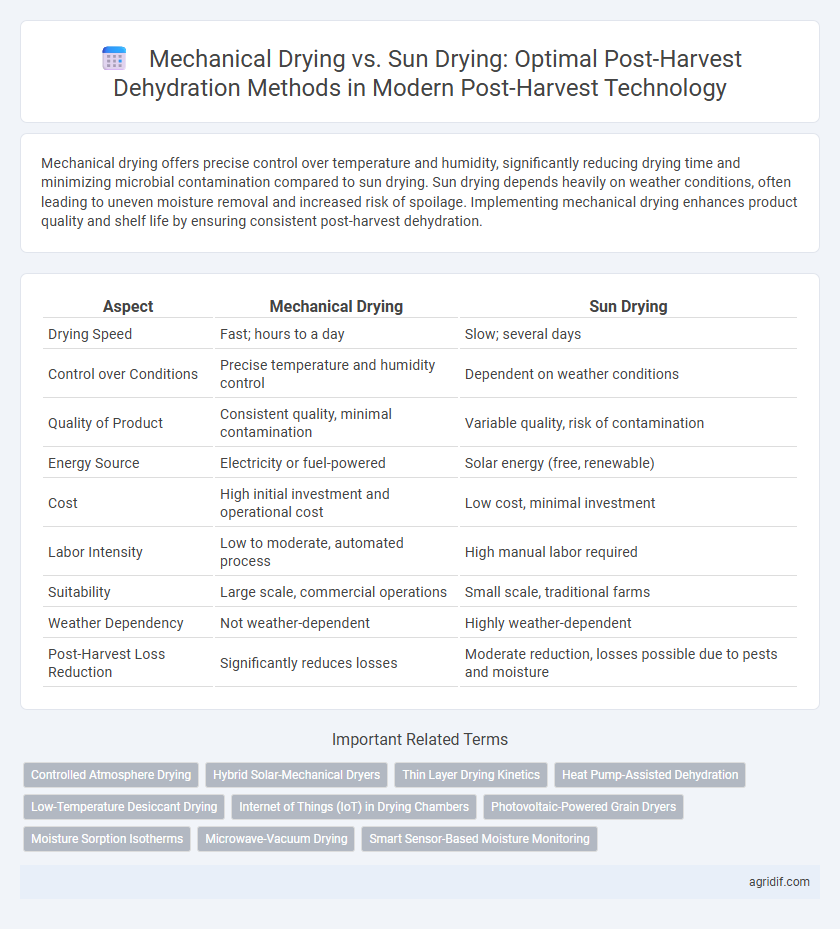

| Aspect | Mechanical Drying | Sun Drying |

|---|---|---|

| Drying Speed | Fast; hours to a day | Slow; several days |

| Control over Conditions | Precise temperature and humidity control | Dependent on weather conditions |

| Quality of Product | Consistent quality, minimal contamination | Variable quality, risk of contamination |

| Energy Source | Electricity or fuel-powered | Solar energy (free, renewable) |

| Cost | High initial investment and operational cost | Low cost, minimal investment |

| Labor Intensity | Low to moderate, automated process | High manual labor required |

| Suitability | Large scale, commercial operations | Small scale, traditional farms |

| Weather Dependency | Not weather-dependent | Highly weather-dependent |

| Post-Harvest Loss Reduction | Significantly reduces losses | Moderate reduction, losses possible due to pests and moisture |

Introduction to Post-Harvest Dehydration Techniques

Mechanical drying offers precise control over temperature and humidity, significantly reducing drying time compared to traditional sun drying methods. Sun drying, while cost-effective, exposes crops to unpredictable weather conditions and contamination risks, leading to inconsistent moisture removal. Effective post-harvest dehydration techniques must balance efficiency, product quality, and operational costs to minimize post-harvest losses.

Principles of Mechanical Drying in Agriculture

Mechanical drying in agriculture utilizes controlled airflow and temperature to rapidly reduce crop moisture content, minimizing microbial growth and enzymatic spoilage. Unlike sun drying, which depends on natural ambient conditions and takes longer, mechanical drying ensures uniform dehydration through the use of heated air circulated by blowers within drying chambers. This precise control over drying parameters enhances product quality, shelf life, and reduces post-harvest losses significantly.

Fundamentals of Sun Drying for Crop Preservation

Sun drying utilizes natural solar radiation to reduce crop moisture content, making it a cost-effective and energy-efficient method for post-harvest dehydration. The effectiveness of sun drying depends on environmental factors such as temperature, humidity, and airflow, which influence drying rates and the prevention of microbial growth. Proper layering, turning, and protection from contaminants are essential practices to maintain crop quality and maximize preservation during the sun drying process.

Efficiency Comparison: Mechanical vs. Sun Drying

Mechanical drying offers significantly faster dehydration times compared to sun drying, reducing moisture content to safe storage levels within hours rather than days. This efficiency minimizes exposure to contaminants and fungal growth, enhancing post-harvest product quality and shelf life. Energy consumption and operational costs vary depending on scale and technology but mechanical drying consistently provides greater control over temperature and humidity, optimizing drying conditions and ensuring uniform moisture removal.

Impact on Crop Quality and Nutrient Retention

Mechanical drying ensures uniform moisture removal, significantly reducing microbial growth and spoilage compared to sun drying, which is subject to environmental variability. The controlled temperature and humidity in mechanical drying enhance nutrient retention, particularly preserving vitamins and antioxidants that degrade under prolonged sun exposure. Consequently, mechanical drying improves crop quality by maintaining color, texture, and nutritional value, thereby extending shelf life and marketability.

Cost Implications and Economic Considerations

Mechanical drying for post-harvest dehydration involves higher initial investment costs due to equipment purchase and maintenance, but it reduces drying time and minimizes spoilage, leading to improved product quality and potential market value. Sun drying, while cost-effective with minimal operational expenses, exposes produce to environmental risks like contamination and uneven drying, potentially resulting in higher post-harvest losses. Economic considerations favor mechanical drying in large-scale operations where faster throughput and quality assurance justify the upfront costs, whereas sun drying remains viable for small-scale farmers prioritizing low-cost methods.

Energy Consumption and Sustainability Assessment

Mechanical drying consumes significantly more energy compared to sun drying, often relying on fossil fuels or electricity, which increases its carbon footprint. Sun drying, while energy-efficient and sustainable, is highly dependent on weather conditions and requires more time, risking product quality and potential contamination. Sustainability assessments favor sun drying for its low energy use and minimal environmental impact, but mechanical drying offers controlled conditions and faster processing suitable for large-scale operations.

Time Management and Processing Speed

Mechanical drying significantly reduces dehydration time compared to sun drying, enabling faster post-harvest processing and minimizing exposure to pests and microbial contamination. Controlled temperature and airflow in mechanical dryers ensure consistent moisture removal, accelerating drying speed and improving overall product quality. In contrast, sun drying is heavily dependent on weather conditions and requires prolonged drying periods, leading to slower processing and increased risk of crop spoilage.

Suitability for Different Crop Types

Mechanical drying offers precise control over temperature and humidity, making it highly suitable for sensitive crops like grains, fruits, and vegetables that require uniform and rapid moisture removal to prevent spoilage. Sun drying is more appropriate for hardy crops such as coffee beans, nuts, and certain spices, where slower dehydration under natural conditions reduces the risk of heat damage and preserves quality. Choosing the appropriate drying method depends on the crop's moisture content, texture, and susceptibility to microbial growth during the post-harvest phase.

Challenges and Future Trends in Drying Technology

Mechanical drying offers controlled temperature and humidity conditions, minimizing microbial growth and enzymatic degradation compared to sun drying, which is highly dependent on weather conditions and increases contamination risks. Challenges in mechanical drying include high energy consumption and initial capital costs, prompting research into solar-assisted and hybrid dryers to improve energy efficiency and sustainability. Future trends focus on integrating smart sensors and IoT technologies for real-time monitoring, optimizing drying parameters, and reducing post-harvest losses while ensuring product quality.

Related Important Terms

Controlled Atmosphere Drying

Mechanical drying offers precise temperature and humidity control, enhancing dehydration efficiency and preserving nutritional quality compared to uncontrolled sun drying. Controlled atmosphere drying further improves post-harvest preservation by regulating oxygen and carbon dioxide levels, reducing microbial growth and oxidative damage.

Hybrid Solar-Mechanical Dryers

Hybrid solar-mechanical dryers combine solar energy and controlled mechanical ventilation to enhance drying efficiency and reduce moisture content more consistently than traditional sun drying, minimizing post-harvest losses. These systems offer improved drying rates, better preservation of nutritional quality, and reduced microbial contamination compared to passive sun drying methods.

Thin Layer Drying Kinetics

Mechanical drying offers precise control over Thin Layer Drying Kinetics by maintaining consistent temperature and airflow, accelerating moisture removal in post-harvest dehydration compared to the variable conditions of sun drying. Sun drying, reliant on ambient environmental factors, often leads to uneven drying rates and prolonged exposure, increasing the risk of microbial growth and quality degradation in harvested crops.

Heat Pump-Assisted Dehydration

Heat pump-assisted dehydration offers precise temperature and humidity control for efficient moisture removal compared to traditional sun drying, reducing drying time by up to 50% and minimizing quality deterioration in grains and fruits. Mechanical drying with heat pumps enhances energy efficiency by recovering latent heat, ensuring uniform dehydration and preserving nutritional content critical in post-harvest technology.

Low-Temperature Desiccant Drying

Low-temperature desiccant drying offers precise moisture control and reduced spoilage risk compared to traditional sun drying, enhancing the preservation of nutritional quality in post-harvest dehydration. Mechanical drying methods generally provide faster drying times but may cause heat stress on sensitive crops, whereas low-temperature desiccant drying operates under controlled humidity and temperature conditions, optimizing product safety and extending shelf life.

Internet of Things (IoT) in Drying Chambers

Mechanical drying using IoT-enabled drying chambers enhances post-harvest dehydration by providing precise control over temperature, humidity, and airflow, resulting in improved product quality and reduced drying time compared to traditional sun drying. IoT sensors and real-time data analytics optimize energy usage and monitor drying parameters, enabling predictive maintenance and minimizing post-harvest losses.

Photovoltaic-Powered Grain Dryers

Photovoltaic-powered grain dryers enable efficient post-harvest dehydration by providing consistent, controllable drying conditions compared to traditional sun drying, reducing moisture content uniformly and minimizing grain spoilage. These mechanical drying systems leverage solar energy, reducing fuel costs and carbon emissions while enhancing drying speed and grain quality preservation.

Moisture Sorption Isotherms

Mechanical drying offers precise control over temperature and humidity, enabling optimal moisture sorption isotherms that maintain product quality and reduce microbial growth during post-harvest dehydration. In contrast, sun drying results in variable moisture sorption isotherms due to fluctuating environmental conditions, leading to inconsistent drying rates and higher risks of spoilage.

Microwave-Vacuum Drying

Microwave-vacuum drying offers significant advantages over traditional sun drying by enabling rapid moisture removal at low temperatures, preserving nutrient quality and reducing microbial growth in post-harvest dehydration. This method enhances energy efficiency and product uniformity, making it a superior choice for drying heat-sensitive agricultural products compared to conventional mechanical drying techniques.

Smart Sensor-Based Moisture Monitoring

Mechanical drying systems equipped with smart sensor-based moisture monitoring offer precise control over drying parameters, ensuring optimal moisture levels and reducing post-harvest losses. Compared to traditional sun drying, this technology enhances efficiency by minimizing over-drying and contamination risks, thereby improving grain quality and shelf life.

Mechanical drying vs sun drying for post-harvest dehydration Infographic

agridif.com

agridif.com