Rapid field heat removal immediately after harvest is crucial for maintaining the quality and extending the shelf life of perishable produce by slowing down respiration and enzymatic activities. Delayed cooling allows field heat to persist, accelerating spoilage, moisture loss, and microbial growth, which compromises texture, flavor, and nutritional value. Employing efficient cooling methods such as forced-air or hydro-cooling right after harvest optimizes freshness and reduces post-harvest losses significantly.

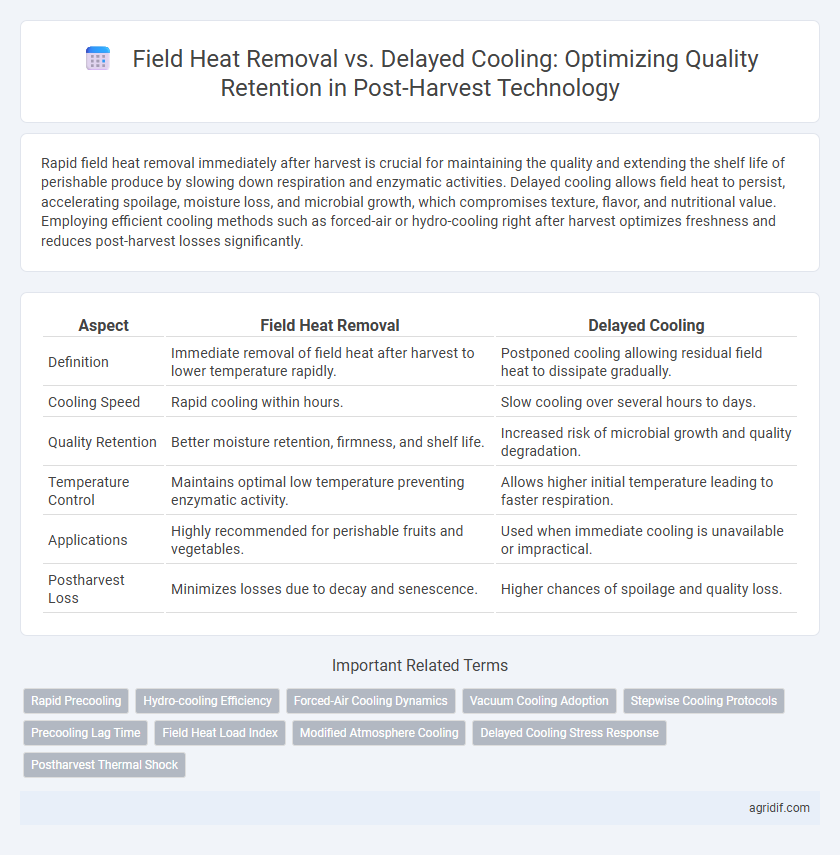

Table of Comparison

| Aspect | Field Heat Removal | Delayed Cooling |

|---|---|---|

| Definition | Immediate removal of field heat after harvest to lower temperature rapidly. | Postponed cooling allowing residual field heat to dissipate gradually. |

| Cooling Speed | Rapid cooling within hours. | Slow cooling over several hours to days. |

| Quality Retention | Better moisture retention, firmness, and shelf life. | Increased risk of microbial growth and quality degradation. |

| Temperature Control | Maintains optimal low temperature preventing enzymatic activity. | Allows higher initial temperature leading to faster respiration. |

| Applications | Highly recommended for perishable fruits and vegetables. | Used when immediate cooling is unavailable or impractical. |

| Postharvest Loss | Minimizes losses due to decay and senescence. | Higher chances of spoilage and quality loss. |

Understanding Field Heat: Its Role in Post-Harvest Quality

Field heat refers to the high temperature retained within freshly harvested produce, significantly influencing respiration rates and moisture loss. Rapid removal of field heat through immediate cooling minimizes enzymatic activity and microbial growth, thereby preserving texture, flavor, and nutritional quality. Delayed cooling allows prolonged high internal temperatures, accelerating deterioration and reducing the post-harvest shelf life of fruits and vegetables.

Fundamentals of Field Heat Removal in Agriculture

Field heat removal is a critical post-harvest process that rapidly reduces the temperature of freshly harvested crops to slow metabolic activity and minimize quality degradation. Effective removal of field heat involves techniques such as forced-air cooling, hydro-cooling, and vacuum cooling, which help maintain firmness, color, and nutritional value by preventing enzymatic and microbial spoilage. Delayed cooling allows continued metabolic processes that accelerate moisture loss and decay, making immediate and efficient field heat removal essential for extending shelf life and preserving post-harvest quality.

Delayed Cooling: Causes and Consequences

Delayed cooling in post-harvest technology results in prolonged exposure of produce to elevated temperatures, accelerating respiration rates and increasing ethylene production that deteriorate quality. This thermal stress triggers moisture loss, microbial growth, and enzymatic breakdown, leading to reduced shelf life and compromised texture, flavor, and nutritional content. Effective management of delayed cooling is critical to minimize field heat retention and maintain optimal post-harvest quality and marketability.

Field Heat Removal vs Delayed Cooling: A Comparative Overview

Field heat removal rapidly reduces the temperature of freshly harvested produce, minimizing respiration rates and delaying spoilage, whereas delayed cooling allows temperature to remain higher for longer, accelerating quality degradation. Studies indicate that immediate field heat removal significantly preserves texture, flavor, and shelf life compared to delayed cooling techniques. Optimizing post-harvest protocols by prioritizing field heat removal enhances product quality retention and reduces post-harvest losses across various fruits and vegetables.

Impact of Immediate Cooling on Shelf Life and Freshness

Immediate cooling through effective field heat removal significantly extends shelf life by halting metabolic activities and reducing enzymatic degradation in harvested produce. Delayed cooling allows continued respiration and moisture loss, accelerating spoilage and quality deterioration. Rapid temperature reduction preserves freshness, texture, and nutritional value, making it essential in post-harvest technology for maintaining optimal product quality.

Quality Losses Associated with Delayed Cooling

Delayed cooling after harvest accelerates respiration and microbial growth, leading to significant quality losses such as wilting, discoloration, and nutrient degradation. Field heat removal immediately post-harvest reduces metabolic activity, thereby preserving texture, flavor, and shelf life of perishable produce. Efficient cooling minimizes enzymatic breakdown and ethylene production, crucial factors in maintaining optimal post-harvest quality.

Physiological Changes During Post-Harvest Cooldown

Field heat removal rapidly lowers the temperature of harvested produce, minimizing respiration rates and enzymatic activities that lead to quality degradation. Delayed cooling allows continued physiological changes such as moisture loss, increased ethylene production, and accelerated senescence, resulting in reduced shelf life and textural firmness. Efficient post-harvest cooldown through immediate field heat removal preserves cellular integrity and slows metabolic processes, maintaining optimal freshness and nutrient retention.

Technology Solutions for Rapid Field Heat Removal

Rapid field heat removal technology significantly enhances post-harvest quality by minimizing metabolic activity and microbial growth in fresh produce immediately after harvest. Advanced cooling methods such as forced-air cooling, hydrocooling, and vacuum cooling efficiently reduce field heat within minutes, preserving texture, flavor, and nutritional value. Implementing these technologies mitigates quality degradation compared to delayed cooling, extending shelf life and reducing post-harvest losses.

Best Practices for Optimizing Post-Harvest Cooling

Field heat removal is critical for maintaining the quality and shelf life of perishable crops by rapidly reducing the initial temperature after harvest to slow respiration and microbial growth. Delayed cooling allows field heat to persist, increasing the risk of quality degradation, moisture loss, and spoilage, especially in highly perishable produce like leafy greens and berries. Best practices for optimizing post-harvest cooling emphasize immediate forced-air cooling or hydrocooling to efficiently remove field heat, ensuring optimal freshness and minimizing post-harvest losses.

Case Studies: Successful Field Heat Removal Strategies

Case studies highlight that rapid field heat removal immediately after harvest significantly improves fruit firmness and extends shelf life compared to delayed cooling, which often results in faster quality degradation. Techniques such as forced-air cooling and hydro-cooling within the first hour post-harvest consistently reduce respiration rates and microbial growth, preserving key nutritional attributes. Successful implementations in commodities like mangoes and leafy greens demonstrate up to 30% reduction in post-harvest losses, validating field heat removal as a critical factor for quality retention in supply chains.

Related Important Terms

Rapid Precooling

Rapid precooling significantly enhances quality retention by swiftly removing field heat from harvested produce, thereby minimizing metabolic activity and delaying spoilage. Compared to delayed cooling, this method effectively maintains freshness, firmness, and nutritional value, reducing weight loss and extending shelf life.

Hydro-cooling Efficiency

Hydro-cooling efficiently removes field heat by rapidly lowering produce temperature through direct water contact, minimizing respiration rates and preserving post-harvest quality more effectively than delayed cooling methods. This technique reduces moisture loss and decay, enhancing shelf life and maintaining texture, color, and nutritional value in fruits and vegetables.

Forced-Air Cooling Dynamics

Forced-air cooling efficiently removes field heat by circulating cold air rapidly through the produce, significantly slowing respiration rates and minimizing moisture loss compared to delayed cooling methods. The dynamics of airflow velocity, uniform temperature distribution, and precise control are critical in optimizing quality retention, reducing decay, and extending shelf life in post-harvest technology.

Vacuum Cooling Adoption

Vacuum cooling rapidly removes field heat by lowering atmospheric pressure, enabling efficient moisture evaporation and accelerating temperature reduction, which significantly enhances post-harvest quality retention compared to delayed cooling methods. Adoption of vacuum cooling technology in perishable produce like leafy greens and berries demonstrates superior preservation of texture, color, and shelf life, making it a critical advancement in post-harvest handling and cold chain management.

Stepwise Cooling Protocols

Stepwise cooling protocols in post-harvest technology optimize field heat removal by gradually reducing temperature, minimizing moisture loss and cellular damage to maintain fruit and vegetable quality. This controlled cooling method outperforms delayed cooling by preventing thermal shock and preserving firmness, color, and nutritional value during storage and transport.

Precooling Lag Time

Rapid field heat removal is critical for minimizing precooling lag time and preserving post-harvest quality by slowing respiration and microbial growth in perishable produce. Delayed cooling extends the lag time, leading to increased moisture loss, texture degradation, and reduced shelf life, emphasizing the importance of immediate cooling interventions.

Field Heat Load Index

Field Heat Load Index (FHLI) quantifies the initial heat burden on harvested produce, directly influencing the rate of quality degradation. Prompt field heat removal effectively reduces FHLI, minimizing respiration and moisture loss, whereas delayed cooling allows elevated temperatures to accelerate spoilage and nutrient loss.

Modified Atmosphere Cooling

Modified Atmosphere Cooling (MAC) effectively removes field heat while maintaining optimal gas composition around produce, slowing respiration rates and reducing moisture loss compared to delayed cooling methods. By maintaining low oxygen and elevated carbon dioxide levels immediately after harvest, MAC enhances quality retention, extends shelf life, and minimizes post-harvest physiological deterioration more efficiently than conventional cooling techniques.

Delayed Cooling Stress Response

Delayed cooling in post-harvest technology slows the removal of field heat, triggering stress responses in fruits and vegetables that may accelerate spoilage by enhancing ethylene production and enzymatic activity. Rapid cooling is more effective for quality retention, as it minimizes cellular stress, reduces respiration rates, and maintains firmness, texture, and nutritional value.

Postharvest Thermal Shock

Rapid field heat removal minimizes postharvest thermal shock by quickly lowering produce temperature, preserving cell structure and extending shelf life. In contrast, delayed cooling allows prolonged high field heat, increasing enzymatic activity and respiration rates, which accelerates quality degradation and reduces storage potential.

Field heat removal vs delayed cooling for quality retention Infographic

agridif.com

agridif.com