Hot water treatment effectively reduces post-harvest diseases by eliminating pathogens on fruit surfaces without leaving chemical residues, making it an eco-friendly alternative. Chemical dips provide rapid and broad-spectrum control of fungal and bacterial infections but may pose risks of chemical residues and resistance development. Selecting the appropriate method depends on crop sensitivity, disease pressure, and regulatory standards for food safety.

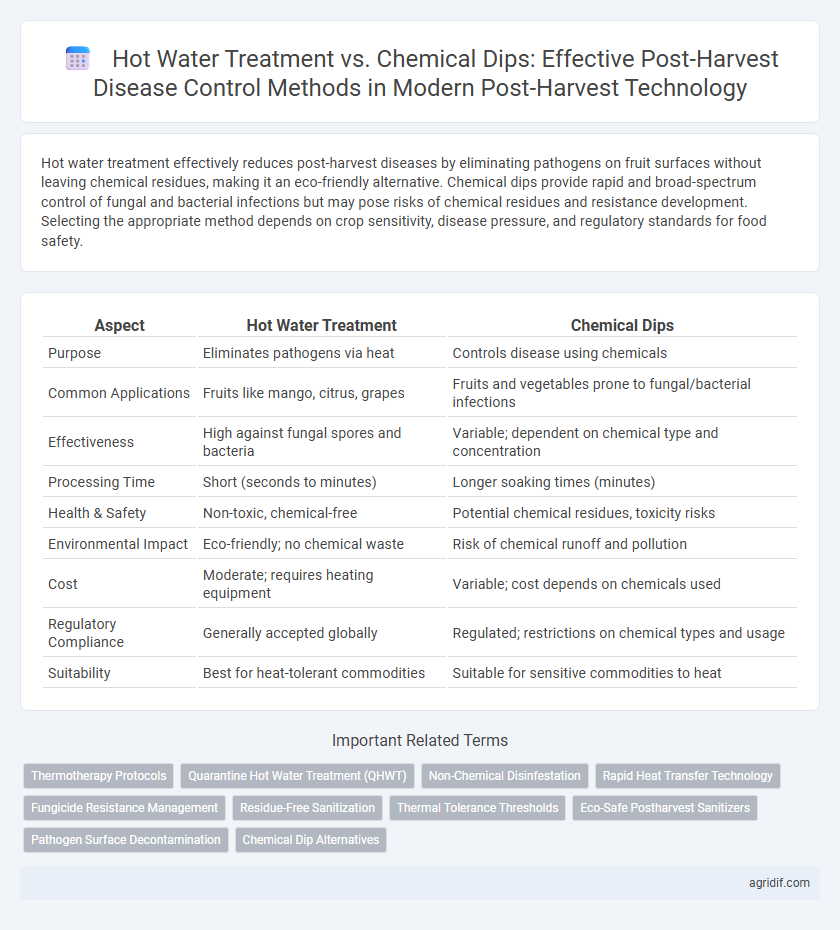

Table of Comparison

| Aspect | Hot Water Treatment | Chemical Dips |

|---|---|---|

| Purpose | Eliminates pathogens via heat | Controls disease using chemicals |

| Common Applications | Fruits like mango, citrus, grapes | Fruits and vegetables prone to fungal/bacterial infections |

| Effectiveness | High against fungal spores and bacteria | Variable; dependent on chemical type and concentration |

| Processing Time | Short (seconds to minutes) | Longer soaking times (minutes) |

| Health & Safety | Non-toxic, chemical-free | Potential chemical residues, toxicity risks |

| Environmental Impact | Eco-friendly; no chemical waste | Risk of chemical runoff and pollution |

| Cost | Moderate; requires heating equipment | Variable; cost depends on chemicals used |

| Regulatory Compliance | Generally accepted globally | Regulated; restrictions on chemical types and usage |

| Suitability | Best for heat-tolerant commodities | Suitable for sensitive commodities to heat |

Overview of Post-Harvest Disease Control Methods

Hot water treatment offers an eco-friendly alternative to chemical dips by using controlled temperature exposure to reduce fungal and bacterial pathogens on fruits and vegetables, minimizing residue risks. Chemical dips, such as chlorine or fungicide solutions, provide rapid disinfection but may leave harmful residues and contribute to environmental concerns. Both methods aim to extend shelf life and maintain produce quality, yet integrating hot water treatment aligns with sustainable post-harvest disease control practices.

Hot Water Treatment: Principles and Applications

Hot Water Treatment (HWT) is a non-chemical method used in post-harvest technology to control diseases by exposing fruits and vegetables to specific temperatures, typically between 50degC and 55degC, for a carefully timed period. This technique effectively reduces pathogens and delays spoilage without leaving chemical residues, making it environmentally friendly and safe for human consumption. Applications of HWT include extending shelf life and maintaining the quality of commodities such as mangoes, avocados, and citrus fruits by inactivating surface fungi and bacteria while minimizing physiological damage.

Chemical Dips: Common Agents and Usage

Chemical dips commonly use fungicides like thiabendazole, imazalil, and sodium hypochlorite to control post-harvest diseases in fruits and vegetables. These agents are effective in reducing fungal pathogens such as Penicillium and Botrytis, enhancing shelf life and maintaining produce quality. The application method typically involves immersion or spraying, with concentrations and exposure times optimized to balance efficacy and minimize residue risks.

Comparative Efficacy Against Major Post-Harvest Pathogens

Hot water treatment (HWT) demonstrates high efficacy in controlling major post-harvest pathogens such as Botrytis cinerea and Penicillium expansum by effectively reducing fungal spore viability without chemical residues. Chemical dips, including fungicides like thiabendazole and imazalil, offer targeted action against a broad spectrum of pathogens but pose risks of chemical residues and pathogen resistance development. Comparative studies indicate that HWT provides a sustainable alternative with comparable or superior disease suppression, particularly when integrated with optimal temperature and exposure duration parameters.

Impact on Produce Quality and Shelf Life

Hot water treatment effectively reduces post-harvest diseases by eliminating surface pathogens while preserving produce firmness and color, thereby extending shelf life without chemical residues. Chemical dips, such as chlorine or fungicides, offer rapid pathogen control but can sometimes lead to phytotoxicity, off-flavors, and residue concerns that may negatively affect produce quality and consumer safety. Selecting hot water treatment optimizes product freshness and marketability by maintaining sensory attributes and minimizing chemical exposure during post-harvest handling.

Safety Considerations for Consumers and Workers

Hot water treatment offers a chemical-free alternative for post-harvest disease control, significantly reducing chemical residues on produce and ensuring safer consumption. Chemical dips, while effective, pose risks of chemical exposure to workers and potential residual toxicity for consumers, necessitating strict handling protocols. Evaluating safety considerations, hot water treatment enhances consumer confidence and worker protection by minimizing the health hazards associated with synthetic fungicides and disinfectants.

Environmental Implications and Residue Concerns

Hot water treatment offers an environmentally friendly alternative to chemical dips by reducing reliance on synthetic fungicides and minimizing chemical residues on fruits and vegetables. This method significantly lowers the risk of environmental contamination and pesticide residues, enhancing food safety and consumer health. In contrast, chemical dips may lead to soil and water pollution, along with potential toxic residues that pose challenges for sustainable agriculture and regulatory compliance.

Cost Analysis: Hot Water vs Chemical Treatments

Hot Water Treatment offers a cost-effective alternative to chemical dips by lowering expenditures on synthetic fungicides and reducing environmental compliance costs. Although initial setup for hot water systems may require higher capital investment, operational costs are generally lower due to reduced chemical input and safer disposal methods. Chemical dips incur ongoing costs for chemicals, application equipment, and worker safety measures, which can increase overall expenses compared to the sustainable and reusable hot water approach.

Adoption Barriers and Practical Implementation

Hot water treatment effectively reduces post-harvest diseases by eliminating pathogens without chemical residues but faces adoption barriers including high energy costs, the need for precise temperature control, and limited infrastructure in small-scale operations. Chemical dips offer easier scalability and quicker application but raise concerns over chemical residues and environmental impact, limiting their acceptance among organic producers and environmentally conscious markets. Practical implementation requires balancing cost, efficacy, and regulatory compliance while training workers to ensure consistent treatment to maximize disease control and maintain produce quality.

Future Trends in Post-Harvest Disease Management

Hot water treatment offers a chemical-free alternative for post-harvest disease control, reducing reliance on synthetic fungicides and addressing consumer demand for residue-free produce. Advances in precision temperature control and exposure time optimization enhance the efficacy of hot water treatments against pathogens like Botrytis cinerea and Penicillium spp. Emerging trends forecast integration of hot water treatment with biological control agents and smart sensors to enable real-time monitoring and sustainable disease management in post-harvest supply chains.

Related Important Terms

Thermotherapy Protocols

Thermotherapy protocols using hot water treatment effectively reduce post-harvest diseases by selectively targeting pathogens while preserving fruit quality, operating typically at temperatures between 48-52degC for 2-10 minutes depending on crop sensitivity. Chemical dips, though widely used for disease control, pose risks of chemical residues and resistance development, making hot water treatment a safer, residue-free alternative in sustainable post-harvest management.

Quarantine Hot Water Treatment (QHWT)

Quarantine Hot Water Treatment (QHWT) is an effective post-harvest disease control method that uses precise temperature and immersion times to eliminate pathogens from fresh produce, reducing reliance on chemical dips that may leave residues. QHWT not only safeguards fruit quality and extends shelf life but also complies with international quarantine regulations, making it a preferred technique for preventing pest and disease transmission during export.

Non-Chemical Disinfestation

Hot water treatment effectively controls post-harvest diseases by using precise temperature exposure to eliminate pathogens without chemical residues, preserving fruit quality and extending shelf life. This non-chemical disinfestation method reduces reliance on synthetic fungicides, aligning with sustainable agricultural practices and consumer demand for residue-free produce.

Rapid Heat Transfer Technology

Rapid Heat Transfer Technology in hot water treatment offers an eco-friendly alternative to chemical dips for post-harvest disease control by uniformly heating produce to precise temperatures, effectively reducing microbial load without chemical residues. This method enhances shelf life and maintains quality by minimizing physiological stress and preventing pathogen proliferation, outperforming conventional chemical treatments in sustainability and consumer safety.

Fungicide Resistance Management

Hot water treatment effectively reduces pathogen load on fruits by exposing them to controlled temperatures, minimizing reliance on chemical fungicides and thereby lowering the risk of fungicide resistance development. Chemical dips, while immediately effective, often contribute to pathogen adaptation and resistance due to repetitive exposure to specific active ingredients, making hot water treatment a sustainable alternative for integrated disease management in post-harvest technology.

Residue-Free Sanitization

Hot water treatment provides residue-free sanitization by using controlled temperature exposure to eliminate post-harvest pathogens without leaving chemical residues on produce, preserving fruit quality and consumer safety. Chemical dips, while effective in disease control, often involve residual chemicals that may impact marketability and raise health concerns.

Thermal Tolerance Thresholds

Hot water treatment effectively controls post-harvest diseases by exposing fruits to temperatures typically between 50degC and 55degC for a defined duration, ensuring pathogen inactivation without compromising the thermal tolerance thresholds of the produce. Chemical dips, while effective, often pose risks of residue accumulation and phytotoxicity, making thermal tolerance thresholds critical in determining the optimal hot water treatment parameters to maximize disease control while preserving fruit quality.

Eco-Safe Postharvest Sanitizers

Hot Water Treatment uses controlled temperatures to effectively reduce microbial load on fruits, preserving quality without chemical residues, while Chemical Dips, often containing chlorine or fungicides, target pathogens but raise concerns over environmental impact and residue safety. Eco-Safe postharvest sanitizers offer a sustainable alternative by combining natural antimicrobial agents that enhance disease control efficacy while minimizing ecological and consumer health risks compared to conventional chemical dips.

Pathogen Surface Decontamination

Hot water treatment effectively reduces surface pathogens on fruits by disrupting microbial membranes and denaturing proteins, offering an eco-friendly alternative to chemical dips that often leave residues and may cause phytotoxicity. Compared to chemical dips like chlorine or fungicides, hot water treatment provides a residue-free solution with lower risk of pathogen resistance, enhancing post-harvest disease control and maintaining fruit quality.

Chemical Dip Alternatives

Chemical dip alternatives such as hot water treatment provide an eco-friendly solution for post-harvest disease control by reducing reliance on synthetic fungicides and minimizing chemical residues on produce. These methods enhance fruit and vegetable shelf life through temperature-controlled pathogen inactivation, supporting sustainable agricultural practices and consumer safety.

Hot Water Treatment vs Chemical Dips for post-harvest disease control Infographic

agridif.com

agridif.com