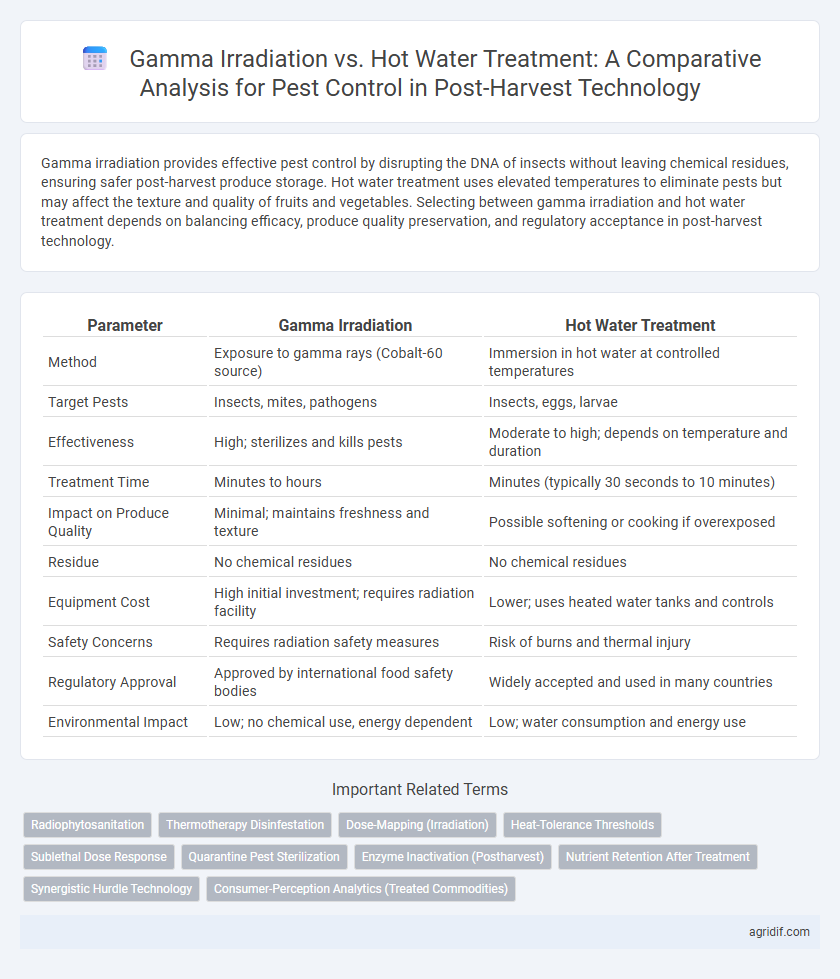

Gamma irradiation provides effective pest control by disrupting the DNA of insects without leaving chemical residues, ensuring safer post-harvest produce storage. Hot water treatment uses elevated temperatures to eliminate pests but may affect the texture and quality of fruits and vegetables. Selecting between gamma irradiation and hot water treatment depends on balancing efficacy, produce quality preservation, and regulatory acceptance in post-harvest technology.

Table of Comparison

| Parameter | Gamma Irradiation | Hot Water Treatment |

|---|---|---|

| Method | Exposure to gamma rays (Cobalt-60 source) | Immersion in hot water at controlled temperatures |

| Target Pests | Insects, mites, pathogens | Insects, eggs, larvae |

| Effectiveness | High; sterilizes and kills pests | Moderate to high; depends on temperature and duration |

| Treatment Time | Minutes to hours | Minutes (typically 30 seconds to 10 minutes) |

| Impact on Produce Quality | Minimal; maintains freshness and texture | Possible softening or cooking if overexposed |

| Residue | No chemical residues | No chemical residues |

| Equipment Cost | High initial investment; requires radiation facility | Lower; uses heated water tanks and controls |

| Safety Concerns | Requires radiation safety measures | Risk of burns and thermal injury |

| Regulatory Approval | Approved by international food safety bodies | Widely accepted and used in many countries |

| Environmental Impact | Low; no chemical use, energy dependent | Low; water consumption and energy use |

Introduction to Post-Harvest Pest Control in Agriculture

Post-harvest pest control in agriculture is essential for minimizing losses and maintaining crop quality during storage and transportation. Gamma irradiation and hot water treatment are two effective techniques used to eliminate pests by disrupting their biological processes or thermal exposure. These methods help extend shelf life, reduce chemical residues, and ensure food safety in fruits, vegetables, and grains.

Understanding Gamma Irradiation in Pest Management

Gamma irradiation effectively disrupts the DNA of pests, preventing reproduction and ensuring long-term control in stored agricultural products. This method penetrates deeply into fruits, vegetables, and grains without compromising their quality or nutritional value, making it a preferred technology in post-harvest pest management. Its ability to treat a wide range of pests simultaneously offers a significant advantage over traditional hot water treatment, which may only target surface-dwelling insects and risks damaging heat-sensitive commodities.

Hot Water Treatment: Principles and Application

Hot water treatment eliminates pests by immersing produce in carefully controlled high-temperature water, effectively disrupting insect metabolism and killing larvae without chemical residues. This method is widely applied to fruits like mangoes and guavas to meet quarantine requirements while preserving quality and shelf life. Precise temperature (typically 46-52degC) and exposure time management are critical to prevent damage while ensuring pest mortality.

Mechanisms of Action: Gamma Irradiation vs Hot Water Treatment

Gamma irradiation controls pests through ionizing radiation that disrupts DNA and cellular functions, leading to mortality or sterility. Hot water treatment kills pests by denaturing proteins and enzymes via thermal exposure, causing physiological stress and mortality. Both methods effectively reduce pest populations but differ in their biological impact and application parameters.

Efficacy Against Common Post-Harvest Pests

Gamma irradiation effectively controls a broad spectrum of common post-harvest pests such as fruit flies, beetles, and moth larvae by disrupting their DNA and preventing reproduction. Hot water treatment offers targeted efficacy against surface-dwelling pests and fungal pathogens but may not penetrate deeply enough to eliminate larvae or eggs inside the produce. Studies indicate gamma irradiation generally provides superior pest control with minimal impact on fruit quality, whereas hot water treatment is limited by temperature sensitivity and shorter residual activity.

Impact on Crop Quality and Shelf Life

Gamma irradiation effectively reduces pest infestation while preserving the nutritional and sensory qualities of crops, extending shelf life without significant texture or flavor degradation. Hot water treatment controls pests through thermal exposure but may cause slight softening and color changes, potentially shortening shelf life due to increased susceptibility to microbial spoilage. Balancing pest control efficiency with minimal quality loss, gamma irradiation offers a preferable post-harvest technology for maintaining crop marketability and longevity.

Safety Considerations and Regulatory Guidelines

Gamma irradiation and hot water treatment are widely used post-harvest technologies for pest control, with distinct safety considerations and regulatory frameworks. Gamma irradiation involves exposure to ionizing radiation, requiring strict adherence to international safety standards like those set by the International Atomic Energy Agency (IAEA) to prevent radiological hazards. Hot water treatment relies on precise temperature and duration control to avoid produce damage, with regulatory guidelines emphasizing worker protection from scalding and ensuring treatment efficacy to meet phytosanitary regulations.

Environmental and Economic Implications

Gamma irradiation offers effective pest control with minimal chemical residues, reducing environmental contamination compared to conventional methods. Hot water treatment requires significant energy inputs and water resources, potentially increasing operational costs and environmental footprint. Economically, gamma irradiation involves higher initial equipment investment but offers scalable, low-maintenance pest control, while hot water treatment incurs ongoing energy and labor expenses.

Adoption Challenges and Industry Perspectives

Gamma irradiation offers effective pest control by damaging insect DNA without leaving residues, yet its high operational costs and regulatory barriers limit widespread adoption. Hot water treatment provides a chemical-free alternative but faces challenges in uniform temperature control and potential quality degradation, affecting market acceptance. Industry stakeholders express concerns over consumer perception, infrastructure investment, and treatment scalability, influencing the preference for integrated pest management strategies.

Future Trends in Post-Harvest Pest Control Technologies

Gamma irradiation and hot water treatment are emerging as key post-harvest pest control technologies with distinct advantages and applications. Future trends emphasize the integration of gamma irradiation's ability to effectively sterilize pests without chemical residues and hot water treatment's eco-friendly, residue-free pest reduction, particularly in organic produce sectors. Advances in sensor technology and controlled environment applications are expected to enhance the precision and efficacy of these treatments, fostering sustainable pest management and extending shelf life in global supply chains.

Related Important Terms

Radiophytosanitation

Gamma irradiation offers precise dose control and deeper penetration, effectively eliminating pests and pathogens without compromising fruit quality during radiophytosanitation. Hot water treatment relies on controlled temperature exposure to eradicate surface pests but risks thermal damage and limited efficacy against internal infestations.

Thermotherapy Disinfestation

Gamma irradiation effectively controls post-harvest pests by disrupting insect DNA, ensuring quarantine security and extending shelf life without chemical residues. Hot water treatment, as a thermotherapy disinfestation method, eliminates pests through precise temperature exposure, preserving fruit quality by avoiding thermal damage while complying with phytosanitary regulations.

Dose-Mapping (Irradiation)

Dose-mapping in gamma irradiation ensures uniform distribution of radiation doses across the commodity, effectively targeting pests without compromising quality, whereas hot water treatment relies on thermal exposure that may unevenly affect produce and cause quality degradation. Precise dose-mapping protocols enhance pest control efficacy in gamma irradiation by minimizing under-dosed zones, a challenge less controllable in hot water applications.

Heat-Tolerance Thresholds

Gamma irradiation effectively controls pests in post-harvest fruits without surpassing heat-tolerance thresholds, preserving quality by avoiding thermal damage. Hot water treatment requires precise temperature management to stay within heat-tolerance limits, as exceeding these thresholds can lead to tissue damage and reduced shelf life.

Sublethal Dose Response

Gamma irradiation and hot water treatment exhibit distinct sublethal dose responses in post-harvest pest control, with gamma irradiation causing DNA damage and oxidative stress that disrupt insect cellular functions while hot water treatment primarily induces thermal stress leading to protein denaturation and enzyme inactivation. Research indicates gamma irradiation at sublethal doses offers precise dose control and deeper penetration, enhancing pest mortality without compromising fruit quality compared to hot water treatment, which may cause surface damage and uneven pest exposure.

Quarantine Pest Sterilization

Gamma irradiation effectively sterilizes quarantine pests by disrupting their DNA, ensuring no viable offspring and preventing pest proliferation during post-harvest handling. Hot water treatment kills pests through lethal exposure to high temperatures but may cause quality degradation, making gamma irradiation a more precise method for quarantine pest control in post-harvest technology.

Enzyme Inactivation (Postharvest)

Gamma irradiation effectively inactivates enzymes such as polyphenol oxidase and peroxidase in postharvest fruits, reducing browning and spoilage while maintaining nutritional quality. Hot water treatment also denatures these enzymes but may cause thermal damage, making gamma irradiation a more precise method for enzyme inactivation and pest control in postharvest technology.

Nutrient Retention After Treatment

Gamma irradiation preserves nutrient content in fruits and vegetables more effectively than hot water treatment, maintaining higher levels of vitamin C, antioxidants, and overall nutritional quality. Hot water treatment, while effective for pest control, tends to cause greater nutrient degradation due to heat exposure, leading to reduced vitamin retention and antioxidative properties post-treatment.

Synergistic Hurdle Technology

Gamma irradiation and hot water treatment combined in synergistic hurdle technology significantly enhance pest control efficacy in post-harvest management by disrupting pest physiology at multiple biological levels. This integrated approach reduces chemical residues and extends shelf life while maintaining the quality and safety of agricultural commodities.

Consumer-Perception Analytics (Treated Commodities)

Gamma irradiation offers a non-chemical, residue-free method preferred by consumers for pest control in treated commodities, enhancing shelf life without compromising nutritional quality. Hot water treatment, while effective, often faces consumer skepticism due to potential quality degradation and altered sensory attributes.

Gamma Irradiation vs Hot Water Treatment for Pest Control Infographic

agridif.com

agridif.com