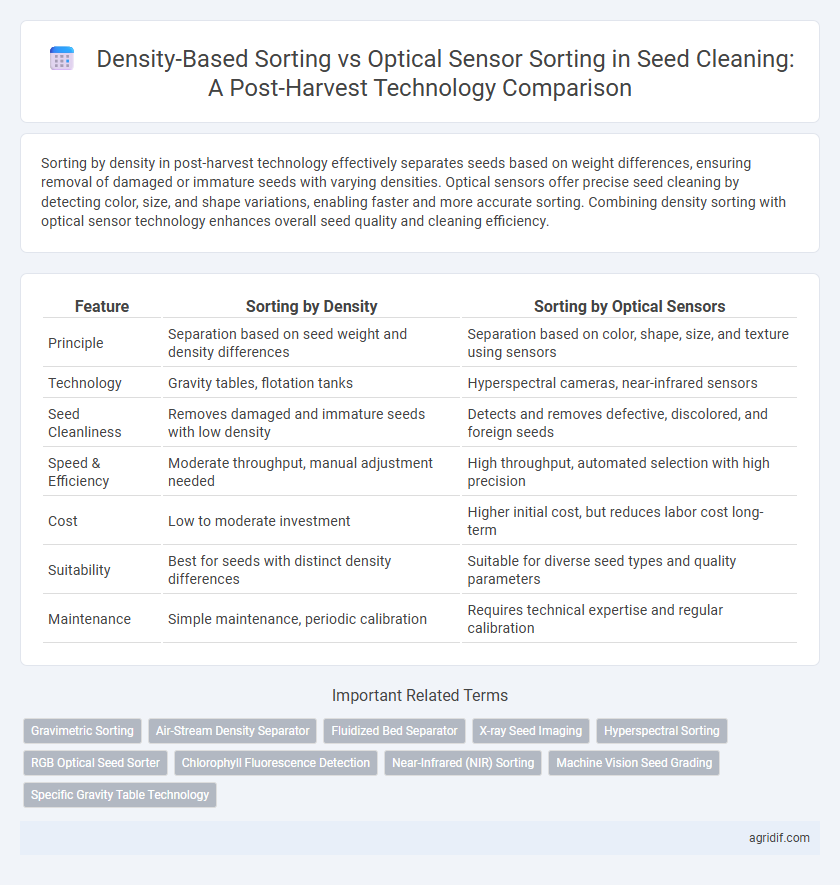

Sorting by density in post-harvest technology effectively separates seeds based on weight differences, ensuring removal of damaged or immature seeds with varying densities. Optical sensors offer precise seed cleaning by detecting color, size, and shape variations, enabling faster and more accurate sorting. Combining density sorting with optical sensor technology enhances overall seed quality and cleaning efficiency.

Table of Comparison

| Feature | Sorting by Density | Sorting by Optical Sensors |

|---|---|---|

| Principle | Separation based on seed weight and density differences | Separation based on color, shape, size, and texture using sensors |

| Technology | Gravity tables, flotation tanks | Hyperspectral cameras, near-infrared sensors |

| Seed Cleanliness | Removes damaged and immature seeds with low density | Detects and removes defective, discolored, and foreign seeds |

| Speed & Efficiency | Moderate throughput, manual adjustment needed | High throughput, automated selection with high precision |

| Cost | Low to moderate investment | Higher initial cost, but reduces labor cost long-term |

| Suitability | Best for seeds with distinct density differences | Suitable for diverse seed types and quality parameters |

| Maintenance | Simple maintenance, periodic calibration | Requires technical expertise and regular calibration |

Introduction to Seed Cleaning: Importance and Methods

Sorting by density in seed cleaning effectively separates seeds based on weight differences, ensuring the removal of damaged or immature seeds that negatively affect crop quality. Optical sensors enhance sorting precision by using light reflectance and image analysis to detect seed color, shape, and surface defects, enabling high-throughput and non-destructive cleaning. Combining density sorting with optical sensing improves overall seed purity, viability, and uniformity, which are critical for optimal germination and yield in agricultural production.

Overview of Post-Harvest Sorting Technologies

Sorting by density in post-harvest seed cleaning utilizes differences in seed weight and buoyancy to separate viable seeds from debris, effectively removing damaged or immature grains through gravity tables or flotation methods. Optical sensors rely on multispectral imaging and color differentiation to detect and discard seeds based on surface characteristics, enabling precise removal of discolored, diseased, or insect-damaged seeds with high accuracy. Both sorting technologies enhance seed quality by optimizing purity and uniformity, though optical sorting offers greater specificity and throughput in automated seed cleaning systems.

Fundamentals of Density-Based Seed Sorting

Density-based seed sorting leverages the fundamental principle that seeds of differing densities respond uniquely to gravity and fluid dynamics, enabling the separation of healthy seeds from damaged or immature ones. This method often employs flotation or air-screening techniques, exploiting specific gravity differences to enhance seed purity and uniformity. Compared to optical sensor sorting, density-based sorting remains a cost-effective and reliable approach for distinguishing viable seeds based on intrinsic physical properties rather than surface characteristics.

Principles and Advancements in Optical Sensor Sorting

Sorting seeds by density relies on the principle that denser seeds settle differently in mediums of varying densities, effectively separating viable seeds from damaged or empty ones. Optical sensor sorting employs advanced imaging technologies such as near-infrared (NIR), multispectral, and hyperspectral sensors to analyze seed color, shape, and surface defects at high speed with precision. Recent advancements in optical sensor sorting enhance seed cleaning by integrating machine learning algorithms and real-time data processing, enabling more accurate defect detection and improved sorting efficiency compared to traditional density-based methods.

Comparative Accuracy: Density Sorting vs Optical Sorting

Sorting seeds by density offers high accuracy in separating viable seeds based on weight and size variations, effectively removing defects like hollow or immature seeds. Optical sorting provides enhanced precision by detecting color, shape, and surface defects, allowing for the identification of subtle quality differences invisible to density methods. Comparative studies reveal optical sensors outperform density sorting in seed purity and germination rates, though combining both methods yields optimal cleaning efficiency in post-harvest seed processing.

Efficiency and Throughput Analysis in Seed Cleaning

Sorting by density in seed cleaning uses buoyancy differences to efficiently separate viable seeds from debris, offering high throughput with minimal energy consumption. Optical sensor sorting, leveraging advanced imaging and spectral analysis, provides precise identification of seed defects and contaminants but often involves higher operational costs and slower processing speeds. Combining both methods can optimize seed cleaning by balancing the high-efficiency throughput of density sorting with the accuracy and detailed inspection capabilities of optical sensors.

Impact on Seed Quality and Purity Levels

Sorting by density in post-harvest seed cleaning effectively removes damaged or immature seeds based on mass differences, enhancing seed quality by reducing low-density defects. Optical sensor sorting utilizes advanced imaging and spectral analysis to identify and eliminate seeds with surface imperfections, discoloration, or fungal infections, significantly improving purity levels. Combining both methods optimizes seed quality and purity by leveraging physical properties and external visual traits for comprehensive seed cleaning.

Cost, Maintenance, and Operational Considerations

Sorting seeds by density involves cost-effective equipment with relatively low maintenance, relying on gravity separation which requires minimal calibration but can be less precise for varied seed types. Optical sensor sorting demands higher initial investment and specialized maintenance due to sophisticated camera and sensor technology, offering rapid, accurate identification and removal of defective seeds through automated processes. Operationally, density sorting is simpler and energy-efficient, whereas optical systems require trained operators and consistent calibration to maintain high throughput and quality standards in seed cleaning.

Technological Integration and Automation Potential

Sorting by density utilizes gravity and fluid dynamics to separate seeds based on specific weight differences, enabling efficient removal of damaged or immature seeds with minimal mechanical intervention. Optical sensor sorting employs high-resolution cameras and advanced algorithms to detect seed color, shape, and surface defects, facilitating precise sorting and classification with real-time data processing and automated feedback control. Integration of these technologies enhances automation potential in seed cleaning by combining physical property-based separation with intelligent visual inspection, resulting in higher throughput, improved seed quality, and reduced labor dependency.

Future Trends in Seed Sorting Technologies

Emerging seed sorting technologies are increasingly integrating optical sensors with advanced machine learning algorithms to enhance accuracy and efficiency beyond traditional density-based methods. Innovations such as hyperspectral imaging and multispectral sensors enable precise differentiation of seeds by chemical composition and health status, supporting higher purity and viability rates. The future of seed cleaning leans toward sensor fusion systems that combine density measurements with optical data to optimize sorting performance and meet evolving agricultural standards.

Related Important Terms

Gravimetric Sorting

Gravimetric sorting leverages seed density variations to effectively separate high-quality seeds from impurities, enhancing purity and germination rates. Unlike optical sensors that rely on surface color and shape, gravimetric technology provides precise separation based on weight differences, ensuring superior seed cleaning performance in post-harvest processing.

Air-Stream Density Separator

The Air-Stream Density Separator efficiently sorts seeds by density using controlled airflow to separate viable seeds from debris based on weight differences, enhancing seed purity and germination rates. Unlike optical sensors that rely on color and shape recognition, this density-based sorting preserves seed integrity and reduces false positives, making it ideal for cleaning seeds with similar visual characteristics but varying densities.

Fluidized Bed Separator

Sorting by density using Fluidized Bed Separators in seed cleaning leverages air flow to separate seeds based on weight differences, enhancing the removal of lighter impurities and defective seeds. Optical sensors complement this by detecting color, shape, and size variations, but Fluidized Bed technology remains more effective for bulk density sorting, ensuring higher purity and uniformity in seed batches.

X-ray Seed Imaging

Sorting by density using floatation or gravity methods effectively separates seeds based on mass and moisture content, but lacks the precision of sorting by optical sensors such as X-ray Seed Imaging, which detects internal seed structures and defects invisible to surface inspection. X-ray Seed Imaging enhances seed cleaning by identifying damage, insect infestations, and maturity levels, leading to higher seed quality and improved germination rates compared to traditional density-based sorting.

Hyperspectral Sorting

Sorting by density separates seeds based on weight differences, effectively removing debris and damaged seeds with altered mass, while hyperspectral sorting utilizes optical sensors to analyze seed spectral signatures, enabling precise detection of seed quality, disease, and contaminants. Hyperspectral sorting offers advanced seed cleaning by capturing detailed spectral data across visible and near-infrared wavelengths, allowing for non-destructive, high-throughput identification of seed varieties and defects that density sorting cannot detect.

RGB Optical Seed Sorter

Sorting by density separates seeds based on weight differences, effectively removing damaged or immature seeds, while RGB optical seed sorters use high-resolution color imaging to detect subtle variations in seed color and shape, enabling precise removal of discolored or defective seeds. RGB optical sensors enhance seed cleaning efficiency by providing real-time analysis and sorting accuracy, outperforming density-based methods in maintaining seed quality and uniformity.

Chlorophyll Fluorescence Detection

Sorting by density in seed cleaning leverages physical differences to separate viable seeds from debris, while optical sensors, particularly those using Chlorophyll Fluorescence Detection, identify seed vitality by measuring chlorophyll content and fluorescence emission to ensure high-quality seed selection. Chlorophyll Fluorescence Detection enhances precision by detecting physiological status and seed maturity, enabling non-destructive, rapid sorting that improves overall post-harvest seed quality and germination rates.

Near-Infrared (NIR) Sorting

Sorting by density leverages seed weight differences to separate impurities but often struggles with subtle quality variations, while optical sensors, especially Near-Infrared (NIR) sorting, detect biochemical properties like moisture and protein content for precise seed quality assessment. NIR sorting enhances germination rates and reduces contamination by identifying internal seed attributes unobservable through density methods, optimizing seed cleaning efficiency in post-harvest technology.

Machine Vision Seed Grading

Sorting by density in seed cleaning leverages gravitational or fluid-based separation to classify seeds based on weight differences, effectively removing impurities and damaged seeds with varying densities. Machine vision seed grading utilizes optical sensors to assess seed size, shape, color, and surface defects, enabling precise and automated sorting that enhances seed quality and uniformity in post-harvest processing.

Specific Gravity Table Technology

Sorting by density using Specific Gravity Table technology effectively separates seeds based on their buoyancy differences, ensuring removal of damaged or low-quality seeds with precision. Optical sensor sorting relies on color, shape, and size detection but often struggles with internal seed defects, making Specific Gravity Tables a superior choice in seed cleaning for enhancing seed viability and uniformity.

Sorting by density vs sorting by optical sensors for seed cleaning Infographic

agridif.com

agridif.com