Wax coating enhances fruit preservation by creating a moisture-resistant barrier that reduces water loss and slows down respiration, extending shelf life. Edible film coatings offer an eco-friendly alternative, forming a thin, palatable layer that protects against microbial contamination while maintaining fruit quality. Both methods improve post-harvest storage, but edible films provide added benefits such as biodegradability and potential incorporation of antimicrobial agents.

Table of Comparison

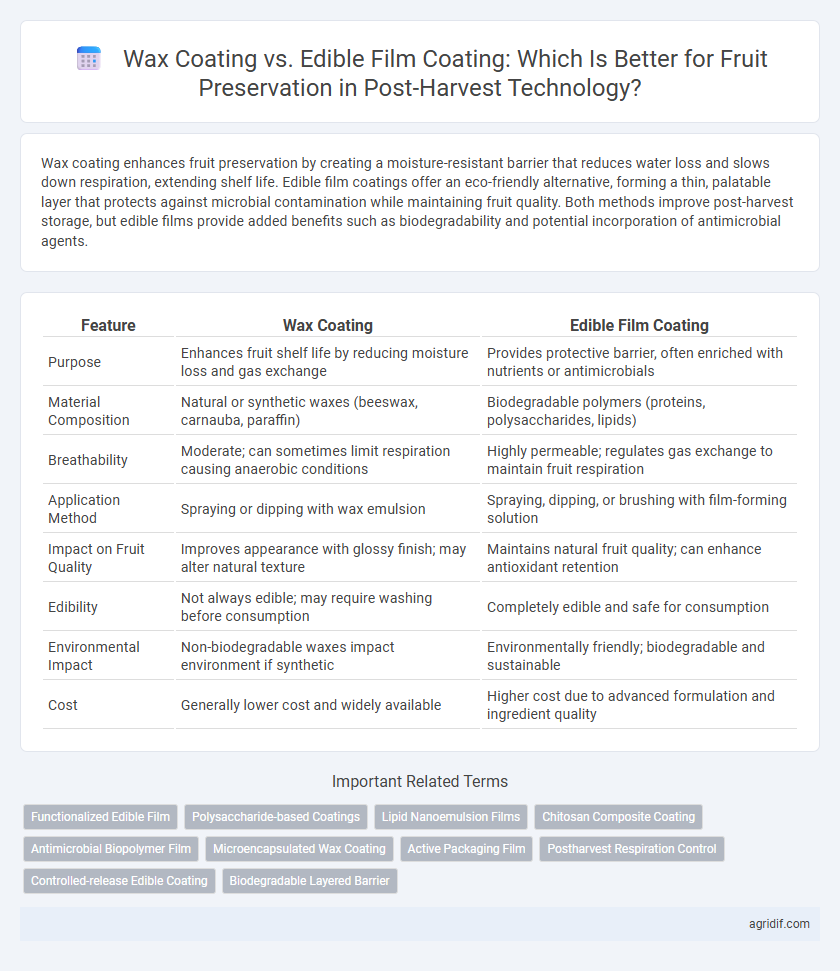

| Feature | Wax Coating | Edible Film Coating |

|---|---|---|

| Purpose | Enhances fruit shelf life by reducing moisture loss and gas exchange | Provides protective barrier, often enriched with nutrients or antimicrobials |

| Material Composition | Natural or synthetic waxes (beeswax, carnauba, paraffin) | Biodegradable polymers (proteins, polysaccharides, lipids) |

| Breathability | Moderate; can sometimes limit respiration causing anaerobic conditions | Highly permeable; regulates gas exchange to maintain fruit respiration |

| Application Method | Spraying or dipping with wax emulsion | Spraying, dipping, or brushing with film-forming solution |

| Impact on Fruit Quality | Improves appearance with glossy finish; may alter natural texture | Maintains natural fruit quality; can enhance antioxidant retention |

| Edibility | Not always edible; may require washing before consumption | Completely edible and safe for consumption |

| Environmental Impact | Non-biodegradable waxes impact environment if synthetic | Environmentally friendly; biodegradable and sustainable |

| Cost | Generally lower cost and widely available | Higher cost due to advanced formulation and ingredient quality |

Introduction to Fruit Preservation Methods

Wax coating and edible film coating are prominent fruit preservation methods that enhance shelf life by reducing moisture loss and delaying ripening processes. Wax coatings form a protective barrier, controlling gas exchange and preventing microbial contamination, while edible films are biodegradable layers made from natural polymers that can incorporate antioxidants and antimicrobials. Both techniques improve fruit quality during storage and transportation, with edible films offering an eco-friendly alternative to synthetic waxes.

Understanding Wax Coating: Composition and Application

Wax coating for fruit preservation primarily consists of natural or synthetic materials such as carnauba wax, shellac, and paraffin, which create a protective barrier on the fruit surface. This coating reduces moisture loss, controls respiration rate, and provides resistance against microbial spoilage, extending the shelf life of fruits like apples, citrus, and avocados. Application methods typically involve dipping, spraying, or brushing, ensuring uniform coverage and enhanced fruit quality during storage and transportation.

Edible Film Coating: Materials and Mechanisms

Edible film coatings for fruit preservation primarily utilize natural polymers such as cellulose, chitosan, and alginate, which form a breathable barrier that regulates gas exchange and moisture loss, thereby extending shelf life. These coatings incorporate antimicrobial and antioxidant agents that inhibit microbial growth and delay enzymatic browning, maintaining fruit quality. Their biodegradable and non-toxic nature offers a sustainable alternative to traditional wax coatings, enhancing fruit safety and consumer acceptance.

Comparative Shelf Life Extension: Wax vs Edible Films

Wax coating and edible film coating are both effective for fruit preservation but differ significantly in shelf life extension. Wax coatings create a moisture barrier that slows down respiration and dehydration, typically extending shelf life by several weeks, depending on the fruit type. Edible films, often made from polysaccharides, proteins, or lipids, provide a more breathable barrier that not only reduces moisture loss but can enhance gas exchange, resulting in a moderate shelf life extension while improving safety and edibility.

Impact on Fruit Quality and Sensory Attributes

Wax coating enhances fruit shelf life by creating a moisture barrier that reduces water loss and delays ripening, significantly preserving firmness and color. Edible film coatings, often composed of biopolymers like chitosan or alginate, improve gas exchange regulation, maintaining fruit freshness while imparting minimal sensory changes such as taste or texture. Comparative studies indicate edible films offer superior breathability and biodegradability, positively affecting aroma and flavor retention compared to conventional wax coatings.

Barrier Properties: Moisture, Gas Exchange, and Respiration Control

Wax coatings provide a robust moisture barrier that effectively reduces water loss in fruits, enhancing shelf life by maintaining turgidity. Edible film coatings offer superior control over gas exchange, regulating oxygen and carbon dioxide diffusion to slow down respiration rates and delay ripening. The integration of both wax coatings and edible films can optimize respiration control and moisture retention, ensuring improved fruit preservation post-harvest.

Food Safety and Consumer Health Considerations

Wax coating provides a protective barrier that reduces moisture loss and delays fruit spoilage but may contain synthetic chemicals raising concerns about potential residues affecting food safety. Edible film coatings, derived from natural sources like polysaccharides and proteins, are generally recognized as safe (GRAS) and can enhance consumer health by being digestible and free from harmful additives. Choosing edible films aligns with increasing consumer demand for clean-label products while maintaining fruit quality and extending shelf life.

Sustainability and Environmental Implications

Wax coating and edible film coating for fruit preservation differ significantly in sustainability and environmental impact. Wax coatings often rely on petroleum-based materials, posing challenges for biodegradability and potential soil contamination, whereas edible film coatings are typically derived from renewable resources such as polysaccharides, proteins, and lipids, enhancing their compostability and reducing ecological footprint. The shift towards edible films aligns with sustainable post-harvest practices by minimizing plastic waste and promoting circular agricultural systems.

Regulatory Standards for Coating Use in Post-harvest

Regulatory standards for wax coating and edible film coating in post-harvest fruit preservation vary globally, emphasizing food safety, chemical composition, and residue limits. Wax coatings must comply with agencies such as the FDA in the US and EFSA in Europe, which regulate permissible additives and ensure coatings do not pose health risks. Edible film coatings undergo strict assessments for biodegradability, allergenicity, and impact on fruit quality, with standards promoting natural, non-toxic ingredients suitable for direct human consumption.

Future Trends and Innovations in Fruit Coating Technology

Emerging advancements in fruit preservation highlight the shift from traditional wax coatings to innovative edible film coatings that enhance shelf life while maintaining fruit safety and nutritional value. Nanotechnology integration and biodegradable biopolymers are driving the development of multifunctional edible films with antimicrobial and antioxidant properties, presenting a sustainable alternative to conventional waxes. Future trends emphasize intelligent coatings embedded with sensors for real-time monitoring of fruit ripeness and spoilage, transforming post-harvest technology through precision preservation and waste reduction.

Related Important Terms

Functionalized Edible Film

Functionalized edible film coatings enhance fruit preservation by providing antimicrobial, antioxidant, and moisture barrier properties, extending shelf life and maintaining quality more effectively than traditional wax coatings. These bio-based films can be tailored with natural extracts or nanomaterials to improve gas permeability and reduce post-harvest decay.

Polysaccharide-based Coatings

Polysaccharide-based coatings in both wax and edible film forms enhance fruit preservation by forming semi-permeable barriers that reduce moisture loss and gas exchange, thereby extending shelf life. Edible films made from polysaccharides such as chitosan and alginate offer superior biodegradability and can carry antimicrobial agents, providing safer and more environmentally friendly alternatives to traditional wax coatings.

Lipid Nanoemulsion Films

Lipid nanoemulsion films enhance fruit preservation by creating a thin, uniform barrier that reduces moisture loss and gas exchange more effectively than traditional wax coatings. These edible films improve shelf life, maintain fruit firmness, and carry bioactive compounds that provide antimicrobial and antioxidant benefits during post-harvest storage.

Chitosan Composite Coating

Chitosan composite coatings combine natural polysaccharide properties with antimicrobial and antifungal effects, significantly enhancing fruit preservation by reducing moisture loss and oxidative damage. Compared to traditional wax coatings, chitosan-based edible films provide superior breathability and biocompatibility, extending shelf life while maintaining fruit quality and safety.

Antimicrobial Biopolymer Film

Wax coatings provide a traditional barrier against moisture loss and enhance fruit gloss, but antimicrobial biopolymer edible films offer superior fruit preservation by actively inhibiting microbial growth and extending shelf life through natural antimicrobial agents embedded in the film matrix. These biopolymer films, derived from renewable resources like chitosan or alginate, improve gas exchange and reduce post-harvest decay more effectively than conventional wax coatings.

Microencapsulated Wax Coating

Microencapsulated wax coating enhances fruit preservation by providing a controlled-release barrier that reduces moisture loss and delays respiration more effectively than traditional wax or edible film coatings. This advanced technology improves shelf life and maintains fruit quality by minimizing oxidation and microbial growth while allowing gas exchange tailored to specific fruit types.

Active Packaging Film

Active packaging films enhance fruit preservation by incorporating antimicrobial and antioxidant agents that extend shelf life beyond traditional wax coatings, which primarily provide a moisture barrier. Unlike wax coatings, active films regulate gas exchange and interact with the fruit's microenvironment, reducing spoilage and maintaining quality more effectively.

Postharvest Respiration Control

Wax coating effectively reduces postharvest respiration by creating a semi-permeable barrier that slows gas exchange, thereby extending fruit shelf life. Edible film coatings, formulated with natural polymers, also modulate respiration rates while enhancing moisture retention and providing additional antimicrobial protection.

Controlled-release Edible Coating

Controlled-release edible coatings enhance fruit preservation by gradually releasing antimicrobial and antioxidant agents, extending shelf life and maintaining quality better than conventional wax coatings. These coatings enable precise modulation of moisture and gas exchange, reducing spoilage while supporting fruit respiration and freshness.

Biodegradable Layered Barrier

Wax coating provides a traditional, hydrophobic barrier that reduces moisture loss and extends shelf life, while edible film coatings utilize biodegradable layered barriers composed of polysaccharides, proteins, and lipids to enhance gas exchange control and antimicrobial properties. These biodegradable coatings offer environmentally friendly alternatives by improving fruit preservation through tailored permeability and natural composition, reducing reliance on synthetic waxes.

Wax Coating vs Edible Film Coating for fruit preservation Infographic

agridif.com

agridif.com