Wet grading uses water to separate produce based on density, enhancing sorting accuracy by eliminating debris and minimizing surface damage. Dry grading relies on air or mechanical vibrations to sort items by size and weight, offering faster processing but with a higher risk of bruising delicate produce. Choosing between wet and dry grading depends on the type of produce and desired quality outcomes in post-harvest technology.

Table of Comparison

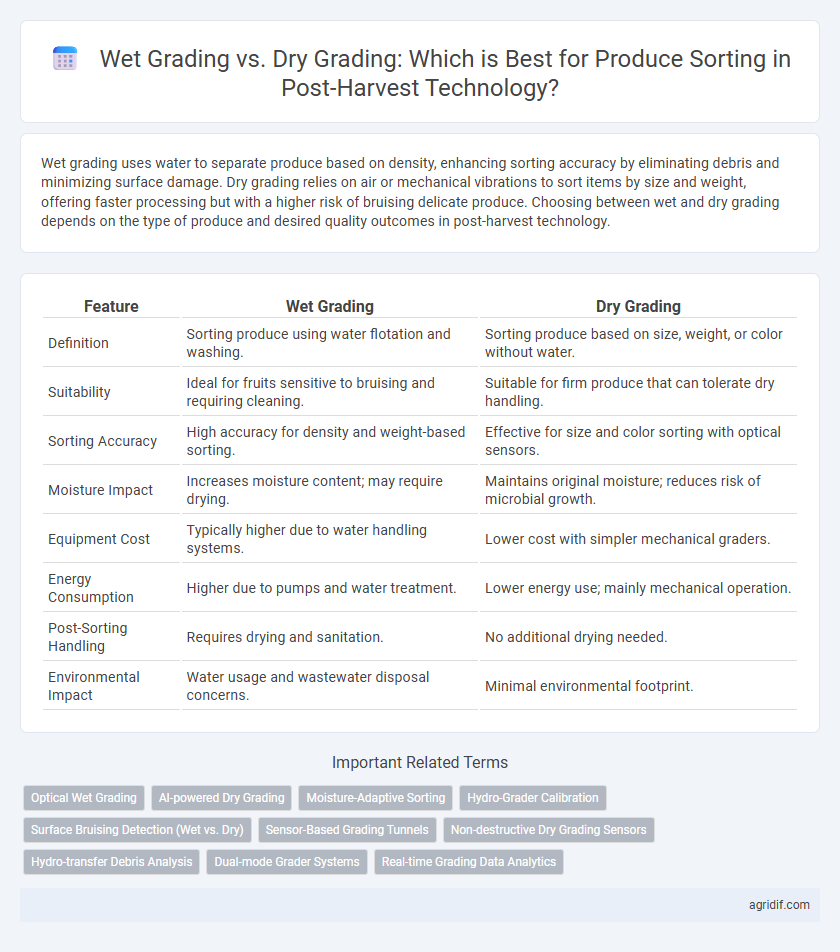

| Feature | Wet Grading | Dry Grading |

|---|---|---|

| Definition | Sorting produce using water flotation and washing. | Sorting produce based on size, weight, or color without water. |

| Suitability | Ideal for fruits sensitive to bruising and requiring cleaning. | Suitable for firm produce that can tolerate dry handling. |

| Sorting Accuracy | High accuracy for density and weight-based sorting. | Effective for size and color sorting with optical sensors. |

| Moisture Impact | Increases moisture content; may require drying. | Maintains original moisture; reduces risk of microbial growth. |

| Equipment Cost | Typically higher due to water handling systems. | Lower cost with simpler mechanical graders. |

| Energy Consumption | Higher due to pumps and water treatment. | Lower energy use; mainly mechanical operation. |

| Post-Sorting Handling | Requires drying and sanitation. | No additional drying needed. |

| Environmental Impact | Water usage and wastewater disposal concerns. | Minimal environmental footprint. |

Introduction to Produce Grading Methods

Produce grading methods include wet grading and dry grading, each serving specific purposes in post-harvest technology. Wet grading employs water or liquid solutions to clean and separate fruits or vegetables based on density and size, enhancing accuracy for delicate produce like tomatoes and berries. Dry grading relies on mechanical screens, air flow, or optical sensors to sort produce by size, color, and quality without moisture, making it suitable for firm products such as apples and potatoes.

Understanding Wet Grading: Principles and Processes

Wet grading involves immersing produce in water to separate items based on density and buoyancy, enhancing the accuracy of sorting by weight and size. This process reduces physical damage and allows for the efficient removal of defective or less dense produce through flotation differences. Utilizing advanced sensors and water flow control, wet grading optimizes the sorting precision for fruits and vegetables, improving overall quality and post-harvest shelf life.

Dry Grading Explained: Key Features and Techniques

Dry grading in post-harvest technology refers to the process of sorting produce based on size, shape, and external quality without the use of water. Key techniques include mechanical sorting using screens, rollers, and optical sensors that detect color, defects, and size variation to ensure uniformity and quality. This method minimizes moisture-related spoilage, reduces microbial contamination risks, and is energy-efficient, making it highly effective for fruits and vegetables that are sensitive to wet conditions.

Advantages of Wet Grading in Post-Harvest Handling

Wet grading in post-harvest handling offers enhanced accuracy in sorting produce by effectively removing surface dirt and debris, leading to better quality assessment and uniform classification. It reduces mechanical damage during grading as the water cushion minimizes fruit-to-fruit and fruit-to-machine contact, preserving product integrity. Furthermore, wet grading boosts efficiency by enabling continuous, rapid sorting and facilitating the detection of defects such as bruises and internal damage that are less visible in dry grading systems.

Benefits of Dry Grading for Produce Sorting

Dry grading preserves the natural texture and appearance of produce, reducing the risk of microbial growth and spoilage during sorting. It enhances efficiency by enabling rapid and accurate size, shape, and color assessment using optical sensors and imaging technology. This method minimizes water consumption and waste, supporting sustainable post-harvest practices and lowering overall processing costs.

Key Differences Between Wet and Dry Grading

Wet grading uses water to separate produce based on density, enhancing accuracy for irregularly shaped items, while dry grading relies on size, weight, and color with equipment like sieves and optical sorters. Wet grading reduces bruising and surface damage due to the cushioning effect of water, making it ideal for delicate fruits, whereas dry grading is faster and requires less water consumption, favoring high-throughput operations. The choice between wet and dry grading impacts post-harvest quality, sorting precision, and operational efficiency in produce handling.

Performance of Wet vs Dry Grading for Various Produce Types

Wet grading enhances sorting accuracy by using water channels to separate produce based on density, making it ideal for fruits like apples, grapes, and tomatoes where size and weight differentiation is critical. Dry grading relies on mechanical or optical sensors to classify produce such as potatoes, onions, and citrus by surface color, shape, and defects but may have lower precision in identifying internal quality. Studies indicate wet grading offers superior performance in reducing damage and improving size uniformity, while dry grading excels in speed and handling large volumes of produce with minimal water usage.

Impact on Produce Quality and Shelf Life

Wet grading preserves produce quality by reducing surface damage and removing debris, which minimizes microbial contamination and extends shelf life. Dry grading, while less resource-intensive, can cause more physical abrasion leading to bruising and faster spoilage. Optimal sorting method selection directly influences produce firmness, appearance, and post-harvest longevity.

Operational Considerations: Cost, Efficiency, and Scalability

Wet grading in post-harvest produce sorting involves washing and submerging fruits or vegetables, increasing water and equipment costs while enhancing sorting accuracy and reducing dust-related issues. Dry grading requires less water and lower operational expenses but may compromise sorting precision and necessitate more frequent maintenance to handle debris and dust accumulation. Scalability favors wet grading systems in large-scale operations due to automated sorting capabilities, whereas dry grading suits smaller setups with limited infrastructure.

Choosing the Right Grading Method for Your Agricultural Needs

Choosing the right grading method for your agricultural produce depends on factors such as crop type, desired quality standards, and processing requirements. Wet grading provides enhanced accuracy by cleaning and removing debris, making it ideal for fruits and vegetables prone to surface impurities, while dry grading offers faster throughput and reduced water usage, suitable for dry crops like grains and nuts. Evaluating the balance between operational costs, environmental impact, and produce sensitivity ensures optimal sorting results and maintains post-harvest quality.

Related Important Terms

Optical Wet Grading

Optical wet grading enhances produce sorting by using high-resolution cameras and water jets to remove surface contaminants, improving accuracy and efficiency compared to dry grading methods. This technology reduces damage to delicate fruits, increases sorting speed, and enables precise quality assessment based on size, color, and external defects under optimal moisture conditions.

AI-powered Dry Grading

AI-powered dry grading systems leverage advanced machine learning algorithms and high-resolution imaging to sort produce with greater accuracy and efficiency compared to traditional wet grading methods, minimizing produce damage and water usage. These systems analyze color, texture, size, and shape in real-time, enabling quicker processing speeds and improved consistency in quality assessment across various types of fresh produce.

Moisture-Adaptive Sorting

Moisture-adaptive sorting in post-harvest technology enhances produce grading accuracy by distinguishing items based on surface moisture content, ensuring optimal classification in both wet and dry grading systems. Wet grading effectively separates produce with varying moisture levels, reducing contamination and spoilage, while dry grading relies on optical and weight-based criteria for moisture-independent sorting.

Hydro-Grader Calibration

Hydro-grader calibration in wet grading ensures precise control of water flow and buoyancy to accurately sort produce by density, size, and quality, enhancing sorting efficiency compared to dry grading methods. Accurate calibration reduces damage and maintains produce quality by minimizing mechanical stress, making wet grading superior for delicate fruits and vegetables.

Surface Bruising Detection (Wet vs. Dry)

Wet grading enhances surface bruising detection by using water as a medium to clean produce, improving visibility of discolorations and defects compared to dry grading, which can miss subtle bruises due to dirt and varying surface textures. Advanced imaging techniques in wet grading offer higher accuracy in identifying bruised areas, enabling better quality sorting and reducing post-harvest losses.

Sensor-Based Grading Tunnels

Sensor-based grading tunnels in wet grading utilize water to gently separate and convey produce, allowing sensors to capture accurate size, shape, and color data without surface contamination. In contrast, dry grading tunnels rely solely on air flow and mechanical handling, which may increase bruising risk and reduce sensor precision due to dirt and dust interference on produce surfaces.

Non-destructive Dry Grading Sensors

Non-destructive dry grading sensors utilize advanced technologies such as near-infrared (NIR) spectroscopy, hyperspectral imaging, and machine vision to accurately assess produce quality, size, and defects without moisture interference. These sensors enhance throughput efficiency and maintain produce integrity by eliminating the need for water, reducing cross-contamination risks and post-sorting drying requirements in post-harvest technology.

Hydro-transfer Debris Analysis

Wet grading uses water as a medium to transport produce, facilitating hydro-transfer debris analysis by enabling the separation of dirt, leaves, and other contaminants based on density differences. Dry grading relies on air flow and mechanical sorting, making it less effective for debris detection but faster and less resource-intensive in post-harvest produce handling.

Dual-mode Grader Systems

Dual-mode grader systems in post-harvest technology combine wet grading and dry grading methods to optimize produce sorting accuracy by utilizing moisture-based and visual quality metrics simultaneously. This integration enhances sorting precision for fruits and vegetables, improving market value and reducing post-harvest losses by efficiently categorizing produce based on surface cleanliness, firmness, and ripeness.

Real-time Grading Data Analytics

Wet grading enhances produce sorting accuracy by using water to separate items based on density, enabling real-time data capture for immediate quality analytics and reducing sorting errors. Dry grading, relying on air or mechanical vibration, provides faster throughput but less precise density differentiation, limiting the granularity of real-time grading data analytics in post-harvest operations.

Wet Grading vs Dry Grading for produce sorting Infographic

agridif.com

agridif.com