Controlled Atmosphere Storage (CAS) regulates oxygen, carbon dioxide, and humidity levels in large-scale grain storage to slow respiration and delay spoilage, ensuring prolonged preservation of grain quality. Modified Atmosphere Packaging (MAP) adjusts the gas composition within sealed packages, providing a cost-effective solution for smaller quantities by reducing microbial growth and oxidation. Both methods optimize grain shelf life, but CAS is ideal for bulk storage, while MAP suits retail and consumer-level needs.

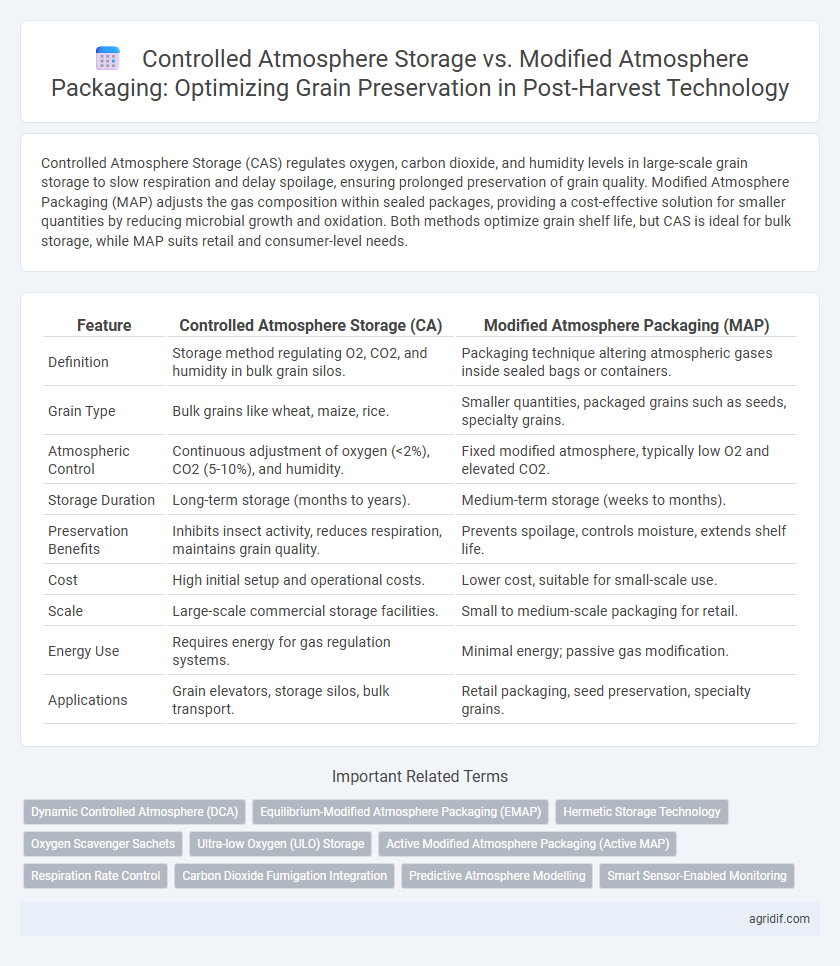

Table of Comparison

| Feature | Controlled Atmosphere Storage (CA) | Modified Atmosphere Packaging (MAP) |

|---|---|---|

| Definition | Storage method regulating O2, CO2, and humidity in bulk grain silos. | Packaging technique altering atmospheric gases inside sealed bags or containers. |

| Grain Type | Bulk grains like wheat, maize, rice. | Smaller quantities, packaged grains such as seeds, specialty grains. |

| Atmospheric Control | Continuous adjustment of oxygen (<2%), CO2 (5-10%), and humidity. | Fixed modified atmosphere, typically low O2 and elevated CO2. |

| Storage Duration | Long-term storage (months to years). | Medium-term storage (weeks to months). |

| Preservation Benefits | Inhibits insect activity, reduces respiration, maintains grain quality. | Prevents spoilage, controls moisture, extends shelf life. |

| Cost | High initial setup and operational costs. | Lower cost, suitable for small-scale use. |

| Scale | Large-scale commercial storage facilities. | Small to medium-scale packaging for retail. |

| Energy Use | Requires energy for gas regulation systems. | Minimal energy; passive gas modification. |

| Applications | Grain elevators, storage silos, bulk transport. | Retail packaging, seed preservation, specialty grains. |

Introduction to Post-Harvest Grain Preservation

Post-harvest grain preservation is crucial for maintaining quality and extending shelf life by minimizing spoilage and insect infestation. Controlled Atmosphere Storage (CAS) regulates oxygen, carbon dioxide, and humidity levels in sealed environments to slow respiration and inhibit microbial growth. Modified Atmosphere Packaging (MAP) involves altering the gas composition within packaging materials to create similar preservation effects on a smaller, more flexible scale, suitable for distribution and retail.

Fundamentals of Controlled Atmosphere (CA) Storage

Controlled Atmosphere (CA) Storage for grain preservation involves precisely regulating oxygen, carbon dioxide, and nitrogen levels to slow respiration and metabolic rates, thereby extending shelf life and reducing spoilage. By maintaining low oxygen (typically 1-2%) and elevated carbon dioxide concentrations, CA storage effectively inhibits insect activity, fungal growth, and enzymatic degradation without compromising grain quality. This method contrasts with Modified Atmosphere Packaging (MAP), which alters the atmosphere inside packaging but lacks the large-scale environmental control fundamental to CA storage systems.

Overview of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) involves altering the composition of gases surrounding grain to inhibit microbial growth and delay spoilage, typically reducing oxygen while increasing carbon dioxide and nitrogen levels. This method extends shelf life by maintaining optimal respiration rates and moisture content, crucial for preserving grain quality during storage. Compared to Controlled Atmosphere Storage, MAP offers scalable, cost-effective protection suitable for various grain volumes and distribution stages.

Key Differences Between CA Storage and MAP

Controlled Atmosphere (CA) Storage maintains a stable environment by regulating oxygen, carbon dioxide, and humidity levels within large storage facilities to prolong grain shelf life and prevent spoilage. Modified Atmosphere Packaging (MAP) involves altering the internal gas composition inside sealed packages, typically reducing oxygen and increasing carbon dioxide to inhibit microbial growth on smaller grain quantities. Key differences include scale of application, with CA suited for bulk storage, while MAP targets packaged products, and the level of environmental control, as CA allows continuous monitoring and adjustment over time, whereas MAP provides a static atmosphere during storage.

Effectiveness in Insect and Pest Control

Controlled Atmosphere Storage (CAS) effectively suppresses insect metabolism and reproduction by maintaining low oxygen and elevated carbon dioxide levels, significantly reducing pest infestations in stored grains. Modified Atmosphere Packaging (MAP) creates a localized altered gas environment around grain products, offering protection against insects but less consistency in gas composition compared to CAS. CAS generally provides superior pest control for bulk storage, while MAP is more suitable for smaller-scale packaging due to its limited capacity to maintain stable atmospheric conditions over time.

Impact on Grain Shelf Life and Quality Retention

Controlled Atmosphere Storage (CAS) regulates oxygen, carbon dioxide, and humidity levels in storage facilities to significantly extend grain shelf life and maintain quality by slowing respiration and inhibiting mold growth. Modified Atmosphere Packaging (MAP) alters the gas composition around the grain within sealed containers, offering localized protection that enhances freshness but may be less effective for large-scale storage. CAS generally provides superior long-term grain preservation and quality retention compared to MAP, making it ideal for bulk grain storage and prolonged shelf life.

Technological Requirements and Scalability

Controlled Atmosphere Storage (CAS) for grain preservation requires advanced infrastructure such as airtight storage facilities, precise gas monitoring systems, and automated control technology to regulate oxygen, carbon dioxide, and humidity levels. Modified Atmosphere Packaging (MAP) relies on specialized packaging films and gas flushing equipment, offering greater scalability for small to medium operations due to lower capital investment and simpler implementation. CAS systems excel in large-scale, long-term grain storage with extensive technological demands, whereas MAP provides flexible, cost-effective solutions suitable for diversified distribution channels.

Cost Analysis: CA Storage Versus MAP

Controlled Atmosphere (CA) Storage involves significant initial investment in advanced monitoring and gas regulation systems to maintain optimal oxygen and carbon dioxide levels, leading to higher upfront costs compared to Modified Atmosphere Packaging (MAP). MAP offers a cost-effective alternative with lower setup expenses by altering packaging atmosphere on a per-unit basis, though ongoing packaging material costs can accumulate over time. Evaluating cost-efficiency between CA and MAP requires considering scale, duration of storage, and the specific grain type, as CA better suits large-scale, long-term storage while MAP excels in short-term, smaller batch preservation.

Environmental Implications of Each Method

Controlled Atmosphere Storage (CAS) reduces oxygen levels and increases carbon dioxide to slow grain respiration, leading to lower greenhouse gas emissions through decreased spoilage and extended storage life. Modified Atmosphere Packaging (MAP) involves altering the internal package gases, often using nitrogen flushing to inhibit microbial growth, which generates less environmental waste due to reduced use of chemical preservatives. CAS requires significant energy inputs for atmosphere regulation, whereas MAP offers a more energy-efficient, scalable option for grain preservation with minimal environmental footprint.

Choosing the Optimal Atmosphere Technology for Grain Storage

Controlled Atmosphere Storage (CAS) regulates oxygen, carbon dioxide, and humidity levels within sealed grain storage facilities, significantly extending shelf life by inhibiting microbial growth and insect activity. Modified Atmosphere Packaging (MAP) alters the gas composition inside sealed packages for smaller grain quantities, offering portability and reduced oxygen exposure but less extensive environmental control than CAS. Selecting the optimal atmosphere technology depends on storage scale, grain type, and economic considerations, with CAS favored for large-scale, long-term preservation and MAP suited for retail distribution and smaller batches.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology maintains precise oxygen, carbon dioxide, and humidity levels in grain storage, significantly reducing respiration rates and fungal growth compared to Modified Atmosphere Packaging (MAP), which relies on passive gas exchange. DCA's real-time monitoring and adjustment capabilities enhance grain preservation by preventing spoilage and maintaining quality during long-term storage.

Equilibrium-Modified Atmosphere Packaging (EMAP)

Equilibrium-Modified Atmosphere Packaging (EMAP) technology in grain preservation regulates gas composition by balancing the grain's respiration rates with the packaging permeability, effectively reducing oxygen levels and increasing carbon dioxide to inhibit microbial growth and delay spoilage. Compared to Controlled Atmosphere Storage (CAS), EMAP offers a cost-effective, scalable solution with precise gas equilibrium, promoting longer shelf life and quality retention without the need for complex infrastructure.

Hermetic Storage Technology

Hermetic storage technology in controlled atmosphere storage effectively limits oxygen levels and increases carbon dioxide concentration, inhibiting grain respiration and pest activity to prolong shelf life. Modified atmosphere packaging also uses gas composition control but is better suited for small-scale storage, whereas hermetic storage offers large-scale, airtight, and moisture-resistant conditions ideal for long-term grain preservation.

Oxygen Scavenger Sachets

Controlled Atmosphere Storage (CAS) maintains grain quality by regulating oxygen levels through sealed environments and gas composition control, whereas Modified Atmosphere Packaging (MAP) utilizes oxygen scavenger sachets to actively reduce oxygen inside grain packages, limiting microbial growth and oxidative damage. Oxygen scavenger sachets in MAP offer targeted oxygen removal, enhancing shelf life and preserving grain nutritional value by minimizing spoilage and insect infestation during storage.

Ultra-low Oxygen (ULO) Storage

Controlled Atmosphere Storage utilizing Ultra-low Oxygen (ULO) levels below 1% effectively slows grain respiration and microbial activity, significantly extending shelf life compared to Modified Atmosphere Packaging, which adjusts gas composition within sealed packages but typically cannot achieve such low oxygen conditions. ULO storage provides superior grain preservation by maintaining near-anaerobic environments in large storage facilities, reducing spoilage and insect infestation without the need for chemical treatments.

Active Modified Atmosphere Packaging (Active MAP)

Controlled Atmosphere Storage (CAS) maintains optimal gas compositions like low oxygen and elevated carbon dioxide levels in large silos to extend grain shelf life, while Active Modified Atmosphere Packaging (Active MAP) uses gas flushing and absorption technologies inside sealed smaller packages to actively adjust and maintain target atmospheres tailored for specific grain types. Active MAP enhances grain preservation by dynamically controlling oxygen and moisture levels, reducing microbial growth and insect infestation more efficiently than passive MAP, making it ideal for high-value grains requiring extended storage and better quality retention.

Respiration Rate Control

Controlled Atmosphere Storage (CAS) regulates oxygen and carbon dioxide levels to significantly reduce grain respiration rates, extending shelf life and maintaining quality during long-term storage. Modified Atmosphere Packaging (MAP) also alters gas composition around the grain but offers a less consistent respiration rate control, making it more suitable for short-term preservation and reduced post-harvest losses.

Carbon Dioxide Fumigation Integration

Controlled Atmosphere Storage (CAS) maintains low oxygen and elevated carbon dioxide levels to inhibit microbial growth and insect infestation in grains, while Modified Atmosphere Packaging (MAP) uses sealed packaging with altered gas compositions to achieve similar preservation effects on a smaller scale. Integrating carbon dioxide fumigation in both CAS and MAP enhances pest control efficacy by increasing CO2 concentration, thereby improving grain quality and extending shelf life through synergistic pest suppression and reduced oxidative damage.

Predictive Atmosphere Modelling

Controlled Atmosphere Storage (CAS) maintains specific gas compositions within large storage facilities to slow grain respiration and microbial growth, while Modified Atmosphere Packaging (MAP) involves adjusting gases inside sealed bags for smaller grain batches. Predictive Atmosphere Modelling integrates data on gas diffusion, grain respiration rates, and environmental variables to optimize storage conditions, reducing spoilage and extending shelf life in both CAS and MAP systems.

Smart Sensor-Enabled Monitoring

Controlled Atmosphere Storage utilizes smart sensor-enabled monitoring systems to precisely regulate oxygen, carbon dioxide, and humidity levels, significantly reducing grain spoilage and insect infestations. Modified Atmosphere Packaging integrates embedded sensors that provide real-time data on gas composition and moisture, optimizing grain preservation by dynamically adjusting internal conditions during storage and transport.

Controlled Atmosphere Storage vs Modified Atmosphere Packaging for grain preservation Infographic

agridif.com

agridif.com