Vacuum packaging extends snack shelf stability by removing air and inhibiting aerobic microbial growth, thereby reducing oxidation and spoilage. Nitrogen flushing replaces oxygen with inert nitrogen gas, slowing lipid oxidation and maintaining product crispness. Combining these techniques can optimize shelf life by enhancing protection against moisture and environmental contaminants.

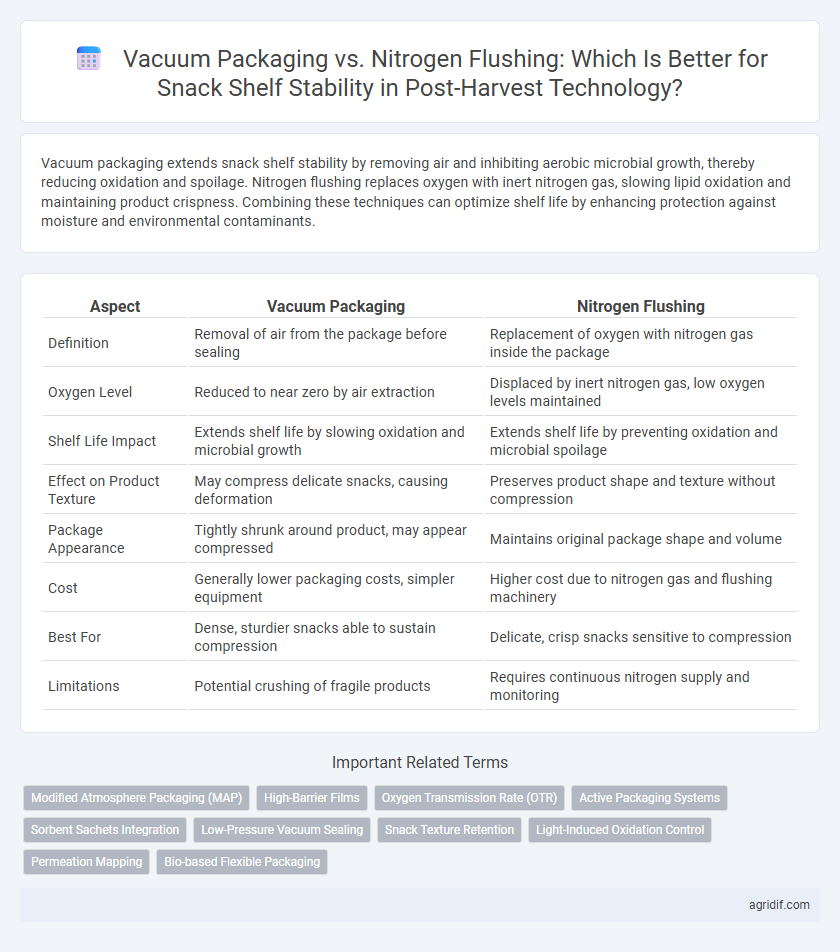

Table of Comparison

| Aspect | Vacuum Packaging | Nitrogen Flushing |

|---|---|---|

| Definition | Removal of air from the package before sealing | Replacement of oxygen with nitrogen gas inside the package |

| Oxygen Level | Reduced to near zero by air extraction | Displaced by inert nitrogen gas, low oxygen levels maintained |

| Shelf Life Impact | Extends shelf life by slowing oxidation and microbial growth | Extends shelf life by preventing oxidation and microbial spoilage |

| Effect on Product Texture | May compress delicate snacks, causing deformation | Preserves product shape and texture without compression |

| Package Appearance | Tightly shrunk around product, may appear compressed | Maintains original package shape and volume |

| Cost | Generally lower packaging costs, simpler equipment | Higher cost due to nitrogen gas and flushing machinery |

| Best For | Dense, sturdier snacks able to sustain compression | Delicate, crisp snacks sensitive to compression |

| Limitations | Potential crushing of fragile products | Requires continuous nitrogen supply and monitoring |

Introduction to Post-Harvest Packaging Technologies

Vacuum packaging removes air from snack packages to inhibit oxidation and microbial growth, significantly enhancing shelf stability by prolonging freshness and texture. Nitrogen flushing replaces oxygen with inert nitrogen gas, preventing rancidity and spoilage while preserving the product's original appearance and taste. Both techniques effectively extend shelf life by controlling oxygen exposure but differ in their impact on product texture and packaging integrity.

Understanding Vacuum Packaging: Principles and Process

Vacuum packaging enhances snack shelf stability by removing oxygen from the package, thereby inhibiting aerobic microbial growth and oxidative rancidity that deteriorate product quality. This process involves placing the snack in a flexible barrier pouch, extracting air through a vacuum sealer, and sealing the package to maintain an oxygen-free environment. Effective vacuum packaging significantly prolongs shelf life by preserving texture, flavor, and nutritional value compared to nitrogen flushing, which replaces air but may not achieve complete oxygen removal.

Nitrogen Flushing Explained: How It Works

Nitrogen flushing enhances snack shelf stability by replacing oxygen within packaging, significantly reducing oxidation and moisture-induced spoilage. This inert gas environment slows lipid rancidity and microbial growth, preserving flavor, texture, and nutritional quality. By minimizing oxygen exposure, nitrogen flushing extends shelf life more effectively than vacuum packaging, especially for oxygen-sensitive snacks.

Oxygen Control: The Key to Snack Shelf Stability

Oxygen control plays a pivotal role in extending snack shelf stability by preventing oxidation and microbial growth, with vacuum packaging effectively removing air to create an oxygen-depleted environment. Nitrogen flushing replaces oxygen with inert nitrogen gas, significantly reducing oxidative rancidity and preserving flavor and texture. Both techniques enhance shelf life, but nitrogen flushing offers superior control in maintaining product quality by minimizing residual oxygen levels.

Moisture and Texture Preservation in Snacks

Vacuum packaging and nitrogen flushing both enhance snack shelf stability by minimizing moisture exposure and preserving texture integrity. Vacuum packaging effectively removes air, reducing oxidative reactions and moisture absorption, which helps maintain crispness in snacks. Nitrogen flushing replaces oxygen with inert gas, further preventing moisture-induced spoilage and sustaining product freshness and crunch over extended storage periods.

Comparative Analysis: Shelf Life Extension

Vacuum packaging significantly reduces oxygen levels, slowing oxidative rancidity and microbial growth, thereby extending snack shelf life by up to 50%. Nitrogen flushing displaces oxygen to prevent oxidation and maintains product texture, often achieving similar or slightly longer shelf life compared to vacuum packaging. Studies indicate nitrogen flushing better preserves crispness and flavor stability, while vacuum packaging excels in reducing moisture loss, making the choice dependent on the specific snack characteristics.

Cost Efficiency and Operational Considerations

Vacuum packaging reduces oxygen exposure, effectively extending snack shelf life while minimizing packaging material costs, making it cost-efficient for small to medium-scale operations. Nitrogen flushing, although requiring higher initial investment in specialized equipment and gases, offers superior oxidation control and product freshness ideal for large-scale production and higher-value snacks. Operationally, vacuum packaging is simpler and faster, whereas nitrogen flushing demands precise gas control and maintenance but ensures better preservation of texture and flavor.

Impact on Snack Flavor and Nutritional Quality

Vacuum packaging preserves snack flavor by minimizing oxidation and moisture loss, effectively maintaining crispness and original taste profiles. Nitrogen flushing displaces oxygen within the packaging, which prevents rancidity and extends shelf life while better retaining volatile flavor compounds and key nutrients like vitamins. Both methods significantly enhance shelf stability, but nitrogen flushing often offers superior protection for flavor integrity and nutritional quality in oxygen-sensitive snacks.

Environmental and Sustainability Aspects

Vacuum packaging reduces oxygen levels by removing air, significantly extending snack shelf life while minimizing the need for preservatives, which lowers chemical waste. Nitrogen flushing replaces oxygen with inert nitrogen gas, preserving product quality without harmful oxidation, but requires continuous nitrogen supply, which may have higher energy consumption. Both methods improve shelf stability, yet vacuum packaging generally offers a smaller carbon footprint and reduced environmental impact due to lower resource use in packaging processes.

Choosing the Right Technology for Your Snack Products

Vacuum packaging extends snack shelf life by removing oxygen, which slows oxidation and microbial growth, making it ideal for crisp and dry snacks. Nitrogen flushing replaces oxygen with inert nitrogen gas, preserving texture and flavor in snacks prone to crushing or staling, such as chips and nuts. Selecting the right technology depends on snack type, desired shelf life, and packaging cost, ensuring optimal freshness and product integrity.

Related Important Terms

Modified Atmosphere Packaging (MAP)

Vacuum packaging removes oxygen to inhibit microbial growth and oxidation, extending snack shelf life by maintaining product freshness under Modified Atmosphere Packaging (MAP) principles. Nitrogen flushing replaces oxygen with inert nitrogen gas, reducing oxidative degradation and preserving texture and flavor, making it highly effective for enhancing snack shelf stability within MAP systems.

High-Barrier Films

High-barrier films significantly enhance shelf stability in snack packaging by minimizing oxygen and moisture transmission, critical in vacuum packaging and nitrogen flushing methods. Vacuum packaging removes air to reduce oxidation, while nitrogen flushing replaces oxygen with inert gas, both relying on the impermeability of high-barrier films to prolong freshness and prevent spoilage.

Oxygen Transmission Rate (OTR)

Vacuum packaging significantly reduces the Oxygen Transmission Rate (OTR), limiting oxygen exposure and effectively extending the shelf stability of snacks by preventing oxidation and rancidity. Nitrogen flushing lowers OTR by displacing oxygen within the package but relies on the barrier properties of the packaging film to maintain low oxygen levels over time.

Active Packaging Systems

Vacuum packaging removes air to inhibit aerobic microbial growth and oxidation, significantly extending snack shelf stability by maintaining product freshness, while nitrogen flushing replaces oxygen with inert nitrogen gas to prevent spoilage and rancidity. Active packaging systems enhance these methods by integrating oxygen scavengers and moisture absorbers, further optimizing the shelf life and quality of snacks through controlled atmosphere and humidity regulation.

Sorbent Sachets Integration

Vacuum packaging combined with sorbent sachets effectively reduces oxygen and moisture, significantly enhancing snack shelf stability by minimizing oxidative rancidity and microbial growth. In contrast, nitrogen flushing relies on inert gas displacement but often benefits from sorbent sachets to control residual oxygen and moisture, ensuring prolonged freshness and crispness in snack products.

Low-Pressure Vacuum Sealing

Low-pressure vacuum sealing significantly extends snack shelf stability by effectively reducing oxygen levels, minimizing oxidative spoilage and microbial growth compared to nitrogen flushing. This method creates a near-airtight environment, preserving texture and flavor while maintaining package integrity under low pressure conditions.

Snack Texture Retention

Vacuum packaging effectively preserves snack texture by removing air and minimizing oxidation, thereby reducing staleness and maintaining crispness over time. Nitrogen flushing displaces oxygen within the packaging, helping retain snack crunchiness and preventing moisture absorption, which enhances long-term shelf stability.

Light-Induced Oxidation Control

Vacuum packaging reduces oxygen presence, significantly limiting light-induced oxidation in snacks by minimizing the interaction between lipids and photo-oxidative agents, thereby enhancing shelf stability. Nitrogen flushing displaces oxygen but may allow residual oxygen to persist, making vacuum packaging more effective in controlling oxidative deterioration caused by light exposure during storage.

Permeation Mapping

Permeation mapping reveals that vacuum packaging significantly reduces oxygen permeability, enhancing snack shelf stability by minimizing oxidative spoilage. Nitrogen flushing alters internal gas composition but offers less control over moisture migration compared to vacuum packaging, impacting long-term freshness.

Bio-based Flexible Packaging

Vacuum packaging removes oxygen to inhibit microbial growth, enhancing snack shelf stability, while nitrogen flushing replaces oxygen with inert gas to prevent oxidation and maintain product freshness; bio-based flexible packaging materials offer sustainable barrier properties essential for both methods in preserving snack quality. Advances in bio-based polymers like PLA and PHA improve oxygen and moisture barriers, making them ideal for vacuum and nitrogen-flush packaging to extend shelf life and reduce environmental impact.

Vacuum Packaging vs Nitrogen Flushing for snack shelf stability Infographic

agridif.com

agridif.com