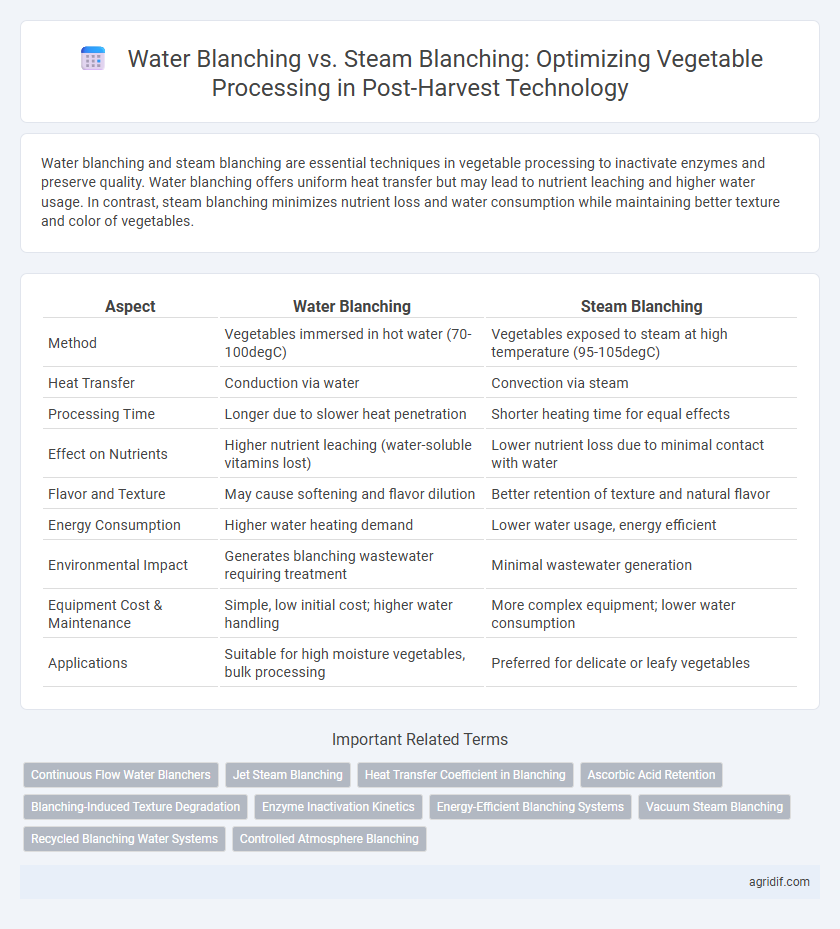

Water blanching and steam blanching are essential techniques in vegetable processing to inactivate enzymes and preserve quality. Water blanching offers uniform heat transfer but may lead to nutrient leaching and higher water usage. In contrast, steam blanching minimizes nutrient loss and water consumption while maintaining better texture and color of vegetables.

Table of Comparison

| Aspect | Water Blanching | Steam Blanching |

|---|---|---|

| Method | Vegetables immersed in hot water (70-100degC) | Vegetables exposed to steam at high temperature (95-105degC) |

| Heat Transfer | Conduction via water | Convection via steam |

| Processing Time | Longer due to slower heat penetration | Shorter heating time for equal effects |

| Effect on Nutrients | Higher nutrient leaching (water-soluble vitamins lost) | Lower nutrient loss due to minimal contact with water |

| Flavor and Texture | May cause softening and flavor dilution | Better retention of texture and natural flavor |

| Energy Consumption | Higher water heating demand | Lower water usage, energy efficient |

| Environmental Impact | Generates blanching wastewater requiring treatment | Minimal wastewater generation |

| Equipment Cost & Maintenance | Simple, low initial cost; higher water handling | More complex equipment; lower water consumption |

| Applications | Suitable for high moisture vegetables, bulk processing | Preferred for delicate or leafy vegetables |

Introduction to Blanching in Post-Harvest Vegetable Processing

Blanching is a critical pre-treatment step in post-harvest vegetable processing that inactivates enzymes responsible for quality degradation, such as polyphenol oxidase and peroxidase. Water blanching involves immersing vegetables in hot water, ensuring uniform heat transfer but potentially leading to nutrient loss and effluent generation. Steam blanching offers efficient heat penetration with reduced nutrient leaching and lower wastewater production, making it increasingly favored in sustainable vegetable processing.

Principles of Water Blanching Technique

Water blanching utilizes hot water immersion, typically between 70-100degC, to inactivate enzymes that cause spoilage and discoloration in vegetables. This method facilitates heat transfer through direct contact, ensuring uniform temperature distribution and effective enzyme denaturation. Temperature control and blanching time, usually ranging from 1 to 10 minutes, are critical factors influencing nutrient retention and product texture in vegetable processing.

Principles of Steam Blanching Technique

Steam blanching uses direct exposure of vegetables to saturated steam at temperatures ranging from 85degC to 100degC, ensuring rapid heat transfer and minimal nutrient loss compared to water blanching. This technique relies on steam's latent heat to inactivate enzymes such as peroxidase and polyphenol oxidase, preserving color, texture, and flavor while reducing microbial load. Steam blanching reduces water usage and cross-contamination risks, making it a preferred method in industrial vegetable processing for maintaining product quality and shelf life.

Comparative Analysis: Water vs Steam Blanching

Water blanching and steam blanching are essential pre-treatment methods in post-harvest vegetable processing, each influencing nutrient retention, texture, and enzymatic activity differently. Water blanching allows uniform heat penetration but often leads to nutrient leaching and water use concerns, while steam blanching minimizes nutrient loss and water consumption, preserving color and flavor more effectively. Comparative studies indicate steam blanching extends shelf life and reduces processing time, offering a more sustainable and quality-preserving option for commercial vegetable processing.

Effects on Nutritional Quality of Vegetables

Water blanching often leads to significant nutrient loss in vegetables, particularly water-soluble vitamins such as vitamin C and B-complex, due to leaching into the blanching water. Steam blanching preserves nutritional quality more effectively by minimizing vitamin degradation and nutrient leaching, maintaining higher levels of antioxidants and phytochemicals. Studies indicate steam blanching retains up to 30% more vitamin C and essential minerals compared to water blanching, making it a superior method for nutrient retention in vegetable processing.

Impact on Color, Texture, and Flavor Retention

Water blanching often causes greater nutrient leaching and color fading in vegetables compared to steam blanching, which better preserves vibrant hues and natural pigments. Texture retention is superior with steam blanching due to reduced water absorption, maintaining firmness and crispness critical for quality processing. Flavor compounds are better retained with steam blanching as it minimizes flavor loss and enzymatic degradation, enhancing overall vegetable quality post-harvest.

Energy and Water Consumption Considerations

Water blanching in vegetable processing consumes significantly more water compared to steam blanching, leading to higher wastewater generation and increased treatment costs. Steam blanching offers better energy efficiency by reducing heat loss and minimizing water usage, which contributes to lower operational expenses in post-harvest technology. Choosing steam blanching optimizes resource consumption and supports sustainable processing practices in the vegetable industry.

Microbial and Enzyme Inactivation Efficiency

Water blanching and steam blanching are critical methods in vegetable processing for microbial and enzyme inactivation. Steam blanching offers superior enzyme inactivation, particularly for peroxidase and polyphenol oxidase, due to higher heat transfer efficiency and reduced contact with water, which limits nutrient leaching. Water blanching effectively reduces microbial load but may cause nutrient loss through leaching, making steam blanching a preferred method for preserving vegetable quality while ensuring safety.

Environmental Implications of Blanching Methods

Water blanching consumes significantly larger volumes of water, leading to increased wastewater generation and higher treatment costs, which poses environmental challenges for sustainable vegetable processing. In contrast, steam blanching uses minimal water, reducing effluent discharge and lowering the risk of water pollution while conserving resources. Energy efficiency is generally higher in steam blanching, contributing to a reduced carbon footprint compared to the prolonged heating and water management required in water blanching.

Choosing the Right Blanching Method for Specific Vegetables

Water blanching offers effective heat transfer for dense vegetables like carrots and potatoes, ensuring uniform cooking and enzymatic inactivation, while steam blanching is preferred for leafy greens and delicate vegetables to minimize nutrient leaching and preserve texture. Selecting the appropriate blanching method depends on vegetable type, desired texture retention, and processing goals, with steam blanching reducing water usage and contamination risk compared to water blanching. Optimizing the blanching technique enhances shelf life, nutrient retention, and overall quality in vegetable processing operations.

Related Important Terms

Continuous Flow Water Blanchers

Continuous flow water blanchers offer precise temperature control and efficient heat transfer during vegetable processing, ensuring uniform enzyme inactivation and improved product quality. Compared to steam blanching, water blanching better maintains color and texture by rapidly cooling vegetables and reducing enzymatic degradation in large-scale operations.

Jet Steam Blanching

Jet steam blanching offers superior heat transfer efficiency and uniform temperature distribution compared to traditional water blanching, resulting in better retention of nutrients and color in vegetables. Its minimal water usage and reduced nutrient leaching make it an eco-friendly and cost-effective method for large-scale post-harvest vegetable processing.

Heat Transfer Coefficient in Blanching

Water blanching exhibits a higher heat transfer coefficient compared to steam blanching, resulting in faster and more uniform heat penetration in vegetables. This superior heat transfer efficiency enhances enzyme inactivation but may lead to higher nutrient leaching during post-harvest processing.

Ascorbic Acid Retention

Water blanching often leads to significant loss of ascorbic acid in vegetables due to leaching into the blanching water, whereas steam blanching better preserves vitamin C by minimizing direct contact with water. Studies indicate steam blanching retains up to 30-50% more ascorbic acid compared to water blanching, enhancing the nutritional quality of processed vegetables.

Blanching-Induced Texture Degradation

Water blanching exposes vegetables to direct hot water, causing leaching of water-soluble nutrients and significant texture softening due to cellular swelling and enzyme activation. Steam blanching reduces nutrient loss and better preserves cell wall integrity, resulting in less texture degradation and improved firmness in processed vegetables.

Enzyme Inactivation Kinetics

Water blanching achieves enzyme inactivation through heat conduction, resulting in faster thermal penetration but increased nutrient leaching compared to steam blanching, which utilizes saturated steam to inactivate enzymes with reduced water usage and better nutrient retention. Kinetic studies reveal that steam blanching often maintains higher enzyme inactivation efficiency at lower energy levels, optimizing texture and color preservation while minimizing quality degradation in vegetable processing.

Energy-Efficient Blanching Systems

Water blanching consumes significant water and energy due to prolonged heating and cooling cycles, whereas steam blanching offers a more energy-efficient alternative by using less water and shorter processing times, reducing thermal degradation and nutrient loss in vegetables. Advanced steam blanching systems with optimized steam injection and recovery mechanisms further enhance energy conservation and maintain product quality in vegetable processing.

Vacuum Steam Blanching

Vacuum steam blanching in vegetable processing preserves nutrients and color more effectively than traditional water blanching by minimizing oxygen exposure and reducing thermal degradation. This method enhances enzyme inactivation and microbial safety while lowering water usage and wastewater production compared to conventional steam blanching.

Recycled Blanching Water Systems

Water blanching in vegetable processing often requires advanced recycled blanching water systems to effectively remove soil and microbes while minimizing water usage and environmental impact. Steam blanching uses less water and reduces effluent treatment needs, but integrating water recycling technology can optimize resource efficiency and maintain product quality in large-scale operations.

Controlled Atmosphere Blanching

Controlled Atmosphere Blanching in vegetable processing utilizes regulated gas compositions to enhance enzyme inactivation more efficiently than traditional water or steam blanching methods. This technique improves nutrient retention and shelf life by minimizing thermal degradation and moisture loss during the blanching process.

Water Blanching vs Steam Blanching for Vegetable Processing Infographic

agridif.com

agridif.com