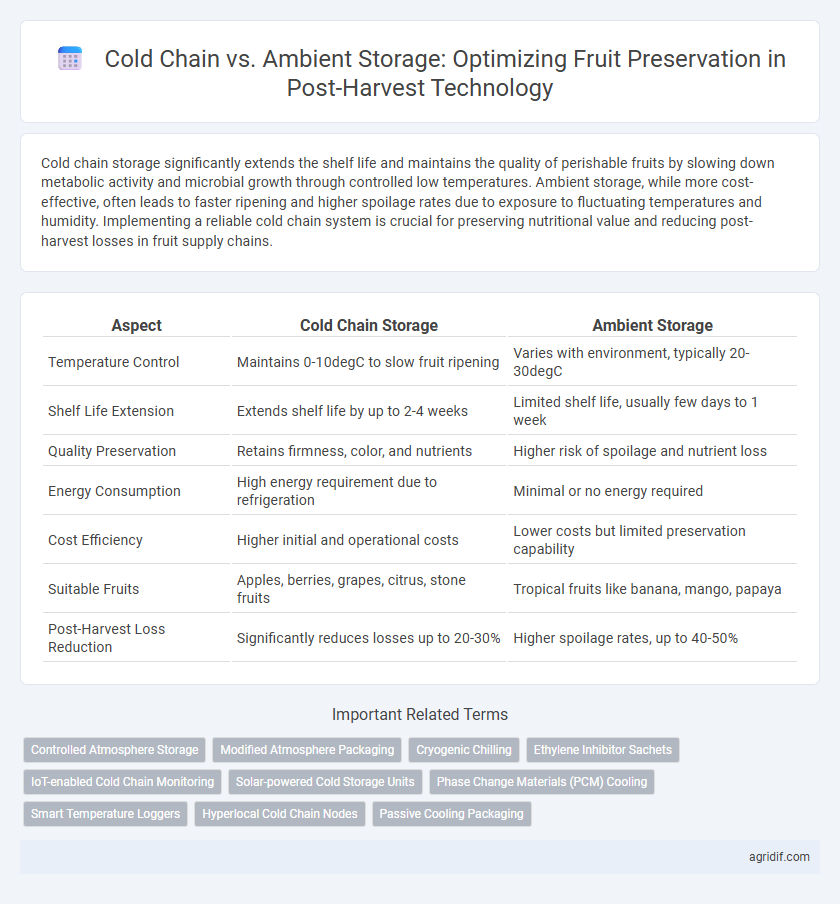

Cold chain storage significantly extends the shelf life and maintains the quality of perishable fruits by slowing down metabolic activity and microbial growth through controlled low temperatures. Ambient storage, while more cost-effective, often leads to faster ripening and higher spoilage rates due to exposure to fluctuating temperatures and humidity. Implementing a reliable cold chain system is crucial for preserving nutritional value and reducing post-harvest losses in fruit supply chains.

Table of Comparison

| Aspect | Cold Chain Storage | Ambient Storage |

|---|---|---|

| Temperature Control | Maintains 0-10degC to slow fruit ripening | Varies with environment, typically 20-30degC |

| Shelf Life Extension | Extends shelf life by up to 2-4 weeks | Limited shelf life, usually few days to 1 week |

| Quality Preservation | Retains firmness, color, and nutrients | Higher risk of spoilage and nutrient loss |

| Energy Consumption | High energy requirement due to refrigeration | Minimal or no energy required |

| Cost Efficiency | Higher initial and operational costs | Lower costs but limited preservation capability |

| Suitable Fruits | Apples, berries, grapes, citrus, stone fruits | Tropical fruits like banana, mango, papaya |

| Post-Harvest Loss Reduction | Significantly reduces losses up to 20-30% | Higher spoilage rates, up to 40-50% |

Introduction to Post-Harvest Fruit Preservation

Post-harvest fruit preservation techniques such as cold chain and ambient storage play crucial roles in maintaining fruit quality and extending shelf life. Cold chain storage involves maintaining fruits at low temperatures from harvest to consumption, effectively slowing down respiration rates, reducing microbial growth, and preserving nutritional value. In contrast, ambient storage relies on natural environmental conditions but often results in faster deterioration and higher post-harvest losses compared to temperature-controlled cold chain systems.

Understanding Cold Chain Storage: Principles and Practices

Cold chain storage maintains fruit quality by controlling temperature, humidity, and ventilation to slow respiration and delay ripening, significantly reducing microbial growth and spoilage. Key principles involve uninterrupted refrigeration from harvest to consumer, ensuring consistent cold temperatures typically between 0degC and 5degC depending on fruit type, and utilizing modified atmosphere packaging to extend shelf life. Efficient cold chain practices minimize metabolic activity and water loss, preserving texture, flavor, and nutritional value far better than ambient storage, which subjects fruit to fluctuating temperatures and accelerated deterioration.

Ambient Storage Methods in Fruit Preservation

Ambient storage methods for fruit preservation rely on maintaining controlled temperature, humidity, and ventilation to slow down metabolic processes and reduce spoilage. Techniques such as evaporative cooling, use of perforated plastic films, and natural ventilation help extend shelf life without the energy demands of cold chain systems. These methods are especially valuable in regions lacking reliable refrigeration infrastructure, providing cost-effective solutions to reduce post-harvest losses.

Comparative Analysis: Cold Chain vs Ambient Storage

Cold chain storage maintains optimal low temperatures and controlled humidity, significantly slowing down enzymatic activity and microbial growth to extend fruit shelf life by up to 2-3 times compared to ambient storage. Ambient storage, typical in markets without refrigeration, exposes fruits to fluctuating temperatures and higher humidity, accelerating spoilage and quality deterioration within days to weeks. Advanced cold chain systems reduce post-harvest losses by up to 30%, preserving nutritional value and marketability far more effectively than ambient conditions.

Impact on Fruit Quality and Shelf Life

Cold chain storage significantly slows down respiration and enzymatic activities in fruits, preserving firmness, color, and nutrient content, thereby extending shelf life from days to weeks compared to ambient storage. Ambient storage accelerates metabolic processes and moisture loss, leading to faster decay, weight loss, and diminished sensory attributes. Maintaining a stable cold chain environment reduces microbial growth and delays ripening, which is crucial for high-value fruits like berries, grapes, and tropical fruits.

Energy and Cost Considerations in Storage Choices

Cold chain storage for fruit preservation involves maintaining temperatures between 0-4degC, significantly reducing respiration rates and extending shelf life, but it demands high energy consumption and investment in refrigeration infrastructure. Ambient storage relies on natural conditions around 20-25degC, offering lower energy costs but risking faster fruit spoilage and quality degradation. Energy-efficient cold chain systems such as solar-powered refrigeration can lower operational costs, while ambient storage suits short-term preservation where electricity access is limited or cost-prohibitive.

Common Challenges and Solutions in Both Storage Methods

Cold chain and ambient storage both face challenges such as temperature fluctuations, humidity control, and microbial contamination that affect fruit quality and shelf life. In cold chain storage, energy consumption and infrastructure costs are significant issues, while ambient storage risks faster ripening and spoilage due to inadequate environmental controls. Solutions include advanced insulation, humidity regulators, ethylene absorbers, and regular monitoring systems to maintain optimal conditions and reduce post-harvest losses.

Case Studies: Cold Chain Success Stories in Agriculture

Cold chain storage significantly extends the shelf life and maintains the quality of perishable fruits by slowing metabolic processes and inhibiting microbial growth, as demonstrated in mango export operations in India, where cold chain logistics reduced post-harvest losses by up to 30%. In contrast, ambient storage often leads to faster deterioration and higher spoilage rates, especially in tropical climates, as seen in tomato supply chains in East Africa struggling with temperature fluctuations and humidity. Case studies from horticultural exports in Chile and Kenya illustrate that investments in refrigerated transport, controlled atmosphere storage, and temperature monitoring technologies result in improved fruit firmness, color retention, and consumer acceptance in international markets.

Innovations and Trends in Post-Harvest Storage Technologies

Innovations in post-harvest storage technologies increasingly favor cold chain systems for fruit preservation, as they significantly extend shelf life by maintaining temperatures between 0degC and 4degC, thereby reducing microbial growth and enzymatic activity. Emerging trends include the integration of IoT sensors and real-time temperature monitoring for enhanced cold chain management, ensuring optimal storage conditions from farm to consumer. Ambient storage innovations focus on modified atmosphere packaging (MAP) and ethylene scavengers to slow ripening processes without refrigeration, providing cost-effective alternatives in regions with limited cold chain infrastructure.

Future Outlook: Sustainable Strategies for Fruit Preservation

Cold chain technology significantly extends fruit shelf life by maintaining optimal low temperatures, reducing spoilage and nutrient loss compared to ambient storage, which exposes fruits to temperature fluctuations and accelerates deterioration. Emerging sustainable strategies emphasize integrating renewable energy-powered cold chain systems and biodegradable packaging to minimize environmental impact while preserving fruit quality. Advances in IoT-enabled smart sensors and blockchain traceability enhance cold chain efficiency, ensuring precise temperature control and transparency from farm to consumer.

Related Important Terms

Controlled Atmosphere Storage

Controlled Atmosphere Storage (CAS) extends fruit shelf life by precisely regulating oxygen, carbon dioxide, and humidity levels, significantly reducing respiration rates and delaying ripening compared to ambient storage. Unlike cold chain storage that primarily maintains low temperatures, CAS optimizes atmospheric conditions to minimize spoilage and preserve firmness, flavor, and nutritional value during long-term storage.

Modified Atmosphere Packaging

Modified Atmosphere Packaging (MAP) enhances fruit preservation by altering gas composition around the produce, effectively extending shelf life in both cold chain and ambient storage conditions. MAP combined with controlled temperature in the cold chain significantly reduces respiration rate and decay, outperforming traditional ambient storage by maintaining fruit firmness and nutrient quality.

Cryogenic Chilling

Cryogenic chilling in post-harvest technology offers superior fruit preservation compared to ambient storage by rapidly reducing temperature to inhibit enzymatic activity and microbial growth, thereby extending shelf life and maintaining nutritional quality. The cold chain's controlled low-temperature environment minimizes respiration rates and delays ripening, unlike ambient storage which exposes fruit to fluctuating temperatures and accelerates degradation.

Ethylene Inhibitor Sachets

Ethylene inhibitor sachets significantly prolong fruit shelf life by slowing down ripening and senescence processes during cold chain and ambient storage conditions. Their effectiveness in reducing ethylene concentrations makes them essential for maintaining fruit quality and minimizing post-harvest losses across diverse storage environments.

IoT-enabled Cold Chain Monitoring

IoT-enabled cold chain monitoring significantly enhances fruit preservation by providing real-time temperature and humidity data, reducing spoilage and extending shelf life compared to ambient storage. Precise control of environmental conditions through smart sensors ensures optimal post-harvest quality, minimizing microbial growth and enzymatic activity in fruits.

Solar-powered Cold Storage Units

Solar-powered cold storage units significantly reduce post-harvest losses by maintaining optimal temperatures for fruit preservation compared to ambient storage, which exposes produce to fluctuating heat and humidity that accelerate spoilage. These units leverage renewable energy to ensure continuous cooling in remote areas, enhancing shelf life and quality while minimizing reliance on fragile grid infrastructure.

Phase Change Materials (PCM) Cooling

Phase Change Materials (PCM) cooling enhances cold chain efficiency by maintaining optimal low temperatures for fruit preservation, effectively slowing respiration and decay compared to ambient storage, which often leads to accelerated spoilage. Integrating PCM in post-harvest technology reduces temperature fluctuations, extends shelf life, and preserves fruit quality by stabilizing the microclimate during transportation and storage.

Smart Temperature Loggers

Smart temperature loggers play a crucial role in maintaining optimal conditions within cold chain systems, ensuring precise monitoring and real-time data collection to prevent spoilage and extend fruit shelf life. Unlike ambient storage, which lacks controlled environment and consistent temperature regulation, cold chain storage combined with smart temperature monitoring significantly reduces microbial growth and enzymatic reactions, preserving fruit quality and freshness longer.

Hyperlocal Cold Chain Nodes

Hyperlocal cold chain nodes enhance fruit preservation by maintaining optimal temperature and humidity control, significantly reducing post-harvest losses compared to ambient storage. These decentralized, temperature-controlled units enable faster cooling and prolonged freshness, crucial for perishable fruits in localized markets.

Passive Cooling Packaging

Passive cooling packaging in cold chain systems significantly extends fruit shelf life by maintaining optimal low temperatures and reducing respiration rates, minimizing microbial growth compared to ambient storage. This eco-friendly solution offers a cost-effective alternative to mechanical refrigeration, ensuring freshness and quality during transportation and storage without continuous energy consumption.

Cold chain vs ambient storage for fruit preservation Infographic

agridif.com

agridif.com