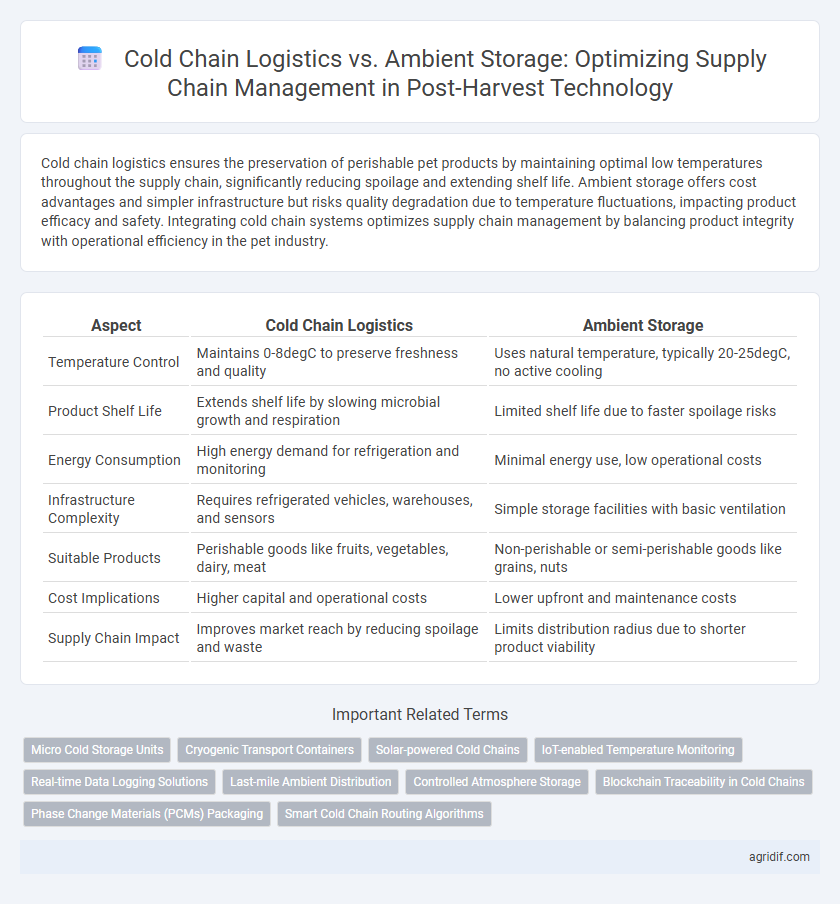

Cold chain logistics ensures the preservation of perishable pet products by maintaining optimal low temperatures throughout the supply chain, significantly reducing spoilage and extending shelf life. Ambient storage offers cost advantages and simpler infrastructure but risks quality degradation due to temperature fluctuations, impacting product efficacy and safety. Integrating cold chain systems optimizes supply chain management by balancing product integrity with operational efficiency in the pet industry.

Table of Comparison

| Aspect | Cold Chain Logistics | Ambient Storage |

|---|---|---|

| Temperature Control | Maintains 0-8degC to preserve freshness and quality | Uses natural temperature, typically 20-25degC, no active cooling |

| Product Shelf Life | Extends shelf life by slowing microbial growth and respiration | Limited shelf life due to faster spoilage risks |

| Energy Consumption | High energy demand for refrigeration and monitoring | Minimal energy use, low operational costs |

| Infrastructure Complexity | Requires refrigerated vehicles, warehouses, and sensors | Simple storage facilities with basic ventilation |

| Suitable Products | Perishable goods like fruits, vegetables, dairy, meat | Non-perishable or semi-perishable goods like grains, nuts |

| Cost Implications | Higher capital and operational costs | Lower upfront and maintenance costs |

| Supply Chain Impact | Improves market reach by reducing spoilage and waste | Limits distribution radius due to shorter product viability |

Introduction to Post-Harvest Supply Chain Management

Cold chain logistics ensures the maintenance of optimal temperature conditions from harvest to consumer, significantly reducing post-harvest losses and preserving the quality of perishable products such as fruits, vegetables, and dairy. In contrast, ambient storage involves storing goods at room temperature, which may be suitable for non-perishable items but increases the risk of spoilage and degradation in fresh produce. Effective post-harvest supply chain management integrates cold chain solutions to enhance shelf life, maintain nutritional value, and meet market demands efficiently.

Defining Cold Chain Logistics in Agriculture

Cold chain logistics in agriculture refers to a temperature-controlled supply chain system that maintains the freshness and quality of perishable produce from harvest to consumer delivery. This approach involves refrigerated storage, transport, and handling to reduce spoilage, extend shelf life, and prevent microbial growth. Compared to ambient storage, cold chain logistics significantly enhances product safety, reduces post-harvest losses, and optimizes supply chain efficiency for fruits, vegetables, dairy, and seafood.

Understanding Ambient Storage Systems

Ambient storage systems in post-harvest technology rely on maintaining products at natural environmental conditions, which reduces energy consumption compared to cold chain logistics. These systems require precise management of temperature, humidity, and ventilation to minimize spoilage and extend shelf life. Understanding the dynamics of ambient storage helps optimize supply chain management by balancing cost efficiency and product quality for perishable goods.

Temperature Control: Key Differences and Their Impact

Cold chain logistics maintains a consistent low temperature, typically between 0degC and 4degC, ensuring the preservation of perishable goods by slowing microbial growth and enzymatic reactions. Ambient storage operates at uncontrolled room temperatures, usually ranging from 15degC to 25degC, which increases the risk of spoilage and reduces shelf life for temperature-sensitive products. Effective temperature control in cold chain logistics directly impacts supply chain efficiency by minimizing product degradation and food waste, whereas ambient storage requires faster distribution to avoid quality loss.

Product Quality and Shelf Life: Cold vs Ambient Storage

Cold chain logistics significantly enhances product quality and extends shelf life by maintaining optimal low temperatures that slow down microbial growth and enzymatic activities in perishable goods. In contrast, ambient storage exposes products to fluctuating temperatures and humidity, accelerating spoilage and reducing freshness. Effective cold chain systems reduce post-harvest losses and ensure consistent supply chain performance by preserving nutritional value and appearance of fruits, vegetables, and other sensitive commodities.

Cost Considerations in Cold Chain vs Ambient Solutions

Cold chain logistics involves higher initial investment and operational costs due to refrigeration equipment, energy consumption, and temperature monitoring systems. Ambient storage offers lower cost alternatives but increases the risk of product spoilage and reduced shelf life, potentially leading to higher losses and decreased product quality. Supply chain managers must balance the cost savings of ambient storage against the benefits of cold chain logistics in preserving perishable goods and minimizing waste.

Infrastructure Requirements and Challenges

Cold chain logistics demands robust infrastructure including refrigerated transport, temperature-controlled warehouses, and reliable power supply to maintain produce freshness and reduce spoilage. Ambient storage requires minimal technical infrastructure but poses challenges in preserving product quality due to fluctuating temperature and humidity levels. Managing investment costs, energy consumption, and infrastructure scalability are critical challenges impacting the efficiency of both cold chain logistics and ambient storage systems within supply chain management.

Sustainability and Environmental Impacts

Cold chain logistics significantly reduce post-harvest losses by maintaining low temperatures, thereby preserving product quality and extending shelf life, which minimizes food waste and lowers greenhouse gas emissions associated with overproduction. In contrast, ambient storage requires less energy but often leads to higher spoilage rates, increasing the carbon footprint through wasted resources and accelerated supply chain inefficiencies. Sustainable supply chain management prioritizes cold chain integration to optimize environmental impacts by balancing energy consumption with reduced food loss and improved resource utilization.

Technological Innovations in Storage and Logistics

Technological innovations in cold chain logistics, such as IoT-enabled temperature monitoring and AI-powered predictive analytics, significantly enhance the quality preservation and shelf life of perishable goods compared to ambient storage. Advanced refrigeration systems integrated with real-time data analytics optimize energy consumption and ensure consistent environmental conditions, reducing spoilage and food waste across supply chains. These innovations facilitate traceability, enable dynamic routing, and improve inventory management, making cold chain logistics a superior solution for maintaining fresh produce integrity from farm to consumer.

Choosing the Right Storage Method for Different Crops

Cold chain logistics preserves perishable crops like fruits, vegetables, and dairy by maintaining controlled low temperatures, significantly extending shelf life and reducing spoilage. Ambient storage suits hardy produce such as grains, potatoes, and onions, relying on ventilated, temperature-stable environments to prevent moisture buildup and decay. Selecting the appropriate storage method depends on the crop's sensitivity to temperature, humidity tolerance, and intended storage duration within the supply chain.

Related Important Terms

Micro Cold Storage Units

Micro cold storage units significantly enhance post-harvest technology by maintaining optimal temperatures, reducing spoilage, and extending shelf life compared to ambient storage, which often leads to rapid quality degradation. These units integrate seamlessly into cold chain logistics, ensuring temperature-controlled environments throughout the supply chain, improving product freshness and reducing post-harvest losses.

Cryogenic Transport Containers

Cryogenic transport containers maintain ultra-low temperatures essential for preserving perishable goods during supply chain management, minimizing spoilage compared to ambient storage methods. Their advanced insulation technology enhances cold chain logistics by ensuring consistent temperature control from harvest to final delivery, significantly extending shelf life and product quality.

Solar-powered Cold Chains

Solar-powered cold chain logistics significantly reduce post-harvest losses by maintaining optimal temperature control throughout the supply chain, ensuring freshness and extending shelf life compared to ambient storage, which exposes produce to fluctuating temperatures and accelerated spoilage. This sustainable technology leverages renewable energy to enhance efficiency, reduce carbon footprint, and improve market accessibility for perishable goods in remote or off-grid regions.

IoT-enabled Temperature Monitoring

IoT-enabled temperature monitoring significantly enhances cold chain logistics by providing real-time data on storage conditions, ensuring optimal temperature control that preserves product quality and extends shelf life. In contrast, ambient storage lacks precise temperature regulation and remote monitoring capabilities, increasing the risk of spoilage and compromising supply chain efficiency in post-harvest management.

Real-time Data Logging Solutions

Cold chain logistics incorporates real-time data logging solutions to monitor temperature, humidity, and other critical variables during post-harvest storage and transportation, ensuring product quality and reducing spoilage. In contrast, ambient storage typically lacks real-time environmental monitoring, increasing the risk of uncontrolled conditions that can compromise perishable goods in the supply chain.

Last-mile Ambient Distribution

Cold chain logistics ensures optimal temperature control throughout the supply chain, minimizing post-harvest losses and preserving produce quality, while ambient storage relies on managing environmental factors without refrigeration, offering cost-effective solutions for durable goods. Last-mile ambient distribution enhances delivery efficiency by reducing dependency on cold storage during final transit, crucial for maintaining freshness in less perishable commodities within urban supply networks.

Controlled Atmosphere Storage

Controlled Atmosphere Storage (CA Storage) within cold chain logistics significantly prolongs the shelf life of perishable produce by precisely regulating oxygen, carbon dioxide, and humidity levels, reducing respiration rates and delaying ripening. Unlike ambient storage, CA Storage minimizes post-harvest losses and maintains quality during extended transportation and distribution in supply chain management.

Blockchain Traceability in Cold Chains

Cold Chain Logistics utilizes blockchain traceability to enhance supply chain management by providing tamper-proof, real-time data on temperature, location, and handling conditions, ensuring optimal freshness and reducing spoilage of perishable goods. In contrast, Ambient Storage lacks such rigorous monitoring, increasing risks of quality degradation and limiting transparency for stakeholders throughout the supply chain.

Phase Change Materials (PCMs) Packaging

Phase Change Materials (PCMs) packaging enhances cold chain logistics by maintaining precise temperature control, reducing spoilage and extending shelf life of perishable goods during transport. In contrast, ambient storage relies on stable environmental conditions but lacks PCM technology, making it less effective for temperature-sensitive supply chains requiring stringent climate control.

Smart Cold Chain Routing Algorithms

Smart cold chain routing algorithms enhance supply chain management by optimizing temperature-controlled transportation, minimizing spoilage, and reducing energy consumption compared to ambient storage methods. These algorithms leverage real-time data and predictive analytics to ensure efficient delivery routes and maintain crop freshness throughout the post-harvest cold chain logistics.

Cold Chain Logistics vs Ambient Storage for supply chain management Infographic

agridif.com

agridif.com