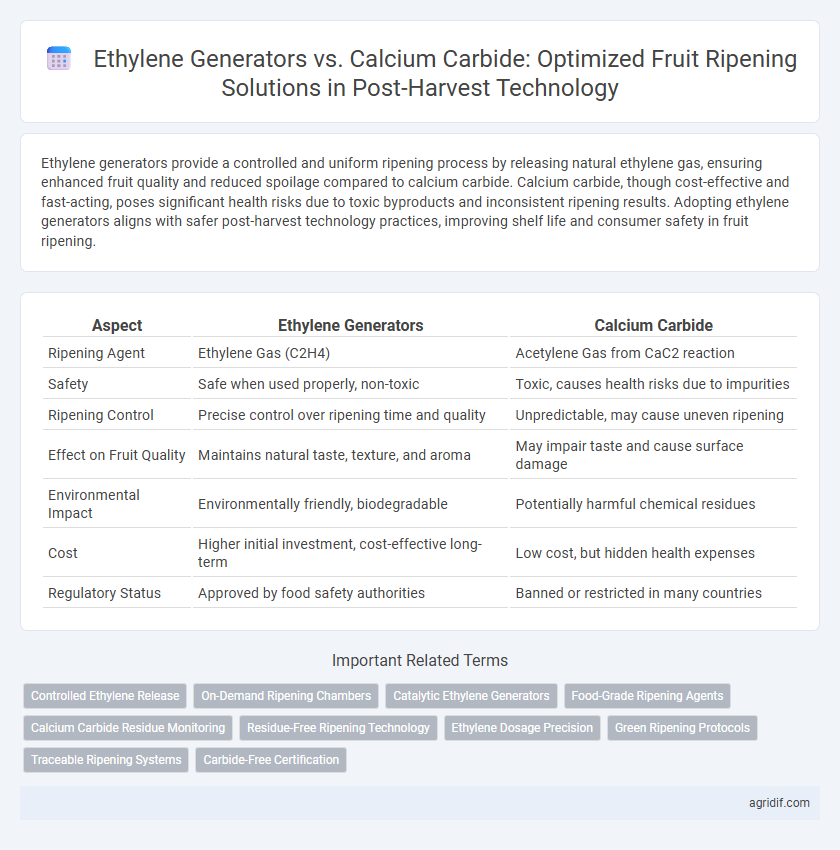

Ethylene generators provide a controlled and uniform ripening process by releasing natural ethylene gas, ensuring enhanced fruit quality and reduced spoilage compared to calcium carbide. Calcium carbide, though cost-effective and fast-acting, poses significant health risks due to toxic byproducts and inconsistent ripening results. Adopting ethylene generators aligns with safer post-harvest technology practices, improving shelf life and consumer safety in fruit ripening.

Table of Comparison

| Aspect | Ethylene Generators | Calcium Carbide |

|---|---|---|

| Ripening Agent | Ethylene Gas (C2H4) | Acetylene Gas from CaC2 reaction |

| Safety | Safe when used properly, non-toxic | Toxic, causes health risks due to impurities |

| Ripening Control | Precise control over ripening time and quality | Unpredictable, may cause uneven ripening |

| Effect on Fruit Quality | Maintains natural taste, texture, and aroma | May impair taste and cause surface damage |

| Environmental Impact | Environmentally friendly, biodegradable | Potentially harmful chemical residues |

| Cost | Higher initial investment, cost-effective long-term | Low cost, but hidden health expenses |

| Regulatory Status | Approved by food safety authorities | Banned or restricted in many countries |

Introduction to Artificial Fruit Ripening Methods

Artificial fruit ripening methods primarily utilize ethylene generators and calcium carbide to induce accelerated maturation. Ethylene generators produce controlled, food-safe ethylene gas that mimics the natural ripening hormone, ensuring uniform fruit softening and color change. Calcium carbide releases acetylene gas upon reaction with moisture, which can be hazardous due to toxic impurities, making ethylene generators the preferred and safer option in modern post-harvest technology.

How Ethylene Generators Work in Post-Harvest Technology

Ethylene generators release controlled amounts of ethylene gas that trigger and regulate the natural ripening process in fruits by activating enzymes that soften fruit tissues and convert starches to sugars. These generators ensure uniform ripening, reduce post-harvest losses, and improve fruit quality during storage and transportation. In contrast to calcium carbide, ethylene generators provide a safer, non-toxic method that aligns with food safety standards and minimizes health risks.

The Science Behind Calcium Carbide Ripening

Calcium carbide releases acetylene gas upon contact with moisture, which acts as an artificial ripening agent by simulating the natural plant hormone ethylene, accelerating the ripening process in fruits. This chemical reaction increases the respiration rate and softens fruit tissues rapidly but can produce hazardous byproducts like phosphine and arsenic, posing health risks. Ethylene generators, in contrast, provide controlled and safer ethylene gas release, ensuring uniform ripening without the toxic residues associated with calcium carbide.

Health and Safety Concerns: Ethylene vs Calcium Carbide

Ethylene generators provide a controlled and safe method for fruit ripening, emitting a naturally occurring plant hormone that poses minimal health risks when used properly. Calcium carbide releases acetylene gas, which is toxic and can cause severe health hazards including respiratory issues and neurological damage, raising significant safety concerns. Regulatory bodies in many countries have banned or restricted calcium carbide use due to its carcinogenic properties and impact on food safety.

Regulatory Guidelines for Fruit Ripening Agents

Ethylene generators comply with international regulatory guidelines such as those set by the FDA and Codex Alimentarius, ensuring safe and controlled fruit ripening without harmful residues. In contrast, calcium carbide is banned or strictly regulated in many countries due to its potential health risks, including producing acetylene gas contaminated with arsenic and phosphorus. Regulatory standards prioritize ethylene use for fruit ripening because it provides predictable results and aligns with food safety protocols worldwide.

Impact on Fruit Quality and Shelf Life

Ethylene generators produce controlled ethylene gas that enhances uniform fruit ripening while preserving texture, flavor, and nutritional quality, resulting in extended shelf life. In contrast, calcium carbide releases acetylene gas, which ripens fruits unevenly and can cause internal fruit damage, reducing quality and leading to a shorter shelf life. Using ethylene generators aligns with post-harvest technology standards for safe, consistent ripening and maintaining fruit marketability.

Economic Considerations: Costs and Availability

Ethylene generators offer a controlled and consistent fruit ripening process, with higher upfront costs but lower long-term expenses due to their reusable nature and precise gas regulation. Calcium carbide is cheaper and widely available, making it attractive for small-scale farmers, but it poses health risks and inconsistent ripening, potentially leading to economic losses from damaged fruit. Considering cost-efficiency, ethylene generators provide better investment value through improved fruit quality and reduced wastage despite higher initial expenditure.

Environmental Impacts of Ripening Agents

Ethylene generators produce controlled and uniform ethylene gas that accelerates fruit ripening with minimal environmental pollution, reducing harmful residues compared to calcium carbide, which releases hazardous acetylene gas and toxic impurities, posing significant health and environmental risks. Calcium carbide's byproducts contaminate soil and water sources, leading to long-term ecological damage, whereas ethylene generators offer a safer, more sustainable alternative in post-harvest technology. Adoption of ethylene generators aligns with environmental regulations and promotes safer agricultural practices in fruit ripening processes.

Adoption Trends in Global Agricultural Markets

Ethylene generators have gained widespread adoption in global agricultural markets due to their consistent and controllable release of ethylene gas, enabling uniform fruit ripening and extending shelf life. In contrast, calcium carbide use is declining globally because of health concerns related to impurities and regulatory restrictions in major fruit-producing countries. Market trends indicate a shift toward safer, technologically advanced ethylene generation methods driven by consumer safety standards and increasing demand for high-quality, evenly ripened fruits.

Future Prospects and Sustainable Alternatives

Ethylene generators offer precise control over fruit ripening, making them a sustainable alternative to calcium carbide, which poses health risks due to toxic gas emissions. Future prospects emphasize the integration of advanced ethylene production methods using bio-based materials to enhance environmental safety and reduce chemical residues. Innovations in sensor technology and controlled atmosphere systems are expected to further promote eco-friendly and efficient ripening processes in post-harvest management.

Related Important Terms

Controlled Ethylene Release

Ethylene generators provide precise and controlled ethylene release, ensuring uniform and safe fruit ripening, while calcium carbide releases acetylene gas, which can be toxic and leads to uneven ripening with potential health hazards. Controlled ethylene technology enhances post-harvest quality by regulating ripening stages, reducing spoilage, and increasing shelf life compared to the inconsistent and hazardous effects of calcium carbide.

On-Demand Ripening Chambers

Ethylene generators provide precise control in on-demand ripening chambers by releasing calibrated doses of ethylene gas, ensuring uniform fruit ripening and reducing chemical residues compared to calcium carbide, which emits harmful acetylene gas and poses health risks. Advanced ripening chambers equipped with ethylene systems optimize temperature, humidity, and gas concentration, enhancing fruit quality, shelf life, and consumer safety in post-harvest technology.

Catalytic Ethylene Generators

Catalytic ethylene generators offer a safer and more controlled method for fruit ripening compared to calcium carbide, producing precise ethylene concentrations without harmful contaminants like arsenic and phosphide residues. These generators enhance post-harvest technology by ensuring uniform ripening, reducing spoilage, and complying with food safety standards globally.

Food-Grade Ripening Agents

Food-grade ethylene generators provide a controlled and uniform release of ethylene gas, ensuring safer and more consistent fruit ripening compared to calcium carbide, which poses health risks due to toxic impurities like arsenic and phosphorus hydride. Regulatory agencies prefer food-grade ethylene for commercial applications to maintain fruit quality and consumer safety in post-harvest technology.

Calcium Carbide Residue Monitoring

Calcium carbide, commonly used for artificial fruit ripening, releases harmful acetylene gas but leaves hazardous residues that contaminate fruits, posing significant health risks. Effective calcium carbide residue monitoring involves regular chemical analysis of fruit samples to detect carbide remnants and ensure compliance with food safety standards, promoting safer post-harvest practices.

Residue-Free Ripening Technology

Ethylene generators provide a residue-free ripening technology by releasing controlled amounts of pure ethylene gas, ensuring uniform fruit ripening without harmful chemical residues. In contrast, calcium carbide releases acetylene gas that can leave toxic residues on fruits, posing health risks and environmental concerns.

Ethylene Dosage Precision

Ethylene generators provide precise control over ethylene dosage, ensuring consistent and uniform fruit ripening compared to calcium carbide, which releases ethylene irregularly and may cause uneven ripening or fruit damage. Controlled ethylene concentration in generators optimizes ripening speed while maintaining fruit quality, enhancing post-harvest handling efficiency.

Green Ripening Protocols

Ethylene generators provide controlled and uniform ripening by releasing precise ethylene gas concentrations, aligning with green ripening protocols that emphasize safety and environmental sustainability. In contrast, calcium carbide emits hazardous acetylene gas and poses health risks, making it unsuitable under modern post-harvest guidelines promoting eco-friendly and non-toxic fruit ripening methods.

Traceable Ripening Systems

Traceable ripening systems using ethylene generators offer controlled, uniform fruit ripening with precise monitoring capabilities, enhancing post-harvest quality and reducing losses compared to calcium carbide, which poses health risks and lacks traceability. Employing ethylene generators supports compliance with food safety regulations and enables data-driven decisions in supply chain management by tracking ripening stages in real-time.

Carbide-Free Certification

Ethylene generators provide a controlled and uniform release of ethylene gas, promoting safe and consistent fruit ripening without harmful residues. Calcium carbide use poses health risks due to acetylene contamination and is banned in many countries, leading to increasing demand for carbide-free certification to ensure consumer safety and regulatory compliance.

Ethylene Generators vs Calcium Carbide for fruit ripening Infographic

agridif.com

agridif.com