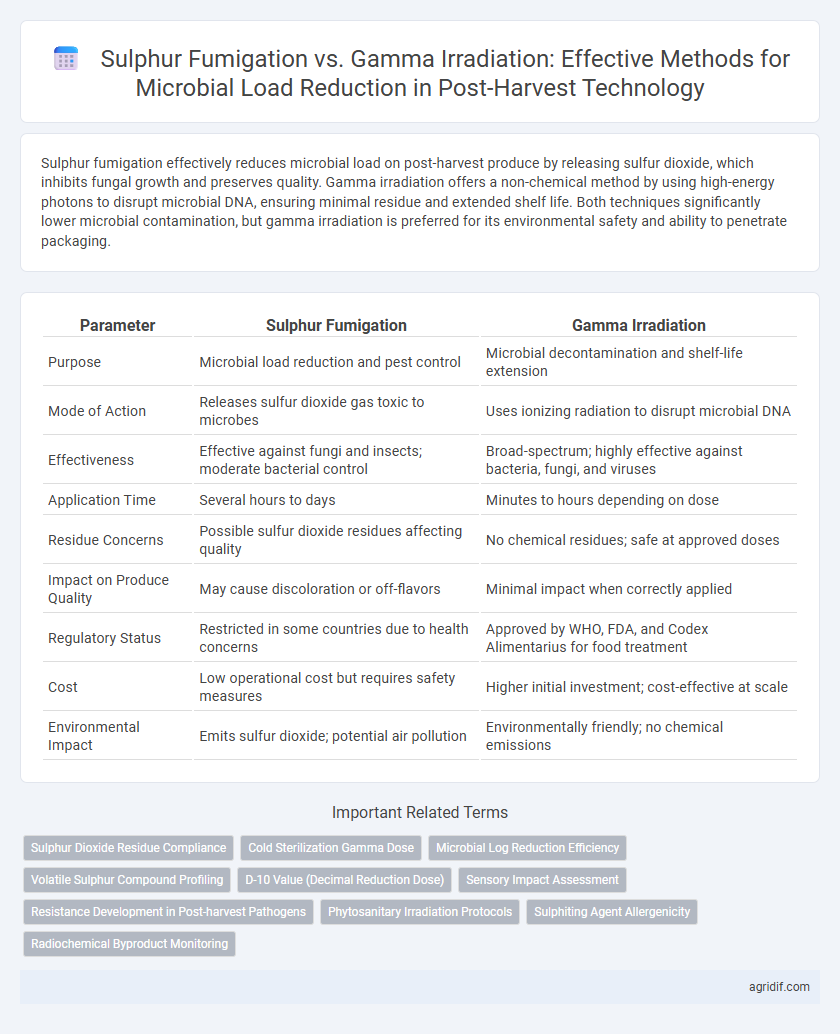

Sulphur fumigation effectively reduces microbial load on post-harvest produce by releasing sulfur dioxide, which inhibits fungal growth and preserves quality. Gamma irradiation offers a non-chemical method by using high-energy photons to disrupt microbial DNA, ensuring minimal residue and extended shelf life. Both techniques significantly lower microbial contamination, but gamma irradiation is preferred for its environmental safety and ability to penetrate packaging.

Table of Comparison

| Parameter | Sulphur Fumigation | Gamma Irradiation |

|---|---|---|

| Purpose | Microbial load reduction and pest control | Microbial decontamination and shelf-life extension |

| Mode of Action | Releases sulfur dioxide gas toxic to microbes | Uses ionizing radiation to disrupt microbial DNA |

| Effectiveness | Effective against fungi and insects; moderate bacterial control | Broad-spectrum; highly effective against bacteria, fungi, and viruses |

| Application Time | Several hours to days | Minutes to hours depending on dose |

| Residue Concerns | Possible sulfur dioxide residues affecting quality | No chemical residues; safe at approved doses |

| Impact on Produce Quality | May cause discoloration or off-flavors | Minimal impact when correctly applied |

| Regulatory Status | Restricted in some countries due to health concerns | Approved by WHO, FDA, and Codex Alimentarius for food treatment |

| Cost | Low operational cost but requires safety measures | Higher initial investment; cost-effective at scale |

| Environmental Impact | Emits sulfur dioxide; potential air pollution | Environmentally friendly; no chemical emissions |

Comparative Overview: Sulphur Fumigation and Gamma Irradiation

Sulphur fumigation effectively reduces microbial load on harvested produce by releasing sulfur dioxide, which inhibits fungal growth and spoilage but may leave chemical residues affecting consumer health. Gamma irradiation employs high-energy photons to disrupt microbial DNA, providing a residue-free, deeper sterilization method that extends shelf life without compromising nutritional quality. Comparative studies indicate gamma irradiation offers superior microbial inactivation and safer produce preservation, while sulphur fumigation remains cost-effective for short-term microbial control.

Mechanisms of Microbial Load Reduction

Sulphur fumigation reduces microbial load by releasing sulfur dioxide gas, which penetrates microbial cells and disrupts their enzymatic activity and cellular respiration, leading to cell death. Gamma irradiation employs high-energy photons to induce DNA damage and generate reactive oxygen species within microbial pathogens, effectively inhibiting replication and causing cellular apoptosis. Both methods achieve microbial load reduction through distinct mechanisms targeting cellular integrity and metabolic functions, enhancing post-harvest preservation.

Efficacy Against Common Post-Harvest Pathogens

Sulphur fumigation effectively reduces microbial load by targeting fungi and bacteria commonly found in post-harvest produce, but its efficacy is often limited by residue concerns and phytotoxicity. Gamma irradiation demonstrates superior efficacy against a broad spectrum of post-harvest pathogens, including both surface and internal microbes, without leaving chemical residues. Studies indicate gamma irradiation significantly decreases pathogen load such as Aspergillus spp., Penicillium spp., and Salmonella, enhancing shelf life while maintaining quality.

Impact on Crop Quality and Shelf Life

Sulphur fumigation effectively reduces microbial load but can cause discoloration and off-flavors, negatively impacting crop quality and consumer acceptance. Gamma irradiation provides significant microbial reduction while preserving nutritional content, texture, and extending shelf life without residual chemicals. Studies show gamma irradiation maintains post-harvest quality better and prolongs freshness compared to sulphur fumigation in fruits and vegetables.

Residual Effects and Food Safety Concerns

Sulphur fumigation effectively reduces microbial load but often leaves sulphur residues that pose potential health risks and alter food sensory qualities. Gamma irradiation provides significant microbial decontamination without chemical residues, maintaining food safety and quality standards. However, consumer acceptance and regulatory limits on irradiation dose remain critical factors in its application for post-harvest treatment.

Regulatory Standards for Post-Harvest Treatments

Sulphur fumigation for microbial load reduction in post-harvest treatments must comply with strict regulatory standards set by agencies like the EPA and Codex Alimentarius, limiting residue levels to ensure food safety. Gamma irradiation is internationally recognized and approved by the WHO and FAO, with established maximum dose limits that preserve product quality while effectively reducing pathogens. Compliance with these regulatory frameworks ensures both technologies meet global food safety requirements and facilitate international trade of treated agricultural produce.

Environmental Implications of Both Methods

Sulphur fumigation effectively reduces microbial load but emits sulfur dioxide, contributing to air pollution and potential respiratory hazards. Gamma irradiation offers microbial control without chemical residues or atmospheric emissions, making it environmentally favorable. However, gamma irradiation requires significant energy input and infrastructure, raising concerns about sustainable energy use and operational costs.

Cost Analysis and Economic Feasibility

Sulphur fumigation incurs lower initial equipment costs but entails recurrent expenses for sulfur supplies and potential market losses due to chemical residues. Gamma irradiation demands high capital investment for radiation facilities yet offers long-term savings through uniform microbial load reduction and extended shelf life, reducing post-harvest losses. Economic feasibility depends on scale, with gamma irradiation proving cost-effective for large-volume operations, while sulphur fumigation suits smaller, resource-limited producers.

Consumer Perception and Market Acceptance

Sulphur fumigation effectively reduces microbial load but raises concerns due to residual sulfur compounds affecting consumer perception and potential health risks, leading to limited market acceptance in organic and health-conscious sectors. Gamma irradiation offers a chemical-free alternative with proven efficacy in pathogen control, enhancing consumer trust through minimal residue and recognized safety by international health organizations. Market acceptance of irradiated products is increasing, driven by growing awareness and demand for safer post-harvest treatments that maintain quality and extend shelf life.

Future Trends in Post-Harvest Microbial Control

Sulphur fumigation has been widely used for microbial load reduction in post-harvest technology but raises concerns due to residual toxicity and environmental impact. Gamma irradiation offers a promising alternative by effectively reducing microbial contamination without leaving harmful residues, aligning with sustainable agricultural practices. Future trends emphasize integrating advanced irradiation techniques with real-time microbial monitoring and nanotechnology to enhance efficacy and safety in post-harvest microbial control.

Related Important Terms

Sulphur Dioxide Residue Compliance

Sulphur fumigation effectively reduces microbial load on post-harvest produce but often leaves residual sulphur dioxide that may exceed regulatory limits, raising compliance issues. Gamma irradiation offers a residue-free alternative for microbial control, ensuring adherence to strict food safety standards without chemical residues.

Cold Sterilization Gamma Dose

Cold sterilization using gamma irradiation at doses between 1 to 10 kGy effectively reduces microbial load on harvested crops without raising temperature or leaving chemical residues, preserving product quality and extending shelf life. Sulphur fumigation, while effective against fungi, often leaves harmful residues and can alter taste and color, making gamma irradiation a safer and more efficient alternative for post-harvest microbial control.

Microbial Log Reduction Efficiency

Sulphur fumigation achieves microbial log reductions typically ranging from 1 to 2 logs, effectively controlling fungal growth but showing limited efficacy against bacterial populations. Gamma irradiation demonstrates superior microbial load reduction, often exceeding 4 log reductions, providing a broader spectrum disinfection by effectively inactivating bacteria, fungi, and insect contaminants in post-harvest commodities.

Volatile Sulphur Compound Profiling

Sulphur fumigation significantly alters the volatile sulphur compound profile, often increasing levels of sulfur dioxide-related residues, which can affect sensory quality and consumer safety, whereas gamma irradiation reduces microbial load without generating such volatile sulfur compounds, preserving the original aroma profile. Comparative studies indicate gamma irradiation offers a more effective microbial decontamination method while maintaining post-harvest quality and minimizing chemical residues associated with sulphur fumigation.

D-10 Value (Decimal Reduction Dose)

Sulphur fumigation typically exhibits higher microbial load reduction but can leave residues, whereas gamma irradiation offers effective decontamination with precise control over dose; the D-10 value for gamma irradiation, representing the decimal reduction dose, generally ranges between 0.2 to 1.0 kGy for common post-harvest pathogens, indicating its efficiency in microbial inactivation. Understanding the D-10 values enables optimization of gamma irradiation doses to minimize microbial load while preserving product quality, unlike sulphur fumigation which may cause spoilage or phytotoxicity at higher concentrations.

Sensory Impact Assessment

Sulphur fumigation significantly reduces microbial load but often imparts a residual odor and alters the color and texture of produce, negatively affecting sensory attributes. Gamma irradiation effectively lowers microbial counts while preserving the natural sensory qualities such as taste, aroma, and appearance, thereby maintaining consumer acceptability.

Resistance Development in Post-harvest Pathogens

Sulphur fumigation often leads to resistance development in post-harvest pathogens due to its repeated use and mode of action, reducing long-term effectiveness in microbial load reduction. In contrast, gamma irradiation disrupts microbial DNA without promoting resistance, offering a more sustainable approach for controlling post-harvest spoilage and extending shelf life.

Phytosanitary Irradiation Protocols

Sulphur fumigation effectively reduces microbial load by releasing sulfur dioxide, which disrupts fungal cell metabolism but poses health and environmental risks, leading to limitations in its application. Phytosanitary irradiation protocols using gamma rays target the DNA of pests and microorganisms, providing a residue-free, eco-friendly alternative with precise dosage control for ensuring quarantine security and extending shelf life in post-harvest technology.

Sulphiting Agent Allergenicity

Sulphur fumigation effectively reduces microbial load in post-harvest treatment but poses allergenicity risks due to sulphiting agents, which can trigger adverse reactions in sensitive individuals. Gamma irradiation offers a safer alternative by eliminating pathogens without introducing allergenic compounds, ensuring improved food safety and consumer health.

Radiochemical Byproduct Monitoring

Gamma irradiation significantly reduces microbial load in post-harvest produce with minimal formation of radiochemical byproducts, which are carefully monitored using advanced radiochemical assays to ensure food safety. In contrast, sulphur fumigation effectively controls microbes but raises concerns about residual sulphur compounds and potential phytotoxicity, necessitating different analytical methods for residue detection.

Sulphur Fumigation vs Gamma Irradiation for microbial load reduction Infographic

agridif.com

agridif.com