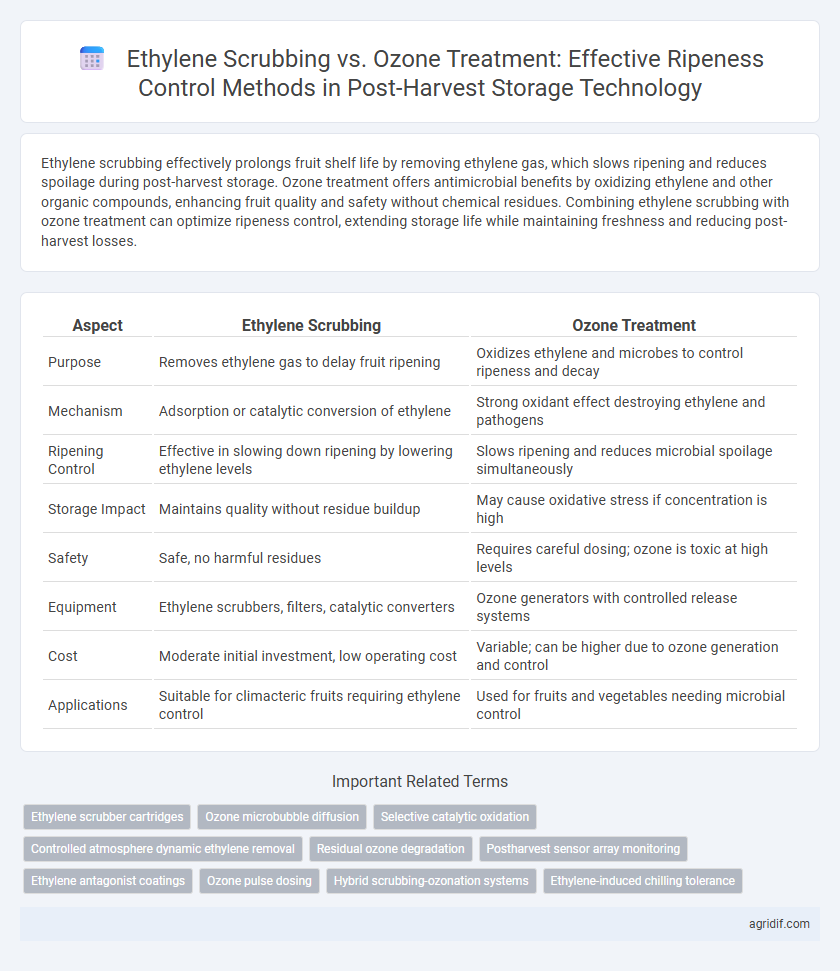

Ethylene scrubbing effectively prolongs fruit shelf life by removing ethylene gas, which slows ripening and reduces spoilage during post-harvest storage. Ozone treatment offers antimicrobial benefits by oxidizing ethylene and other organic compounds, enhancing fruit quality and safety without chemical residues. Combining ethylene scrubbing with ozone treatment can optimize ripeness control, extending storage life while maintaining freshness and reducing post-harvest losses.

Table of Comparison

| Aspect | Ethylene Scrubbing | Ozone Treatment |

|---|---|---|

| Purpose | Removes ethylene gas to delay fruit ripening | Oxidizes ethylene and microbes to control ripeness and decay |

| Mechanism | Adsorption or catalytic conversion of ethylene | Strong oxidant effect destroying ethylene and pathogens |

| Ripening Control | Effective in slowing down ripening by lowering ethylene levels | Slows ripening and reduces microbial spoilage simultaneously |

| Storage Impact | Maintains quality without residue buildup | May cause oxidative stress if concentration is high |

| Safety | Safe, no harmful residues | Requires careful dosing; ozone is toxic at high levels |

| Equipment | Ethylene scrubbers, filters, catalytic converters | Ozone generators with controlled release systems |

| Cost | Moderate initial investment, low operating cost | Variable; can be higher due to ozone generation and control |

| Applications | Suitable for climacteric fruits requiring ethylene control | Used for fruits and vegetables needing microbial control |

Understanding Ethylene and Ozone in Post-Harvest Storage

Ethylene, a natural plant hormone, accelerates ripening and senescence, making ethylene scrubbing crucial for prolonging the shelf life of fruits and vegetables in post-harvest storage. Ozone treatment, a powerful oxidizing agent, breaks down ethylene and microbial contaminants, enhancing storage quality and reducing decay. Both ethylene scrubbing and ozone treatment optimize storage conditions by managing ripeness and reducing spoilage in controlled environments.

Mechanisms of Ethylene Scrubbing for Ripeness Control

Ethylene scrubbing controls ripeness by actively removing ethylene gas from storage environments, using materials like potassium permanganate or activated carbon to oxidize or adsorb ethylene molecules. This mechanism slows down the fruit's ethylene-induced ripening processes, extending shelf life and maintaining quality. The efficiency of ethylene scrubbing depends on factors such as scrubbing material capacity, storage temperature, and initial ethylene concentration.

Ozone Treatment: How It Works in Storage Facilities

Ozone treatment in storage facilities operates by releasing ozone gas, which reacts with ethylene--a natural plant hormone responsible for ripening--thus breaking it down and slowing the ripening process. This method extends shelf life by effectively reducing ethylene concentration around fruits and vegetables, inhibiting decay and microbial growth. Ozone's strong oxidizing properties ensure continuous ethylene removal, making it a powerful alternative to traditional ethylene scrubbing systems in post-harvest ripeness control.

Comparative Effectiveness: Ethylene Scrubbing vs Ozone Treatment

Ethylene scrubbing effectively reduces ethylene concentrations in storage environments, delaying fruit ripening and extending shelf life by targeting ethylene gas directly. Ozone treatment, while also inhibiting ripening, offers antimicrobial benefits that reduce decay but may cause oxidative damage to sensitive produce at higher concentrations. Comparative studies show ethylene scrubbing provides more precise control over ripeness without compromising produce quality, whereas ozone's dual action requires careful management to balance ripening delay and potential tissue damage.

Impact on Fruit and Vegetable Quality During Storage

Ethylene scrubbing effectively reduces ethylene concentration in storage environments, slowing ripening and maintaining firmness in fruits like apples and tomatoes, thereby extending shelf life and preserving nutritional quality. Ozone treatment offers antimicrobial benefits that reduce decay and spoilage in stored produce such as berries and leafy greens, while also modulating ethylene levels to delay ripening. Careful control of ozone concentration is critical to prevent oxidative damage and maintain texture, color, and flavor during storage.

Safety Considerations in Ethylene and Ozone Applications

Ethylene scrubbing systems effectively reduce ethylene concentration to delay ripening but require regular maintenance to prevent microbial growth and ensure safe operation. Ozone treatment offers antimicrobial benefits and ethylene degradation but poses risks of respiratory irritation and material corrosion if ozone levels are not carefully controlled. Ensuring worker safety involves monitoring ozone concentrations within permissible exposure limits and implementing proper ventilation and protective equipment protocols during both ethylene and ozone applications.

Technical Requirements and Implementation Costs

Ethylene scrubbing systems require specialized adsorbent materials such as potassium permanganate or activated carbon, along with integrated ventilation to continuously remove ethylene gas, demanding moderate capital investment and periodic maintenance costs. Ozone treatment involves ozone generators with precise control mechanisms to maintain safe concentration levels, necessitating higher initial equipment costs and robust safety protocols due to ozone's oxidative nature. Implementation expenses for ethylene scrubbing are generally lower, but ozone treatment offers rapid ripeness control benefits that may justify increased upfront and operational expenditures in large-scale storage facilities.

Environmental Impacts of Ethylene and Ozone Treatments

Ethylene scrubbing effectively reduces ethylene concentration in storage environments, minimizing premature ripening and spoilage while producing minimal environmental pollutants. Ozone treatment, a strong oxidizing agent, degrades ethylene and microbial contaminants but generates reactive oxygen species that require careful management to prevent environmental harm. Both technologies contribute to extended shelf life and reduced food waste, but ethylene scrubbing offers a more environmentally benign profile by avoiding ozone's potential oxidative impact on air quality and equipment.

Case Studies: Success Stories and Field Data

Ethylene scrubbing and ozone treatment have demonstrated significant success in extending shelf life and controlling ripeness during storage, with case studies showcasing up to 50% reduction in spoilage for climacteric fruits like apples and tomatoes. Field data from commercial storage facilities reveal ethylene scrubbers maintain consistent low ethylene concentrations, delaying ripening by up to 14 days, while ozone treatment effectively reduces microbial load and ethylene levels, enhancing fruit quality. Comparative studies emphasize ozone's dual benefits in pathogen suppression and ethylene oxidation, whereas ethylene scrubbing excels in targeted ethylene removal, making both technologies valuable for tailored post-harvest management.

Future Trends in Ripeness Control Technologies

Ethylene scrubbing and ozone treatment represent two advanced methods for managing ripeness in post-harvest storage, each leveraging specific gas interactions to delay fruit senescence and maintain quality. Future trends emphasize integration of smart sensor technologies with ethylene scrubbing systems to enable real-time monitoring and adaptive control, enhancing precision in ripeness regulation. Emerging research on ozone treatment focuses on optimizing dosage and exposure timing to maximize antimicrobial benefits while minimizing oxidative stress, positioning it as a complementary technology in controlled atmosphere storage environments.

Related Important Terms

Ethylene scrubber cartridges

Ethylene scrubber cartridges effectively absorb and neutralize ethylene gas, significantly slowing down the ripening process and extending the shelf life of perishable produce during storage. Compared to ozone treatment, ethylene scrubbing offers a safer, residue-free solution with targeted control over ethylene concentration, reducing spoilage and maintaining optimal fruit quality.

Ozone microbubble diffusion

Ozone microbubble diffusion enhances ethylene scrubbing efficiency by accelerating ethylene oxidation, thereby extending fruit shelf life and maintaining quality during storage. This advanced ozone application promotes uniform gas distribution and improved penetration in storage environments, outperforming conventional ethylene removal methods.

Selective catalytic oxidation

Selective catalytic oxidation in ethylene scrubbing efficiently removes ethylene gas, slowing fruit ripening by targeting the ethylene molecule with catalysts like platinum or palladium. Ozone treatment, while effective in oxidizing ethylene and microbial contaminants, can be less selective and may cause oxidative damage to sensitive produce during storage.

Controlled atmosphere dynamic ethylene removal

Controlled atmosphere dynamic ethylene removal technologies effectively reduce ethylene concentration in storage environments, delaying fruit ripening and extending shelf life by maintaining optimal ripening stages. Compared to ozone treatment, ethylene scrubbing offers targeted removal of ethylene without the oxidative risks associated with ozone, preserving fruit quality and reducing spoilage rates in post-harvest storage.

Residual ozone degradation

Ethylene scrubbing effectively removes ethylene gas to delay fruit ripening, while ozone treatment not only degrades ethylene but can lead to residual ozone accumulation causing oxidative damage to produce. Managing residual ozone degradation is critical, as excessive ozone residues may deteriorate storage quality and shelf life despite its strong ethylene oxidation capabilities.

Postharvest sensor array monitoring

Ethylene scrubbing and ozone treatment both serve as critical interventions for ripeness control by reducing ethylene concentration in storage environments, with ethylene scrubbers selectively adsorbing ethylene gas while ozone treatment oxidizes ethylene molecules. Integration of postharvest sensor arrays, including electrochemical and photoacoustic sensors, enables continuous, real-time monitoring of ethylene and ozone levels, optimizing treatment efficacy and extending shelf life for perishable commodities.

Ethylene antagonist coatings

Ethylene antagonist coatings effectively inhibit ethylene action, delaying ripening and extending the shelf life of fruits during storage by reducing ethylene sensitivity at the cellular level. Unlike ozone treatment, which oxidizes ethylene and pathogens, ethylene antagonist coatings provide a chemical barrier that maintains fruit firmness and quality without the oxidative stress associated with ozone exposure.

Ozone pulse dosing

Ozone pulse dosing in post-harvest storage effectively controls fruit ripeness by degrading ethylene gas, thereby slowing down the ripening process and extending shelf life. Compared to traditional ethylene scrubbing, ozone treatment offers antimicrobial benefits and reduces microbial decay while maintaining optimal fruit quality during prolonged storage periods.

Hybrid scrubbing-ozonation systems

Hybrid scrubbing-ozonation systems combine ethylene removal and microbial control, enhancing ripeness regulation and extending storage life of fruits by reducing ethylene concentration and suppressing spoilage pathogens. These integrated systems optimize post-harvest quality by balancing the oxidative power of ozone with selective ethylene adsorption, improving storage outcomes compared to standalone treatments.

Ethylene-induced chilling tolerance

Ethylene scrubbing effectively reduces ethylene concentration in storage environments, directly mitigating ethylene-induced ripening and enhancing chilling tolerance in harvested produce. In contrast, ozone treatment oxidizes ethylene molecules but may cause oxidative stress, making ethylene scrubbing a preferred method for maintaining ripeness control and extending post-harvest shelf life.

Ethylene scrubbing vs ozone treatment for ripeness control in storage Infographic

agridif.com

agridif.com